Академический Документы

Профессиональный Документы

Культура Документы

Drill Rig Plant Pre Acceptance Checklist

Загружено:

Rubén López LemaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Drill Rig Plant Pre Acceptance Checklist

Загружено:

Rubén López LemaАвторское право:

Доступные форматы

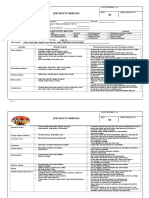

DRILL RIG PLANT PRE-ACCEPTANCE CHECKLIST

PLANT DETAILS

Plant Owner: Address: Ph:

Plant Make: Plant Model: Plant Serial No: Hours / KM’s:

Roads Reg No: Reg Expiry: Project Registration No: Project Asset No:

Last Service Date / Hrs: Next service Date / Hrs: Comcare/ State registration No Expire date:

MINIMUM REQUIREMENTS (If the minimum requirements are not met, a plant sticker will not be issued and the item of plant is not to commence work)

Verify Check Requirement Verify Check Requirement

Operator and Maintenance Manual available Plant Hazard Assessment Sighted & Current (within 2 yrs):

Logbook / Service Records (checked ok): Plant Hazard Assessment Inspection Date: / /

Audible Alarm and other Warning Devices fitted, operable and Daily Prestart Inspection Checklist is available for use.

suitable for site conditions

Fire Extinguisher Fitted and charged

Revision No: 1 Document Number: JH-FRM-PAE-001-29 Page 1 of 2

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 15/05/2018

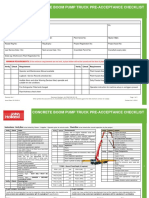

DRILL RIG PLANT PRE-ACCEPTANCE CHECKLIST

Instructions: Verify Box to be ticked by Owner / Supplier / Operator prior to arrival onsite. Check Box to be ticked after visual inspection by the project

Verify Check Cabin Verify Check Environmental Verify Check Undercarriage

Cleanliness Clean, free of organic materials (mud, Tracks complete and undamaged

Door operational dirt, weeds or seeds) prior to arrival Idlers / Rollers

Engine baffling or noise reduction Drivers free from leaks

Deadman Pedal /Switch operational

equipment fitted as per manufacturers

Handrails and ladders fitted and secure specifications Track Adjuster Sprockets.

Seat adjustments operational secure Smoke from internal combustion engines Articulation bearings and Retainers

Seat belt fitted and in good working order should not be visible for more than ten Verify Check Hydraulics System

Instruments operational & labelled seconds Rams

Levers / Controls Operational Hoses / Connectors

Pedals in good condition Pins / Mounting

Air conditioning operational (check for excessive wear, leaks and

ROPs Canopy to meet AS 2294 creep)

Hydraulic isolator

UHF Radio Fitted (If not fitted, has a hand held radio

been supplied) Verify Check Engine

Warning devices and other lights (flashing, head, tail, Engine Mountings

etc) are appropriate for the environment in which plant Engine Guarding

is being used. (check environment noise criteria Exhaust Guarding

particularly if working out of hours)

Warning Signs - Danger Beware Overhead Wires & Oil Leaks/check levels

Underground Services Coolant Leaks/check levels

Warning Signs - Seat Belt Must Be Worn Coolant System

Warning Signs - Noise Warning Signage Vee Belt Condition

Verify Check Rigging Gear Air Cleaner System

Chains, wire rope inspected within last 12 months Battery Condition / Mounting

Soft slings within 3 months Verify Check Drill Head

Rigging, fittings & slings have Manufacture’s ID / Guarding installed

Working Load Limit (WLL) attached Hydraulics

Wire line, pulleys, guides, steel cable Anchor points fitted for fall restraint

Verify Check Running Controls systems

Brake operational

Drivers free from leaks

PLANT OWNER / OCCUPIER PLANT VERIFIER

I certify that the described plant has met the inspection criteria stipulated within this checklist and is I certify that I have verified that the described plant has met the inspection criteria stipulated within this

being serviced and maintained in accordance with the manufacturer’s specifications checklist and is being serviced and maintained in accordance with the manufacturer’s specifications

Name: Signature: Date: Name: Signature: Date:

Revision No: 1 Document Number: JH-FRM-PAE-001-29 Page 2 of 2

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 15/05/2018

Вам также может понравиться

- Jumbo Drilling Rig Plant Pre Acceptance ChecklistДокумент3 страницыJumbo Drilling Rig Plant Pre Acceptance ChecklistRubén López LemaОценок пока нет

- JH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistДокумент3 страницыJH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistYoung Lin SaengОценок пока нет

- JH FRM Pae 001 60 Piling Rig Plant Pre Acceptance ChecklistДокумент2 страницыJH FRM Pae 001 60 Piling Rig Plant Pre Acceptance ChecklistMuhammad Shahzad100% (1)

- Concrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsДокумент2 страницыConcrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsBassam HSEОценок пока нет

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistДокумент2 страницыJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenОценок пока нет

- Rigging Up Checklist: Rig ModelДокумент2 страницыRigging Up Checklist: Rig Model89simbuОценок пока нет

- Checklist For Heavy Equipment - 1Документ15 страницChecklist For Heavy Equipment - 1Katita ChascaОценок пока нет

- Drilling Rigs Inspection ChecklistДокумент14 страницDrilling Rigs Inspection ChecklistRizwan Farid100% (3)

- Inspection Checklist Drill Rig PDFДокумент2 страницыInspection Checklist Drill Rig PDFAbdo Ojaimy100% (2)

- Checklist of Rig EquipmentДокумент11 страницChecklist of Rig EquipmentKachur AlekseyОценок пока нет

- Moving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaДокумент28 страницMoving RIG Mobilization & Risk Assessment: Harmand - Cv. Marga Sari UtamaHSE PT. GROGOL SARANA TRANSJAYAОценок пока нет

- Well Drilling Rig ChecklistДокумент1 страницаWell Drilling Rig ChecklistAli AlahmaОценок пока нет

- Fire Extinguisher ChecklistДокумент1 страницаFire Extinguisher ChecklistSafety Man ShopОценок пока нет

- Loading-Unloading-Low-Loader Risk AssmntДокумент10 страницLoading-Unloading-Low-Loader Risk AssmntStansilous Tatenda NyagomoОценок пока нет

- Finlay Training Services Ad24a98430Документ1 страницаFinlay Training Services Ad24a98430Christian MakandeОценок пока нет

- Lifting Hoisting Hazard HuntДокумент1 страницаLifting Hoisting Hazard Hunt曹庆园100% (1)

- Drilling Rig Checklist Rev1Документ29 страницDrilling Rig Checklist Rev1Abdulsani3357Оценок пока нет

- Dropped Object PreventionДокумент118 страницDropped Object PreventionRazvan-Teodor PuscasuОценок пока нет

- Mobile Crane Operation Procedure1Документ11 страницMobile Crane Operation Procedure1AkimBiОценок пока нет

- Table of Contents Iadc Safety Meeting TopicsДокумент4 страницыTable of Contents Iadc Safety Meeting TopicsfarisОценок пока нет

- Visible Safety and Induction: Hse Management Visit ChecklistДокумент6 страницVisible Safety and Induction: Hse Management Visit ChecklistHARSHALОценок пока нет

- WS QHSE Std23 3313701 07Документ24 страницыWS QHSE Std23 3313701 07ralph100% (1)

- 4.01 IOEC Rigs Commisioning Project HSE PlanДокумент59 страниц4.01 IOEC Rigs Commisioning Project HSE Planhshobeyri100% (2)

- Drilling Rig Safety Inspection Check ListДокумент17 страницDrilling Rig Safety Inspection Check ListKiryaki Francis100% (1)

- Rig OrientationДокумент35 страницRig OrientationaymenmoatazОценок пока нет

- GN-Permit To Work SystemДокумент13 страницGN-Permit To Work SystemchachaОценок пока нет

- JSA - Rig Move OperationsДокумент3 страницыJSA - Rig Move OperationsShahid Alam100% (4)

- Rig Specific Emergency Response Plan Rev1Документ33 страницыRig Specific Emergency Response Plan Rev1bilou100% (1)

- Well Services QHSE Standard 23 Guideline 09: CT Reel Swivel and Stub Shaft Inspection and TestДокумент11 страницWell Services QHSE Standard 23 Guideline 09: CT Reel Swivel and Stub Shaft Inspection and TestCiprianHnОценок пока нет

- HSE Presentation of Project To BPДокумент12 страницHSE Presentation of Project To BPswelitshhОценок пока нет

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportДокумент1 страницаAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithОценок пока нет

- Safe Work Procedure-Set Up RigsДокумент4 страницыSafe Work Procedure-Set Up RigsAsif KhanzadaОценок пока нет

- Dismantling of Concrete Pump TowerДокумент1 страницаDismantling of Concrete Pump TowerChandruОценок пока нет

- 10 Questions For Line of FireДокумент2 страницы10 Questions For Line of FireGary Moses100% (1)

- Oil Field Drill Rig Safety (HSE)Документ34 страницыOil Field Drill Rig Safety (HSE)omer dafallahОценок пока нет

- Inspection Checklist - Drill RigДокумент2 страницыInspection Checklist - Drill RigDuvan Bence83% (30)

- Crane ChecklistДокумент3 страницыCrane ChecklistAbdul Rehman SheikhОценок пока нет

- Safe Work Method Statement WorksheetДокумент5 страницSafe Work Method Statement Worksheetgoodspeed_phОценок пока нет

- Onshore Rig Inspection ChecklistДокумент113 страницOnshore Rig Inspection ChecklistGregorio Otero Sosa100% (2)

- JSA Formet New Structural Steel FabricationДокумент7 страницJSA Formet New Structural Steel Fabricationsakthi venkatОценок пока нет

- Name Signature Date Name Signature Date Name Signature DateДокумент1 страницаName Signature Date Name Signature Date Name Signature DateMithlesh Singh100% (1)

- Land Rig Acceptance MasterДокумент17 страницLand Rig Acceptance Masterislam atif100% (1)

- Drill Rig Safety PDFДокумент83 страницыDrill Rig Safety PDFMuhammad Tarique BhattiОценок пока нет

- Engine: Daily Check List - Piling RigДокумент3 страницыEngine: Daily Check List - Piling RigrehanОценок пока нет

- Safe Work Procedure - Dump Truck: Company NameДокумент4 страницыSafe Work Procedure - Dump Truck: Company Nameangkatan 2014Оценок пока нет

- Luffing Tower Crane Preshift InspectionДокумент1 страницаLuffing Tower Crane Preshift InspectionEdmond KeraОценок пока нет

- Introduction and General Service SafetyДокумент47 страницIntroduction and General Service SafetyJoko Sukariono100% (2)

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahДокумент14 страницMobile Elevated Work Platforms (MEWP) Program: Provo, UtahStephanie ScottОценок пока нет

- Tower Crane Daily Inspection Form PDFДокумент1 страницаTower Crane Daily Inspection Form PDFMd Imteyaz AnsariОценок пока нет

- JSA DrillingДокумент12 страницJSA DrillingAbdus SamadОценок пока нет

- Crawler Crane Annual InspectionДокумент3 страницыCrawler Crane Annual InspectionMark SolmundsonОценок пока нет

- JSA HEMP Well Services Pg36-40Документ5 страницJSA HEMP Well Services Pg36-40Ashok Suresh100% (1)

- Fall Protection Survey of RIG 40Документ3 страницыFall Protection Survey of RIG 40Kevin Josh Bonales100% (1)

- Daily Checks (Floorman)Документ1 страницаDaily Checks (Floorman)Abdul Hameed OmarОценок пока нет

- EDC-61 Rig SurveyДокумент14 страницEDC-61 Rig SurveyMostafa Elghifary100% (1)

- Side Boom ChecklistДокумент6 страницSide Boom Checklistsaqib100% (1)

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistДокумент2 страницыJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

- Concrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistДокумент2 страницыConcrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistTFattahОценок пока нет

- JH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistДокумент2 страницыJH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistStansilous Tatenda NyagomoОценок пока нет

- Piling Rig Plant Pre-Acceptance ChecklisДокумент3 страницыPiling Rig Plant Pre-Acceptance Checklisosama F. MohamedОценок пока нет

- Buncefield Volume 2Документ208 страницBuncefield Volume 2Hammy223Оценок пока нет

- Raw:/storage/emulated/0/download/1623980378472 - 1623980347729 - PE 4 Module 2Документ11 страницRaw:/storage/emulated/0/download/1623980378472 - 1623980347729 - PE 4 Module 2Marvin Espenocilla EspeñoОценок пока нет

- Essay Writing TipsДокумент4 страницыEssay Writing TipsSubhasish MitraОценок пока нет

- 3 - 0 - D Copia403mfen 404mfen Smy113840 1Документ253 страницы3 - 0 - D Copia403mfen 404mfen Smy113840 1Serge MaciaОценок пока нет

- Ssg-Ng01012401-Gen-Aa-5880-00012 - C01 - Ssags Nigerian Content PlanДокумент24 страницыSsg-Ng01012401-Gen-Aa-5880-00012 - C01 - Ssags Nigerian Content PlanStroom Limited100% (2)

- Prepared by M Suresh Kumar, Chief Manager Faculty, SBILD HYDERABADДокумент29 страницPrepared by M Suresh Kumar, Chief Manager Faculty, SBILD HYDERABADBino JosephОценок пока нет

- 2022+ACCF+111+Class+test+2 Moderated+versionДокумент8 страниц2022+ACCF+111+Class+test+2 Moderated+versionLucas LuluОценок пока нет

- Chapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16Документ81 страницаChapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16mohamed hemdanОценок пока нет

- Chemical Recycling of Textile PolymersДокумент8 страницChemical Recycling of Textile PolymersVaishali RaneОценок пока нет

- Guide: Daily ReferenceДокумент8 страницGuide: Daily ReferenceGalina TodorovaОценок пока нет

- LIP Reading Using Facial Feature Extraction and Deep LearningДокумент5 страницLIP Reading Using Facial Feature Extraction and Deep LearningInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Ebook Essentials of Kumar Clarks Clinical Medicine PDF Full Chapter PDFДокумент67 страницEbook Essentials of Kumar Clarks Clinical Medicine PDF Full Chapter PDFjanet.cochran431100% (19)

- Particle FilterДокумент16 страницParticle Filterlevin696Оценок пока нет

- Tata Motors - Strategic ManagementДокумент16 страницTata Motors - Strategic ManagementVaishakh MenonОценок пока нет

- Augusta Issue 1145 - The Jail ReportДокумент24 страницыAugusta Issue 1145 - The Jail ReportGreg RickabaughОценок пока нет

- ATMPP Diabetes Change and Review Proposal Npa 2012-18Документ8 страницATMPP Diabetes Change and Review Proposal Npa 2012-18Juha TamminenОценок пока нет

- Sacramento County Compensation Survey Board of SupervisorsДокумент13 страницSacramento County Compensation Survey Board of SupervisorsCBS13Оценок пока нет

- D2 1 PDFДокумент148 страницD2 1 PDFsubas khanalОценок пока нет

- Webinar WinCC SCADA NL 29052018Документ62 страницыWebinar WinCC SCADA NL 29052018AlexОценок пока нет

- Lesson 3 - Practical ResearchДокумент17 страницLesson 3 - Practical ResearchBenОценок пока нет

- Social Skills Assessments For Children With Autism Spectrum Disorders 2165 7890.1000122Документ9 страницSocial Skills Assessments For Children With Autism Spectrum Disorders 2165 7890.1000122Shinta SeptiaОценок пока нет

- Checkpoints Before Transformer InstallationДокумент3 страницыCheckpoints Before Transformer InstallationBeaBustosОценок пока нет

- NTCC Project - Fake News and Its Impact On Indian Social Media UsersДокумент41 страницаNTCC Project - Fake News and Its Impact On Indian Social Media UsersManan TrivediОценок пока нет

- 1778 3557 1 SM PDFДокумент4 страницы1778 3557 1 SM PDFjulio simanjuntakОценок пока нет

- Usp3 ComДокумент5 страницUsp3 ComMike MelgaОценок пока нет

- Reconductoring Using HTLS Conductors. Case Study For A 220 KV Double Circuit Transmission LINE in RomaniaДокумент7 страницReconductoring Using HTLS Conductors. Case Study For A 220 KV Double Circuit Transmission LINE in RomaniaJose ValdiviesoОценок пока нет

- Network Tools and Protocols Lab 2: Introduction To Iperf3Документ17 страницNetwork Tools and Protocols Lab 2: Introduction To Iperf3Fabio MenesesОценок пока нет

- RenewalPremium 1123186Документ1 страницаRenewalPremium 1123186Suhas Renu85Оценок пока нет

- Cutting Conics AsДокумент3 страницыCutting Conics Asbabe09Оценок пока нет

- Assignment ProblemДокумент3 страницыAssignment ProblemPrakash KumarОценок пока нет