Академический Документы

Профессиональный Документы

Культура Документы

Utl

Загружено:

Miguel OrhlИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Utl

Загружено:

Miguel OrhlАвторское право:

Доступные форматы

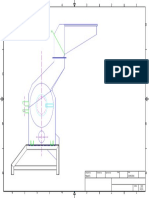

UTL Spiral / Ribbon

UTL U Trough

Ideal for free flowing materials.

Innovative features provide faster, improved mixing and cleaning.

The UTL Ribbon blender is preconfigured, offering short loadtimes, easy cleaning and

simple operation. Affordable, Proven, Productive, Ergonomic, Adaptable and using innovative Lean

manufacturing principles it has APPEAL.

UTL mixers are used in a wide range of industries and applications. Uses include:

Disinfectants Coatings Spices Pigments

Lime and cement Soups Plastic pellets Fruit pie fillings

Food ingredients Ceramics Cake and pastry mixes Vitamins and minerals

Sugars Animal feeds Seasonings Waste reclamation

Winkworth Machinery Ltd

Mixer House

Stroudley Road, Basingstoke

Hampshire RG24 8FW

mixer.co.uk +44 (0)1256 305 600 info@mixer.co.uk

UTL Spiral / Ribbon

UTL U Trough

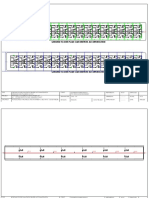

Model UTL 100 UTL 240 UTL 430 UTL 660 UTL 1000

Working volume (litres) 100 240 430 660 1000

Stainless steel (316) Y Y Y Y Y

Standard configuration

Shaft seal - lip type Y Y Y Y Y

Push-pull slide valve (stainless steel 100mm 100mm 150mm 150mm 200mm

slide, aluminium body)

Lid One piece, rear One piece, rear One piece, rear 2 part, axial mid 2 part, axial mid

hinged hinged hinged hinge hinge

Lid support Compression hinge Compression hinge Gas strut Gas strut (front - Gas strut (front -

rear fixed) rear fixed)

Lid safety interlock Y Y Y Y Y

Fully welded pan assembly - welds Y Y Y Y Y

as laid crack and crevice free

Fully welded blade assembly - welds Y Y Y Y Y

as laid crack and crevice free

Internal mill finish Y Y Y Y Y

External mill finish Y Y Y Y Y

Extra cost - options:

Control panel Y Y Y Y Y

Pivoting slide outlet valve Y Y Y Y Y

Full stainless slide valve Y Y Y Y Y

Pivoting plug valve Y Y Y Y Y

Pneumatic valve Y Y Y Y Y

Bomb door N N N Y Y

Lid inlets Y Y Y Y Y

Inspection hatch Y Y Y Y Y

Packed gland shaft seals Y Y Y Y Y

At we design each machine to suit your specific needs. The abbreviated option chart (above) is a

External

guide tofinish - satin

assist beaddeveloping the specification

with Y Y machine. To get

of your Y your project Ystarted please call

Y our

sales team

Internal finish who willpan,

- polished be blade

delighted to help

Y you. Y Y Y Y

assembly and lid

are application specialists in the complex and

challenging world of mixing. Since 1924, years of experience,

knowledge and client feedback have enabled to design

and manufacture bespoke mixing machinery for almost every

mixing need.

’s current range includes the expertise and products originating from BPT Skerman and Premier

Colloid Mills. For high shear in-line mixing we offer Ystral products and for low shear we have the Lindor

“gentle touch” rotary drum blenders.

This complements the extensive range of proprietary mixer designs which are extensively used across all

industries for mixing stiff gums, pastes, powders, liquids, etc, most of which are available at our Mixing Test

Centre at our Basingstoke HQ.

mixer.co.uk +44 (0)1256 305 600 info@mixer.co.uk

Вам также может понравиться

- Alternator MountingДокумент2 страницыAlternator MountingNick Ildefonso Fuenmayor AntunezОценок пока нет

- Service-Parts Wp2 Catalog 10-21-21Документ9 страницService-Parts Wp2 Catalog 10-21-21dilipОценок пока нет

- Nido Edge Dock Leveler - ND-DL-10Документ5 страницNido Edge Dock Leveler - ND-DL-10Web AdminОценок пока нет

- Rotating - Iapetus J Tech201010142Документ8 страницRotating - Iapetus J Tech201010142RenardОценок пока нет

- BitДокумент7 страницBitRubhy DiazОценок пока нет

- Dugard BrochureДокумент16 страницDugard Brochurepc100xohmОценок пока нет

- ICF - Must Change ItemsДокумент6 страницICF - Must Change ItemssangramjitОценок пока нет

- Innovative Machines: Power InnovationДокумент10 страницInnovative Machines: Power InnovationHari PrasadОценок пока нет

- CWPL Services - ChecklistДокумент16 страницCWPL Services - ChecklistLewisОценок пока нет

- Frameless Swing Door Double In-Line Panels: For Technical Assistance, Call Other Questions, CallДокумент9 страницFrameless Swing Door Double In-Line Panels: For Technical Assistance, Call Other Questions, CallChristel KuppersОценок пока нет

- Water Consumption EstimatorДокумент1 страницаWater Consumption Estimatorlol photoboothОценок пока нет

- All Gear Lathe MachineДокумент2 страницыAll Gear Lathe MachineMihir Machine Tools Gujarat Pvt LtdОценок пока нет

- Tingle Tension System ManualДокумент12 страницTingle Tension System ManualGarieo CostraОценок пока нет

- ЗеркалаДокумент98 страницЗеркалаВладимир ВдовенкоОценок пока нет

- OKcon GX20Документ1 страницаOKcon GX20learningzabatОценок пока нет

- Unistryt Pipe Supports CatalogueДокумент14 страницUnistryt Pipe Supports CatalogueMehedi ChowdhuryОценок пока нет

- Crankcase BreatherДокумент1 страницаCrankcase BreatherNick Ildefonso Fuenmayor AntunezОценок пока нет

- Sym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedДокумент6 страницSym-Metric Actuators: Cubic Worm Gear Actuators UK Designed and ManufacturedmattiaОценок пока нет

- Quotation: To Deliver ToДокумент7 страницQuotation: To Deliver ToJamesОценок пока нет

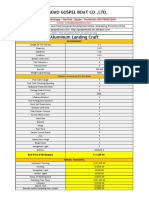

- 7.9M Aluminum Landing CraftДокумент2 страницы7.9M Aluminum Landing CraftGreen ArcticОценок пока нет

- EK Catalog IreneДокумент40 страницEK Catalog Irenethiru_tsn87Оценок пока нет

- HP Catalogue-NewДокумент5 страницHP Catalogue-NewNasree NiswongОценок пока нет

- Aspect Wetroom Panels-1Документ1 страницаAspect Wetroom Panels-1Weiwei ShuОценок пока нет

- 40 MM Diameter Incremental Rotary Encoders: E40 SeriesДокумент2 страницы40 MM Diameter Incremental Rotary Encoders: E40 SeriesShahariar HasanОценок пока нет

- Ari 3200425Документ1 страницаAri 3200425Moe Thiri ZunОценок пока нет

- Hidroozcelik - Brosur 2014Документ12 страницHidroozcelik - Brosur 2014Nikola AngjelkovskiОценок пока нет

- Pre CastДокумент3 страницыPre Castshailiza velaniОценок пока нет

- Screw Conveyors PDFДокумент121 страницаScrew Conveyors PDFzackii90Оценок пока нет

- Winterhoff - Quality Trailers SystemДокумент52 страницыWinterhoff - Quality Trailers SystemMichal MilczarekОценок пока нет

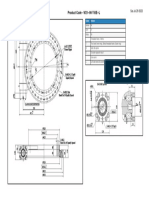

- Product Code - W21 - 90-T-BE - L: Sat Jul 29 2023Документ1 страницаProduct Code - W21 - 90-T-BE - L: Sat Jul 29 2023Saravanakumar NОценок пока нет

- Quotation Scheme Jstomi: Equiptech (PVT.) LTDДокумент4 страницыQuotation Scheme Jstomi: Equiptech (PVT.) LTDvasiliy vasilievichОценок пока нет

- Quotation Solitair vc09, vc10 RevisedДокумент3 страницыQuotation Solitair vc09, vc10 RevisedSagar MishraОценок пока нет

- SS & SC All Gear Lathe MachineДокумент2 страницыSS & SC All Gear Lathe MachineMihir Machine Tools Gujarat Pvt LtdОценок пока нет

- Componant ShelfДокумент2 страницыComponant Shelfapi-3805767Оценок пока нет

- Gyproc White Book C07 S05 GypLyner IWLДокумент15 страницGyproc White Book C07 S05 GypLyner IWLOlivia SaferОценок пока нет

- H RV100 e 2002 01 PDFДокумент2 страницыH RV100 e 2002 01 PDFMELEK MECHRIОценок пока нет

- Cyclonic Separator 1500 TCDДокумент1 страницаCyclonic Separator 1500 TCDnghiОценок пока нет

- URT Service Options 2015-09-02Документ1 страницаURT Service Options 2015-09-02NY DanyОценок пока нет

- Ortco (ROTARY SLIP)Документ41 страницаOrtco (ROTARY SLIP)sitaОценок пока нет

- 11 - Car Driver's Accommodation UnitДокумент2 страницы11 - Car Driver's Accommodation UnitfebousОценок пока нет

- OKcon GX025Документ1 страницаOKcon GX025dyx542nkgbОценок пока нет

- Specifications: All New Grand LivinaДокумент3 страницыSpecifications: All New Grand LivinarooswahyoeОценок пока нет

- A6-L 3D Printer Installation Instructions2019.6.28Документ46 страницA6-L 3D Printer Installation Instructions2019.6.28Bruno LópezОценок пока нет

- Automatic Qto Sheet v0Документ6 страницAutomatic Qto Sheet v0kamaluddin168Оценок пока нет

- Right Angle Valve 1.5Документ1 страницаRight Angle Valve 1.5olympia sajuОценок пока нет

- Catalogue VBM Products For Mining Industry eSKİДокумент44 страницыCatalogue VBM Products For Mining Industry eSKİEmrah MertyürekОценок пока нет

- FT Valvula Acero 300 LBS Crane 33xu.fДокумент1 страницаFT Valvula Acero 300 LBS Crane 33xu.fFernando CarreñoОценок пока нет

- Jot Brochure 2021-22Документ60 страницJot Brochure 2021-22Darshan MakwanaОценок пока нет

- 2018 Westeel Cross Vault Bunded Tanks WebДокумент4 страницы2018 Westeel Cross Vault Bunded Tanks WebyshutОценок пока нет

- IMGVVALVE Product Catalog 2024Документ32 страницыIMGVVALVE Product Catalog 2024Sai PrasathОценок пока нет

- Slip Type Elevator - Shanghai Oilwell Solutions Co., LTDДокумент2 страницыSlip Type Elevator - Shanghai Oilwell Solutions Co., LTDHanyОценок пока нет

- SMC Air Cylinder PDFДокумент121 страницаSMC Air Cylinder PDFRandy FajardoОценок пока нет

- Hep FlowДокумент4 страницыHep Flowpeter3972Оценок пока нет

- HYUNDAI+elevator pdf-2Документ2 страницыHYUNDAI+elevator pdf-2Bryan RamirezОценок пока нет

- UNP UPN DatasheetДокумент3 страницыUNP UPN DatasheetHaytham SemaanОценок пока нет

- WWW - Ykkap Agen - Com NEXSTA CatalogДокумент33 страницыWWW - Ykkap Agen - Com NEXSTA CatalogXaverius NandaОценок пока нет

- BR-R8070 SM-BH90 SM-RT800 SM-BH90: ULTEGRA Disc BrakeДокумент1 страницаBR-R8070 SM-BH90 SM-RT800 SM-BH90: ULTEGRA Disc BrakeMAYINNОценок пока нет

- Drawing Oliver ValveДокумент1 страницаDrawing Oliver ValveANTONIUS TRIMARTANTOОценок пока нет

- Janki Oil ToolsДокумент55 страницJanki Oil ToolsInderjeet HoodaОценок пока нет

- Health Safety and Environment PolicyДокумент2 страницыHealth Safety and Environment PolicyMiguel OrhlОценок пока нет

- Chevron 2013 CR GlossaryДокумент1 страницаChevron 2013 CR GlossaryMiguel OrhlОценок пока нет

- EEII CeramicHeating ProductFlyer 140129 ScreenДокумент2 страницыEEII CeramicHeating ProductFlyer 140129 ScreenMiguel OrhlОценок пока нет

- Ehs - Company Policy: Environmental - Health - SafetyДокумент1 страницаEhs - Company Policy: Environmental - Health - SafetyMiguel OrhlОценок пока нет

- 34 2 1 Chain Conveyor RL RM in Line Shutter GB@GBДокумент1 страница34 2 1 Chain Conveyor RL RM in Line Shutter GB@GBMiguel OrhlОценок пока нет

- Chain Conveyor GB@GBДокумент8 страницChain Conveyor GB@GBMiguel OrhlОценок пока нет

- Motridal CocleeДокумент8 страницMotridal CocleeMiguel OrhlОценок пока нет

- Plano Mecánico Puente GruaДокумент1 страницаPlano Mecánico Puente GruaAbel Valderrama PerezОценок пока нет

- RibbonBlendes PaulOAbbeДокумент4 страницыRibbonBlendes PaulOAbbeMiguel OrhlОценок пока нет

- Tank Drawings Example PDFДокумент2 страницыTank Drawings Example PDFMiguel OrhlОценок пока нет

- Rotary ConditionerДокумент7 страницRotary ConditionerMiguel OrhlОценок пока нет

- Nestix Cutting EsiteДокумент3 страницыNestix Cutting EsiteMiguel OrhlОценок пока нет

- Integrated Talent MGT Matters 2844606Документ4 страницыIntegrated Talent MGT Matters 2844606Miguel OrhlОценок пока нет

- Nestix Cutting EsiteДокумент3 страницыNestix Cutting EsiteMiguel OrhlОценок пока нет

- Automatic Car ShelterДокумент1 страницаAutomatic Car ShelterMiguel OrhlОценок пока нет

- Examplefile: Rendering Engine Browser Platform (S) Engine Version Css GradeДокумент1 страницаExamplefile: Rendering Engine Browser Platform (S) Engine Version Css GradeMiguel OrhlОценок пока нет

- Code of Business Conduct and EthicsДокумент5 страницCode of Business Conduct and EthicsMiguel OrhlОценок пока нет

- Conveyor Belt EBS 40 M1 100x450 2M8 U0 V U0 BR EasyДокумент2 страницыConveyor Belt EBS 40 M1 100x450 2M8 U0 V U0 BR EasyMiguel OrhlОценок пока нет

- 2014 Invoice Style PDFДокумент1 страница2014 Invoice Style PDFMiguel OrhlОценок пока нет

- Automatic Wall Shutter-Single Panel MODEL 502: Ratings Features FrameДокумент1 страницаAutomatic Wall Shutter-Single Panel MODEL 502: Ratings Features FrameMiguel OrhlОценок пока нет

- 3 PDFДокумент1 страница3 PDFMiguel OrhlОценок пока нет

- Auto Exhaust Damper MODEL 611: Ratings Features FrameДокумент1 страницаAuto Exhaust Damper MODEL 611: Ratings Features FrameMiguel OrhlОценок пока нет

- Weiler MixerSS ENGДокумент2 страницыWeiler MixerSS ENGMiguel OrhlОценок пока нет

- Apple A9Документ10 страницApple A9Savithri NandadasaОценок пока нет

- Limak 2017 Annual ReportДокумент122 страницыLimak 2017 Annual Reportorcun_ertОценок пока нет

- Simple and Compound Gear TrainДокумент2 страницыSimple and Compound Gear TrainHendri Yoga SaputraОценок пока нет

- Parth Valves and Hoses LLP.: Test & Guarantee CertificateДокумент1 страницаParth Valves and Hoses LLP.: Test & Guarantee CertificateSURYAKANTОценок пока нет

- YcivДокумент68 страницYcivBelhassen Saddadi100% (2)

- DFM54 EngДокумент2 страницыDFM54 EngAnonymous KWO434Оценок пока нет

- 2x18 AWG Shielded Fire Alarm and Control Cable - 5M11802103Документ2 страницы2x18 AWG Shielded Fire Alarm and Control Cable - 5M11802103Alvaro Coy H.Оценок пока нет

- 2009 PMI CatalogueДокумент124 страницы2009 PMI Cataloguedesbennett004Оценок пока нет

- Republic Act No. 10913 - Anti-Distracted Driving ActДокумент4 страницыRepublic Act No. 10913 - Anti-Distracted Driving Act...Оценок пока нет

- Ecg Signal Thesis1Документ74 страницыEcg Signal Thesis1McSudul HasanОценок пока нет

- BME (Steel)Документ8 страницBME (Steel)Mohil JainОценок пока нет

- STOD-OTP-PMT-0805-HS-SPE-0001 Specification For Temporary Construction Camps and Ancillary FacilitiesДокумент25 страницSTOD-OTP-PMT-0805-HS-SPE-0001 Specification For Temporary Construction Camps and Ancillary Facilitiesjfl2096Оценок пока нет

- UT TransducersДокумент20 страницUT TransducersSamanyarak AnanОценок пока нет

- Fusible PVC SpecificationsДокумент17 страницFusible PVC Specificationsamir_hayfaОценок пока нет

- Ex Delta Ex Delta - Dia: OVAL CorporationДокумент8 страницEx Delta Ex Delta - Dia: OVAL CorporationDaniela GuajardoОценок пока нет

- Fasteners Lecture 11-20-03Документ67 страницFasteners Lecture 11-20-03laponggaОценок пока нет

- R123 UpdateДокумент2 страницыR123 Updateasayed_1@hotmail.comОценок пока нет

- National Power Training Institute: Admission Notice: 2020-21Документ3 страницыNational Power Training Institute: Admission Notice: 2020-21a.jainОценок пока нет

- RE 2017 EOT Brochure 4AДокумент20 страницRE 2017 EOT Brochure 4AOrangutan SolutionsОценок пока нет

- Electrochlorination IntroductionДокумент42 страницыElectrochlorination Introductiondubaisrinivasulu100% (8)

- Bomba FlightДокумент2 страницыBomba FlightGustavo HRОценок пока нет

- CT2000 Manual EN 20151202 PDFДокумент634 страницыCT2000 Manual EN 20151202 PDFKhang NguyenОценок пока нет

- Lifting Plan For CranesДокумент9 страницLifting Plan For CranesBibin JohnОценок пока нет

- Excel CatДокумент132 страницыExcel Catjuanf_scribdОценок пока нет

- Review of C++ Programming: Sheng-Fang HuangДокумент49 страницReview of C++ Programming: Sheng-Fang HuangIfat NixОценок пока нет

- Electric Power Station PDFДокумент344 страницыElectric Power Station PDFMukesh KumarОценок пока нет

- MB m.2 Support Am4Документ2 страницыMB m.2 Support Am4HhhhCaliОценок пока нет

- Rubber FaberДокумент10 страницRubber FabersoldatechОценок пока нет

- tt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFДокумент20 страницtt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFelmek jayaОценок пока нет

- Language Processing System:-: CompilerДокумент6 страницLanguage Processing System:-: CompilerRenganathan rameshОценок пока нет