Академический Документы

Профессиональный Документы

Культура Документы

Safety Shower Eyewash

Загружено:

KesavanVeeraИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Safety Shower Eyewash

Загружено:

KesavanVeeraАвторское право:

Доступные форматы

Emergency Eyewash and Shower Equipment

Standard Operating Procedure

Environmental Health & Safety

Doc. No.: 1

Rev. No.: 0

Safety Showers and Eyewash Stations

Regulatory Authority or Standard

The Texas A&M Health Science Center (HSC) is committed to meeting compliance with all

applicable federal, state and local rules, regulations, policies and procedures. The HSC’s

Environmental Health and Safety (EHS) office has the responsibility of supporting these

compliance obligations through regulating and developing safety and environmental policies and

procedures for all HSC components.

This document for Emergency Eyewash and Shower Equipment was developed in compliance

with the American National Standards Institute (ANSI) standard Z358.1 (Emergency Eyewash

and Shower Equipment) and inspection criteria and maintenance operations unique to the Texas

A&M Health Science Center work environment.

Change History

Revision Interim Effective

Number Change No. Date Description of Change

000 0 March 1, 2011 Original Document

Safety Showers and Eyewash Stations

Table of Contents

Section 1. Introduction ............................................................................................................. 1

Section 2. Scope......................................................................................................................... 1

Section 3. Operations / Departments Affected ....................................................................... 1

Section 4. Definitions ................................................................................................................ 1

Section 5. Responsibilities ........................................................................................................ 2

Section 6. Selection Criteria .................................................................................................... 4

Section 7. Installation ............................................................................................................... 7

Section 8. Inspection Procedures ............................................................................................ 9

Section 9. Maintenance, Repair and Training ................................................................... 111

Section 10. References ............................................................................................................ 122

Appendix A Hazard Assessment........................................................................................... 13

Safety Showers and Eyewash Stations

Section 1. Introduction

The purpose of this Standard Operating Procedure is to outline the requirements for the

installation, inspection, use and maintenance of Emergency Eyewash and Emergency Shower

Equipment.

Section 2. Scope

The HSC will provide Emergency showers and/or eyewash stations wherever mandated by rule,

regulation or consensus standards, or whenever a hazard assessment determines areas where

corrosive materials or infectious agents are present, or where there is a reasonable probability of

injury to the eyes or skin occurring as a result of exposure to hazardous chemicals or materials.

Section 3. Operations / Departments Affected

This program applies to all plumbed and non-plumbed emergency eyewash and emergency

shower equipment located in all HSC facilities.

Section 4. Definitions

Emergency Shower: A device designed to deliver flushing fluid in sufficient volume in order to

enable the user to have water cascading over the entire body while the hands are free.

Emergency Eyewash: A device used to provide fluid to irrigate and flush both eyes

simultaneously at a velocity low enough to be non-injurious to the user.

Eye/Face Wash: A device used to provide fluid to irrigate and flush both the face and the eyes

simultaneously.

Combination Unit: An interconnected assembly of drenching and flushing equipment that is

supplied by a single flushing fluid source.

Drench Hose: A supplemental device consisting of a flexible hose connected to a flushing fluid

supply that is used to provide fluid to irrigate face and body areas.

Personal Eyewash: A supplementary device that supports plumbed or self-contained eyewash

units, by delivering immediate flushing fluid to the eyes or body.

Plumbed Eyewash: An eyewash unit that is permanently connected to a source of potable water

in order to irrigate both eyes

Safety Showers and Eyewash Stations Page 1

Potable water: Water that is suitable for drinking

Flushing fluid: Potable water, preserved water, preserved buffered saline solution or other

medically acceptable solutions manufactured and labeled in accordance with applicable federal

regulations.

Flow Pressure: The pressure of the flushing fluid exerted in the wall of the pipe near the outlet

while the faucet/outlet is fully open and flowing.

Flow Regulator: A mechanical device intended to control the flow of flushing fluid through the

pipe.

Stay-open valve: A valve that, once activated, must be closed manually by the user.

Tepid: Moderately warm; lukewarm

Hazardous Material: Any substance or compound that has the capability of producing adverse

effects on human health and safety.

Section 5. Responsibilities

5.1 Laboratory Supervisor

x Ensure that the necessary emergency eyewash and shower equipment are located on the

same level as the hazards.

x Ensure unobstructed access to the safety shower/eyewash equipment so that it requires no

more than 10 seconds to reach (no more than 55 feet walking distance).

x Ensure that all employees and students who may need the emergency eyewash and

shower equipment are trained on their location and use.

x Ensure that emergency eyewash stations within the laboratory are activated weekly and a

weekly activation log is maintained.

x Request maintenance for immediate repair, modification or installation of

eyewash/shower equipment.

x Inform Environmental Health & Safety (EHS) before removing any emergency

eyewash/shower equipment from the laboratory.

5.2 Environmental Health & Safety

x Ensure that supervisors, employees, and students are notified of their responsibilities as

outlined in this Standard Operating Procedure.

x Ensure that all employees and students have received instruction regarding operation and

maintenance of emergency eyewash and shower equipment as needed.

x Coordinate with facilities management for inspection, modification, repair, maintenance,

and installation of emergency shower and eyewash units, as necessary.

Safety Showers and Eyewash Stations Page 2

x Ensure that each department is aware of their responsibilities under this program.

x Maintain an updated inventory of emergency eyewash and safety shower units.

x Assist with building plan review and selection from a list of recommended units during

new construction or major renovation.

x Provide assistance, necessary equipment and inspection tags required to test emergency

eyewash/shower equipment as required by departments.

x Conduct annual inspection to ensure that the emergency eyewash and shower equipment

is functioning properly.

x Monitor that the provided emergency eyewash station weekly activation log is

maintained by each laboratory.

x Conducting hazard assessments (using the guidance provided in Appendix A)

x Evaluating and approving personal eyewash bottles.

x Identifying emergency eyewashes and showers that are no longer needed and submitting

a request to Facilities Management for their removal.

x Providing technical assistance to Facilities Management and other personnel in the

selection, installation, maintenance, and testing of emergency eyewashes and showers.

x Conducting an annual review of all elements of the emergency eyewash and shower

program.

5.3 Facilities Maintenance

x Perform immediate modifications, repair, maintenance, and installation of emergency

eyewash and shower equipment as required.

x Inform EHS after installation, repair, and modification of eyewash and/or shower

equipment so that EHS can inspect/re-inspect the units.

x Executes all work orders for the installation or repair of emergency eyewash and shower

equipment on a high priority basis.

x Conducts annual flow rate testing and compliance assessment.

x Maintains written records of flow rate testing and compliance assessment.

x Notifying facility EHS staff of changes in work areas or work processes and practices

that require a Hazard Assessment to evaluate the need for new installations, or for the

removal of existing emergency eyewashes or showers.

x Testing all emergency equipment after installation to ensure that it meets the

manufacturer’s installation requirements.

x Units that fail testing must be repaired immediately. If deficiencies cannot be

immediately corrected, the area supervisor must be notified and the unit must be tagged

“DO NOT USE”. The area supervisor must notify all affected employees and EHS when

emergency equipment is out of service. A portable unit may be temporarily required to

meet the need for an emergency eyewash and shower.

Safety Showers and Eyewash Stations Page 3

Section 6. Selection Criteria

6.1 Hazard Assessment

6.1.1 A hazard assessment (see Appendix A) will be performed in areas of the facility

when

(1) Interpretation of code, guideline or standard is needed.

(2) When reviewing project specifications for all new construction and

renovation projects to determine the need for eyewash and shower units,

including proper selection and installation.

(3) Every time the workplace conditions change.

6.1.2 When deemed necessary by the hazard assessment, ANSI-approved emergency

eyewashes and/or showers must be installed in newly constructed areas. All

unapproved eyewashes and showers must be replaced with ANSI-approved units

during renovation projects.

6.1.3 Only the American National Standards Institute (ANSI)-approved emergency

eyewashes, showers, and drenching equipment may be purchased and installed in

accordance with the manufacturer’s specification to maintain the ANSI approval.

6.1.4 Selection of the emergency eyewashes and equipment must be approved by the

facility EH&S staff.

6.2 Safety Showers

6.2.1 ANSI requires that a means shall be provided Fig. Emergency shower

to ensure controlled flow of flushing fluid at a

velocity low enough to be non-injurious to the

user.

6.2.2 The safety shower equipment shall be

designed so that it can be activated in 1 second or

less, and it remains operational without user

assistance (stay-open valve) until intentionally

closed.

6.2.3 The shower equipment shall be capable of

delivering flushing fluid at a minimum volume of

75.7 liters per minute (20 gpm) for at least 15

minutes.

Safety Showers and Eyewash Stations Page 4

6.2.4 The spray pattern of the shower shall

Fig. Plumbed eyewash and shower diagram

have a minimum diameter of at least 50.8 cm

(20 in.) at 152.4 cm (60 inches) above the

surface on which the user stands.

6.2.5 The center of the spray pattern shall be

located at least 40.6 cm (16 in.) from any

obstruction.

6.3 Emergency Eyewashes

6.3.1 ANSI requires that a means shall be

Fig. Emergency Eyewash Unit

provided to ensure controlled flow of flushing

fluid at a velocity low enough to be non-

injurious to the user.

6.3.2 The emergency eyewash unit shall be

designed so that it can be activated in 1 second

or less, and once activated; it remains

operational without requiring the use of

operator’s hand until intentionally closed.

Safety Showers and Eyewash Stations Page 5

6.3.3 The eyewash equipment shall be capable

of delivering fluid to both eyes simultaneously Fig. Emergency Eyewash Unit

at a volume of not less than 1.5 liters per

minute (0.4 gpm) for minimum 15 minutes.

6.4 Drench Hose

6.4.1 Drench hoses are considered to be

secondary to emergency eyewash and shower

equipment. Monocular and dual-head drench Fig. Hand-held drench hose

hoses do not meet ANSI standards for

emergency eyewash or safety shower as

because they are not hands free. Therefore,

having a drench hose does not replace the need

for an emergency eyewash/safety shower.

6.4.2 Drench hoses may be used to "spot"

rinse an area when a full shower is not

required, to assist a victim when the victim is

unable to stand or is unconscious, or to wash

under a piece of clothing before the clothing is

removed.

6.5 Water Temperature

The ANSI Z358.1-2009 recommends that the flushing fluid shall be "tepid". However,

ANSI provides a guideline that the flushing fluid temperature in the range of 270C-35°C

(80°F -95°F) is considered suitable.

Safety Showers and Eyewash Stations Page 6

6.6 Privacy consideration

Normal showers should not be used in-lieu of an emergency shower for drenching and

removing chemicals. Shower enclosure, if used, shall provide at least 86.4 cm (34 in.) in

diameter of unobstructed area inside.

Section 7. Installation

7.1 Emergency Shower

7.1.1 It is the installer’s responsibility to ensure that all safety shower units are

assembled and installed in compliance with ANSI Z358.1-2009 and the

manufacturer’s instructions.

7.1.2 All laboratories, newly constructed or renovated, or any room used for similar

purposes wherein corrosives, flammable liquids, toxins, bio-hazardous wastes, or

radiological materials are handled as well as other work-areas where hazardous

materials are used; such as mechanical rooms, pH neutralization systems,

battery charging areas, spraying operations, and high dust areas shall have

a safety shower for emergency use.

7.1.3 The shower location shall be identified Fig. Safety Shower Sign

with highly visible signs. The sign shall be

visible within the area served by the shower

and shall consists of symbols that require users

to have any language skill to understand.

7.1.4 The shower shall be designed and installed so that the flushing fluid column is

between 208.3 cm (82 in.) and 243.8 cm (96 in.) in height from the surface on

which the user stands.

7.1.5 Safety shower shall be in accessible location requiring no more than 10 seconds

to reach. It shall be positioned no more than 55 feet from the furthest corner of the

room.

Safety Showers and Eyewash Stations Page 7

7.1.6 The shower unit shall be located on the same level as the hazard. The location

area shall be well-lit and the path shall be unobstructed.

7.1.7 Safety shower shall deliver tepid flushing fluid. The equipment shall be protected

from freezing or freeze- protected equipment shall be installed, as necessary.

7.1.8 If shut off valves are installed in the supply line for maintenance purposes,

provisions shall be made to prevent unauthorized shut off.

7.2 Emergency Eyewash

7.2.1 It is the installer’s responsibility to ensure that all emergency eyewash units are

assembled and installed in compliance with ANSI Z358.1-2009 and the

manufacturer’s instructions.

7.2.2 All laboratories, newly constructed or renovated, or any room used for similar

purposes wherein corrosives, flammable liquids, toxins, bio-hazardous wastes, or

radiological materials are handled as well as other work-areas where hazardous

materials are used; such as mechanical rooms, pH neutralization systems, battery

charging areas, spraying operations, and high dust areas must have a hands-free

eyewash unit.

7.2.3 Emergency eyewash units shall be in accessible locations requiring no more than

10 seconds to reach. It shall be positioned no more than 55 feet from the furthest

corner of the room.

7.2.4 The eyewash unit shall be positioned with the flushing fluid nozzle between 83.8

cm (33 in.) and 114.3 cm (45 in.) in height from the surface on which the user

stands, and a minimum of 15.3 cm (6 in.) from the wall or nearest obstruction.

7.2.5 The location area shall be well-lit and the path shall be free of obstructions.

Fig. Emergency Eyewash Sign

7.2.6 Emergency eyewash unit shall be located

in an area identified with highly visible signs.

The sign shall be visible within the area served

by the

eyewash unit and shall consists of symbols that

require users to have any language skill to

understand.

Safety Showers and Eyewash Stations Page 8

7.2.7 The eyewash unit shall be located on the same level as the hazard. The ANSI

Z358.1 requires that the eyewash unit should be located immediately adjacent

to the hazard in case of handling strong acid or alkali.

7.2.8 The eyewash unit shall deliver tepid flushing fluid. The equipment shall be

protected from freezing or freeze- protected equipment shall be installed, as

necessary.

7.2.9 If shut off valves are installed in the supply line for maintenance purpose,

provisions shall be made to prevent unauthorized shut off.

Section 8. Inspection Procedures

8.1 Emergency Eyewash Equipment

Weekly flushing of emergency eyewash units in compliance with the ANSI Z358.1-2009

shall be conducted by the laboratories. Weekly check cards will be provided to the

laboratories (one card per eyewash). Verification of weekly flushing and distribution of a

new annual check card will be conducted by EHS laboratory inspection staff during

regularly scheduled laboratory inspections. If units are not being checked weekly by

laboratory staff, EHS inspectors will record this as a Deficiency on the Laboratory

Inspection Report.

8.1.1 Method

Respective laboratory personnel shall follow the same method as outlined in this

“Standard Operating Procedure” for weekly activation of emergency eyewash units

situated in their laboratory.

Before activating the eyewash unit, check if the unit is connected to any types of drainage

system. Apply appropriate water collection method as necessary. A plastic cup, a strong

zip-lock bag, or a small bucket may be used depending on the design of the eyewash unit.

The Safety office can provide any necessary testing equipment.

8.1.1.1 Turn the valve on to full open position (activation of the unit). The

eyewash nozzles shall have a dust protecting cover, which shall be

automatically removed upon activation of the unit.

8.1.1.2 Verify that the eyewash unit opens within one second of opening the valve

and it remains open without operator’s further assistance (stay-open valve)

until intentionally closed.

Safety Showers and Eyewash Stations Page 9

8.1.1.3 The emergency eyewash unit shall provide flushing fluid to both eyes

simultaneously. The flushing streams shall rise to approximately equal

heights on both sides.

8.1.1.4 Record the test as passes or failed, sign and date the inspection tag. Dry

the eyewash sink and floor using a sponge.

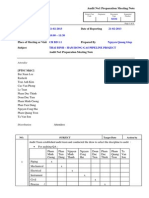

Fig- Weekly Eyewash Activation log

8.1.2 Performance Evaluation:

Emergency eyewash equipment will pass EHS’s annual inspection, if all of the following criteria

are met.

8.1.2.1 The unit shall be hands-free (stay-open valve); once activated; it can be

used without the use of operator’s hands until intentionally closed.

8.1.2.2 The valve shall be simple to operate and shall go from “off” to “on”

position in 1 second or less.

8.1.2.3 It shall not take more than 1 second to open the unit once the valve is full

open.

Safety Showers and Eyewash Stations Page 10

8.1.2.4 Operator shall not require a separate motion to remove the dust protection

cover of the eyewash unit.

8.1.2.5 The unit shall be capable of delivering a minimum of 1.5 liter/minute

(0.4gpm) of flushing fluid for at least 15 minutes.

8.1.2.6 The unit shall deliver flushing fluid to both eyes simultaneously at a

velocity low enough to be non-injurious to the user.

8.1.2.7 The flushing fluid temperature shall be tepid. Temperature in the range of

27-35°C (about 80-95°F) is considered suitable.

Section 9. Maintenance, Repair and Training

9.1 Emergency eyewash unit shall be activated weekly for a period long enough to verify

operation and ensure that flushing fluid is available. Weekly activation prevents sediment

build-up within the eyewash unit and minimizes microbial contamination in the stagnant

water.

9.2 It is department’s responsibility to ensure that emergency eyewash and safety shower

equipment that does not pass inspection is repaired immediately by contacting Facilities or

EHS.

9.3 Whenever an emergency eyewash or safety shower is non-functional, immediately contact

the Facilities to fix it. Do not handle hazardous materials in that work-area until the unit

is returned to proper service.

9.4 Any party removing emergency eyewash or safety shower equipment from service, must

notify EHS and the affected department beforehand.

9.5 Individuals who may be exposed to hazardous materials shall be instructed in the location

and proper use of emergency eyewash and safety shower equipment.

9.6 The ANSI Z358.1requires that all emergency eyewash and safety shower equipment shall be

inspected annually.

Safety Showers and Eyewash Stations Page 11

Section 10. References

1. American National Standard Institute, ANSI Z358.1-2009, American National Standard for

Emergency Eyewash and Shower Equipment, September 14, 2009.

2. Occupational Safety & Health Administration [OSHA] 29 CFR 1910.1450, Occupational

Exposure to Hazardous Chemicals in Laboratories.

3. Department of Veterans Affairs, VHA Directive 2009-026, Location, Selection, Installation,

Maintenance, and Testing of Emergency Eyewash and Shower Equipment.

Safety Showers and Eyewash Stations Page 12

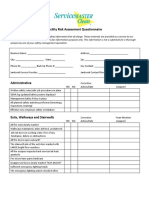

Appendix A

Hazard Assessment Form

Safety Showers and Eyewash Stations Page 13

EMERGENCY EYEWASH AND SAFETY SHOWER

HAZARD ASSESSMENT FORM

IDENTIFICATION

IDENTIFICATION NUMBER: PICTURE OR DIAGRAM

(IF EXISTING):

LOCATION:

RESPONSIBLE SERVICE AREA:

ASSESSMENT DATE:

SURVEYOR NAME:

A. INVESTIGATION

1. CHEMICALS IN AREA: 2. CONDITIONS OF USE:

B. RISK ASSESSMENT CODE (RAC)

1. SEVERITY CLASSIFICATION: 2. PROBABILITY ESTIMATE:

Class I - Catastrophic - Marginal (may cause death or

permanently disabling injury). Estimate A - Likely to occur immediately.

Class II - Critical (may cause severe injury or severe Estimate B - Probably will occur in time.

occupational illness).

Estimate C - May occur in time.

Class III - Marginal (may cause minor occupational injury

or illness). Estimate D – Unlikely to occur.

Class IV - Negligible (probably would not affect personnel

safety or health).

3. RAC DETERMINATION:

Probability Estimate

A B C D

I 1 1 2 3

II 1 2 3 4

Severity

Class III 2 3 4 5

IV 3 4 5 6

If the results of the evaluation determine that the RAC is 1 or 2, an eyewash or shower is required. If the results of the evaluation determine

that the RAC is 4, 5 or 6, an eyewash or shower is not required. A RAC of 3 indicates that the eyewash or shower is optional.

C. FINDING

REQUIRED OPTIONAL NOT REQUIRED

-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐ -‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐-‐

Applicable Assessment Criteria-‐ Regulations/Consensus Standards/ VA Directives/ TAMU Standard Operating Procedures

x OSHA 1910.1048(i)(3) : If there is any possibility that an employee's eyes may be splashed with solutions containing 0.1 percent or

greater formaldehyde, the employer shall provide acceptable eyewash facilities within the immediate work area for emergency use.

x OSHA 29 CFR 1910.151(c) Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities

for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.

x Center for Disease and Control and Prevention, Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th Edition, 2007

x American National Standards Institute (ANSI) Z358.1-2009

x VA General Safety Guidebook

x VHA DIRECTIVE 2009-026, May 2009

x Texas A&M University Standard Operating Procedure, Emergency Eyewash and Safety Shower, 12/01/2009

____________________________________

Surveyor Signature

Вам также может понравиться

- DotCom Secrets ChallengeДокумент60 страницDotCom Secrets ChallengeWilliams Barros100% (1)

- Bagging and Tagging ProcedureДокумент21 страницаBagging and Tagging ProcedureKingsley EtimОценок пока нет

- Pre Startup Checklist For New Installations or AlterationsДокумент3 страницыPre Startup Checklist For New Installations or Alterationsjoesuhre100% (1)

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Pressure Relieving Device Inspection ProcedureДокумент2 страницыPressure Relieving Device Inspection Procedurecamasa2011Оценок пока нет

- Audit Record Sheet - PipingДокумент6 страницAudit Record Sheet - Pipingcuongpham301Оценок пока нет

- SOP - Eyewash and Safety Shower (Signed)Документ2 страницыSOP - Eyewash and Safety Shower (Signed)yusuf al aziz100% (1)

- Follow UpДокумент14 страницFollow Upmohd hameedОценок пока нет

- Maintenance Training ActivitiesДокумент16 страницMaintenance Training ActivitiesSuleman Tariq100% (1)

- Breaking Lines, Isolating and Release of EquipmentДокумент69 страницBreaking Lines, Isolating and Release of Equipmentanubiseth100% (1)

- Eye Wash STD and ProceduresДокумент14 страницEye Wash STD and ProceduresBrijendra Pratap Singh0% (1)

- Air Compressor Air Compressor: (Small) (Small)Документ1 страницаAir Compressor Air Compressor: (Small) (Small)alcrosalitaОценок пока нет

- Design Considerations For WFI Distillation Systems Part 1Документ6 страницDesign Considerations For WFI Distillation Systems Part 1Jason WangОценок пока нет

- Air Filter PDFДокумент15 страницAir Filter PDFArun KarthikeyanОценок пока нет

- Saic G 2002Документ32 страницыSaic G 2002jerinОценок пока нет

- PEDcertification Rules Issue2 2013-07-25Документ5 страницPEDcertification Rules Issue2 2013-07-25RevanОценок пока нет

- 03 - Process Flow DiagramДокумент18 страниц03 - Process Flow DiagramNaomy Simarmata100% (1)

- 11 Steps of Automation ProjectДокумент12 страниц11 Steps of Automation ProjectKok MunОценок пока нет

- CB&I Code of ConductДокумент28 страницCB&I Code of Conductandruta1978Оценок пока нет

- Job Description: Essential FunctionsДокумент2 страницыJob Description: Essential FunctionsChris StroudОценок пока нет

- Charge Hand Over Between The Shifts - 1Документ7 страницCharge Hand Over Between The Shifts - 1Solomon GamanuelОценок пока нет

- 250 00 Pipe Labeling ProcedureДокумент11 страниц250 00 Pipe Labeling ProcedureFrancis GarciaОценок пока нет

- Sample Loss of Power Supply Contingency PlanДокумент5 страницSample Loss of Power Supply Contingency PlanAimee Denosta100% (1)

- Scope of Work - 029-2015 - Updated 14.10.2015Документ10 страницScope of Work - 029-2015 - Updated 14.10.2015Balkunde0% (1)

- Notes To File Guidance 04-20-12Документ3 страницыNotes To File Guidance 04-20-12Sashwat TanayОценок пока нет

- Project Change Log TemplateДокумент11 страницProject Change Log TemplatePrathamesh ShevaleОценок пока нет

- Pre-Task Planning, Risk AnalysisДокумент39 страницPre-Task Planning, Risk Analysismyfelb100% (1)

- TB 43-0142 Safety Inspection and Testing of Lifting DevicesДокумент36 страницTB 43-0142 Safety Inspection and Testing of Lifting DevicesChiheb KaanicheОценок пока нет

- Organogram PFCДокумент5 страницOrganogram PFCAniket JaggiОценок пока нет

- Comment Sheet For Compressor VendorДокумент5 страницComment Sheet For Compressor VendorBui Khoi NguyenОценок пока нет

- General Chemical & Resin Consortium Inc.: No. Description/Item Completed/Done Yes NoДокумент1 страницаGeneral Chemical & Resin Consortium Inc.: No. Description/Item Completed/Done Yes NoRhannie GarciaОценок пока нет

- Unit 4 Use of Standard Operating ProceduresДокумент13 страницUnit 4 Use of Standard Operating ProceduresEileen LeeОценок пока нет

- Sample Chiller SpecificationДокумент5 страницSample Chiller Specificationjlcheefei9258Оценок пока нет

- Attachment 23 Criticality Assessment v3Документ3 страницыAttachment 23 Criticality Assessment v3bo.ratchadapornОценок пока нет

- Problem Solving FrameworkДокумент2 страницыProblem Solving FrameworkGeoffОценок пока нет

- Qa-Qc Plan For Sharq R-0aДокумент163 страницыQa-Qc Plan For Sharq R-0akbldamОценок пока нет

- QMS-03 Rev 1 Procedure For Design ControlДокумент22 страницыQMS-03 Rev 1 Procedure For Design ControlbanglvhОценок пока нет

- Living With Defects and Fitness For ServiceДокумент16 страницLiving With Defects and Fitness For ServiceNatraji100% (1)

- Facility Risk Assessment QuestionnaireДокумент5 страницFacility Risk Assessment QuestionnaireGrayОценок пока нет

- LaboratoryДокумент9 страницLaboratoryANOOPVAОценок пока нет

- CQM Student Study GuideДокумент272 страницыCQM Student Study GuideHenry Florendo100% (1)

- GP 02 01 01Документ23 страницыGP 02 01 01Anonymous fvO1W3Оценок пока нет

- Check List For Contract ReviewДокумент1 страницаCheck List For Contract ReviewavaisharmaОценок пока нет

- Process Safety Management InspectionДокумент33 страницыProcess Safety Management InspectionAnonymous mNQq7oj100% (2)

- Construction Manager Interview QuestionsДокумент2 страницыConstruction Manager Interview QuestionsRAHAMAN NAFISATОценок пока нет

- Assessment Checklist ISO 9001:2015Документ25 страницAssessment Checklist ISO 9001:2015Arati GuptaОценок пока нет

- Procedure For Pressure Guage and Relief Valve CalibrationДокумент9 страницProcedure For Pressure Guage and Relief Valve CalibrationDaniel MartinezОценок пока нет

- Rfi TrackingДокумент42 страницыRfi Trackinganand100% (2)

- Equipment SpecificationДокумент8 страницEquipment SpecificationPraveen ChandrakarОценок пока нет

- Mandatory Appendix 10Документ3 страницыMandatory Appendix 10leytonruizОценок пока нет

- Generic Project Risk AssessmentДокумент8 страницGeneric Project Risk AssessmenttucaharaОценок пока нет

- Isolation and Release of EquipmentДокумент34 страницыIsolation and Release of Equipmenthazopman100% (1)

- Refinery Operation and Maintenance Lecture2Документ26 страницRefinery Operation and Maintenance Lecture2Kirunda AndrewОценок пока нет

- Total Quality Management (TQM) : What Is TQM?: Primary Elements of TQMДокумент6 страницTotal Quality Management (TQM) : What Is TQM?: Primary Elements of TQMrenjithОценок пока нет

- Job Safety Environmental Analysis Pre-Task BriefingДокумент5 страницJob Safety Environmental Analysis Pre-Task BriefingFerman TokgözoğluОценок пока нет

- Design For MaintainabilityДокумент7 страницDesign For MaintainabilityEmilian PopaОценок пока нет

- The Power of Design ReviewДокумент15 страницThe Power of Design ReviewNgoc Sang HuynhОценок пока нет

- Preservation of Idle Static and Rotary MДокумент28 страницPreservation of Idle Static and Rotary MMaheshwar polepally100% (1)

- Policy and Procedure of Employee SatisfactionДокумент8 страницPolicy and Procedure of Employee SatisfactionAbdur Rashid KhanОценок пока нет

- Quality Documents and Their ControlДокумент3 страницыQuality Documents and Their ControlVelmurugan BalasubramanianОценок пока нет

- Safety Showers and Eyewashes: University of Tennessee Safety Guide HM-020Документ7 страницSafety Showers and Eyewashes: University of Tennessee Safety Guide HM-020Idada EzekielОценок пока нет

- Emergency Eyewash and Drench Shower ProgramДокумент16 страницEmergency Eyewash and Drench Shower ProgramperezismaelОценок пока нет

- Useful Tips To Avoid Preanalytical Errors in Blood Gas TestingДокумент7 страницUseful Tips To Avoid Preanalytical Errors in Blood Gas TestingKesavanVeeraОценок пока нет

- Management of Hazardous Chemicals ProgrammeДокумент32 страницыManagement of Hazardous Chemicals ProgrammeKesavanVeeraОценок пока нет

- Kerana Habitat Yang Berlainan.: - Supplying Resources For Medical, Ecological ResourcesДокумент5 страницKerana Habitat Yang Berlainan.: - Supplying Resources For Medical, Ecological ResourcesKesavanVeeraОценок пока нет

- Overview On Chemical MGMT - NREДокумент39 страницOverview On Chemical MGMT - NREKesavanVeeraОценок пока нет

- Uric AcidДокумент30 страницUric AcidKesavanVeeraОценок пока нет

- Full Blood PictureДокумент29 страницFull Blood PictureKesavanVeera100% (1)

- Reducing Preanalytical Errors in Blood Gas Testing: Christopher R. Mccudden, PH.D., Facb, Fcacb, DabccДокумент47 страницReducing Preanalytical Errors in Blood Gas Testing: Christopher R. Mccudden, PH.D., Facb, Fcacb, DabccKesavanVeeraОценок пока нет

- ABGДокумент16 страницABGKesavanVeeraОценок пока нет

- XT1800i CustomerДокумент74 страницыXT1800i CustomerKesavanVeeraОценок пока нет

- Interim Guideline For Prevention and Control of Human Rabies in MalaysiaДокумент17 страницInterim Guideline For Prevention and Control of Human Rabies in MalaysiaKesavanVeera100% (1)

- Hazardous Chemical PresentationДокумент31 страницаHazardous Chemical PresentationKesavanVeeraОценок пока нет

- SJK Bi K2 Set2Документ8 страницSJK Bi K2 Set2KesavanVeeraОценок пока нет

- Time Management: Urgent Not Urgent Important Not ImportantДокумент6 страницTime Management: Urgent Not Urgent Important Not ImportantKesavanVeeraОценок пока нет

- Quality Assurance Activities in Coagulation - IPPT - 97Документ56 страницQuality Assurance Activities in Coagulation - IPPT - 97KesavanVeeraОценок пока нет

- Verb To BeДокумент3 страницыVerb To BeKesavanVeeraОценок пока нет

- Hypo Nat Re MiaДокумент15 страницHypo Nat Re MiaKesavanVeeraОценок пока нет

- Case-Baskin RobbinsДокумент3 страницыCase-Baskin RobbinsAkanksha DОценок пока нет

- Andritz Plant PDFДокумент4 страницыAndritz Plant PDFRavi RenganathanОценок пока нет

- Computer Graphics and Multimedia NotesДокумент18 страницComputer Graphics and Multimedia Notesrosewelt444Оценок пока нет

- Revenue AdministrationДокумент3 страницыRevenue AdministrationMontasir BalambagОценок пока нет

- AB InbevДокумент13 страницAB InbevNikhil Gautam100% (1)

- 3a Essential Oils and Oleoresins PDFДокумент49 страниц3a Essential Oils and Oleoresins PDFSravani reddyОценок пока нет

- Bài giải NN6 ADJUSTEDДокумент106 страницBài giải NN6 ADJUSTEDĐoan ThụcОценок пока нет

- 4.2 Marketing PlanningДокумент32 страницы4.2 Marketing Planningavik senguptaОценок пока нет

- Aristo Interactive Geography 2nd Edition Book C5Документ81 страницаAristo Interactive Geography 2nd Edition Book C5thomas011122100% (1)

- Andrews C145385 Shareholders DebriefДокумент9 страницAndrews C145385 Shareholders DebriefmrdlbishtОценок пока нет

- D3s3-Types of EnterprisesДокумент35 страницD3s3-Types of Enterprisesrakesh19865Оценок пока нет

- Labayog v. MY San BiscuitsДокумент2 страницыLabayog v. MY San BiscuitsrubdrОценок пока нет

- Spec Contract Appointment Letter.Документ5 страницSpec Contract Appointment Letter.zeeshan100% (1)

- Total Price Adjustment SheetДокумент1 страницаTotal Price Adjustment SheetpraveshОценок пока нет

- Automaties ContentДокумент2 страницыAutomaties Contentjazzvijay4951Оценок пока нет

- 2 MIDTERMS Election Law 1 of 3 IV Election Period PDFДокумент17 страниц2 MIDTERMS Election Law 1 of 3 IV Election Period PDFCha Ca100% (1)

- BS 01881-129-2011Документ16 страницBS 01881-129-2011heheОценок пока нет

- Om-Chapter 4Документ16 страницOm-Chapter 4wubeОценок пока нет

- Sara Campbell ResumeДокумент3 страницыSara Campbell Resumeapi-520202114Оценок пока нет

- Your Leadership Style - Why Understanding Yourself MattersДокумент3 страницыYour Leadership Style - Why Understanding Yourself MattersRaulОценок пока нет

- 11 Affidavit of Martin McGahan, Chief Restructuring OfficerДокумент45 страниц11 Affidavit of Martin McGahan, Chief Restructuring OfficerDentist The MenaceОценок пока нет

- Case Brief: People v. RosenthalДокумент7 страницCase Brief: People v. Rosenthalmichael jan de celisОценок пока нет

- History ProjectДокумент12 страницHistory Projectapi-655735279Оценок пока нет

- Module 1.3 - Partnership Dissolution PDFДокумент3 страницыModule 1.3 - Partnership Dissolution PDFMila MercadoОценок пока нет

- Astm A582 Grade s30300Документ3 страницыAstm A582 Grade s30300Molla SachnovskyОценок пока нет

- Design of Jigs and Fixtures 2 MarksДокумент16 страницDesign of Jigs and Fixtures 2 MarksParamasivam Veerappan100% (1)

- MertKOBAK CV 2022Документ7 страницMertKOBAK CV 2022halit vatanseverОценок пока нет

- Alliances MergedДокумент87 страницAlliances MergedSiddhant SinghОценок пока нет

- MY Salary Guide 2021 v3Документ42 страницыMY Salary Guide 2021 v3Jenna10JoshОценок пока нет