Академический Документы

Профессиональный Документы

Культура Документы

Solar Desalination Using Phase Change Materials and Vacuum Pump

Загружено:

JASC UGC JOURNAL PUBLICATION (1076-5131)Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Solar Desalination Using Phase Change Materials and Vacuum Pump

Загружено:

JASC UGC JOURNAL PUBLICATION (1076-5131)Авторское право:

Доступные форматы

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

Solar Desalination Using Phase Change Materials and Vacuum

Pump

Kiran C H1, Chetanakumara Veerabhadrappa U2, Chethan H N3,

Madhu M S4, Maruthi H T5.

12345Department

Alva’sOf

1,2,3,4,5. Mechanical

Institute Engineering,

Of Engineering And Alva’s Institute

Technology. Of Engineering

Department And Technology.

Of Mechanical Engineering,Mangalore

Mangalore

1ckmkiran@aiet.org.in, 2chethuvu@gmail.com, 3chethanhnking@gmail.com

4madhums41175@gmail.com, 5maruthiht40@gmail.com

Abstract—estimating the growth of population and industrial development leads to demand of water resources. Water

resources covered the one third of the earth, in these less than 1% is suitable for industrial and domestic uses. With rapid

growth of population, industrial development leading to deforestation and declination of water. This leads to scarcity of

drinking water for growth of population. To overcome the crisis an alternate solution is rain harvesting and desalination.

Because of the climate change due to pollution rainfalls is decline year by year.so desalination is better solution for this crisis.

It is estimates that 22million m3 of freshwater being produced per day by desalination process in worldwide, but only 1% is

due to solar energy. Direct and indirect methods are used for desalinate the sea water to the freshwater. Most of the methods

like desalination, Multi stage flash distillation and reverse osmosis, are energy depended and consume electric power and

fossil fuels. Demands water is more so supply should be less expensive, so solar desalination is better compared to

conventional methods. The main objective of the proposed project is that by using free energy converting the saline water

to the necessity water by using principle of the thermal and low pressure vessels leads to change in latent heat and sensible

heat. Possible outcome is to provide suitable combination to get better yield of drinking water from saline water. The

efficiency of solar still varied for the beam radiation of 312.5 W/m2 to 925 W/m2. A maximum distilled yield is 1.5 to 2.2

ltr/day is obtained with 0.54 m2 area.

Keywords: Saline water, low pressure vessel, solar energy, Desalination, direct method, Heat energy

storage, Phase change material.

I. INTRODUCTION

A. General

Water is the major fundamental for the life to sustain Earth’s composition consists of 97.5% of water is regarded as the

sea water (brackish water) and the 1-2% is available for domestic’s usage. According to the world health organization (WHO),

it is necessary for person to have a minimum water consumption of 15-20 L for the basic needs.

Water is a basic necessity of man along with food and air. Fresh water resources usually available are rivers, lakes and

underground water reservoirs. About 71% of the planet is covered in water, yet of all of that 96.5% of the planet’s water is

found in oceans, 1.7% in groundwater, 1.7% in glaciers and the ice caps and 0.001% in the air as vapour and clouds, only

2.5% of the Earth’s water is freshwater and 98.8% of that water is in ice and groundwater. Less than 1% of all freshwater is

in rivers, lakes and the atmosphere.

Human beings need 1 or 2 liters of water a day. The minimum requirement for normal life in developing countries

(which includes cooking, cleaning and washing cloths) is 20 liters per day. Drinking water with acceptable quality has been

unevenly distributed worldwide.

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:103

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

The major scarcity of water occurs in under developed areas, or villages. The major problems faced by society is due to

drinking water, so to overcome this, many techniques have been introduced, few of them are thermal process, Multi stage

flash (MSF), Membrane process, Nano filtration, Hybrid process that involves both phase change and membrane distillation,

hence this water requires an innovative technique which can be both sustainable and cost effective to produce portable

water. Solar desalination is a technique used to remove the salt content in brackish water using solar energy. There are two

desalination techniques, they are, Direct and Indirect.

B. About solar energy:

Solar energy is a very large energy, inexhaustible source of energy. The power from the sun intercepted by the earth is

approximately 1.8×1011 MW, which is many thousands times larger than present all commercial energy consumption rate

on the earth. Thus in principle, solar energy could supply all the present and future energy needs of the world on a continuous

basis. This makes it one of the most promising of all the unconventional energy sources.

The sun radiates the energy uniformly in all direction in the form of electromagnetic waves. When absorbed by body, it

increases its temperature. It is a clean, inexhaustible, abundantly and universally available renewable energy, solar energy has

the greatest potential of all the sources of renewable energy and if only a small amount of this form of energy could be used,

it will be one of the most important supplies of energy, especially when other sources in the country have depleted.

This solution is solar water distillation. It is not a new process, but it has not received the attention that it deserves.

Perhaps this is because it is such a low-tech and flexible solution to water problems. Nearly anyone is capable of building a

still and providing themselves with completely pure water from very questionable sources. 3.8x1024 joules of solar radiation

is absorbed by earth and atmosphere per year. Solar power where sun hits atmosphere is 1017 watts and the total demand is

1013 watts. Therefore, the sun gives us 1000 times more power than we need. If we can use 5% of this energy, it will be 50

times what the world will require.

C. About Phase change material:

A phase change material absorbs and releases thermal energy in order to maintain a regulated temperature. When a PCM

is in its' solid phase it will absorb heat as the external temperature rises. The temperature of the PCM rise until the PCM's

melt point is reached after the external temperature the decreases then PCM start to release the energy which is absorbed

from it. During the phase change process PCM will absorb large amount of heat with no change in temperature.

The melting point of the PCM will different for each type of PCM. Generally, PCM used as a heat storage unit in day

time and use the stored energy in night time to increases the efficiency of the system. Phase change materials have two

favorable properties. They have a very high heat storage density and they store and release a considerable amount of heat at

a constant temperature. This makes PCMs in many applications an interesting alternative to other heat storage mediums.

Phase materials are classified as,

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:104

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

D. Concept of solar desalination:

Distillation is one of many processes available for water purification, and sunlight is one of several forms of heat energy

that can be used to power that process. To dispel a common belief, it is not necessary to boil water to distil it. Simply

elevating its temperature, short of boiling, will adequately increases the evaporation rate. In fact, although vigorous boiling

hastens the desalination process it also can force unwanted residue into the distillate, defeating purification.

Solar desalination is a technique to desalinate water using solar energy. There are two basic methods of achieving

desalination using this technique; Direct and Indirect. In the direct method, a solar collector is coupled with a distilling

mechanism and the process is carried out in one simple cycle. Indirect solar desalination employs two separate system; a

solar collection array, consisting of photovoltaic and or fluid base thermal collectors, and separate conventional desalination

plant.

The Saline Water Conversion Corporation (SWCC) of Saudi Arabia is currently operating small scale single purpose

thermal desalination plants with water production capacities ranging from 250 to 9000 m3/day. The heat required for the

evaporation of the water droplets can be supplied/ recovered from the following sources: sun, light, double walled insulated

glassing effect, black colour effect, heat generated by the vacuum pump, heat collected from the PV panels and latent heat

recovered from the generated vapour.

II. METHODOLOGY

The main objective of this method is to get portable water from the brackish water with the help of solar energy. This

can be made in a two different ways; they are direct and indirect method. Here we are using direct method to convert

brackish water into portable water. We have done desalination without PCM, with PCM, without vacuum and with vacuum

to compare the productivity of each system.

Initially the brackish water is passed to the closed system with constant flow rate. By reducing the pressure inside the system

through vacuum pump, the pressure inside the system reduces then boiling point of the water also reduces. So by using

direct solar energy we can boil the brackish water at temperature range of 45-60 degree.

Fig 1: Experimental Setup:

We are using phase change material which is placed beneath. The PCM get heated and melts when its temperature

reaches it melting point, and when the melting process is complete its temperature continues to rise based on the intensity

of solar radiation and length of the day. In this process the energy is stored in the PCM which is released back after decline

of atmospheric temp. The maximum energy released from it observed by brackish water and some energy will be lost based

on the insulation in system. Due to this, the water evaporates and is adhered to glass slab, then the condensed vapour flow

down gradually. As the brine concentration in the system increases, it has to be discharge out of the system. The cycle repeats

from morning to evening. The vapour from the glass slab is collected in the collector through pipes and are portable. The

portable water is passed through the bio grades to form a drinking water.

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:105

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

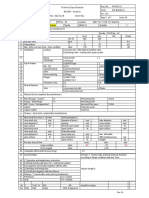

III. EXPERIMENTAL SETUP

Fig 2: 2-Dimensional view of the setup

Above picture shows the experimental setup which we have used and it consists of following parts:

A Wood: It is used as insulator which does not allow the heat to pass out. Plywood of 12mm thick is used for this setup.

Fig A: Plywood used in the experiment

B Phase Change Material: It has the ability to absorb the heat in the day time and liberate that heat during night time. The

main purpose of using PCM is to increase the yield of freshwater. Fully refined paraffin wax in the form of slab is used for

our work.

Specifications:

Melting point- 55℃ to 58℃.

Colour - white.

Density- 900 kg/m3.

Flash point- 235℃.

Fig B: Paraffin wax

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:106

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

C Aluminium sheet: It is placed above the PCM and water is fed on top of this sheet. Aluminium sheet absorbs more amount

of heat and transfers it to both water and PCM. Sheet of 2mm thick is used for our system.

Specifications:

Density- 2.7 gm/cm3.

Latent heat of fusion-400 j/g

Thermal conductivity-237 w/m K.

Fig C: Aluminium sheet

D Glass: The main purpose of using glass is that it condenses the water vapour. This glass is tilted to an angle so that maximum

solar radiation can pass through it.

Specifications:

Thickness - 4mm.

Transmitivity-89%.

Density-2500 kg/m3.

Fig D: Clear glass of 4 mm thick

E Vacuum pump: - It is used to remove the air present inside the chamber and reduce the pressure to required level.

Specifications:

Power- 0.25HP, 240V.

Capacity- 50lpm.

Speed- 2880RPM.

Fig E: Vacuum pump of 0.25 HP

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:107

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

F Vacuum gauge: - Gauge is used to measure the amount of air that is taken out or pressure inside the chamber.

Fig F: vacuum gauge

IV. EXPERIMENTAL ANALYSIS OF SOLAR STILL

A For glass sheet:

When the solar radiation incident on the glass, the glass which will transfer the radiation through it to heat the water

and absorbs some amount of heat. Due to temperature variation between the glass sheet and atmosphere some amount of

heat will liberated to atmosphere and rest of the energy is utilized for heating the water.

Energy balance equation for glass sheet

= + , + ,

Where QI = Energy of the solar radiation on the glass cover.

Qcond = Energy transfer through glass.

( − )

=

Where K = Thermal conductivity of glass.

A = surface area of glass sheet.

L = Thickness of glass sheet.

TH and TC = Higher temperature and lower temperature.

Qconv, atm = Energy exchange between outer layer of glass and atmosphere.

= ( − )

where h = convection heat transfers co-efficient.

A= surface area of glass sheet.

Qconv, ch = Energy exchange between inner layer of glass and the chamber.

B For brackish water:

The solar radiation after transfer through glass sheet it incident directly on the water surface. Due to high intensity,

temperature of water increases and some amount of heat will transfer to aluminium sheet and chamber because of

temperature difference between them.

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:108

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

Energy balance of the brackish water

= +

Where QI = heat energy incident on the water surface.

Q1 = Energy exchange between water surface and chamber (Convection).

=ℎ ( − )

Where h = convection heat transfers co-efficient.

A= surface area of glass sheet.

TW and TC = Temperature of Water and Temperature of chamber respectively

Q2 = energy exchange between water and aluminium sheet (Convection).

=ℎ ( − )

Where TW and Tal are the temperature of water and aluminium sheet respectively.

C For basin liner (aluminium sheet):

When the water gets heated convection takes place between the water and aluminium sheet due to temperature

variation. The heat is transfer from higher energy to lower energy so during day time the water gets heated and some amount

of heat energy transfer to aluminium sheet and it transfer to PCM. During the night time the heat transfer will takes places

in reverse process from PCM to water through aluminium sheet.

Energy balance for basin liner

. = , + ,

Where Qconv = Heat transfer from water to aluminium sheet.

QCond,Al = Heat transfer through aluminium sheet.

Qcond, PCM =Heat transfer from aluminium sheet to PCM.

D For phase change material:

When the heat transfers from aluminium sheet to PCM, it starts to absorb the heat till it completely melts and it transfer

its phase from solid to liquid, during melting of PCM takes place PCM will absorbs more heat and it stores the heat. After

the sunset the temperature in the system will reduces, so that temperature difference between the PCM and water the heat

will transfer from PCM to water through aluminium sheet till the water temperature equal to PCM temperature.

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:109

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

Energy balance equation

= +

Where QStored = Heat stored in the phase change material.

QConv = Heat transfer through convection process.

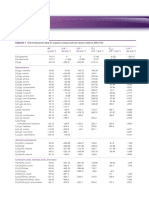

V. RESULTS AND DISCUSSION

A Desalination without PCM:

Experimental analysis has made to study the effect solar radiation, vacuum pressure and phase change material on the

system performance.

The variation of water temperature in the system for different interval of time as shown in the figure 3. The temperature of

water in the system is high at noon where higher solar radiations is obtained.

Fig 3: variation in glass temperature in hourly basis for different time intervals.

Fig.4: Variation in distillate yield for different interval of time

As the intensity of solar radiation increases, yield also increases. From the figure 4, we can clearly see that from noon 12

to 2pm there is more yield because the intensity of solar radiation is more at that time. Radiation in evening is less compared

to noon and hence the yield will be less.

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:110

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

Fig. 5: variation in glass temperature for different days of experiment

Solar radiations fall on water by passing through the glass. The glass transmits the radiation and by doing that it absorbs

some heat and temperature of glass increases. From figure 5 we can observe the temperature of the glass for different interval

of time. The temperature of the glass is similar to that of water temperature.

B Desalination with PCM and without vacuum.

Fig.6: distillated water yield with respect to time.

Desalination with phase change material increases the yield. As we can see from graph 6, at the night we can get

some yield. Implementing PCM reduces the water temperature compared to desalination without PCM. The overall output

will be more compared to desalination without PCM.

Fig.7: variation in water temperature

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:111

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

Water temperature during day time is less in this system compared to desalination without PCM. Figure 7 shows

the variation of water temperature with time. As we can see from the graph, the temperature of water during night time is

more compared to other system because of PCM.

Fig 8: variation of glass temperature with time

The figure 8 shows the variation in PCM temperature with respect to time. The PCM temperature will be similar to

that of room temperature initially and gradually temperature of PCM increases by absorbing the heat. Due to latent heat, the

phase change takes place from solid to liquid and vice-versa. From the graph we can clearly see that the temperature of PCM

decreases after 5pm, because it liberates the heat absorbed to the water.

C Desalination with PCM and with vacuum

Fig 9: variation in PCM temperature for different pressure and time

PCM temperature in desalination with vacuum remains almost same as that of without vacuum. There will be slight

variation in temperature with respect to pressure which is as shown in above figure 9. The latent heat transfer remains the

same for any pressure.

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:112

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

Fig 10: yield obtained for different time intervals and pressure

The figure 10 shows the fresh water production for different pressure throughout the day. As we can see that the

yield increases gradually by decreasing the pressure. For pressure 0.99, 0.98, 0.97 bar the yield obtained is 1.535, 1.605, 1.715

lt/day. And yield per day based on the intensity of solar radiation also.

Fig 11: water temperature in the system with respect to time

As the pressure decreases, boiling point of the water also decreases. The temperature of water depends on solar

intensity, and by decreasing the pressure we cannot increase the temperature of water. From the figure 11, we can see the

variation in temperature of water with time and it is clearly observed that temperature remains almost same for every

pressure.

VI. CONCLUSION

The water extracted from the saline water is distillated and are not portable water. So to get portable water, we have to add

some minerals.

As the pressure inside the chamber decreases, the yield per day also increases.

Water level inside the chamber also effects the fresh water production. As the water level decreases, yield increases.

If the mass of PCM increases, then the absorption of heat by PCM will be more which reduces the yield.

Glass thickness also effects the fresh water production. If the glass used is of less thickness, then output will be more.

To withstand the vacuum pressure, the glass thickness should be more and insulator used must have more strength.

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:113

JASC: JOURNAL OF APPLIED SCIENCE AND COMPUTATIONS ISSN NO: 0076-5131

FUTURE SCOPE

The experiment was conducted up to 0.97 Bar vacuum pressure because wood can’t withstand the high vacuum, by using

the high strength material with very less thermal conductivity in the construction of the experiment to create vacuum up to

0.6 Bar will give the more yield per day.

While selecting the glass, glass having high thermal conductivity, high transmitivity with more thickness to allows the

radiation through it and resists the vacuum pressure.

FUNDING

This work is funded by Karnataka state council of science and technology, 41st series student project programme (SSP)

Grant (Ref.no: 41S_BE_0950).

ACKNOWLEDGEMENT

We gratefully acknowledge the Karnataka state council and science and technology for their financial support.

REFERENCES

[1] R. Saravanam, J. Joseph, S. Renganarayanan, “Studies on single stage solar desalination system for domestic applications”, Desalination, 173

(2005) 77-82.

[2] Ashish M. Gujarathi, Hasan Mousa, “Modeling and analysis the productivity of solar desalination units with phase change materials”, renewable

energy 95(2016)225-232.

[3] Farooq R. Siddiqui, Nabil A.S. Elminshawy, Mohammad F. Addas, “Desalination and performance improvement of a solar desalination

system by using solar heater: Experimental and theoretical approach”, Desalination 399 (2016) 78-87.

[4] Osman Ahmed Hamed, Hiroshi Kosaka, Khalid H. Bamardouf, Khalid Al-Shail, Ahmed S. Al-Ghamdi, “Concentrating solar power for

seawater thermal desalination, Desalination 396 (2016) 70-78.

[5] Mohamed Asbik, Omar Ansari, Abdellah Bah, Nadia Zari, Abdelaziz Mimet, Hamdy Elghetany, “Exergy analysis of solar desalination

still combined with heat storage system using phase change material (PCM)”, Desalination 381 (2016) 26-37.

[6] Abderrahmane Diaf, Assia Cherfa, Lamia Karadaniz, Z. Tigrine, “A technical-economical study of solar desalination”, Desalination 377

(2016) 123-127.

[7] Hanen Ben Halima, Nader Frikha, Slimane Gabsi, “Experimental study of a bubble basin intended for water desalination system”,

Desalination 406 (2017) 10-15.

[8] Adrian Pugsley, Aggelos Zacharopoulos, Jayanth Deb Mondol, Mervyn Smyth, “Global applicability of solar desalination”, Reneweble Energy

88 (2016) 200-219.

VOLUME 5 ISSUE 5 MAY-2018 PAGE NO:114

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- CSVANET - Cuckoo Search For Efficient Optimal Path Selection WithДокумент11 страницCSVANET - Cuckoo Search For Efficient Optimal Path Selection WithJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Assessing The Properties of Geopolymer Concrete - A ResearchДокумент14 страницAssessing The Properties of Geopolymer Concrete - A ResearchJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Design and Implementation of Wearable Wireless Health Monitoring ModuleДокумент6 страницDesign and Implementation of Wearable Wireless Health Monitoring ModuleJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Implementation and Comparison of Location Aware Routing Protocol With Existing AODV Routing Protocol Using Network SimulatorДокумент7 страницImplementation and Comparison of Location Aware Routing Protocol With Existing AODV Routing Protocol Using Network SimulatorJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Behavioral Rigidity and Entrepreneurial Inclination of Potential EntrepreneursДокумент6 страницBehavioral Rigidity and Entrepreneurial Inclination of Potential EntrepreneursJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- Impact of Job Satisfaction and Work Environment of College Teachers in Ernakulam Distrct of KeralaДокумент5 страницImpact of Job Satisfaction and Work Environment of College Teachers in Ernakulam Distrct of KeralaJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Strengthening of Self-Healing Concrete by Adding Fungus and Bacteria - A ReviewДокумент6 страницStrengthening of Self-Healing Concrete by Adding Fungus and Bacteria - A ReviewJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Food Processing Units of Ssi and Level of Amount Spent On Other Items of Working Capital in Kerala, Eranakulum DistrictДокумент5 страницFood Processing Units of Ssi and Level of Amount Spent On Other Items of Working Capital in Kerala, Eranakulum DistrictJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- A Study On Problem Faced by Consumers Towards Online Shopping With Special Reference To Tiruppur DistrictДокумент4 страницыA Study On Problem Faced by Consumers Towards Online Shopping With Special Reference To Tiruppur DistrictJASC UGC JOURNAL PUBLICATION (1076-5131)Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 6.0 Biology Lab ManualДокумент49 страниц6.0 Biology Lab ManualJacob SmithОценок пока нет

- Eisco Industrial Catalogue - FinalДокумент276 страницEisco Industrial Catalogue - FinalSOHAM AlhatОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- General Purpose ValvesДокумент46 страницGeneral Purpose ValvesbataОценок пока нет

- Handling of Hygroscopic Products System-TechnikДокумент4 страницыHandling of Hygroscopic Products System-TechnikMudassir FarooqОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- WW-WASG03 Electrical Wire Sizes-WEB 7-7-11 PDFДокумент1 страницаWW-WASG03 Electrical Wire Sizes-WEB 7-7-11 PDFSemion VirtudazoОценок пока нет

- Waste Management Write-UpДокумент5 страницWaste Management Write-UpGounassegaraneDuraisamy100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Adsc of Amorphous Sugar - Mettler ToledoДокумент3 страницыAdsc of Amorphous Sugar - Mettler ToledoMarthaLuceroPerezОценок пока нет

- 810.00 MR-N, NC, NSДокумент110 страниц810.00 MR-N, NC, NSnqh2009100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Atkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Документ7 страницAtkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Roselle Mea EderОценок пока нет

- Plug Design Case StudyДокумент24 страницыPlug Design Case StudyAnonymous EsZwKlnBОценок пока нет

- CADD Unit 4 TPДокумент7 страницCADD Unit 4 TPmohitОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Assignment 07 AДокумент3 страницыAssignment 07 AsundusОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Iso 14687 3 2014Документ11 страницIso 14687 3 2014Tatiana Sainara Maia FernandesОценок пока нет

- Nafees Nastaleeq v1.02Документ2 страницыNafees Nastaleeq v1.02latifshaikh20Оценок пока нет

- Masel Catalog - WiresДокумент30 страницMasel Catalog - WiresOrtho OrganizersОценок пока нет

- The Municiplaity of Busia Solid Waste Management PlanДокумент15 страницThe Municiplaity of Busia Solid Waste Management PlanToi JanetОценок пока нет

- Waterborne Acrylic Primer Nacorr Synergy With Halox SZP-391: Formulation Ci-101Документ2 страницыWaterborne Acrylic Primer Nacorr Synergy With Halox SZP-391: Formulation Ci-101Swapnil AlandОценок пока нет

- Ok Kadar Abu KencurДокумент7 страницOk Kadar Abu KencurMuhamad IqbalОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- (MySchoolChildren) SKEMA Biologi Percubaan SPM 2012 SBP QДокумент27 страниц(MySchoolChildren) SKEMA Biologi Percubaan SPM 2012 SBP QIsmaliza IshakОценок пока нет

- A S M Fahad Hossain Assistant Professor Dept. of CE, AUSTДокумент30 страницA S M Fahad Hossain Assistant Professor Dept. of CE, AUSTMahadi HasanОценок пока нет

- AIChE Journal Volume 23 Issue 6 1977 (Doi 10.1002/aic.690230602) Karl Gardner Jerry Taborek - Mean Temperature Difference - A ReappraisalДокумент10 страницAIChE Journal Volume 23 Issue 6 1977 (Doi 10.1002/aic.690230602) Karl Gardner Jerry Taborek - Mean Temperature Difference - A Reappraisalneozero2006Оценок пока нет

- Everyday Science PDFДокумент101 страницаEveryday Science PDFMahmood SyedОценок пока нет

- CRC 2-26Документ2 страницыCRC 2-26saranОценок пока нет

- Biomechanical Properties of A New Fiber-Reinforced CompositesДокумент10 страницBiomechanical Properties of A New Fiber-Reinforced Compositesazam ahmedОценок пока нет

- Chemical Bonding and Molecular Structure - Lecture NotesДокумент51 страницаChemical Bonding and Molecular Structure - Lecture NotesEdith EatonОценок пока нет

- Evaporation-An IntroductionДокумент23 страницыEvaporation-An IntroductionKusmakarОценок пока нет

- Test1 Goc & Poc Tough by S.K.sinha See Chemistry Animations atДокумент3 страницыTest1 Goc & Poc Tough by S.K.sinha See Chemistry Animations atmyiitchemistry100% (1)

- Detailed Storage Tank SizingДокумент18 страницDetailed Storage Tank SizingBooLat Johorean100% (3)

- SLR Strainer Data SheetДокумент7 страницSLR Strainer Data SheetKailas NimbalkarОценок пока нет

- Quiz BiochemistryДокумент100 страницQuiz BiochemistryMedShare88% (25)