Академический Документы

Профессиональный Документы

Культура Документы

6.neutilization System

Загружено:

BARNALI MUKHERJEEОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

6.neutilization System

Загружено:

BARNALI MUKHERJEEАвторское право:

Доступные форматы

Doc. No.

APNRL/IMS/SOP/OP/055

STANDARD OPERATING Issue No. 01 Rev. No. 01

PROCEDURE

Adhunik Power & Natural Resources

Page 1 of 2

Ltd

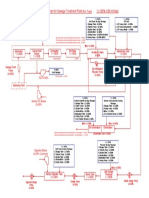

OPERATION & CONTROL PHILOSOPHY FOR NEUTRALIZATION

SYSTEM

PURPOSE:

To neutralize chemical laden water collected during DM plant operation.

SCOPE:

This document provides the Standard Operating Procedure details of

NEUTRALIZATION SYSTEM

Effluent Neutralization System:

Wastewater generated from DM unit is collected by gravity to

Neutralization pit. Neutralization pit is having two compartments and two (2)

disposal pumps are provided for each compartment. Level switches are provided

in each compartment for pump protection. Acid or Alkali is dosed to neutralize

pH of the waste within permissible range. Air scoring arrangement is provided

for proper chemical mixing.

The neutralized effluent is disposed to Effluent Treatment Plant by four (4)

numbers (2w +

2s) of DM Neutralized Effluent disposal pumps. At the outlet of the pump pH

transmitter is provided to measure the pH of the outlet effluent. If the pH value

is beyond the limit than the neutralized effluent pump recirculation valve is

opened until the desired pH valve achieved through chemical dosing.

OPERATION

Operation of all pumps, blowers and pneumatically operated valves is

manually controlled from OWS.

Pre – Start Inspection:

Before starting of the neutralization, make the following inspection

1. Sufficient water level in N-pit. Atleast 60% water level availability to be

ensured

2. Air blower and associated air distribution system is in healthy condition

Approved By: Issued By: Date:

Doc. No.APNRL/IMS/SOP/OP/055

STANDARD OPERATING Issue No. 01 Rev. No. 01

PROCEDURE

Adhunik Power & Natural Resources

Page 2 of 2

Ltd

START UP:

1. Open the valve of the air line for respective N-Pit whose water is to be

neutralized

2. Start the air blower

3. Check the pH of water in the N-Pit

4. If pH is in between 5.5 – 9, no need for neutralization as it is with in the

range of Central Pollution Control Board guidlines

5. If the pH is less than 5.5, than NaOH is to be added. If the pH is more than

9, than HCl is to be added

6. Accordingly fill the HCl/NaOH measuring tank & measure the initial level

7. Open the HCl/NaOH inlet valve at the inlet of N – Pit

8. Open the discharge valve of the HCl/NaOH measuring tank to 25%. The

HCl/NaOH will start dosing in the respective N-pit. The air blower is to be

continuously kept in service to ensure uniform mixing

9. Keep measuring the pH at every 10 mins interval

10. When the pH comes in the range of 5.5 – 9, close the discharge valve of

the HCl/NaOH tank

11. Note the final level of HCl/NaOH in the tank and calculate the

consumption

12. Close the HCl/NaOH inlet valve at the inlet of N – Pit

13. Stop the air blower

14. The water is neutralized within the guidelines of CPCB and can be used as

effluent for ETP

15. Start the N – Pit pumps and transfer the neutralized water to ETP

ALARM

Alarm on Hardwired Annunciation window at DM Neutralized

effluent disposal pump trip condition

Alarm on Hardwired Annunciation window at N-Pit Level High.

Approved By: Issued By: Date:

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Full Report Wastewater Paling Latest BiaДокумент44 страницыFull Report Wastewater Paling Latest BiaSyazwi HakimiОценок пока нет

- Septic Tank Sizing - SPLENDORДокумент1 страницаSeptic Tank Sizing - SPLENDORRashel HasanОценок пока нет

- Schematic Diagram For Sewage Treatment Plant 2 x100% (180 M /day)Документ1 страницаSchematic Diagram For Sewage Treatment Plant 2 x100% (180 M /day)siva242245Оценок пока нет

- Chapter 3 WastewaterДокумент115 страницChapter 3 WastewaterNur Iffatin100% (1)

- Anaerobic Baffled Reactor (ABR)Документ7 страницAnaerobic Baffled Reactor (ABR)Anastasya Putri SafinaОценок пока нет

- Sewage TreatmentДокумент15 страницSewage Treatmentvipin_nair01100% (1)

- F - M RatioДокумент4 страницыF - M RatioGarimaSinghОценок пока нет

- 2730, Brochure Multiflo 2013 EN Draft v07 PDFДокумент8 страниц2730, Brochure Multiflo 2013 EN Draft v07 PDFstojanovalidija0% (1)

- Bod Cod Toc - Gaman HiteshДокумент29 страницBod Cod Toc - Gaman HiteshDevendra SharmaОценок пока нет

- Modified Cluster System Approach To WastДокумент10 страницModified Cluster System Approach To WastGraziella NavacciОценок пока нет

- Class 7 CHP 18Документ3 страницыClass 7 CHP 18GiteshОценок пока нет

- KSB Sewabloc Sewatec CharakterystykiДокумент112 страницKSB Sewabloc Sewatec Charakterystykilouis etienneОценок пока нет

- Water Pollution ControlДокумент22 страницыWater Pollution Controlksbbs100% (2)

- 1 s2.0 S2213343722013239 MainДокумент11 страниц1 s2.0 S2213343722013239 MainFarah TalibОценок пока нет

- EE2 Module 1 TeacherДокумент44 страницыEE2 Module 1 Teacherlakshmi dileepОценок пока нет

- Northern California Master Geographic Letter List: CountiesДокумент28 страницNorthern California Master Geographic Letter List: CountiesPrajwal DSОценок пока нет

- The First Water Filters Made From Charcoal, Wool, and Sponge Were Created For Home Application in The 1700sДокумент4 страницыThe First Water Filters Made From Charcoal, Wool, and Sponge Were Created For Home Application in The 1700sjoanОценок пока нет

- WW Recycling Bangalore PPT 1Документ25 страницWW Recycling Bangalore PPT 1Vishwas BhatОценок пока нет

- Water Pollution & TreatmentДокумент20 страницWater Pollution & TreatmentPed SalvadorОценок пока нет

- Quantity of Wastewater Sanitary EngineeringДокумент7 страницQuantity of Wastewater Sanitary EngineeringHanRo MaharjanОценок пока нет

- Udaipur ArticleДокумент4 страницыUdaipur ArticleVipul UttamchandaniОценок пока нет

- Plan of Wastewater Treatment FacilityДокумент2 страницыPlan of Wastewater Treatment FacilityLouieОценок пока нет

- Pollution of The WaterДокумент25 страницPollution of The WaterJeprox Martinez100% (1)

- Data Sheet: Clarifier AP: Description Lamella SeparatorДокумент2 страницыData Sheet: Clarifier AP: Description Lamella SeparatorTuesou MachereОценок пока нет

- circular-STP Process SelectionДокумент16 страницcircular-STP Process SelectionVijay KumarОценок пока нет

- Contoh Perhitungan Desain STPДокумент23 страницыContoh Perhitungan Desain STPFortaengineering FortaenviroОценок пока нет

- De Jager - D - DTech Thesis 2013 FINALДокумент247 страницDe Jager - D - DTech Thesis 2013 FINALbobbymayaaОценок пока нет

- Activity 7Документ3 страницыActivity 7Elizer EleccionОценок пока нет

- Bal VigyanДокумент24 страницыBal VigyanVenom SnakeОценок пока нет

- Community Wastewater Treatment and DisposalДокумент18 страницCommunity Wastewater Treatment and DisposalJestoni FloresОценок пока нет