Академический Документы

Профессиональный Документы

Культура Документы

MasterEmaco SBR ECO v1 PDF

Загружено:

mcsomashekaraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MasterEmaco SBR ECO v1 PDF

Загружено:

mcsomashekaraАвторское право:

Доступные форматы

MasterEmaco®SBR ECO

Eco-FriendlySBR Latex for sustainable repair & waterproofing solutions.

DESCRIPTION • Corrosion control:Prevents corrosion of

embedded steel.

MasterEmaco SBR ECO is an eco-friendly blue • High Dispersion technology:Allows for better

coloured, Styrene-Butadiene co-polymer (SBR) workability at slightly reduced water.

latex liquid,free of APEO, formaldehyde, ammonia

and low VOC. The product compliments PROPERTIES

MasterEmaco SBR 2, daily use SBR latex.

Aspect Blue coloured, styrene

MasterEmaco SBR ECO, being environmentally

friendly is safe to handle as neat liquid or with butadiene co-polymer

concrete for repair and waterproofing applications. latex.

pH 8±1

RECOMMENDED USES Relative density 1.02 ± 0.01 at 25oC

Solid content 37±1%

• Concrete repair: Spalled concrete, repairing

floors, beams and pre-cast slabs, chajjas etc.

APPLICATION

• Bond Coat: For bonding new concrete to old

concrete, plaster, stone/brick masonry.

Surface preparation

• Plaster repair: For repairing plaster or making

water proof plaster which is better than normal • Remove all loose concrete, grease, mould

oil or curing compound from concrete and

plaster.

steel surfaces using wire brush, scrubber.

• Floor screeds and toppings: Abrasion

resistant and non-dusting floors. • Saw cut the concrete areas to a square or

rectangular profile to a minimum 10mm

• Waterproofing:Basements side walls and

depth at the extreme edges.

rafts, lift pits, inspection pits, sunken/overhead

water tank,sunken portions of bathrooms and • Roughen the surface free of loose

toilets, balconies, chajjas, exposed roofs particles and dust and saturate with water.

before finished screed. • Remove excess/standing water.

• Other typical applications: Bedding tiles,

fixing or re-fixing slip bricks. Bonding slurry

• Mix 1½ parts cement to 1 part

MasterEmaco SBR ECOby weight of

FEATURES AND BENEFITS

cement.

• Mix to a lump-free creamy, consistency for

• Eco-Friendly, safe to handle: Free of APEO, 2-3minutes by slowly adding

Formaldehyde, Ammonia, Low VOC. MasterEmaco SBR ECO.

• Multiple applications: Robust product that is • Using a stiff brush, work the bonding slurry

economical, easy to handle and store. well into the damp surface. When the bond

• Easy to Mix: Faster mixing to enhance worker coat is tacky apply mortar/screed overlay.

efficiency.

• Shrinkage/crack control:High flexural / As waterproofing slurry:

tensile strength to control cracking. • Mix 2 parts cement to 1 part

• Mortar modifier- Improved flexibility, no MasterEmaco SBR ECO by weight of

bleeding, lower water cement ratio and high cement.

resistance to water penetration. • Mix to a lump-free creamy, consistency for

• Improves physical/mechanical properties – 2 -3 minutes by slowly adding

higher abrasion resistance, good adhesion to MasterEmaco SBR ECO.

building materials similar thermal • Using a stiff brush, work first coat of

characteristics to concrete. waterproofing slurry well into the damp

surface.

MasterEmaco®SBR ECO

• After the first coat has dried, apply second • The MasterEmaco SBR ECO modified

coat at right angle to first followed by mix should be placed over the still wet

mortar/screed overlay. Average time gap bonding slurry, well compacted by hand

between two coats is 3 to 4 hours. and trowelled to finish using a wooden

float or steel trowel.

Mix Design: Mortar& Screed. Curing:Moisture cure for 24 hours and then allow

• Mix Design Repair Mortar: 10 Litre of to dry slowly.

MasterEmaco SBR ECO: 50kg of

Cement: 150kg of sieved sand: 10litres of ESTIMATING DATA

water.

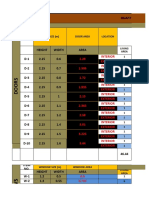

• Mix Design Floor Topping/Screed. 10 Mixing ratios

Litre of MasterEmaco SBR ECO: 50Kg of Usage Mixing Ratio

Cement: 75Kg of sand: 75kg of coarse Bonding 1(polymer) :1.5(cement)

aggregate (6mm down): 10litres of water. Waterproofing 1(polymer) :2(cement)

slurry

Mixing Process Mortar/Screed: Hand applied 1(polymer):5(cement):15(sand):1

• Use fresh, lump free cement, well graded Repair mortar (water)

sand/aggregates free of excessive fines. Floor 1(polymer):5(cement):7.5(sand):7.5

Screeds/PCC coarser aggregate:1 (water)

• Mix sand and cement and coarse

Topping

aggregate in Pan Type mixer for 1 -2

minutes. Hand mixing is only permissible

Coverage

when the total weight of the mix is less

Bonding Coat: 4 to 4.5m2 for mix of

than 25kg.

1LitreMasterEmaco SBR ECO and 1.5kg of

• Mix required quantity of MasterEmaco cement.

SBR ECO and water for 2 minutes in a

separate container, to avoid excessive air Waterproofing slurry:2 m2 in two coats for mix of

entrapment. 1 Litre MasterEmaco SBR ECO and 2kg of

• Finally, without delay, add the liquid mix cement.

slowly into the mixer containing the mixed

powdered sand/coarse aggregate and Repair Mortar/Concrete Screed: 10 Litre of

cement until the required consistency is MasterEmaco SBR ECO per 50kg of cement.

achieved.

PACKAGING

Rendering to vertical surfaces

• Apply the bonding slurry to the prepared

surface and then apply the MasterEmaco MasterEmaco SBR ECO is supplied in 1, 5,

SBR ECO rendor onto the wet bonding 20Litre

slurry.

• Application Thickness: 5 to 25mm. SHELF LIFE

• Greater thickness can lead to slumping.

• Apply multiple layers in rapid succession, Store under cover, out of direct sunlight and

within 15 to 30 minutes of the previous protect from extremes of temperature. In tropical

layer. climates the product must be stored in an air-

• Finish the surface using a wooden float or conditioned environment.

steel trowel. Shelf life is 12 months when stored as above.

• Apply modified slurry coat on the first layer PRECAUTIONS

in case application of second layer is

delayed to long time gaps. For the full health and safety hazard information

• and how to safely handle and use this product,

Screeds and toppings, applied to horizontal please make sure that you obtain a copy of the

surfaces BASF Material Safety Data Sheet (MSDS) from

• Application thickness 10mm to 40mm. our office or our website.

MasterEmaco®SBR ECO

MasterEmaco SBR 2 /01/0615

The technical information and application advice given in this BASF Construction Chemicals publication are based

STATEMENT OF on the present state of our best scientific and practical knowledge. As the information herein is of a general nature,

RESPONSIBILITY no assumption can be made as to a product's suitability for a particular use or application and no warranty as to its

(Disclaimer) accuracy, reliability or completeness either expressed or implied is given other than those required by law. The

user is responsible for checking the suitability of products for their intended use.

® = registered trademark of BASF group in many countries

Field service where provided does not constitute supervisory responsibility. Suggestions made by BASF

NOTE Construction Chemicals either orally or in writing may be followed, modified or rejected by the owner, engineer or

contractor since they, and not BASF Construction Chemicals, are responsible for carrying out procedures

appropriate to a specific application.

BASF India Limited

Construction Chemicals Division

Plot.No.12,TTC Area

Thane BelapurRoad,Turbhe

Navi Mumbai - 400705,India

Tel: +91 22 67127600, Fax: +91 22 67917358

E-mail: construction-india@basf.com , www.master-builders-solutions.basf.in

Вам также может понравиться

- MasterEmaco SBR 2v1Документ3 страницыMasterEmaco SBR 2v1Zulfikar A. SheriОценок пока нет

- MasterEmaco SBR 2 improves strength and reduces crackingДокумент3 страницыMasterEmaco SBR 2 improves strength and reduces crackingRadja NurОценок пока нет

- MasterEmaco SBR 3 PDFДокумент3 страницыMasterEmaco SBR 3 PDFMd. Shahadat HossainОценок пока нет

- Emaco Nanocrete R3 - PDS - ASEAN - 241110Документ3 страницыEmaco Nanocrete R3 - PDS - ASEAN - 241110Andri AjaОценок пока нет

- Expanbond SBRДокумент5 страницExpanbond SBRAmar WadoodОценок пока нет

- Myk Arment Rearm Coat ZPДокумент4 страницыMyk Arment Rearm Coat ZPpraveenpatel.pp7143Оценок пока нет

- Cementitious polymer modified thin layer fairing mortarДокумент2 страницыCementitious polymer modified thin layer fairing mortarVelmurugan BalasubramanianОценок пока нет

- Cemfair SmoothДокумент2 страницыCemfair Smoothosama mohОценок пока нет

- SBR bonding agent increases water resistance and durability of mortar and concreteДокумент2 страницыSBR bonding agent increases water resistance and durability of mortar and concreteHtun ZarniОценок пока нет

- Faircrete SBR Mortar and Screed Modifier Cum Bonding AgentДокумент2 страницыFaircrete SBR Mortar and Screed Modifier Cum Bonding Agentkk777kk77777Оценок пока нет

- MasterEmaco 2525 v1-0816Документ2 страницыMasterEmaco 2525 v1-0816Muhammad AzrinОценок пока нет

- Masteremaco S 5400: High-Strength, Shrinkage Compensated, Fiber Reinforced, Structural Repair MortarДокумент2 страницыMasteremaco S 5400: High-Strength, Shrinkage Compensated, Fiber Reinforced, Structural Repair MortarSetyo poernomoОценок пока нет

- Weber Euroflor DesignДокумент3 страницыWeber Euroflor DesignMaya Trad wehbeОценок пока нет

- Emaco Nanocrete AP PDS ASEAN 060409Документ2 страницыEmaco Nanocrete AP PDS ASEAN 060409EkoAndriAntoОценок пока нет

- MasterEmaco - S 348 v2Документ2 страницыMasterEmaco - S 348 v2Umeshchandra PatilОценок пока нет

- Emulsion 93 - NZ - PDSДокумент3 страницыEmulsion 93 - NZ - PDSPraneet KumarОценок пока нет

- Fullproof Damp FreeДокумент1 страницаFullproof Damp Freesinghanishant8Оценок пока нет

- Cemcoat PuttyДокумент2 страницыCemcoat Puttyosama mohОценок пока нет

- PACTOBond SBR-DatasheetДокумент2 страницыPACTOBond SBR-DatasheethidiОценок пока нет

- Basf Masteremaco s5400 TdsДокумент2 страницыBasf Masteremaco s5400 TdsAnonymous ahdhFMaОценок пока нет

- S BR CombinedДокумент6 страницS BR CombinedsajjaduetОценок пока нет

- Cerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationДокумент2 страницыCerabond 28: High Polymer Modified Tile Fixing Mortar For Internal & External Vertical ApplicationBharat KoraleОценок пока нет

- Abe Construction Chemicals Duraflex DatasheetДокумент2 страницыAbe Construction Chemicals Duraflex DatasheetEthanОценок пока нет

- Ds Duralatex 1Документ2 страницыDs Duralatex 1KeJeОценок пока нет

- LANKO 732 concrete repair mortarДокумент2 страницыLANKO 732 concrete repair mortarjet toledoОценок пока нет

- Nitobond SBR TDSДокумент3 страницыNitobond SBR TDSstephanus AndiОценок пока нет

- Cempatch SBR100 - TDSДокумент2 страницыCempatch SBR100 - TDSAhmed SamyОценок пока нет

- MasterEmaco S5400 ASEAN v1.3 0113Документ2 страницыMasterEmaco S5400 ASEAN v1.3 0113Muhammad Fadhil ImansyahОценок пока нет

- AJ220335-LCV-CVL-MTL-0001 - Cement & Civil Repair MaterialsДокумент8 страницAJ220335-LCV-CVL-MTL-0001 - Cement & Civil Repair Materialsmohammed mustafaОценок пока нет

- Masteremaco - S 348 v2Документ2 страницыMasteremaco - S 348 v2shahzadОценок пока нет

- Duraflex DSДокумент2 страницыDuraflex DSFeyiОценок пока нет

- Cempatch SBR 100Документ2 страницыCempatch SBR 100Mohammed OmerОценок пока нет

- Materials for Repairs Chapter - Epoxy, Gypsum and Quick-Setting MortarsДокумент19 страницMaterials for Repairs Chapter - Epoxy, Gypsum and Quick-Setting MortarsashishОценок пока нет

- MasterEmaco 2525 ASEAN V1.4 0713Документ2 страницыMasterEmaco 2525 ASEAN V1.4 0713Muhammad Fadhil ImansyahОценок пока нет

- Masteremaco S 5410 Ci Tds PDFДокумент3 страницыMasteremaco S 5410 Ci Tds PDFSolomon AhimbisibweОценок пока нет

- Barra Emulsion 57DДокумент2 страницыBarra Emulsion 57Dnadeesha100% (2)

- SikaCeram - 100 Basic PDFДокумент3 страницыSikaCeram - 100 Basic PDFMoatz HamedОценок пока нет

- CIKOtile SPДокумент2 страницыCIKOtile SPMahmoud OmarОценок пока нет

- Sikatop 107 Seal Pds enДокумент3 страницыSikatop 107 Seal Pds ensahal_akОценок пока нет

- Nitobond - SBR FosrocДокумент6 страницNitobond - SBR FosrocVedachalam ManiОценок пока нет

- MasterEmaco - S 348 v1Документ2 страницыMasterEmaco - S 348 v1vahab_shaik0% (1)

- PDS Monolevel 844SPДокумент3 страницыPDS Monolevel 844SPerawrestlingОценок пока нет

- Sika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairДокумент3 страницыSika SBR 100: SBR Based Multipurpose Polymer For Waterproofing and RepairJoeОценок пока нет

- Premix Skim Coat: High Quality Cementitious RenderingДокумент2 страницыPremix Skim Coat: High Quality Cementitious RenderingHaytham KhairyОценок пока нет

- Masteremaco 2525: Solvent Free Epoxy Binder, Structural Adhesive and General Purpose PrimerДокумент2 страницыMasteremaco 2525: Solvent Free Epoxy Binder, Structural Adhesive and General Purpose PrimerSetyo poernomoОценок пока нет

- Davco TTB ECO Brochure 1Документ2 страницыDavco TTB ECO Brochure 1hinal pОценок пока нет

- 13 - TDS - Emaco S43 NTДокумент3 страницы13 - TDS - Emaco S43 NTaahtagoОценок пока нет

- NG NP Sikatop Seal 107Документ3 страницыNG NP Sikatop Seal 107NourhoudaОценок пока нет

- Dura FlexДокумент2 страницыDura FlexMuktaf Ajib El WatsiОценок пока нет

- Zemcoat Water Resistant Technical Data SheetДокумент1 страницаZemcoat Water Resistant Technical Data SheetAiris Joy RojasОценок пока нет

- Masteremaco S 650: Fast Setting High Strength Thixotropic Roadway Patching MortarДокумент2 страницыMasteremaco S 650: Fast Setting High Strength Thixotropic Roadway Patching MortarRavi kumarОценок пока нет

- Sika PDS E SikaLatexДокумент2 страницыSika PDS E SikaLatexlwin_oo2435Оценок пока нет

- Rheomac 707 PDFДокумент3 страницыRheomac 707 PDFMohamed KhanОценок пока нет

- MasterCast 141MДокумент5 страницMasterCast 141Mrobin rezkОценок пока нет

- Appendix 4 TDS & MSDSДокумент8 страницAppendix 4 TDS & MSDSmohsin.meizaОценок пока нет

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoОт EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoОценок пока нет

- Fiber-Bridging Constitutive Law of Engineered Cementitious CompositesДокумент13 страницFiber-Bridging Constitutive Law of Engineered Cementitious CompositesmcsomashekaraОценок пока нет

- Is 13830 - 1993 Pesticide - Method For Determination of Residues in Agricultural and Food Commodities, Soil and Water - CaptafolДокумент7 страницIs 13830 - 1993 Pesticide - Method For Determination of Residues in Agricultural and Food Commodities, Soil and Water - CaptafolPrapa KaranОценок пока нет

- Extruded Poly (Ethylene-Co-Octene) /fly Ash Composites - Value Added Products From An Environmental PollutantДокумент1 страницаExtruded Poly (Ethylene-Co-Octene) /fly Ash Composites - Value Added Products From An Environmental PollutantmcsomashekaraОценок пока нет

- Fiber-Bridging Constitutive Law of Engineered Cementitious CompositesДокумент13 страницFiber-Bridging Constitutive Law of Engineered Cementitious CompositesmcsomashekaraОценок пока нет

- Sound Insulation Performance of Aerated Concrete WallsДокумент10 страницSound Insulation Performance of Aerated Concrete WallsmcsomashekaraОценок пока нет

- AD KF-abyДокумент1 страницаAD KF-abymcsomashekara100% (1)

- Value Edu2005 PDFДокумент132 страницыValue Edu2005 PDFmcsomashekaraОценок пока нет

- 365 Daily QuotesДокумент13 страниц365 Daily QuotesmcsomashekaraОценок пока нет

- JfskafmДокумент101 страницаJfskafmmcsomashekaraОценок пока нет

- Report ISI2006-3 Tensile Creep and Shrinkage of PVA-ECCДокумент26 страницReport ISI2006-3 Tensile Creep and Shrinkage of PVA-ECCmcsomashekaraОценок пока нет

- IMS-Kalmatron - Ultra-High Performance Concrete (UHPC)Документ2 страницыIMS-Kalmatron - Ultra-High Performance Concrete (UHPC)mcsomashekaraОценок пока нет

- 3D Print Structures with Lunar RegolithДокумент3 страницы3D Print Structures with Lunar RegolithmcsomashekaraОценок пока нет

- Item Qtty Amount Item2 Qtty2 Amount2Документ4 страницыItem Qtty Amount Item2 Qtty2 Amount2mcsomashekaraОценок пока нет

- 6Wxg/Rq (Qjlqhhuhg&Hphqwlwlrxv &Rpsrvlwhvzlwk'Liihuhqw) Leuhv$&Ulwlfdo 5hylhzДокумент5 страниц6Wxg/Rq (Qjlqhhuhg&Hphqwlwlrxv &Rpsrvlwhvzlwk'Liihuhqw) Leuhv$&Ulwlfdo 5hylhzಶಿವರಾಜ್ ಪಾಟೀಲ್Оценок пока нет

- Brushbond RFX PDFДокумент2 страницыBrushbond RFX PDFpiyu114Оценок пока нет

- PDFДокумент7 страницPDFmcsomashekaraОценок пока нет

- 5767 Nano Dur Compound 5Документ4 страницы5767 Nano Dur Compound 5mcsomashekaraОценок пока нет

- Product Evaluation of Hebel AAC PanelsДокумент3 страницыProduct Evaluation of Hebel AAC PanelsmcsomashekaraОценок пока нет

- Construction and Building Materials: Olga Burgos-Montes, Marta Palacios, Patricia Rivilla, Francisca PuertasДокумент10 страницConstruction and Building Materials: Olga Burgos-Montes, Marta Palacios, Patricia Rivilla, Francisca PuertasKarthikeyan BalasubramanianОценок пока нет

- MasterEmaco SBR ECO Eco-Friendly SBRДокумент3 страницыMasterEmaco SBR ECO Eco-Friendly SBRmcsomashekaraОценок пока нет

- Additive Construction Using Basalt Regolith FinesДокумент10 страницAdditive Construction Using Basalt Regolith FinesmcsomashekaraОценок пока нет

- HEBEL AAC Lintel Load RatingsДокумент2 страницыHEBEL AAC Lintel Load RatingsmcsomashekaraОценок пока нет

- ECC: A Review of Engineered Cementitious CompositesДокумент7 страницECC: A Review of Engineered Cementitious CompositesmcsomashekaraОценок пока нет

- Construction and Building Materials: Olga Burgos-Montes, Marta Palacios, Patricia Rivilla, Francisca PuertasДокумент10 страницConstruction and Building Materials: Olga Burgos-Montes, Marta Palacios, Patricia Rivilla, Francisca PuertasKarthikeyan BalasubramanianОценок пока нет

- AD KF-abyДокумент1 страницаAD KF-abymcsomashekara100% (1)

- Repair and Renovate Concrete and Masonry with KF-F SprayДокумент1 страницаRepair and Renovate Concrete and Masonry with KF-F SpraymcsomashekaraОценок пока нет

- Software To Calculate Concrete Mix DesignДокумент5 страницSoftware To Calculate Concrete Mix DesignmcsomashekaraОценок пока нет

- Repair and Renovate Concrete and Masonry with KF-F SprayДокумент1 страницаRepair and Renovate Concrete and Masonry with KF-F SpraymcsomashekaraОценок пока нет

- Victor C. Li: E. Benjamin Wylie Collegiate ProfessorДокумент4 страницыVictor C. Li: E. Benjamin Wylie Collegiate ProfessormcsomashekaraОценок пока нет

- LCP Formdek: Permanent Steel FormworkДокумент5 страницLCP Formdek: Permanent Steel FormworkGarfieldОценок пока нет

- Parameters Dakshinchithra Sargaalaya Choki Dhani National Crafts Museum InferenceДокумент3 страницыParameters Dakshinchithra Sargaalaya Choki Dhani National Crafts Museum InferenceAyisha HAZEENAОценок пока нет

- CPWD-Works Manual 2012Документ174 страницыCPWD-Works Manual 2012sivanandОценок пока нет

- Dead Load ReferenceДокумент3 страницыDead Load ReferenceCheng Por Eng100% (2)

- Structural Notes and DetailsДокумент1 страницаStructural Notes and DetailsMohammad AlkahteebОценок пока нет

- Final TaraДокумент17 страницFinal TaraAnkita Somwanshi Rajput71% (7)

- Column:C2 900X900: Basic Design ParametersДокумент2 страницыColumn:C2 900X900: Basic Design ParametersAnonymous tBhJoH5wgMОценок пока нет

- Stainless Steel Cable Ties SPEEDWELLДокумент2 страницыStainless Steel Cable Ties SPEEDWELLBirjuAJotwaniОценок пока нет

- Bullflex Tunnel Support PackerДокумент131 страницаBullflex Tunnel Support Packerdafo407Оценок пока нет

- Debris House Maximizes Small Kerala SiteДокумент15 страницDebris House Maximizes Small Kerala Sitepriti kochetaОценок пока нет

- Final Comparative Analysis On Planning PДокумент9 страницFinal Comparative Analysis On Planning Parchitect AJОценок пока нет

- DPCДокумент6 страницDPCaquagirl_738444244Оценок пока нет

- Renaissance ArchitectureДокумент12 страницRenaissance ArchitecturePaulaTrishaValleОценок пока нет

- Floorplan Duxton 35Документ2 страницыFloorplan Duxton 35Rajeev SharanОценок пока нет

- Quantity of cement, sand and doors for new homeДокумент14 страницQuantity of cement, sand and doors for new homeRoland CepedaОценок пока нет

- History of - 6: ArchitectureДокумент31 страницаHistory of - 6: ArchitectureBobinder chauhanОценок пока нет

- EBrochure Aerium ApartmentДокумент12 страницEBrochure Aerium ApartmentAnton TanОценок пока нет

- KLH - Cornell-Cookson - Contra Fuego - ERD10 - ERD20Документ2 страницыKLH - Cornell-Cookson - Contra Fuego - ERD10 - ERD20NELSONОценок пока нет

- Hoysala Architecture - Classic Example With Somnathpura TempleДокумент15 страницHoysala Architecture - Classic Example With Somnathpura TempleNandeesha Ramesh33% (3)

- Precast Concrete Panel Systems For Full-Depth Pavement Repairs - Field TrialsДокумент84 страницыPrecast Concrete Panel Systems For Full-Depth Pavement Repairs - Field TrialsTim LinОценок пока нет

- Cereal Plant Update 4Документ6 страницCereal Plant Update 4Eliezer Charles NgahyomaОценок пока нет

- Kiwispan Product Brochure 2009Документ12 страницKiwispan Product Brochure 2009fahim007Оценок пока нет

- Structures and Obstruction Removal Project Cost EstimationДокумент591 страницаStructures and Obstruction Removal Project Cost EstimationShella May QuimpanОценок пока нет

- Adapting UML for Object Oriented Systems Engineering (OOSEMДокумент8 страницAdapting UML for Object Oriented Systems Engineering (OOSEMjenyrennyОценок пока нет

- Manpower ScheduleДокумент30 страницManpower ScheduleAyhie GarciaОценок пока нет

- Bill No. 2 Site Work: December 2008 Jeddah Residential Tower Bills of QuantitiesДокумент10 страницBill No. 2 Site Work: December 2008 Jeddah Residential Tower Bills of QuantitiesJohn Paul PagsolinganОценок пока нет

- Intro BridgesДокумент44 страницыIntro BridgesnoddyjohnОценок пока нет

- Rennee Son C. Bancud, C.E.: Personal DataДокумент5 страницRennee Son C. Bancud, C.E.: Personal DataRennee Son BancudОценок пока нет

- Shotcrete and Its Potential Applications On Ontario ConstructionДокумент63 страницыShotcrete and Its Potential Applications On Ontario ConstructionEmre SayınОценок пока нет

- PWD RequirementsДокумент10 страницPWD Requirementsoj_ordeОценок пока нет