Академический Документы

Профессиональный Документы

Культура Документы

Requirement For LS SAW Process

Загружено:

AnilkumarGopinathanNairОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Requirement For LS SAW Process

Загружено:

AnilkumarGopinathanNairАвторское право:

Доступные форматы

Requirements for Long Seam Sub Merged Arc Welding Process

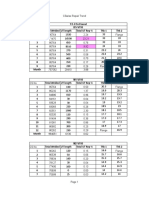

1. 2 Welder / Shift

Man Power (HR) 2. 2 Supporter / Shift

1. Helmet

2. Goggles

3. Mask & Welder Mask

4. Ear Plug

Safety PPE's (HR & VED) 5. Shoe

6. Gloves

7. Safety Belt

8. Apron

1. Column Boom – 2

2. Power Source – 4

3. Rotator – 4

4. AG7 Grinding Machine – 2

Machine (PM) 5. AG5 Grinding Machine – 2

6. Flux Ovan – 2

7. Pre - Heat Set – 1

7. Compressor – 2

8. Laser Light – 2

1. Coil

2. Flux

3. SAW Welding set

Material (VED & IED) 4. LPG – 1

5. Slag Box – 2

6. Fire Extinguisher

1. Screw Driver – 2

2. Adjustable Spanner – 2

3. Coil Cutter – 2

4. Cutting Plier – 2

Tools (VED) 5. Starting piece removal tool – 1

6. Wire Brush – 2

7. Cleaning Brush - 2

8. Chisel – 2

9. Utility storage Bero with identification

1. Thermo Chalk 100°c – 1

Instruments (QA) 2. Thermo Chalk 250°c - 1

1. Log Note

2. History card

3. WPS Synopsis

Documents (HR & VS) 4. Marker

5. Chalk Piece

6. CLIT Sheet

7. Paper Punch

1. Broom

2. Dust Collector

3. Flux removal plate or Auto Flux Removal set

Work Station Cleaning (HR) 4. Waste Management Bin

5. Slag Bin – 2

1. EOT

Material Handling (VED & PM) 2. EOT Chains

1. APS Principles

2. SOP

3. CCR, CTP & CTQ (Gamesa& Vestas)

Methods (VS & QA) 4. Do's & Dont's

5. 5S Sheet

6. WPS Synopsis (Gamesa & Vestas)

Вам также может понравиться

- Item Approx Price ActualДокумент2 страницыItem Approx Price ActualAnilkumarGopinathanNairОценок пока нет

- Trading Book - DSДокумент9 страницTrading Book - DSAnilkumarGopinathanNairОценок пока нет

- SL No Date Stock Long/Short Buy Price Sell Price Qty Leverage Profit/LossДокумент27 страницSL No Date Stock Long/Short Buy Price Sell Price Qty Leverage Profit/LossAnilkumarGopinathanNairОценок пока нет

- Weld 1Документ18 страницWeld 1AnilkumarGopinathanNairОценок пока нет

- WeldДокумент22 страницыWeldAnilkumarGopinathanNairОценок пока нет

- EuclidДокумент15 страницEuclidAnilkumarGopinathanNairОценок пока нет

- Trading Book - AGДокумент7 страницTrading Book - AGAnilkumarGopinathanNairОценок пока нет

- Weld 1Документ18 страницWeld 1AnilkumarGopinathanNairОценок пока нет

- Supplier Kpi From Vs - Fab, NDT & QCДокумент4 страницыSupplier Kpi From Vs - Fab, NDT & QCAnilkumarGopinathanNairОценок пока нет

- Supplier Kpi From Ved - Purc, Stores & LogДокумент18 страницSupplier Kpi From Ved - Purc, Stores & LogAnilkumarGopinathanNairОценок пока нет

- Daily ExpenseДокумент33 страницыDaily ExpenseAnilkumarGopinathanNairОценок пока нет

- Daily Attendance Report July 2018Документ9 страницDaily Attendance Report July 2018AnilkumarGopinathanNairОценок пока нет

- Daily Attendance Report July 2018Документ9 страницDaily Attendance Report July 2018AnilkumarGopinathanNairОценок пока нет

- Address To ApplyДокумент1 страницаAddress To ApplyAnilkumarGopinathanNairОценок пока нет

- Unit-1 5S & EHS ScoreДокумент1 страницаUnit-1 5S & EHS ScoreAnilkumarGopinathanNairОценок пока нет

- WEEK 22 LS Repair TrendДокумент2 страницыWEEK 22 LS Repair TrendAnilkumarGopinathanNairОценок пока нет

- Img 412114601Документ1 страницаImg 412114601AnilkumarGopinathanNairОценок пока нет

- Deputy Manager - Ied SGM - IedДокумент2 страницыDeputy Manager - Ied SGM - IedAnilkumarGopinathanNairОценок пока нет

- UT Performance 8-05-2018Документ13 страницUT Performance 8-05-2018AnilkumarGopinathanNairОценок пока нет

- UT Performance 5-05-2018Документ13 страницUT Performance 5-05-2018AnilkumarGopinathanNairОценок пока нет

- Copy of Copy of Copy of Copy of WEEK 29 COMPLETEDДокумент58 страницCopy of Copy of Copy of Copy of WEEK 29 COMPLETEDAnilkumarGopinathanNairОценок пока нет

- UT Performance 24-04-2018Документ13 страницUT Performance 24-04-2018AnilkumarGopinathanNairОценок пока нет

- UT Performance 13-04-2018.odsДокумент151 страницаUT Performance 13-04-2018.odsAnilkumarGopinathanNairОценок пока нет

- WEEK 22 LS Repair TrendДокумент2 страницыWEEK 22 LS Repair TrendAnilkumarGopinathanNairОценок пока нет

- UT Performance March 2018 GraphДокумент12 страницUT Performance March 2018 GraphAnilkumarGopinathanNairОценок пока нет

- UT Performance 13-04-2018.odsДокумент151 страницаUT Performance 13-04-2018.odsAnilkumarGopinathanNairОценок пока нет

- Bay: Section No: Date: Cs No O/S Amps Voltage Welder Id M/C No Remarks Bevel Width Bevel Depth No of Pass Travel Speed Welding MonitorДокумент1 страницаBay: Section No: Date: Cs No O/S Amps Voltage Welder Id M/C No Remarks Bevel Width Bevel Depth No of Pass Travel Speed Welding MonitorAnilkumarGopinathanNairОценок пока нет

- ISO 15614-1 2012 190 ISO 15609-1 2004 98 ISO 9606-1 2013 190 ISO 14732 2013 164 ISO 4063 2010 190 Total 832Документ1 страницаISO 15614-1 2012 190 ISO 15609-1 2004 98 ISO 9606-1 2013 190 ISO 14732 2013 164 ISO 4063 2010 190 Total 832AnilkumarGopinathanNairОценок пока нет

- Unit-1 5S & EHS ScoreДокумент2 страницыUnit-1 5S & EHS ScoreAnilkumarGopinathanNairОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 777GДокумент15 страниц777GJuan Ricardo Bolivar Pilco100% (1)

- Sustainability 02 00400 PDFДокумент28 страницSustainability 02 00400 PDFGemmer BatuyongОценок пока нет

- H-Xtenda Typical System Layouts: Technical DatasheetДокумент8 страницH-Xtenda Typical System Layouts: Technical DatasheetsergioОценок пока нет

- Groundwater Aeration Towers, Degasifiers, Air Strippers: Advanced Odor Removal SystemsДокумент1 страницаGroundwater Aeration Towers, Degasifiers, Air Strippers: Advanced Odor Removal SystemsherikОценок пока нет

- N E W S L E T T E R: Electronic Staging of Composite Propellant Rocket MotorsДокумент8 страницN E W S L E T T E R: Electronic Staging of Composite Propellant Rocket Motorsdrforbin666Оценок пока нет

- Marketing VoltasДокумент31 страницаMarketing VoltasNiraj Kumar100% (1)

- Shutdown Maintenance Raw Mill Section July 2017Документ3 страницыShutdown Maintenance Raw Mill Section July 2017vinodsnОценок пока нет

- Typical Box CulvertДокумент1 страницаTypical Box CulvertDeepak Pandey100% (1)

- Australian StandardДокумент14 страницAustralian StandardEsme P. W. LauОценок пока нет

- rr321401 Principles of Machine DesignДокумент8 страницrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- Ieee Papers On Automotive Embedded SystemsДокумент12 страницIeee Papers On Automotive Embedded SystemssathishОценок пока нет

- 3D Pushblock: GR-100 & GR-200 Instruction ManualДокумент12 страниц3D Pushblock: GR-100 & GR-200 Instruction ManualMad CowОценок пока нет

- Wassara Start-Up Guide Jet-GroutingДокумент8 страницWassara Start-Up Guide Jet-GroutingdeliaabreguОценок пока нет

- GSX1300R - 99500-39187-03E - Pag 257Документ1 страницаGSX1300R - 99500-39187-03E - Pag 257Tarso BrasilОценок пока нет

- Screw TurbineДокумент12 страницScrew TurbineTanvi0% (1)

- SBJX 20170913Документ20 страницSBJX 20170913mОценок пока нет

- Motor Cat 3054C 1104D Perkins PDFДокумент133 страницыMotor Cat 3054C 1104D Perkins PDFnacho75% (4)

- Formwok (WBLFF)Документ15 страницFormwok (WBLFF)Ryan BaoОценок пока нет

- EN 10210-1 - 2006 - Table 2 PDFДокумент1 страницаEN 10210-1 - 2006 - Table 2 PDFvimal_mech123Оценок пока нет

- f4 Plasma Spray GunДокумент2 страницыf4 Plasma Spray GunMuhammad ZulfaqarОценок пока нет

- Volvo vt880Документ8 страницVolvo vt880ForomaquinasОценок пока нет

- Berkeley Pump SeriesДокумент36 страницBerkeley Pump SeriesJMFPОценок пока нет

- Compact Wastewater Pumps4Документ8 страницCompact Wastewater Pumps4MartinDiazОценок пока нет

- FastEPBAdvance NAT2014 PDFДокумент13 страницFastEPBAdvance NAT2014 PDFBob MoncrieffОценок пока нет

- D2840 Oi PDFДокумент42 страницыD2840 Oi PDFrowanОценок пока нет

- 11B Engine MechanicalДокумент17 страниц11B Engine Mechanicalcrysttina100% (1)

- CNSLДокумент18 страницCNSLrafeekОценок пока нет

- Grid Slab or Waffle SlabДокумент2 страницыGrid Slab or Waffle Slabjncame33% (3)

- KOBELCO Arm Shock CountermeasureДокумент204 страницыKOBELCO Arm Shock CountermeasurePHÁT NGUYỄN THẾ100% (8)