Академический Документы

Профессиональный Документы

Культура Документы

Prosedur Pengendalian Operasional: Operational Control Procedures

Загружено:

ISUKepri.ComОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Prosedur Pengendalian Operasional: Operational Control Procedures

Загружено:

ISUKepri.ComАвторское право:

Доступные форматы

TITLE DOC. NO.

REV EFFECTIVE DATE

PROSEDUR PENGENDALIAN OPERASIONAL

CAST-II-HSE-09 00 01 October 2016

OPERATIONAL CONTROL PROCEDURES

PROSEDUR PENGENDALIAN OPERASIONAL

OPERATIONAL CONTROL PROCEDURES

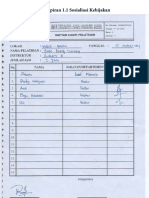

TANDA TANGAN DIBAWAH INI MENJELASKAN PERSIAPAN DAN PERSETUJUAN DARI SEMUA HALAMAN DALAM

PROSEDUR INI DAN TERMASUK TANGGAL PERSETUJUAN

THIS SIGNATURE BELOW INDICATED PREPARATION AND APPROVAL OF ALL THE NUMBERED PAGES IN THIS

PROCEDURE UP TO AND INCLUDING THE DATE OF APPROVAL

PENUNJUKAN DISIAPKAN OLEH DITINJAU OLEH DISETUJUI OLEH

DESIGNATION PREPARED BY REVIEWED BY APPROVED BY

NAMA

NAME Leo Kennedy Roby Syahputra Dewi Yuliana

POSISI HSE-RSO Manajer Mutu Direktur

POSITION HSE-RSO Quality Manager Director

TANDATANGAN

SIGNATURE

TANGGAL

01 October 2016 01 October 2016 01 October 2016

DATE

DOKUMENT INI TERDAFTAR DI MASTER LIST SISTEM DOKUMEN MANAJEMEN MUTU PERUSAHAAN YANG DI

KENDALIKAN OLEH MANAJER QHSE DARI PT. CAST INSPECTION AND ENGINEERING DAN MUNGKIN TIDAK

DAPAT DIUBAH, REVISI DAN ATAU DALAM BENTUK APAPUN TANPA SEIJIN YANG BERWENANG.

THIS DOCUMENT IS REGISTERED IN THE COMPANY QUALITY MANAGEMENT SYSTEM DOCUMENT MASTER LIST

THAT IS CONTROLLED BY QHSE MANAGER OF PT. CAST INSPECTION AND ENGINEERING AND MAY NOT BE

AMENDED, REVISED AND OR IN ANY WAY ALTERED WITHOUT HIS/HER AUTHORITY.

THIS PROCEDURE IS INVALID WITHOUT COVER PAGE AND SIGNATURE AND COMPANY STAMP LEFT BLANK.

© PT. CAST INSPECTION & ENGINEERING BATAM Page 1 of 8

CONFIDENTIAL DOCUMENT, ALL RIGHT RESERVED

TITLE DOC. NO. REV EFFECTIVE DATE

PROSEDUR PENGENDALIAN OPERASIONAL

CAST-II-HSE-09 00 01 October 2016

OPERATIONAL CONTROL PROCEDURES

REVISION HISTORY

PREPARED REVIEWED APPROVED

REV DATE DESCRIPTION

BY BY BY

Roby Dewi

00 01/10/16 First Release Leo Kennedy

Syahputra Yuliana

THIS PROCEDURE IS INVALID WITHOUT COVER PAGE AND SIGNATURE AND COMPANY STAMP LEFT BLANK.

© PT. CAST INSPECTION & ENGINEERING BATAM Page 2 of 8

CONFIDENTIAL DOCUMENT, ALL RIGHT RESERVED

TITLE DOC. NO. REV EFFECTIVE DATE

PROSEDUR PENGENDALIAN OPERASIONAL

CAST-II-HSE-09 00 01 October 2016

OPERATIONAL CONTROL PROCEDURES

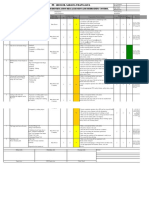

DAFTAR DISTRIBUSI

DISTRIBUTION LIST

DISTRIBUTION

STATUS DEPARTMENT PIC

NO.

01 Original QHSE QHSE Coordinator

02 Controlled Copy NDT NDT Manager

03 Controlled Copy HT HT Manager

04 Controlled Copy HRGA HRGA Coordinator

05 Controlled Copy FINANCE FINANCE Coordinator

06 Controlled Copy LOGISTIC LOGISTIC Coordinator

07 Controlled Copy BD BD Manager

THIS PROCEDURE IS INVALID WITHOUT COVER PAGE AND SIGNATURE AND COMPANY STAMP LEFT BLANK.

© PT. CAST INSPECTION & ENGINEERING BATAM Page 3 of 8

CONFIDENTIAL DOCUMENT, ALL RIGHT RESERVED

TITLE DOC. NO. REV EFFECTIVE DATE

PROSEDUR PENGENDALIAN OPERASIONAL

CAST-II-HSE-09 00 01 October 2016

OPERATIONAL CONTROL PROCEDURES

DAFTAR ISI

LIST OF CONTENTS

1. TUJUAN 5

PURPOSE

2. RUANGLINGKUP 5

SCOPE

3. DEFINISI 5

DEFINITIONS

4. ACUAN 5

REFERENCE

5. PROSEDUR DAN TANGGUNG JAWAB 6

PROCEDURES AND RESPONBILITY

6. DOKUMEN PENDUKUNG 8

DOCUMENT SUPPORT

7. REKAMAN PENDUKUNG 8

RECORD SUPPORT

THIS PROCEDURE IS INVALID WITHOUT COVER PAGE AND SIGNATURE AND COMPANY STAMP LEFT BLANK.

© PT. CAST INSPECTION & ENGINEERING BATAM Page 4 of 8

CONFIDENTIAL DOCUMENT, ALL RIGHT RESERVED

TITLE DOC. NO. REV EFFECTIVE DATE

PROSEDUR PENGENDALIAN OPERASIONAL

CAST-II-HSE-09 00 01 October 2016

OPERATIONAL CONTROL PROCEDURES

1. TUJUAN

PURPOSE

Prosedur ini digunakan sebagai panduan penerapan K3 di kegiatan operasi

PT. CAST INSPECTION AND ENGINEERING untuk menjamin pencegahan

dan pengendalian risiko K3 yang timbul akibat kegiatan operasi tersebut.

This procedure is used to guide the implementation of K3 in the operations

of PT. INSPECTION AND ENGINEERING CAST to ensure the prevention and

control of risks arising from activities K3 which arise the operation.

2. RUANG LINGKUP

SCOPE

Prosedur ini diberlakukan untuk proses manajemen perubahan di PT. CAST

INSPECTION AND ENGINEERING.

This procedure is applied to the process of Change Management in PT. CAST

INSPECTION AND ENGINEERING.

3. DEFINISI

DEFINITIONS

Keselamatan Kerja (Occupational Safety) adalah suatu keadaan atau factor

yang menjamin atas keamanan bekerja baik bagi pekerja, tamu

perusahaan, atau siapapun yang berada di tempat kerja termasuk yang

berada di lingkungan sekitar tempat kerja terhadap potensi bahaya

yang diprediksi dapat terjadi.

Safety (Occupational Safety) is a condition or factor that guarantees the

security of working both for the workers, a company, or anyone who is in

the workplace, including those in the workplace environment against the

potential hazards that could occur.

4. ACUAN

REFERENCES

4.1 Pedoman Sistem Manajemen MUTU & K3 PT. CAST INSPECTION AND

ENGINEERING.

Guidelines Management System QUALITY & K3 PT. CAST INSPECTION

AND ENGINEERING.

4.2 Undang-undang No. 1 tahun 1970 tentang Keselamatan Kerja.

Act No. 1 1970 on Work Safety.

4.3 OSHAS 18001:2007 Klausul 4.4.6 Prosedur Pengendalian Operasional.

OSHAS 18001: 2007 Clause 4.4.6 Operational Control Procedures.

THIS PROCEDURE IS INVALID WITHOUT COVER PAGE AND SIGNATURE AND COMPANY STAMP LEFT BLANK.

© PT. CAST INSPECTION & ENGINEERING BATAM Page 5 of 8

CONFIDENTIAL DOCUMENT, ALL RIGHT RESERVED

TITLE DOC. NO. REV EFFECTIVE DATE

PROSEDUR PENGENDALIAN OPERASIONAL

CAST-II-HSE-09 00 01 October 2016

OPERATIONAL CONTROL PROCEDURES

5. PROSEDUR DAN TANGGUNG JAWAB

PROCEDURE AND RESPONSIBILITY

5.1 Prosedur Umum

General Procedures

Semua pekerja dan tamu perusahaan yang memasuki area operasi

wajib mematuhi semua peraturan dan ketentuan aspek K3.

All guest workers and companies that entered the area of operation

shall comply with all rules and regulations K3 aspects.

5.2 Prosedur Pada Tempat Kerja

Procedure in the Workplace

a. Pintu Keluar Masuk Orang / Pekerja / Barang harus disediakan

secara khusus.

Exit Sign People / Workers / goods must be reserved exclusively.

b. Lampu Penerangan

Lighting

Lampu penerangan harus tersedia dalam jumlah yang cukup dan

memenuhi aspek K3.

− Lamp lighting should be available in sufficient quantities and

fulfills the K3.

− Sumber tenaga untuk penerangan harus tersedia dan memenuhi

aspek K3

− Sources of energy for lighting should be available and fulfills the

K3

c. Ventilasi / Sirkulasi Udara

Ventilation / Air Circulation

− Di tempat kerja yang tertutup, harus dibuat ventilasi yang

sesuai untuk mendapat sirkulasi udara segar.

In the workplace closed, it should be suitable ventilation to get

fresh air circulation.

− Jika diperlukan untuk mencegah bahaya terhadap kesehatan

dari udarayang dikotori oleh debu, gas–gas atau dari sebab-

sebab lain, harus dibuatkan ventilasi untuk pembuangan udara

kotor (exhaust).

If necessary to prevent danger to the health of udarayang

dirtied by dust, gases or from other causes, should be made for

the disposal of dirty air vent (exhaust).

− Jika secara teknis tidak mungkin bisa menghilangkan debu, gas

yang berbahaya, tenaga kerja wajib menggunakan alat

pelindung diri (Alat Perlindungan Pernafasan, Respirator) yang

sesuai.

If it is technically impossible to remove dust, harmful gases,

workers are required to use personal protective equipment

(Respiratory Protection Equipment, respirator) as appropriate.

THIS PROCEDURE IS INVALID WITHOUT COVER PAGE AND SIGNATURE AND COMPANY STAMP LEFT BLANK.

© PT. CAST INSPECTION & ENGINEERING BATAM Page 6 of 8

CONFIDENTIAL DOCUMENT, ALL RIGHT RESERVED

TITLE DOC. NO. REV EFFECTIVE DATE

PROSEDUR PENGENDALIAN OPERASIONAL

CAST-II-HSE-09 00 01 October 2016

OPERATIONAL CONTROL PROCEDURES

5.3 Rambu Peringatan/Larangan/Anjuran

Signs warning / ban / Suggested

a. Penempatan rambu-rambu peringatan/larangan/anjuran harus

dipasang sesuai dengan kondisi di tempat kerja.

Placement of signs warning / ban / recommendations must be

installed in accordance with the conditions in the workplace.

b. Rambu peringatan/larangan/anjuran harus mudah dilihat dan dapat

dibaca.

Signs warning / ban / recommendation should be visible and legible

5.4 Alat Pelindung Diri

Personal Protective Equipment

a. Alat pelindung diri diidentifikasi berdasarkan hasil penilaian risiko.

Personal protective equipment is identified based on the results of

the risk assessment.

b. Alat pelindung diri (APD) diberikan kepada pekerja sesuai dengan

jenis

pekerjaannya untuk memberikan perlindungan yang cukup, dan AP

D dipelihara oleh pekerja.

Personal protective equipment (PPE) provided to the workers in

accordance with the type of work to provide adequate protection,

and APD maintained by workers.

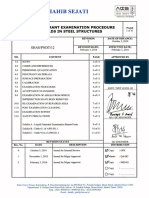

6. DOKUMEN PENDUKUNG

SUPPORTING DOCUMENTS

6.1 CAST-II-HSE-01 Pedoman Pelaksanaan Hazard Identifikasi dan

Pengendalian Resiko

CAST-II-HSE-01 Guidelines on the Implementation of Hazard

Identification and Risk Control

6.2. CAST-II-HSE-19 APD/PPE

7. REKAMAN PENDUKUNG

RECORDING SUPPORT

7.1 CAST-IV-HSE-01-01 Formulir Identifikasi Bahaya, Penilaian dan

Pengendalian Risiko (Formulir HIRADC)

Form Hazard Identification, Risk Assessment and Control (Form

HIRADC)

7.2 MSDS (Material Safety Data Sheet)

MSDS (Material Safety Data Sheet)

7.3 Surat Izin Kerja Aman/ Work Permit(Mengikuti Project)

Safe Work Permit (Follow Project)

THIS PROCEDURE IS INVALID WITHOUT COVER PAGE AND SIGNATURE AND COMPANY STAMP LEFT BLANK.

© PT. CAST INSPECTION & ENGINEERING BATAM Page 7 of 8

CONFIDENTIAL DOCUMENT, ALL RIGHT RESERVED

TITLE DOC. NO. REV EFFECTIVE DATE

PROSEDUR PENGENDALIAN OPERASIONAL

CAST-II-HSE-09 00 01 October 2016

OPERATIONAL CONTROL PROCEDURES

MATERIAL SAFETY DATA SHEET

THIS PROCEDURE IS INVALID WITHOUT COVER PAGE AND SIGNATURE AND COMPANY STAMP LEFT BLANK.

© PT. CAST INSPECTION & ENGINEERING BATAM Page 8 of 8

CONFIDENTIAL DOCUMENT, ALL RIGHT RESERVED

Вам также может понравиться

- BU3-ENV-SOP-010 (01) Waste ManagementДокумент25 страницBU3-ENV-SOP-010 (01) Waste ManagementJoel Osteen RondonuwuОценок пока нет

- Tool Box MeetingДокумент3 страницыTool Box MeetingS SusilatamaОценок пока нет

- HSE Department Training ReportДокумент2 страницыHSE Department Training Reportrama panji saputraОценок пока нет

- Curriculum Vitae - HSE Lead - Rista SitungkirДокумент5 страницCurriculum Vitae - HSE Lead - Rista SitungkirSyahri MaryadiОценок пока нет

- Layout Pintu Air 2Документ5 страницLayout Pintu Air 2Fahmi NoviandriОценок пока нет

- Erp 5C 82Документ26 страницErp 5C 82Yogaraja MathialaganОценок пока нет

- Hse Program Matrix 2017: For Field Personnel For JKT Management & StaffsДокумент1 страницаHse Program Matrix 2017: For Field Personnel For JKT Management & Staffsmalimsaidi_160040895Оценок пока нет

- Mom 26 12 2017Документ13 страницMom 26 12 2017apri4dyОценок пока нет

- Electrical Distribution Board InspectionДокумент1 страницаElectrical Distribution Board InspectionAdhy DarmawanОценок пока нет

- Temuan Inspeksi Mess - 250818Документ6 страницTemuan Inspeksi Mess - 250818Cecep GunawanОценок пока нет

- Environment MP SoilДокумент17 страницEnvironment MP SoilRusihan HSE100% (1)

- Lintech Daily Activity Report - 2021!06!01Документ6 страницLintech Daily Activity Report - 2021!06!01mahindra hardinataОценок пока нет

- Jam Kerja AlatДокумент8 страницJam Kerja AlatMeldha KuОценок пока нет

- M-MK3L-02 HSE PLAN-dikonversiДокумент52 страницыM-MK3L-02 HSE PLAN-dikonversiVENTY100% (1)

- S-1598 SDS (Flocculant)Документ5 страницS-1598 SDS (Flocculant)Rininta Triananda NoorОценок пока нет

- 122 Triethylene GlycolДокумент6 страниц122 Triethylene Glycoleng20072007Оценок пока нет

- HSE Daily Report SummaryДокумент12 страницHSE Daily Report SummaryZenonia ThreeОценок пока нет

- No. Program Kerja Schedule: Kepemimpinan Dan KomitmentДокумент5 страницNo. Program Kerja Schedule: Kepemimpinan Dan KomitmentMade GileeОценок пока нет

- Form Inspeksi PH AirДокумент4 страницыForm Inspeksi PH AirMoresbehmanОценок пока нет

- QHSE Dashboard: Start Date Project Code Name of Reporting HSE PersonДокумент2 страницыQHSE Dashboard: Start Date Project Code Name of Reporting HSE PersonBrian Rolando Cerros FonsecaОценок пока нет

- Hse Monthly Report Ke-2Документ8 страницHse Monthly Report Ke-2perdinalОценок пока нет

- Full MKAPR Evidence Audit SMK3-04 MedcoДокумент114 страницFull MKAPR Evidence Audit SMK3-04 MedcoSALIM ALI AFIFFОценок пока нет

- PRE-INSPECTION REPORT FOR VACUUM TRUCK AND WATER TRUCKДокумент4 страницыPRE-INSPECTION REPORT FOR VACUUM TRUCK AND WATER TRUCKtirtamas berkah makmur100% (1)

- Matrix K3LL DHJ Tambun 2014Документ3 страницыMatrix K3LL DHJ Tambun 2014Anonymous miBouC6jXОценок пока нет

- Drill Pad Handover Checklist From Operation To Drill SupervisorДокумент1 страницаDrill Pad Handover Checklist From Operation To Drill SupervisorAji SatrioОценок пока нет

- Permit To Work: Surat Izin KerjaДокумент3 страницыPermit To Work: Surat Izin Kerjaluki0% (1)

- Prose Dur QH Sse 2016Документ198 страницProse Dur QH Sse 2016danaokhtavianusОценок пока нет

- Form Harga Bahan KimiaДокумент1 страницаForm Harga Bahan Kimiahasrat budimanОценок пока нет

- Grafik Kecelakaan 2016 PDFДокумент2 страницыGrafik Kecelakaan 2016 PDFragilОценок пока нет

- 28 (MPH) Planned Task ObservationsДокумент3 страницы28 (MPH) Planned Task ObservationsLwandziso DlaminiОценок пока нет

- HSE Plan - PT Anugrah Pacific KencanaДокумент15 страницHSE Plan - PT Anugrah Pacific Kencananew auctionОценок пока нет

- Sswj-2 Station Facility: Rekayasa IndustriДокумент4 страницыSswj-2 Station Facility: Rekayasa IndustriArieОценок пока нет

- 2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1Документ1 страница2021.12.12 - Pinched Finger (MTC) - Rantau - Zona 1BennyОценок пока нет

- Hira Hazid Hazop LPG Sagama PlantДокумент32 страницыHira Hazid Hazop LPG Sagama PlantFreddy ManullangОценок пока нет

- Reducing Bending Line Consumable CostsДокумент11 страницReducing Bending Line Consumable Costslombak3 2017100% (1)

- Daftar Inventaris APARДокумент8 страницDaftar Inventaris APARNie SuryОценок пока нет

- Laporan Bulanan K3: Project Warehouse Unit 9Документ5 страницLaporan Bulanan K3: Project Warehouse Unit 9Haris Setyo UtomoОценок пока нет

- SOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)Документ1 страницаSOP-LEE-01 Pengendalian Dokumen & Informasi (Rev 00)FendiОценок пока нет

- PT. TOTAL SAFETY ENERGY TRAINING SCHEDULEДокумент13 страницPT. TOTAL SAFETY ENERGY TRAINING SCHEDULEyono DaryonoОценок пока нет

- Departmetit: Malrtehance Cost t5% Expenditurc BudsetДокумент1 страницаDepartmetit: Malrtehance Cost t5% Expenditurc Budsetrobby damanikОценок пока нет

- Maping Kotak P3K P2Документ4 страницыMaping Kotak P3K P2riyadigeng19gmailcomОценок пока нет

- HIRADC Geodipa EnglishhДокумент19 страницHIRADC Geodipa EnglishhdvggfdhdbdfvbОценок пока нет

- Weekly Hse Report New Retaining Wall Cil 1: Project No. Document No. RevДокумент6 страницWeekly Hse Report New Retaining Wall Cil 1: Project No. Document No. RevcaturzzzzzОценок пока нет

- Present Manfaat CSR Bagi PerusahaanДокумент20 страницPresent Manfaat CSR Bagi PerusahaanMikhaila purnomoОценок пока нет

- Behavior Based Safety Observer Training - Day #1: Drilling Steering Committee DuriДокумент49 страницBehavior Based Safety Observer Training - Day #1: Drilling Steering Committee DuriAjie Dwi YuniarsoОценок пока нет

- Jadwal Audit InternalДокумент1 страницаJadwal Audit InternalRollyОценок пока нет

- Matrix Training & Program HSE - OFPS Plaju 19.56Документ4 страницыMatrix Training & Program HSE - OFPS Plaju 19.56NurhalizaОценок пока нет

- 3 DUMP Truck Inspection FormДокумент2 страницы3 DUMP Truck Inspection FormIdam YoОценок пока нет

- Hse PlanДокумент69 страницHse PlanshafiqhaikalОценок пока нет

- Form Izin Kerja K3Документ1 страницаForm Izin Kerja K3Zelynka Nanda MaryesaОценок пока нет

- (Hse Plan) : Pt. Grogol Sarana TransjayaДокумент3 страницы(Hse Plan) : Pt. Grogol Sarana TransjayaHSE PT. GROGOL SARANA TRANSJAYAОценок пока нет

- Inspeksi & Summary PPEДокумент3 страницыInspeksi & Summary PPESuhendraОценок пока нет

- Form Laporan Bulanan Kontraktor 2022Документ2 страницыForm Laporan Bulanan Kontraktor 2022Admin VendorОценок пока нет

- Hse Minimum Requirements For SubcontractorsДокумент4 страницыHse Minimum Requirements For SubcontractorsMy pouОценок пока нет

- Training Program Peogram Pelatihan: NO. Training Training Type Location Month Realization Date (In-House / OJT)Документ4 страницыTraining Program Peogram Pelatihan: NO. Training Training Type Location Month Realization Date (In-House / OJT)MillaNChakrabortyОценок пока нет

- Prosedur Peraturan Perundangan Dan Persyaratan: Regulations Rules Procedure and RequirementsДокумент9 страницProsedur Peraturan Perundangan Dan Persyaratan: Regulations Rules Procedure and RequirementsISUKepri.Com100% (1)

- Quality Manual 02. Normative References: Title Document No. REV Effective DateДокумент3 страницыQuality Manual 02. Normative References: Title Document No. REV Effective DateISUKepri.ComОценок пока нет

- 608-P-002 Rev. 0 Existing Rotating EquipmentДокумент21 страница608-P-002 Rev. 0 Existing Rotating Equipmentzachari.alamsyahОценок пока нет

- Prosedur Penetran TestingДокумент11 страницProsedur Penetran TestingIkhsan DalimuntheОценок пока нет

- Liquid Penetrant Exam Procedure for Steel WeldsДокумент11 страницLiquid Penetrant Exam Procedure for Steel WeldsAchmad SupriyadiОценок пока нет

- Quality Manual 06. Planning: Title Document No. REV Effective DateДокумент4 страницыQuality Manual 06. Planning: Title Document No. REV Effective DateISUKepri.ComОценок пока нет

- Quality Manual 07. Support: Title Document No. REV Effective DateДокумент7 страницQuality Manual 07. Support: Title Document No. REV Effective DateISUKepri.ComОценок пока нет

- Quality Manual 08. Operation: Title Document No. REV Effective DateДокумент11 страницQuality Manual 08. Operation: Title Document No. REV Effective DateISUKepri.ComОценок пока нет

- Quality Manual 02. Normative References: Title Document No. REV Effective DateДокумент3 страницыQuality Manual 02. Normative References: Title Document No. REV Effective DateISUKepri.ComОценок пока нет

- 0027b4ba4dc2615dd45ed1a5a68c0da4Документ3 страницы0027b4ba4dc2615dd45ed1a5a68c0da4ISUKepri.ComОценок пока нет

- Quality Manual 04. Context of Pt. Cast Inspection and Engineering BatamДокумент5 страницQuality Manual 04. Context of Pt. Cast Inspection and Engineering BatamISUKepri.ComОценок пока нет

- d341f66ae862684eac4f26c599c1f101Документ6 страницd341f66ae862684eac4f26c599c1f101ISUKepri.ComОценок пока нет

- Quality Manual 03. Term & Definitions: Title Document No. REV Effective DateДокумент4 страницыQuality Manual 03. Term & Definitions: Title Document No. REV Effective DateISUKepri.ComОценок пока нет

- 2b2c7c3ac23d96ad77c9e0ec418ec4e4Документ8 страниц2b2c7c3ac23d96ad77c9e0ec418ec4e4ISUKepri.ComОценок пока нет

- 5106e0884f174219e9835af4da2d19caДокумент7 страниц5106e0884f174219e9835af4da2d19caISUKepri.ComОценок пока нет

- e0c41c33503f7a1bc45eee47c8d40385Документ7 страницe0c41c33503f7a1bc45eee47c8d40385ISUKepri.ComОценок пока нет

- 8bba1ff2ab3245c7cb26f8cc27d43e7aДокумент6 страниц8bba1ff2ab3245c7cb26f8cc27d43e7aISUKepri.ComОценок пока нет

- 1825c732acdef1f3f5c98907e0316ae4Документ8 страниц1825c732acdef1f3f5c98907e0316ae4ISUKepri.ComОценок пока нет

- 9c5ae8b8c2d95c9a2b8a18df85db7223Документ13 страниц9c5ae8b8c2d95c9a2b8a18df85db7223ISUKepri.ComОценок пока нет

- 824e0fb9f9eaca718c5b3c25fd2ba96aДокумент6 страниц824e0fb9f9eaca718c5b3c25fd2ba96aISUKepri.ComОценок пока нет

- 46cb9ef340762ff78e7890727744a50aДокумент7 страниц46cb9ef340762ff78e7890727744a50aISUKepri.ComОценок пока нет

- CAST/II/SM/21 Rev.0Документ8 страницCAST/II/SM/21 Rev.0ISUKepri.ComОценок пока нет

- CAST/II/SM/19 Rev.4Документ13 страницCAST/II/SM/19 Rev.4ISUKepri.ComОценок пока нет

- 2f00d7694757c2f230f52e2e71ca7d52Документ11 страниц2f00d7694757c2f230f52e2e71ca7d52ISUKepri.ComОценок пока нет

- 42335280465e35ec73784f52b80cfa3aДокумент6 страниц42335280465e35ec73784f52b80cfa3aISUKepri.ComОценок пока нет

- CAST-POL-DIR-06 Rev.0Документ1 страницаCAST-POL-DIR-06 Rev.0ISUKepri.ComОценок пока нет

- 22b5d5b25f1ad5e24b19eca9ca10ad20Документ13 страниц22b5d5b25f1ad5e24b19eca9ca10ad20ISUKepri.ComОценок пока нет

- Prosedur Peraturan Perundangan Dan Persyaratan: Regulations Rules Procedure and RequirementsДокумент9 страницProsedur Peraturan Perundangan Dan Persyaratan: Regulations Rules Procedure and RequirementsISUKepri.Com100% (1)

- 7ec6ce2e17102752aef08524116387c6Документ9 страниц7ec6ce2e17102752aef08524116387c6ISUKepri.ComОценок пока нет

- 53435c8d7b75b212c47e866e4119091fДокумент14 страниц53435c8d7b75b212c47e866e4119091fISUKepri.ComОценок пока нет

- CAST-II-HSE-01 Rev.0Документ15 страницCAST-II-HSE-01 Rev.0ISUKepri.ComОценок пока нет

- CAST-POL-DIR-05 Rev.0Документ1 страницаCAST-POL-DIR-05 Rev.0ISUKepri.ComОценок пока нет

- CAST/II/SM/08 Rev.13Документ32 страницыCAST/II/SM/08 Rev.13ISUKepri.ComОценок пока нет

- CAST/II/SM/20 Rev.0Документ8 страницCAST/II/SM/20 Rev.0ISUKepri.ComОценок пока нет

- G.O.MS - No. 578 Dt. 31-12-1999Документ2 страницыG.O.MS - No. 578 Dt. 31-12-1999gangaraju88% (17)

- Nabina Saha ThesisДокумент283 страницыNabina Saha Thesissurendra reddyОценок пока нет

- Chapter 3 Guide of PAM Code of ConductДокумент6 страницChapter 3 Guide of PAM Code of ConductQi YeongОценок пока нет

- R PosДокумент4 страницыR PosBirendra EkkaОценок пока нет

- Skippers United Pacific, Inc. v. DozaДокумент2 страницыSkippers United Pacific, Inc. v. DozaAntonio BartolomeОценок пока нет

- Court Affirms Murder Conviction in Pablo Estomo Killing CaseДокумент15 страницCourt Affirms Murder Conviction in Pablo Estomo Killing CaseInah Manalang- VillaОценок пока нет

- Guide Internal Control Over Financial Reporting 2019-05Документ24 страницыGuide Internal Control Over Financial Reporting 2019-05hanafi prasentiantoОценок пока нет

- NOMAC Health and Safety AcknowledgementДокумент3 страницыNOMAC Health and Safety AcknowledgementReynanОценок пока нет

- Thread - o - Ring - Fittings (TD Williamson) PDFДокумент4 страницыThread - o - Ring - Fittings (TD Williamson) PDFRahul RaghukumarОценок пока нет

- Spanish Colonial System in the PhilippinesДокумент3 страницыSpanish Colonial System in the PhilippinesCathy RafolsОценок пока нет

- The Moral Logic of Survivor's GuiltДокумент5 страницThe Moral Logic of Survivor's GuiltKeyton OwensОценок пока нет

- The Elite and EugenicsДокумент16 страницThe Elite and EugenicsTheDetailerОценок пока нет

- BPT Bulletproof Standards SmallДокумент1 страницаBPT Bulletproof Standards Smallalex oropezaОценок пока нет

- Tuanda vs. SandiganbayanДокумент2 страницыTuanda vs. SandiganbayanJelena SebastianОценок пока нет

- Clean Water Act and RA 9275 rolesДокумент3 страницыClean Water Act and RA 9275 rolesKristela Alexis OsorioОценок пока нет

- Ksa New Reg FormДокумент2 страницыKsa New Reg Formbeautifulvideo722Оценок пока нет

- SSS v. Favila, GR No. 170195, March 28, 2011Документ1 страницаSSS v. Favila, GR No. 170195, March 28, 2011MonicaCelineCaroОценок пока нет

- Constitutional Law (Relationship Between Council of Minister and President)Документ16 страницConstitutional Law (Relationship Between Council of Minister and President)Sharjeel AhmadОценок пока нет

- Kashmir Highway sports club membership formДокумент2 страницыKashmir Highway sports club membership formSarah HafeezОценок пока нет

- Beamer Template 2Документ12 страницBeamer Template 2Jmab Ayala Bellido100% (1)

- Cambridge IGCSE: 0450/22 Business StudiesДокумент12 страницCambridge IGCSE: 0450/22 Business StudiesTshegofatso SaliОценок пока нет

- Oxford Research Encyclopedia of Latin American History: CloseДокумент21 страницаOxford Research Encyclopedia of Latin American History: CloseemiroheОценок пока нет

- Lea2 Comparative Models in Policing Syllabus Ok Converted 1Документ6 страницLea2 Comparative Models in Policing Syllabus Ok Converted 1Red Buttrerfly RC100% (2)

- Explore the philosophical and political views on philanthropyДокумент15 страницExplore the philosophical and political views on philanthropykristokunsОценок пока нет

- Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceДокумент9 страницDate Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceN.prem kumarОценок пока нет

- Lc-2-5-Term ResultДокумент44 страницыLc-2-5-Term Resultnaveen balwanОценок пока нет

- To Sell or Scale Up: Canada's Patent Strategy in A Knowledge EconomyДокумент22 страницыTo Sell or Scale Up: Canada's Patent Strategy in A Knowledge EconomyInstitute for Research on Public Policy (IRPP)Оценок пока нет

- TL01 Behold Terra LibraДокумент15 страницTL01 Behold Terra LibraKeyProphet100% (1)

- WR CSM 20 NameList 24032021 EngliДокумент68 страницWR CSM 20 NameList 24032021 EnglivijaygnluОценок пока нет

- Got - Hindi S04 480pДокумент49 страницGot - Hindi S04 480pT ShrinathОценок пока нет