Академический Документы

Профессиональный Документы

Культура Документы

IATF 16949 Documentation Toolkit Guide

Загружено:

Oscar Solis Martir0 оценок0% нашли этот документ полезным (0 голосов)

2K просмотров4 страницыList of Documents IATF 16949 2016 Documentation Toolkit English

Оригинальное название

List of Documents IATF 16949 2016 Documentation Toolkit En

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документList of Documents IATF 16949 2016 Documentation Toolkit English

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

2K просмотров4 страницыIATF 16949 Documentation Toolkit Guide

Загружено:

Oscar Solis MartirList of Documents IATF 16949 2016 Documentation Toolkit English

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

IATF 16949:2016 Documentation Toolkit

https://advisera.com/16949academy/iatf-16949-2016-documentation-toolkit/

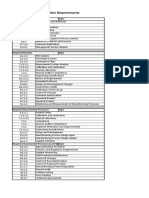

Note: The documentation should preferably be implemented in the order in which it is listed here.

Doc. IATF 16949 Mandatory

No. Name of Document

Code requirement document

1 00 Procedure for Document and Record Control 7.5

2 00.1 Appendix 1 – List of Internal Documents 7.5

3 00.2 Appendix 2 – List of External Documents 7.5

4 00.3 Appendix 3 – List of Types of Records 7.5

Appendix 4 – Registry of Records for Detention/ Central

5 00.4 7.5

Archive

6 01 Project Plan

7 02 Quality Policy 5.2

8 02.1 Appendix 1 – Quality Objectives 6.2

9 02.2 Appendix 2 – Corporate Responsibility Policy 5.1.1.1

10 03 Quality Manual 7.5.1.1

Procedure for Determining Context of the

11 04 4.1; 4.2

Organization and Interested Parties

Appendix 1 – List of Interested Parties and Customer

12 04.1 4.2; 4.3.2

Specific Requirements

13 04.2 Appendix 2 – Conformance Evaluation Record 4.2

14 04.3 Appendix 3 – Scope of the Quality Management System 4.3

7.1.2; 7.1.3;

15 05 Procedure for Competence, Training and Awareness

7.2; 7.3

16 05.1 Appendix 1 – Training Program 7.2; 7.2.2

17 05.2 Appendix 2 – Training Record 7.2, 7.3.1

18 05.3 Appendix 3 – Record of Attendance 7.3

19 05.4 Appendix 4 – Operators Job Rotation Matrix 7.2.2

20 05.5 Appendix 5 – Awareness Training Report 7.3, 7.3.1

21 06 Procedure for Addressing Risks and Opportunities 6.1

22 06.1 Appendix 1 – Registry of Key Risks and Opportunities 6.1

23 06.2 Appendix 2 – Contingency Plan 6.1.2.3

24 06.3 Appendix 3 – Procedure for FMEA Risk Assessment 6.1.2.1

25 06.4 Appendix 4 – Design & Process FMEA Form 6.1.2.1

26 06.5 Appendix 5 – Preventive Action Record 6.1.2.2

27 07 Product Safety Procedure 4.4.1.2

28 07.1 Appendix 1 – Product Safety Testing Record 4.4.1.2

29 08 Sales Procedure 8.2

ver 2.5, 2017-10-31 Page 1 of 4

30 08.1 Appendix 1 – Customer Requirement Review Checklist 8.2.2; 8.2.3

31 08.2 Appendix 2 – Registry of Customer Complaints 8.2

8.2.3.1,

32 08.3 Appendix 3 – Feasibility Study Report

8.2.3.1.1

4.4.1.2; 8.3;

33 09 Procedure for Design and Development

8.3.2;

34 09.1 Appendix 1 – Project Task 8.3.2; 8.3.3

35 09.2 Appendix 2 – Project Plan and Review 8.3.2; 8.3.4;

36 09.3 Appendix 3 – Change Review Record 8.3.6

37 09.4 Appendix 4 – Design Review Minutes 8.3.5

7.1.3.1,

38 09.5 Appendix 5 – Plant and Lines Layout

8.3.5.2

39 09.6 Appendix 6 – Validation Plan 7.1.3.1

40 09.7 Appendix 7 – Control Plan 8.5.1.1

41 09.8 Appendix 8 – List of Alternate Controls 8.5.6.1.1

42 10 Production Part Approval Process Procedure 8.3.4.4

43 10.1 Appendix 1 – PPAP Record 8.3.4.4, 8.3.6

44 10.2 Appendix 2 – Work Instruction Template 8.5.1.2

8.7.1.4,

45 10.3 Appendix 3 – Rework Instruction Template *

8.7.1.5

46 10.4 Appendix 4 – List of Appearance Items 8.6.3

47 11 Procedure for Purchasing and Evaluation of Suppliers 4.4.1.2; 8.4

8.4.1;

48 11.1 Appendix 1 – Checklist for Evaluation of Suppliers 8.4.1.1,

8.4.1.2

49 11.2 Appendix 2 – List of Approved Suppliers 8.4.1

50 11.3 Appendix 3 – Registry of Complaints about Suppliers 8.4

51 11.4 Appendix 4 – Request and Order for Purchasing 8.4.1

52 11.5 Appendix 5 – Incoming Inspection Control Plan and Log 8.4.2 **

53 12 Procedure for Production and Service Provision 8.5

54 12.1 Appendix 1 – Production Scheduling and Follow Form 8.5.1.7

8.5.6; 8.5.2;

55 12.2 Appendix 2 – Production Change Review Record Form

8.6

56 12.3 Appendix 3 – First and Last Part Approval Form 8.5.1.3

8.7.1.1,

57 12.4 Appendix 4 – Internal Failures Report Form

8.7.1.2

58 12.5 Appendix 5 – Deviation Request and Approval Form 8.7.1.1

59 12.6 Appendix 6 – Production Restart Checklist 8.5.1.4

60 12.7 Appendix 7 – Inventory Form 8.5.4, 8.5.4.1

ver 2.5, 2017-10-31 Page 2 of 4

Appendix 8 – Notification to a Customer about Changes

61 12.8 8.5.3

on their Property

62 12.9 Appendix 9 – Quality Plan 8.5

63 13 Workplace Organization (5S) Procedure 7.1.4, 7.1.4.1

64 13.1 Appendix 1 – Workplace Organization (5S) Audit Form 7.1.4, 7.1.4.1

65 14 Warehousing Procedure 8.5.4; 8.5.4.1

Appendix 1 – Record of Warehousing Parameters

66 14.1 8.5.4

Control

Procedure for Management of Nonconformities and

67 15 8.7; 10.2

Corrective Actions

68 15.1 Appendix 1 – Nonconformity Record 8.7; 10.2.2

Appendix 2 – Registry and Status of Nonconformities

69 15.2 10.2.2

and Corrective Actions

70 15.3 Appendix 3 – Problem Solving 8D Template 10.2.3

71 15.4 Appendix 4 – Lesson Learned Template 7.1.6

72 15.5 Appendix 5 – Report of Warranty Failures 10.2.5

73 15.6 Appendix 6 – Warranty Incidents Analysis Report 10.2.5

74 15.7 Appendix 7 – Product User Instruction Template 10.2.5

7.1.5.2;

Procedure for Equipment Maintenance and Measuring

75 16 8.5.1.5;

Equipment

8.5.1.6

76 16.1 Appendix 1 – List of Equipment 7.1.5.2.1

Appendix 2 – Plan for Preventive Maintenance of

77 16.2 7.1.5

Equipment

8.5.1.5,

78 16.3 Appendix 3 – MTBF and MTTR Downtime Dashboard

8.5.1.6

79 16.4 Appendix 4 – Maintenance and Calibration Record 7.1.5.2

8.5.1.5,

80 16.5 Appendix 5 – Maintenance Work Instruction Template

8.5.1.68

81 17 Procedure for Control of Gauges 7.1.5.1.1

82 17.1 Appendix 1 – Measurement System Analysis Plan 7.1.5.1.1

83 17.2 Appendix 2 – Measurement System Analysis Form 7.1.5.1.1

8.5.1.5,

84 17.3 Appendix 3 – Red Rabbits List

8.5.1.6

85 18 Laboratory Management Procedure 7.1.5.3

86 18.1 Appendix 1 – Internal Laboratory Scope 7.1.5.3.1

87 18.2 Appendix 2 – External Laboratory Acceptance Checklist 7.1.5.3.2

88 18.3 Appendix 3 – Test Schedule Form 7.1.5.3

89 19 Procedure for Measuring Customer Satisfaction 9.1.2

90 19.1 Appendix 1 – Customer Satisfaction Questionnaire 9.1.2

91 19.2 Appendix 2 – Report of Customer Satisfaction 9.1.2

ver 2.5, 2017-10-31 Page 3 of 4

92 19.3 Appendix 3 – Monitoring of Customer Satisfaction 9.1.2

93 19.4 Appendix 4 – Customer Satisfaction Dashboard 9.12

94 20 Procedure for Internal Audit 9.2

95 20.1 Appendix 1 – Internal Audit Program 9.2.2.2

96 20.2 Appendix 2 – Internal QMS Audit Checklist 9.2.2.1

97 20.3 Appendix 3 – Manufacturing Process Audit Checklist 9.2.2.3

98 20.4 Appendix 4 – Product Audit Checklist 9.2.2.4

99 20.5 Appendix 5 – Second Party Audit Checklist 8.4.2.4.1

100 20.6 Appendix 6 – Internal Audit Report for QMS Audits 9.2.2

101 20.7 Appendix 7 – List of Qualified Internal Auditors 7.2.3

102 21 Procedure for Continual Improvement 10.1

103 21.1 Appendix 1 – Statistical Process Control Form 9.1.1.2

104 21.2 Appendix 2 – Capability Form 9.1.1.2

105 22 Procedure for Management Review 9.3

106 22.1 Appendix 1 – Matrix of Key Performance Indicators 9.1.3

107 22.2 Appendix 2 – Data Analysis Report 9.1.3

108 22.3 Appendix 3 – Management Review Minutes 9.3.3

* The document is not mandatory if the organization does not perform rework and repair activities.

** The document is not mandatory if incoming inspection is not performed, and alternative methods

are applied (e.g. PPAP before serial phase, then JIT deliveries).

ver 2.5, 2017-10-31 Page 4 of 4

Вам также может понравиться

- IATF 16949 - Internal Audit ChecksheetДокумент11 страницIATF 16949 - Internal Audit ChecksheetHem Upadhyay91% (11)

- Checklist of Documentation As Per IATF 16949:2016Документ10 страницChecklist of Documentation As Per IATF 16949:2016Arun Kumar Sharma100% (2)

- Control Plan AIAGДокумент1 страницаControl Plan AIAGAhmad Firdaus100% (1)

- Automating The Procure To Pay ProcessДокумент47 страницAutomating The Procure To Pay Processfloatingbrain88% (8)

- IATF Auditor Guide PDFДокумент32 страницыIATF Auditor Guide PDFJosé Carlos GarBad100% (4)

- IATF 16949 - Training MaterialДокумент199 страницIATF 16949 - Training MaterialKamal Mulchandani89% (9)

- Iatf 16949 TrainingДокумент136 страницIatf 16949 Trainingpreetam kumar100% (1)

- Iatf 16949Документ27 страницIatf 16949Shahrukh Patel100% (2)

- ISO 9001-2015/IATF 16949:2016 Internal & 2nd party auditor trainingДокумент7 страницISO 9001-2015/IATF 16949:2016 Internal & 2nd party auditor trainingSudhagarОценок пока нет

- Asset Management Policy Manual: 1.0 ObjectiveДокумент13 страницAsset Management Policy Manual: 1.0 ObjectiveArup DattaОценок пока нет

- VDA 6.3 Process Audit OverviewДокумент18 страницVDA 6.3 Process Audit OverviewdavidОценок пока нет

- IATF 16949-2016 Intro and Clauses PDFДокумент274 страницыIATF 16949-2016 Intro and Clauses PDFneetuyadav2250% (2)

- Turtle Diagrams - IATF - 16949 - 2016Документ8 страницTurtle Diagrams - IATF - 16949 - 2016Sathyaprakash Hs100% (1)

- Checklist of Documentation For IATF 16949 - 2016Документ11 страницChecklist of Documentation For IATF 16949 - 2016Deepak kumarОценок пока нет

- APQP Supplier ProcedureДокумент20 страницAPQP Supplier ProcedurepharmatonОценок пока нет

- T2 VSA With RequirementДокумент8 страницT2 VSA With RequirementSandeep K Malhotra100% (3)

- Free Ts 16949 Audit ChecklistДокумент8 страницFree Ts 16949 Audit ChecklistKumaravel100% (1)

- Plant and Process Engineering WorkflowДокумент43 страницыPlant and Process Engineering WorkflowSuhas Jadhal100% (12)

- Sample ManualДокумент17 страницSample ManualBALAJI83% (6)

- Internal Audit ChecklistДокумент37 страницInternal Audit ChecklistSumeet Rathee100% (5)

- Mandatory Documents IATF 16949Документ10 страницMandatory Documents IATF 16949Jm Venki100% (10)

- Iso Iatf Quality System Manual PDFДокумент53 страницыIso Iatf Quality System Manual PDFKrishnamoorthyОценок пока нет

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionОт EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- IATF Auditor Guide for IATF 16949 4th EditionДокумент45 страницIATF Auditor Guide for IATF 16949 4th Editionelevendot100% (2)

- VDA 6.3 2016 Training Kit V0Документ99 страницVDA 6.3 2016 Training Kit V0Sudhagar94% (17)

- IATF Requirements TrainingДокумент193 страницыIATF Requirements TrainingDhinakaran80% (5)

- Quality Manual TemplateДокумент67 страницQuality Manual TemplateMohini Marathe100% (4)

- Customer Specific Requirements MatrixДокумент4 страницыCustomer Specific Requirements Matrixhmp9060% (5)

- Iatf 16949 Clause To Eqms ModuleДокумент8 страницIatf 16949 Clause To Eqms Modulepodrao100% (3)

- Manual ProceduresДокумент140 страницManual ProceduresWes Westberg60% (5)

- Iatf 3year Internal Audit PlanДокумент6 страницIatf 3year Internal Audit Planrajesh sharmaОценок пока нет

- IATF 16949 Documentation Toolkit GuideДокумент4 страницыIATF 16949 Documentation Toolkit GuideRahul SharmaОценок пока нет

- IATF 16949 - 2016: Presented by - Kuldeep TanwarДокумент193 страницыIATF 16949 - 2016: Presented by - Kuldeep Tanwarsololips100% (2)

- IATF - 16949 - 2016 Awareness TrainingДокумент58 страницIATF - 16949 - 2016 Awareness Trainingharish pu0% (3)

- Checklist of ISO14001 Mandatory Documentation enДокумент8 страницChecklist of ISO14001 Mandatory Documentation enAlok KumarОценок пока нет

- IATF 16949 Mandatory Documents ListДокумент2 страницыIATF 16949 Mandatory Documents ListLuis Alejandro60% (5)

- IATF 16949 ClientsДокумент126 страницIATF 16949 ClientsKumaravel100% (1)

- MCQ For Online Exam. - 205-OSCM PDFДокумент20 страницMCQ For Online Exam. - 205-OSCM PDFSaddam Shaikh100% (1)

- IATF Awareness TrainingДокумент81 страницаIATF Awareness TrainingMR KonarengineeringОценок пока нет

- Oracle eAM Asset Acquisition ProcessДокумент53 страницыOracle eAM Asset Acquisition ProcessxeexeОценок пока нет

- MH02 - MM Procure To Pay - Business BlueprintДокумент32 страницыMH02 - MM Procure To Pay - Business BlueprintwiesenerОценок пока нет

- 01.IATF 16949 AwarnessДокумент48 страниц01.IATF 16949 AwarnessMahi Reddy88% (8)

- IATF 16949 - 2016-Exam Paper With AnswersДокумент11 страницIATF 16949 - 2016-Exam Paper With Answersrashwin singhОценок пока нет

- IATF 16949 mandatory documentsДокумент3 страницыIATF 16949 mandatory documentsOscar Solis MartirОценок пока нет

- IATF 16949 mandatory documentsДокумент3 страницыIATF 16949 mandatory documentsOscar Solis MartirОценок пока нет

- IATF 16949-2016 Audit ChecklistДокумент129 страницIATF 16949-2016 Audit ChecklistRajeshLSОценок пока нет

- Manufacturing Process Audit ScorecardДокумент1 страницаManufacturing Process Audit ScorecardSachin Kumbhar100% (1)

- 01 Iatf16949-2016 Awp PDFДокумент64 страницы01 Iatf16949-2016 Awp PDFKamakhya Gupta100% (1)

- A3 Management: Lean Enterprise Program UCSD ExtensionДокумент71 страницаA3 Management: Lean Enterprise Program UCSD Extensionstolen mechieducОценок пока нет

- IATF 16949 DocumenДокумент1 страницаIATF 16949 Documenpunitg_2Оценок пока нет

- IATF 16949 2016 Gap ToolДокумент353 страницыIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- COVER SHEET SUBMISSIONДокумент6 страницCOVER SHEET SUBMISSIONSeval GünaltayОценок пока нет

- Supply Chain Financial MetricsДокумент67 страницSupply Chain Financial MetricsQasimButtar0% (1)

- Iatf 16949 PPT Training AwarenessДокумент46 страницIatf 16949 PPT Training Awarenesssharif197488% (16)

- FABM1 Q4 Module 8 Terminologies Used in Merchandising BusinessДокумент20 страницFABM1 Q4 Module 8 Terminologies Used in Merchandising BusinessrioОценок пока нет

- Automotive Quality Management System Manual: Century Metal Recycling LimitedДокумент7 страницAutomotive Quality Management System Manual: Century Metal Recycling LimitedsunilОценок пока нет

- IATF 16949:2016 Training on Quality Management Systems and Audit ConceptsДокумент62 страницыIATF 16949:2016 Training on Quality Management Systems and Audit ConceptsMadhukar Sinha100% (6)

- Go digital with safety checklistsДокумент84 страницыGo digital with safety checklists88No1FanОценок пока нет

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Документ5 страницClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhaneОценок пока нет

- CS Customer - Plant Turtle Diagram 07Документ1 страницаCS Customer - Plant Turtle Diagram 07Alex100% (1)

- IATF 16949-2016 Soft PDFДокумент58 страницIATF 16949-2016 Soft PDFDhinakaran92% (159)

- Clause Matrix Iatf 16949Документ10 страницClause Matrix Iatf 16949ikesh mОценок пока нет

- A Next Generation Operating Model For Source To PayДокумент8 страницA Next Generation Operating Model For Source To PayJosé António Cardoso RodriguesОценок пока нет

- Clausul IATFДокумент8 страницClausul IATFAhmad ZainuddinОценок пока нет

- Blank Turtle DiagramДокумент1 страницаBlank Turtle Diagrammrtelephone1100% (2)

- Best Practices MaintenanceДокумент52 страницыBest Practices MaintenanceOscar Solis Martir100% (3)

- IATF 16949:2016 IntroductionДокумент20 страницIATF 16949:2016 IntroductionDisha Shah100% (4)

- Personal Selling Project ReportДокумент115 страницPersonal Selling Project ReportVAIJAYANTI JENAОценок пока нет

- IATF 16949 2016 Mandatory ProcedureДокумент1 страницаIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- ISO 9001:2015 IATF 16949:2016 Correlation Matrix (Gap Analysis) USL International Quality Solutions Consultancy Services For ISO, IRIS, AS, IATFДокумент4 страницыISO 9001:2015 IATF 16949:2016 Correlation Matrix (Gap Analysis) USL International Quality Solutions Consultancy Services For ISO, IRIS, AS, IATFKarthikeyan Janarthanan83% (6)

- IATF 16949 Frequently Asked Questions October 2017Документ12 страницIATF 16949 Frequently Asked Questions October 2017Armando FloresОценок пока нет

- Fmea Vda AiagДокумент63 страницыFmea Vda AiagfquysxlahyytpxpwgqОценок пока нет

- PDOC 596 PEP 01 Project Execution Plan Rev 3Документ90 страницPDOC 596 PEP 01 Project Execution Plan Rev 3Showki Wani80% (5)

- Global BikeДокумент24 страницыGlobal BikeJuan0% (1)

- Curso SPCДокумент59 страницCurso SPCOscar Solis MartirОценок пока нет

- HOQ ExamplesДокумент9 страницHOQ ExamplesHorasAkdОценок пока нет

- How To Export Outlook Exchange Calendar To Google CalendarДокумент1 страницаHow To Export Outlook Exchange Calendar To Google CalendarOscar Solis MartirОценок пока нет

- Mandatory Documents and Records Required by ISO 14001:2015: (Clause 6.1.2)Документ2 страницыMandatory Documents and Records Required by ISO 14001:2015: (Clause 6.1.2)BhargavОценок пока нет

- Checklist of OHSAS 18001 Mandatory Documentation enДокумент8 страницChecklist of OHSAS 18001 Mandatory Documentation enMiguelGarcés100% (1)

- Year PlannerДокумент1 страницаYear PlannerOscar Solis MartirОценок пока нет

- Mandatory Documents and Records Required by ISO 14001:2015: (Clause 6.1.2)Документ2 страницыMandatory Documents and Records Required by ISO 14001:2015: (Clause 6.1.2)BhargavОценок пока нет

- Balancing Work CellsДокумент5 страницBalancing Work CellsOscar Solis MartirОценок пока нет

- HP 48G Series User's GuideДокумент612 страницHP 48G Series User's GuideOscar Solis Martir100% (1)

- Pic Basic Compiler Reference ManualДокумент24 страницыPic Basic Compiler Reference ManualOscar Solis MartirОценок пока нет

- Measuring ErrorsДокумент20 страницMeasuring ErrorsOscar Solis MartirОценок пока нет

- HP 48G Series User's GuideДокумент612 страницHP 48G Series User's GuideOscar Solis MartirОценок пока нет

- HP11c Quick Reference GuideДокумент4 страницыHP11c Quick Reference GuideOscar Solis MartirОценок пока нет

- PIP FormДокумент3 страницыPIP FormOscar Solis MartirОценок пока нет

- Time Stydy SheetДокумент2 страницыTime Stydy SheetOscar Solis MartirОценок пока нет

- Ch08 Project SchedulingДокумент51 страницаCh08 Project SchedulingOscar Solis MartirОценок пока нет

- Supervisor AccountДокумент2 страницыSupervisor AccountOscar Solis MartirОценок пока нет

- CV RanjitДокумент3 страницыCV RanjitIto LawputraОценок пока нет

- EDU1B1DYДокумент19 страницEDU1B1DYRahul JainОценок пока нет

- Supply Chain ModuleДокумент13 страницSupply Chain ModuleFrancisco C. ArianОценок пока нет

- 4 Erp ModulesДокумент32 страницы4 Erp ModulesDasarath NaiduОценок пока нет

- Irrigation Tender Midlands Province 2023Документ44 страницыIrrigation Tender Midlands Province 2023tawandaОценок пока нет

- Ellen Lent-Wunderlich RN, MS, CPHQ: HighlightsДокумент5 страницEllen Lent-Wunderlich RN, MS, CPHQ: Highlightsapi-2349150Оценок пока нет

- Security Bidding Doc 2021Документ56 страницSecurity Bidding Doc 2021joseph iii goОценок пока нет

- Final SCMДокумент92 страницыFinal SCMNiro ThakurОценок пока нет

- Internal Controls Policy (Adopted 2-14-2019) PDFДокумент39 страницInternal Controls Policy (Adopted 2-14-2019) PDFMarina OleynichenkoОценок пока нет

- Sap Create Vendor MasterДокумент11 страницSap Create Vendor MasterRahul KajaveОценок пока нет

- Consumer BehaviorДокумент99 страницConsumer BehaviorNeamat HassanОценок пока нет

- LSCM Group Project - Group1 - Automobile Inustry - Tata MotorsДокумент36 страницLSCM Group Project - Group1 - Automobile Inustry - Tata Motorsdebashreeta swainОценок пока нет

- Inventory Management of Beximco Pharmaceuticals LimitedДокумент9 страницInventory Management of Beximco Pharmaceuticals LimitedMashrur Rahman0% (1)

- Logistic ManagerДокумент9 страницLogistic ManagerFrotanОценок пока нет

- Laboratory Information Management SystemДокумент14 страницLaboratory Information Management SystemAmethystОценок пока нет

- Understanding Inventory Valuation and ReportingДокумент57 страницUnderstanding Inventory Valuation and ReportingA. MagnoОценок пока нет

- Chapter 7 - Accounting For MaterialsДокумент24 страницыChapter 7 - Accounting For MaterialsTim ParasОценок пока нет

- Referent Axis 1Документ12 страницReferent Axis 1ANGIE MARCELA FANDINO CORTESОценок пока нет