Академический Документы

Профессиональный Документы

Культура Документы

Instrument Cold Loop Check: @T @S @D @SS @SSD @PD

Загружено:

nayumОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Instrument Cold Loop Check: @T @S @D @SS @SSD @PD

Загружено:

nayumАвторское право:

Доступные форматы

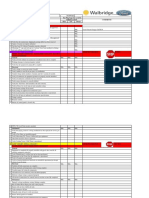

INSTRUMENT COLD LOOP CHECK

ITR No I15B

Item/Tag No. @T System No. @S

Item/Tag Description @D Sub System No. @SS

Sub System Description @SSD

Location @L Print Date @PD

INFORMATION

Controller Tag No. Signal Range

Initiator Tag No. Cal range

Final Element Tag No. JB Number

Reference Drgs Cabinet Number

Temp Detection Loop Drawing No.

Controller Action Direct Reverse Valve Action Direct Reverse

No. Items to be Checked OK N/A Punch List no.

Verify the device calibration check sheet I06-A &

1

Installation check sheet I03-A has been completed.

Verify the cable has been installed terminated and

2 tested as per Cable Installation & Testing check sheet I-

04A completed.

Verify loop details are correct against Project / Vendor

information

3 i.e. P & ID's, I/O schedule, Data sheet / Instrument

index / Alarm & Trip schedule (including Rack / Slot /

Channel location for all I/O devices).

4 Verify the calibration certificate of the test equipment

5 Visually inspect equipment for external damage

Verify no dust inside Enclosure /Cabinet / Panel and

6

insulation surfaces are clean.

Verify Instruments & its Accessories /Electrical

7

equipment/Panel externally clean.

Verify each Instrument is calibrated, accepted and

8 confirm the duration of the calibration certificate is still

valid.

Test and ensure that loop is WIRED and tested for its

9

integrity properly from Instrument to Cabinet.

Verify no dust inside Enclosure /Cabinet / Panel and

10

insulation surfaces are clean.

Verify Instruments & its Accessories /Electrical

11

equipment/Panel externally clean.

Reference Drawings:

1. Cabinet / JB drawing

2. Instrument Location Drawings

3. Loop Drawing

4. Vendor Drawings if applicable

COMMENT(S) / ADDITIONAL INFORMATION:

COMPLETED BY CONTRACTOR VERIFIED BY PMT/OWNER

Designation

Company

Name

Signature

Date

Вам также может понравиться

- Instrument Loop CheckДокумент3 страницыInstrument Loop Checknayum100% (1)

- Tank Gauging Systems: @T @S @D @SS @SSD @PDДокумент2 страницыTank Gauging Systems: @T @S @D @SS @SSD @PDnayumОценок пока нет

- I11c Instrument Close Loop Check PG 1Документ1 страницаI11c Instrument Close Loop Check PG 1Momo ItachiОценок пока нет

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AДокумент2 страницыJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyОценок пока нет

- JX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AДокумент2 страницыJX Nippon Oil & Gas Exploration Inspection Test Record (Itr) - AAmyОценок пока нет

- Neutral Earthing Resistor E34-A Inspection Test Record (Itr) - AДокумент1 страницаNeutral Earthing Resistor E34-A Inspection Test Record (Itr) - AMomo ItachiОценок пока нет

- ITR-C (Instrument) 16cДокумент1 страницаITR-C (Instrument) 16cMomo ItachiОценок пока нет

- ITR-A E Gas Turbine GeneratorДокумент1 страницаITR-A E Gas Turbine GeneratorMomo ItachiОценок пока нет

- E21-C Motor Operated ValveДокумент2 страницыE21-C Motor Operated Valveyskushwah16Оценок пока нет

- Package Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Документ1 страницаPackage Name Factory Acceptance Test Check Sheet Shutdown Valve, Blow Down Valve Inspection & Installation Instrument I-010 Rev 0Musab ShabbirОценок пока нет

- ITR-A E TrasmissionДокумент1 страницаITR-A E TrasmissionMomo ItachiОценок пока нет

- SDV, BDV, Esdv ChecklistДокумент2 страницыSDV, BDV, Esdv ChecklistMusab Shabbir67% (3)

- Safety Shower / Eye Wash: @T @S @D @B @C @PDДокумент2 страницыSafety Shower / Eye Wash: @T @S @D @B @C @PDyskushwah16Оценок пока нет

- E05-C Cathodic Protection SystemДокумент3 страницыE05-C Cathodic Protection Systemyskushwah16Оценок пока нет

- Sample Icep RewpДокумент210 страницSample Icep RewpShawn RainОценок пока нет

- Pre-Commissioning Inspection / Calibration (Pressure Relief Valve) DN-M007-BДокумент5 страницPre-Commissioning Inspection / Calibration (Pressure Relief Valve) DN-M007-BRozh SammedОценок пока нет

- Heat Exchanger: Heater FO BlendingДокумент1 страницаHeat Exchanger: Heater FO Blendingyskushwah16Оценок пока нет

- I08c ICP ESD Station Test PG 1Документ1 страницаI08c ICP ESD Station Test PG 1Momo ItachiОценок пока нет

- FR-045 23.03.a2023Документ3 страницыFR-045 23.03.a2023dileepОценок пока нет

- ElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check ListДокумент2 страницыElectroMechanical Completion-INTRINSICALLY SAFE (IS) - System Check Listhuseyinyuksel1903Оценок пока нет

- Telecom Equipment: @T @S @D @SS @SSD @PDДокумент2 страницыTelecom Equipment: @T @S @D @SS @SSD @PDnayumОценок пока нет

- 5.2. Internal Light & Wiring Device Function TestДокумент2 страницы5.2. Internal Light & Wiring Device Function TestMariam AwadОценок пока нет

- F-I-01 - Transmitter & Gauge Calibration ReportДокумент1 страницаF-I-01 - Transmitter & Gauge Calibration ReportPrathamesh OmtechОценок пока нет

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksДокумент1 страницаEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Item Checklist Description Result RemarksmeeОценок пока нет

- SKN Jambimerang Construction Checksheet E20-A Gas Turbine: InformationДокумент1 страницаSKN Jambimerang Construction Checksheet E20-A Gas Turbine: InformationsuparnaОценок пока нет

- ITR-A E Submarine CableДокумент1 страницаITR-A E Submarine CableMomo ItachiОценок пока нет

- ElectroMechanical Completion-INSTRUMENT INSTALLATIONДокумент1 страницаElectroMechanical Completion-INSTRUMENT INSTALLATIONhuseyinyuksel1903Оценок пока нет

- Itr Ew 07a - EngДокумент1 страницаItr Ew 07a - Engwassim nasriОценок пока нет

- Air Handling Units COB AHU-10AДокумент3 страницыAir Handling Units COB AHU-10AHernan RomeroОценок пока нет

- ITR No.: QI-J09e Att. Hazardous Equipment Inspection Schedule Project Name: JTB Tag No: F-INSTДокумент2 страницыITR No.: QI-J09e Att. Hazardous Equipment Inspection Schedule Project Name: JTB Tag No: F-INSTwinandra 97Оценок пока нет

- Installation of Thermowell & Temperature Elements Check ListДокумент1 страницаInstallation of Thermowell & Temperature Elements Check ListZulfequar R. Ali KhanОценок пока нет

- Epic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Ups Installation ChecklistДокумент1 страницаEpic For Upgradation of Ac Ups Units in Ngl3, Mesaieed: Title: Ups Installation ChecklistmeeОценок пока нет

- Inspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Документ5 страницInspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Navid HashemiОценок пока нет

- Itr Ew 05a - EngДокумент1 страницаItr Ew 05a - Engwassim nasriОценок пока нет

- Air Cooled Chiller ChecklistДокумент3 страницыAir Cooled Chiller ChecklistDevendra DhumalОценок пока нет

- Inspection and Test Plan: Fabrication / In-Process InspectionДокумент17 страницInspection and Test Plan: Fabrication / In-Process InspectionGLEDSON100% (1)

- ITR-B (Mecanical) M35BДокумент1 страницаITR-B (Mecanical) M35BMomo ItachiОценок пока нет

- @T @S @D @SS @SSD @PDДокумент2 страницы@T @S @D @SS @SSD @PDnayumОценок пока нет

- Electrical Equipment InspectionДокумент1 страницаElectrical Equipment InspectionMarthin PurbaОценок пока нет

- P&ID ChecklistДокумент4 страницыP&ID ChecklistMeoОценок пока нет

- I13c Process Analyser Test PG 1Документ1 страницаI13c Process Analyser Test PG 1Momo ItachiОценок пока нет

- Indeecon User Manual Dry BlockДокумент7 страницIndeecon User Manual Dry BlockVEGA CALIBRATIONSОценок пока нет

- Hvac Static Pressure Test: @T @S @D @SS @SSD @PDДокумент2 страницыHvac Static Pressure Test: @T @S @D @SS @SSD @PDnayumОценок пока нет

- FR-04421 03 2023Документ2 страницыFR-04421 03 2023dileepОценок пока нет

- Aux RelayДокумент1 страницаAux RelaysupermannonОценок пока нет

- Installation of Level Recorder - Radar Type For High Temperatures Check ListДокумент1 страницаInstallation of Level Recorder - Radar Type For High Temperatures Check ListZulfequar R. Ali KhanОценок пока нет

- ICM-CD-6119.06 Check Sheet PSVДокумент1 страницаICM-CD-6119.06 Check Sheet PSVShivani DubeyОценок пока нет

- Symbols (P&ID) : InstrumentationДокумент58 страницSymbols (P&ID) : InstrumentationJAYJAYОценок пока нет

- Material Inspection Check ListДокумент2 страницыMaterial Inspection Check ListSERT-QA/QC- BUZОценок пока нет

- Function Test Certificate Form Fi-01 Instruments & Instrument LoopsДокумент1 страницаFunction Test Certificate Form Fi-01 Instruments & Instrument LoopsKhaled FatnassiОценок пока нет

- ICM-CD-6120.06 Check Sheet CV & Ancillaries CalibratonДокумент2 страницыICM-CD-6120.06 Check Sheet CV & Ancillaries CalibratonShivani DubeyОценок пока нет

- Instrumentation Switch ChecklistДокумент9 страницInstrumentation Switch ChecklistAli Mukhtar ShigriОценок пока нет

- Instrument Check List PDFДокумент9 страницInstrument Check List PDFBrijesh Srivastav100% (1)

- Instrumentation Switch ChecklistДокумент9 страницInstrumentation Switch Checklistgeorge stanley paceteОценок пока нет

- Instrumentation Switch ChecklistДокумент9 страницInstrumentation Switch ChecklistIñaki EseberriОценок пока нет

- Instrument Commissioning Checklist PDFДокумент9 страницInstrument Commissioning Checklist PDFBrijesh Srivastav100% (1)

- Formatos CHECKLIST PDFДокумент9 страницFormatos CHECKLIST PDFHarold David Gil MuñozОценок пока нет

- Instrument Check List PDFДокумент9 страницInstrument Check List PDFIgor PaivaОценок пока нет

- Inspection Report For Installation of Fire & Gas DetectorsДокумент1 страницаInspection Report For Installation of Fire & Gas Detectorsnayum0% (1)

- NCR ProcedureДокумент5 страницNCR ProcedurenayumОценок пока нет

- E110 - Motor Installation Checklist Rev 00 11.11Документ2 страницыE110 - Motor Installation Checklist Rev 00 11.11nayumОценок пока нет

- Inspection Report For Installation of JB, Juncation BoxДокумент1 страницаInspection Report For Installation of JB, Juncation BoxnayumОценок пока нет

- Inspection Report For Installation of PanelДокумент1 страницаInspection Report For Installation of PanelnayumОценок пока нет

- Checklist For Cable Try Fabrication and EractionДокумент2 страницыChecklist For Cable Try Fabrication and Eractionnayum100% (1)

- Description of Check: Switch Houses Inspection ChecklistДокумент1 страницаDescription of Check: Switch Houses Inspection ChecklistnayumОценок пока нет

- p0022 Cs e 0015 Testing DataДокумент1 страницаp0022 Cs e 0015 Testing DatanayumОценок пока нет

- Inspection Report For S.S. Tubing of Transmitters, Etc.Документ1 страницаInspection Report For S.S. Tubing of Transmitters, Etc.nayumОценок пока нет

- p0022 Cs e 0010 Grounding System IrДокумент1 страницаp0022 Cs e 0010 Grounding System IrnayumОценок пока нет

- Sheet 1 of 1 Rev 1 Equipment Grounding Installation and Connection ChecklistДокумент1 страницаSheet 1 of 1 Rev 1 Equipment Grounding Installation and Connection ChecklistnayumОценок пока нет

- Hvac Static Pressure Test: @T @S @D @SS @SSD @PDДокумент2 страницыHvac Static Pressure Test: @T @S @D @SS @SSD @PDnayumОценок пока нет

- P0022 CS E 002 CableTrenchesДокумент1 страницаP0022 CS E 002 CableTrenchesnayumОценок пока нет

- P0022 CS E 0013 Lighting PanelДокумент1 страницаP0022 CS E 0013 Lighting PanelnayumОценок пока нет

- @T @S @D @SS @SSD @PDДокумент2 страницы@T @S @D @SS @SSD @PDnayumОценок пока нет

- P0022 CS E 0013 Lighting PanelДокумент1 страницаP0022 CS E 0013 Lighting PanelnayumОценок пока нет

- Cable Pulling and Laying Inspection Checklist: P0022-CS-E-004Документ1 страницаCable Pulling and Laying Inspection Checklist: P0022-CS-E-004nayumОценок пока нет

- Telecom Equipment: @T @S @D @SS @SSD @PDДокумент2 страницыTelecom Equipment: @T @S @D @SS @SSD @PDnayumОценок пока нет

- Quality PlanДокумент31 страницаQuality PlannayumОценок пока нет

- Hvac Static Pressure Test: @T @S @D @SS @SSD @PDДокумент2 страницыHvac Static Pressure Test: @T @S @D @SS @SSD @PDnayumОценок пока нет

- Quality PlanДокумент31 страницаQuality PlannayumОценок пока нет

- Hvac Static Pressure Test: @T @S @D @SS @SSD @PDДокумент2 страницыHvac Static Pressure Test: @T @S @D @SS @SSD @PDnayumОценок пока нет

- Cable Pulling and Laying Inspection Checklist: P0022-CS-E-004Документ1 страницаCable Pulling and Laying Inspection Checklist: P0022-CS-E-004nayumОценок пока нет

- I12BДокумент2 страницыI12BnayumОценок пока нет

- H03BДокумент2 страницыH03BnayumОценок пока нет

- Cable Tray Installation ProcedureДокумент11 страницCable Tray Installation ProcedurenayumОценок пока нет

- DVD Home Cinema System: Owner'S ManualДокумент45 страницDVD Home Cinema System: Owner'S ManualDiego MarroquínОценок пока нет

- Motorola Confidential Restricted: Product Technology APCДокумент32 страницыMotorola Confidential Restricted: Product Technology APCCiro SneiderОценок пока нет

- E-Globe G2 User Guide S-63 1.1Документ23 страницыE-Globe G2 User Guide S-63 1.1krupa kumar100% (1)

- LG ds325b-dx325b Rev02 PDFДокумент86 страницLG ds325b-dx325b Rev02 PDFJoao Jose Santos NetoОценок пока нет

- A Ele Spe 800 30021 0Документ29 страницA Ele Spe 800 30021 0ZaidiОценок пока нет

- Digital Scale 340368 - A - D - IE - ENДокумент47 страницDigital Scale 340368 - A - D - IE - ENDimitar KirovОценок пока нет

- Discussions On SLT Replications IssuesДокумент50 страницDiscussions On SLT Replications IssuesTayi Sriram0% (1)

- (+) What Do CAN Bus Signals Look Like - Industrial - Technical Articles - TI E2E Support ForumsДокумент4 страницы(+) What Do CAN Bus Signals Look Like - Industrial - Technical Articles - TI E2E Support ForumsEdmundo FrazãoОценок пока нет

- Automatic Control Systems - Electronics and Communication Engineering Questions and Answers - 1Документ9 страницAutomatic Control Systems - Electronics and Communication Engineering Questions and Answers - 1Rian RiveraОценок пока нет

- ECE357 Course InformationДокумент7 страницECE357 Course InformationVictor HughesОценок пока нет

- EC6702 Optical Communication and Networks PDFДокумент16 страницEC6702 Optical Communication and Networks PDFGuОценок пока нет

- Intelligent Provisioning 2.30 (Updated 12:2015)Документ6 страницIntelligent Provisioning 2.30 (Updated 12:2015)Sahatma SiallaganОценок пока нет

- DRA - Transformers KSAДокумент16 страницDRA - Transformers KSAAhmet TosunОценок пока нет

- Decimal To BC-Encoder V2Документ10 страницDecimal To BC-Encoder V2Anurag RoyОценок пока нет

- IGCSE Physics - Student GuideДокумент36 страницIGCSE Physics - Student Guiden0tsewОценок пока нет

- Verilog TutorialДокумент92 страницыVerilog TutorialAmmar AjmalОценок пока нет

- General Description Features: Ittybitty RC Timer / OscillatorДокумент10 страницGeneral Description Features: Ittybitty RC Timer / OscillatorIyon ManakarraОценок пока нет

- Heathkit CR-1Документ2 страницыHeathkit CR-1SamRОценок пока нет

- Interpretation of Mass Spectra-4EdДокумент329 страницInterpretation of Mass Spectra-4EdJF Echeverria100% (1)

- IJERT 3 Phase Induction Motor ProtectionДокумент3 страницыIJERT 3 Phase Induction Motor Protectionwondi BETОценок пока нет

- (2m246 - ( - 277 - 317 - 274 - 272 - ) .XLS) - B0ADBCB1C7FCДокумент6 страниц(2m246 - ( - 277 - 317 - 274 - 272 - ) .XLS) - B0ADBCB1C7FCCesarS100% (1)

- Coumputer History PDFДокумент4 страницыCoumputer History PDFFurqan AfzalОценок пока нет

- Instruction Manual: Voltage Regulator Model: APR 125-5 Part Number: 9 1688 00 100Документ22 страницыInstruction Manual: Voltage Regulator Model: APR 125-5 Part Number: 9 1688 00 100Guilherme ChiminelliОценок пока нет

- Keeps Your Scale Working: Unequalled ReliabilityДокумент4 страницыKeeps Your Scale Working: Unequalled ReliabilitywintermacОценок пока нет

- Wavelet Transform Approach To Distance: Protection of Transmission LinesДокумент6 страницWavelet Transform Approach To Distance: Protection of Transmission LinesthavaselvanОценок пока нет

- Toshiba Satellite E55 ZRMAA Compal LA-A481P Rev1.0 SchematicДокумент55 страницToshiba Satellite E55 ZRMAA Compal LA-A481P Rev1.0 SchematicdataОценок пока нет

- Install Update Readme PDFДокумент8 страницInstall Update Readme PDFDildar AlamОценок пока нет

- NPR in SIS 2011Документ10 страницNPR in SIS 2011manu_chatОценок пока нет

- Dcse Id 3174 PDFДокумент17 страницDcse Id 3174 PDFAnonymous yMgM6SОценок пока нет

- SIB11 CalculationДокумент2 страницыSIB11 CalculationNaveen VengaldasОценок пока нет