Академический Документы

Профессиональный Документы

Культура Документы

Tabela Materiais PDF

Загружено:

Ronaldo Rodrigues0 оценок0% нашли этот документ полезным (0 голосов)

376 просмотров1 страницаO documento lista diferentes tipos de ferro fundido, incluindo suas propriedades técnicas essenciais, como:

1) Ferro fundido dúctil de acordo com a norma DIN EN 1563, com diferentes graus de ferro fundido dúctil com variações na resistência à tração, limite de escoamento e alongamento;

2) Ferro fundido dúctil austenítico de acordo com a norma DIN EN 1564, com diferentes graus de ADI com propriedades mecânicas aprimoradas;

3) Ferro fundido

Исходное описание:

Оригинальное название

TABELA MATERIAIS.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документO documento lista diferentes tipos de ferro fundido, incluindo suas propriedades técnicas essenciais, como:

1) Ferro fundido dúctil de acordo com a norma DIN EN 1563, com diferentes graus de ferro fundido dúctil com variações na resistência à tração, limite de escoamento e alongamento;

2) Ferro fundido dúctil austenítico de acordo com a norma DIN EN 1564, com diferentes graus de ADI com propriedades mecânicas aprimoradas;

3) Ferro fundido

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

376 просмотров1 страницаTabela Materiais PDF

Загружено:

Ronaldo RodriguesO documento lista diferentes tipos de ferro fundido, incluindo suas propriedades técnicas essenciais, como:

1) Ferro fundido dúctil de acordo com a norma DIN EN 1563, com diferentes graus de ferro fundido dúctil com variações na resistência à tração, limite de escoamento e alongamento;

2) Ferro fundido dúctil austenítico de acordo com a norma DIN EN 1564, com diferentes graus de ADI com propriedades mecânicas aprimoradas;

3) Ferro fundido

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Materials / technical parameters

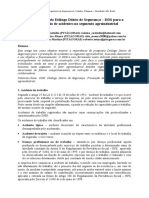

Ductile iron – according to DIN EN 1563 – selection

Guaranteed properties on separately cast test specimens*

Letter Material Diameter Tensile 0,2 -%- Elongation at Brinell Essential

symbol number of the tensile strength Yield rupture hardness structural

test specimen Rm strength % HB constituents

mm N/mm² N/mm²

ferritic/

EN-GJS-400-15 5.3106 12 400 250 15 135-180 pearlitic

ferritic/

EN-GJS-500-7 5.3200 12 500 320 7 170 –230 pearlitic

ferritic/

EN-GJS-600-3 5.3201 12 600 380 3 200 –250 pearlitic

predominantly

EN-GJS-700-2 5.3300 12 700 420 2 235 –285 pearlitic

EN-GJS-400-18-

LT 5.3103 12 400 240 18 130 –165 ferritic

EN-GJS-450-18 5.3108 12 450 350 18 170-200 ferritic

EN-GJS-500-14 5.3109 12 500 400 14 185-215 ferritic

EN-GJS-600-10 5.3110 12 600 470 10 200-230 ferritic

With silicon and molybdenum alloyed cast iron with nodular graphite according to DIN EN 16124 Selection – excerpt

EN-GJS- predominantly

SiMo45-10 5.3117 12 550 460 5 200-250 ferritic

* Particularly in case of wall thicknesses of more than 50 mm and compact cast parts, we recommend agreements between the

manufacturer and the consumer.

Ausferritic ductile iron (ADI) – according to DIN EN 1564

Letter Material Diameter Tensile 0,2 -%- Elongation at Brinell Essential

symbol number of the tensile strength Yield rupture hardness structural

test specimen Rm strength % HB constituents

mm N/mm² N/mm²

austenitic/

EN-GJS-800-10 5.3400 12 800 500 10 250-310 ferritic

austenitic/

EN-GJS-900-8 5.3402 12 900 600 8 280-340 ferritic

austenitic/

EN-GJS-1050-6 5.3403 12 1050 700 6 320-380 ferritic

austenitic/

EN-GJS-1200-3 5.3404 12 1200 850 3 340-420 ferritic

austenitic/

EN-GJS-1400-1 5.3405 12 1400 1100 1 380-480 ferritic

Gray cast iron – according to DIN EN 1561 – selection

Guaranteed properties on separately cast test specimens *

Letter Material Diameter Tensile Brinell Essential

symbol number of the tensile strength hardness structural

test specimen Rm HB constituents

mm N/mm²

EN-GJL-150 5.1200 20 150 –250 165 –205 ferritic/pearlitic

EN-GJL-200 5.1300 20 200 –300 185 –225 pearlitic

EN-GJL-250 5.1301 20 250 –350 205 –250 pearlitic

EN-GJL-300 5.1302 20 300 –400 225 –270 pearlitic

* Tensile strength and Brinell hardness in the cast part strongly depend on the wall thickness.

Malleable cast iron – according to DIN EN 1562 – selection

Letter Material Diameter Tensile 0,2 -%- Elongation at Brinell Essential

symbol number of the tensile strength Yield rupture hardness structural

test specimen N/mm² strength % max. HB constituents

mm N/mm2

EN-GJMW-400- 9 360 200 8 220 core: (lamellar to fine-grained )

5 EN-JM 1030 12 400 220 5 220 perlite + temper carbon

EN-GJMW-450- 9 400 230 10 220 Core: (grained)

7 EN-JM 1040 12 450 260 7 220 perlite + temper carbon

Decarburization to

EN-GJMW-360- 9 320 170 15 220 < 0,3 % C-content in case of

12 EN-JM 1020 12 360 190 12 220 wall thicknesses of < 8 mm

Alloyed types of material upon request.

Вам также может понравиться

- NBR15118 - 2011Документ32 страницыNBR15118 - 2011Diego BorgesОценок пока нет

- Catálogo Técnico Compressor - MSW 40 Fort - Art - MSW 40 Fort - 425 - W 8400 (40 - Ad)Документ6 страницCatálogo Técnico Compressor - MSW 40 Fort - Art - MSW 40 Fort - 425 - W 8400 (40 - Ad)Seg-ita Seg Industrial100% (1)

- Gerenciamento de risco de incêndio em edificações tombadas pelo patrimônio histórico e cultural: uma ênfase no Recôncavo da BahiaОт EverandGerenciamento de risco de incêndio em edificações tombadas pelo patrimônio histórico e cultural: uma ênfase no Recôncavo da BahiaОценок пока нет

- NBR 13325-2 - Dispositivos de AncoragemДокумент38 страницNBR 13325-2 - Dispositivos de AncoragemCaio CézarОценок пока нет

- Emprego do Método AHP para Priorização de Projetos de Automação em uma Linha de Produção de CarroceriasОт EverandEmprego do Método AHP para Priorização de Projetos de Automação em uma Linha de Produção de CarroceriasОценок пока нет

- Tabela Preços - Varão RoscadoДокумент21 страницаTabela Preços - Varão RoscadodografeiroОценок пока нет

- Análise de Riscos Do Uso de Um Sistema de Proteção Contra Quedas Com Linha de Vida Horizontal Como Proteção de Periferia Na Construção Civil BrasileiraДокумент29 страницAnálise de Riscos Do Uso de Um Sistema de Proteção Contra Quedas Com Linha de Vida Horizontal Como Proteção de Periferia Na Construção Civil BrasileirambranchteinОценок пока нет

- N 2349Документ11 страницN 2349edcam13Оценок пока нет

- RES 04b Ebm ProblemasДокумент2 страницыRES 04b Ebm ProblemasLINDOARTE MOREIRAОценок пока нет

- Folder Skid Nfpa 20 Versao WebДокумент4 страницыFolder Skid Nfpa 20 Versao WebKAIQUE AMERICO DOS SANTOSОценок пока нет

- Barreira Optica Grade e Cortina de Luz e Scanner LaserДокумент7 страницBarreira Optica Grade e Cortina de Luz e Scanner Laserrodrigomachado507Оценок пока нет

- Inc - Planta de Comb. A Incendios Pav - Superior - Reev-00Документ1 страницаInc - Planta de Comb. A Incendios Pav - Superior - Reev-00César Roberto Nascimento GuimarãesОценок пока нет

- Memorial DescritivoДокумент32 страницыMemorial DescritivojuliopanseraОценок пока нет

- Plano de Manutenção - Carregadeira W20Документ1 страницаPlano de Manutenção - Carregadeira W20Fellipe GabirobaОценок пока нет

- Soldagem No Estado Sólido TrabalhoДокумент17 страницSoldagem No Estado Sólido TrabalhoVictor Hugo100% (1)

- Descr Téc EkkeДокумент8 страницDescr Téc EkkeDiego Tarachuka de FreitasОценок пока нет

- Laudo Técnico - Edf. Floresta Tropical - VF - R1Документ31 страницаLaudo Técnico - Edf. Floresta Tropical - VF - R1Mixel FranklinОценок пока нет

- Modelo de Planilha OrçamentáriaДокумент2 страницыModelo de Planilha OrçamentáriaSTC Serv TecОценок пока нет

- Memorial DescritivoДокумент41 страницаMemorial DescritivoDomingos João AlfândegaОценок пока нет

- Artigo Sobre DDSДокумент10 страницArtigo Sobre DDSMaria Heugênia VilelaОценок пока нет

- N-1852 G 1emДокумент58 страницN-1852 G 1emMariomourajuniorОценок пока нет

- Máquina Segura em Seis Passos PDFДокумент172 страницыMáquina Segura em Seis Passos PDFAlmir Ferreira BorgesОценок пока нет

- R717 Apostila01Документ89 страницR717 Apostila01wagnerОценок пока нет

- Manual Canhão Monitor Mecânica ReunidaДокумент19 страницManual Canhão Monitor Mecânica ReunidaLeandro Augusto100% (1)

- Plano de Manutenção Industrial - Exaustores - Móveis KatzerДокумент1 страницаPlano de Manutenção Industrial - Exaustores - Móveis KatzerJaisson VidalОценок пока нет

- Suzano - LT 138KV - Ribas - MS - 002 - Operação de Equipamento MotosserraДокумент15 страницSuzano - LT 138KV - Ribas - MS - 002 - Operação de Equipamento MotosserraGustavo de DeusОценок пока нет

- Trabalho Tolerancia e AjusteДокумент15 страницTrabalho Tolerancia e Ajustematheus perinОценок пока нет

- 18 - 05 - 03 Esteira V2 SRG PDFДокумент2 страницы18 - 05 - 03 Esteira V2 SRG PDFLOURISVAN COSTAОценок пока нет

- 7 - Projeto GC ElevadorДокумент12 страниц7 - Projeto GC ElevadorMarcio PerroniОценок пока нет

- Modelo 100Документ4 страницыModelo 100douglas00251Оценок пока нет

- ROS - Registro de Ocorrência de SegurançaДокумент1 страницаROS - Registro de Ocorrência de SegurançaWesley AssunçãoОценок пока нет

- Abnt NBR 15358Документ3 страницыAbnt NBR 15358isiscarvalho1978Оценок пока нет

- PFV - 30tPS - Forzan Prensa ReciclagemДокумент2 страницыPFV - 30tPS - Forzan Prensa ReciclagemVagner Francisco de Freitas0% (1)

- Caldeira TCCДокумент257 страницCaldeira TCCCintiaRoneiОценок пока нет

- Índice de Normas PetrobrasДокумент16 страницÍndice de Normas PetrobrasmttriosОценок пока нет

- Tabela Apreciação de Risco de Equipamentos Padaria IbiraДокумент7 страницTabela Apreciação de Risco de Equipamentos Padaria IbiraDesirê PaulettiОценок пока нет

- 1569602927modelo RdoДокумент6 страниц1569602927modelo RdoMoyra B SantosОценок пока нет

- 3 Passos para Fazer Uma Análise de Risco e Atender A NR12 - NR12Sem SegredosДокумент9 страниц3 Passos para Fazer Uma Análise de Risco e Atender A NR12 - NR12Sem SegredosSinesio SilgueiroОценок пока нет

- NR 12 - Cilindro SovadorДокумент14 страницNR 12 - Cilindro SovadorCPSST100% (1)

- NBR 16325-1 - Dispositivos de Ancoragem Tipo A B e DДокумент44 страницыNBR 16325-1 - Dispositivos de Ancoragem Tipo A B e DCaio CézarОценок пока нет

- Manual Talha de Corrente TC 500-1000-2000-3000Документ6 страницManual Talha de Corrente TC 500-1000-2000-3000Charles SouzaОценок пока нет

- Catalogo - Industrial - Linha Branca - v082018 - ViewДокумент17 страницCatalogo - Industrial - Linha Branca - v082018 - ViewTiago Carnovali PessoaОценок пока нет

- Relatório Modelo - Projeção de Vida Remanescente CaldeiraДокумент6 страницRelatório Modelo - Projeção de Vida Remanescente Caldeirajos luizОценок пока нет

- Catálogo - Andaime Tubo Equipado - (ORGUEL, 2019)Документ3 страницыCatálogo - Andaime Tubo Equipado - (ORGUEL, 2019)caiotoadОценок пока нет

- Defesa 22.589.231-6Документ6 страницDefesa 22.589.231-6Fábio Aurelio OliveiraОценок пока нет

- Redutor Catalago Linha GSDДокумент12 страницRedutor Catalago Linha GSDWagner Barbosa Mendonça0% (1)

- Norma N120 Rev E 150Документ20 страницNorma N120 Rev E 150Olavo Oliveira Jr.100% (1)

- FolderCores Industriais NR 26Документ2 страницыFolderCores Industriais NR 26Luiz Rodrigues AlvesОценок пока нет

- Controle de Manutenção de Máquinas e Equipamento Cor Do MêsДокумент945 страницControle de Manutenção de Máquinas e Equipamento Cor Do MêsVANDERSONОценок пока нет

- Prontuario Ata Caldeira lh17 9066Документ16 страницProntuario Ata Caldeira lh17 9066Hudson Leonardo MacacheroОценок пока нет

- NBR 09967 - 1987 - Talhas Com Acionamento MotorizadoДокумент9 страницNBR 09967 - 1987 - Talhas Com Acionamento MotorizadoCreysson82Оценок пока нет

- Modelo Relatório de Inspeção de SegurançaДокумент2 страницыModelo Relatório de Inspeção de SegurançaSarah Verissimo100% (1)

- PMOC Focus ExaustãoДокумент1 страницаPMOC Focus ExaustãoCIA DO ARОценок пока нет

- Aula 5 .2023.2 Metodo Estado Limite Complementar 2Документ12 страницAula 5 .2023.2 Metodo Estado Limite Complementar 2Rafael BartzОценок пока нет

- Katalog 05 enДокумент36 страницKatalog 05 enAlireza KhodabandehОценок пока нет

- AcosInoxidaveis EspecificacoestecnicasДокумент1 страницаAcosInoxidaveis EspecificacoestecnicasJosé ReinaldoОценок пока нет

- 11 Metalurgia 30 Questoes Final11Документ12 страниц11 Metalurgia 30 Questoes Final11Gustavo Davi100% (1)

- Lista de Exercícios - Materiais IДокумент4 страницыLista de Exercícios - Materiais IRafael StangeОценок пока нет

- Materiais de Construção Mecânica 3Документ20 страницMateriais de Construção Mecânica 3fabiofambhОценок пока нет

- Diagramas de Equilibrio1Документ4 страницыDiagramas de Equilibrio1Ana Maria LoretoОценок пока нет

- Soldadura PDFДокумент7 страницSoldadura PDFAntonio MarinhoОценок пока нет

- 2017-4.1 Columbia - HavelДокумент19 страниц2017-4.1 Columbia - HavelSandro FelixОценок пока нет

- Apostila Tratamentos Supericial FatecДокумент216 страницApostila Tratamentos Supericial FatecWesleyОценок пока нет

- Diagramas TTT e TACДокумент3 страницыDiagramas TTT e TACJotaОценок пока нет

- 1014005-Diagramas de Fases Ferro-CementitaДокумент49 страниц1014005-Diagramas de Fases Ferro-CementitaHenrique ToziОценок пока нет

- Formação de Ferrita Delta Na Soldagem de Aço Inoxidável Super MartensíticoДокумент13 страницFormação de Ferrita Delta Na Soldagem de Aço Inoxidável Super MartensíticoAntonio GalvãoОценок пока нет

- matconstmecanicaPB Comcapa PDFДокумент67 страницmatconstmecanicaPB Comcapa PDFHeitor Gonçalez BoviОценок пока нет

- Tecnico - A - de - Inspecao - de - Equipamentos - e - Instalaces - Junior 2018Документ11 страницTecnico - A - de - Inspecao - de - Equipamentos - e - Instalaces - Junior 2018Yuuta AlternativoОценок пока нет