Академический Документы

Профессиональный Документы

Культура Документы

Control Plan Ingersol Rand

Загружено:

rgrao85Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Control Plan Ingersol Rand

Загружено:

rgrao85Авторское право:

Доступные форматы

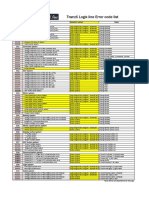

Control Plan Page of

Issue Date: Effectivity Date: Rev.: Revision Date

Part No & Rev.: Spec No & Rev.: Part Name:

Company Name: Location:

Manufacturing Process: Equipment:

Approvals

IR Quality Supplier QA Manager Supplier Mfg Manager

Initials Date Initials Date Initials Date

Control Location Abbreviations

A. Rec Insp D. In Process G. Out of Box Audit RI - Receiving Inspection 1X/2H - One Time/Two Hours 2X/S - Two Times per Shift

B. Material Receipt E. Last Piece H. Tool OBA - Out of Box Audit 1X/SU - One Time per Start-up FGI - Finished Goods Inventory

C. Setup Approval F. Final Inspection DMR - Defective Material Report

Process

Product

Key /

Inspection Control Location &

# Operation / Process Machine, Cavity, etc. Standard Specification Tolerance Size Freq. Control Method Cpk

Device Reaction Plan

Charac.

7 - Control Plan - Form 1 of 2

Control Plan Page 1 of 1

Issue Date: 9/2/2008 Effectivity Date: 9/2/2008 Rev.: 0 Revision Date 9/2/2008

Part No & Rev.: ABC12345-0987D Spec No & Rev.: 123DFFRZ Part Name: Widget

Company Name: Location:

ABC Molding Kokomo, IN.

Manufacturing Process: Equipment:

Injection Molding Husky 1000T Press

Approvals

IR Quality Supplier QA Manager Supplier Mfg Manager

Initials C. Knowles Date 8/15/2008 Initials S. Brown Date 8/12/2008 Initials B. Kaelin Date 8/11/2008

Control Location Abbreviations

A. Rec Insp D. In Process G. Out of Box Audit RI - Receiving Inspection 1X/2H - One Time/Two Hours 2X/S - Two Times per Shift

B. Material Receipt E. Last Piece H. Tool OBA - Out of Box Audit 1X/SU - One Time per Start-up FGI - Finished Goods Inventory

C. Setup Approval F. Final Inspection DMR - Defective Material Report

Process

Product

Key /

Inspection Control Location &

# Operation / Process Machine, Cavity, etc. Standard Specification Tolerance Size Freq. Control Method Cpk

Device Reaction Plan

Charac.

Plastic Inj. Free of Visual Continuo 100% Injection Press.

3 Machine No. 1-5 18 Appearance 100% us Notify Supervisor

Molding blemishes Inspection Inspection

1st piece Injection Press.

No Blemishes Flow lines Check sheet Adjust & re-check

buy-off

1st piece Injection Press.

Sink Marks Check sheet Adjust & re-check

buy-off

Mounting hole Hole "x" 1st buy-off Injection Press.

Machine No. 1-5 19 Fixture #10 Check sheet 1.92 Adjust & re-check

location locations piece per run

Machine No. 1-5

EXAMPLE 20 Dimension

25 ± 1mm

Gap 3 ± .

5mm

Fixture #10

5 pcs

1st

piece

hourly

buy-off

per run

X-bar R

Chart

Check sheet

1.45

Measurement Lab.

Quarantine & adjust

Production floor.

Adjust & re-check

Check gap

Gap 3 ± . X-bar R Production floor.

Fixture #10 21 Perimeter fit to fixture 4 5 pcs hourly 1.66 Adjust & re-check

5mm Chart

locations

Review of

See

set-up card Each 1st piece

Machine No. 1-5 22 attached set-

and machine set-up buy-off

up card

settings

Inspector

verifies

settings

7 - Control Plan - Example 2 of 2

Вам также может понравиться

- Hyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YДокумент2 страницыHyundai Transys Knob Assy FR Seat H/Adj RH 88023-K3000 NNB/T9YubraghuОценок пока нет

- M/s Qavi & Brothers: VIP Activity Plan & StatusДокумент5 страницM/s Qavi & Brothers: VIP Activity Plan & StatusMurtaza AhmedОценок пока нет

- BNY ADR Work AllocationДокумент13 страницBNY ADR Work AllocationimaarhaОценок пока нет

- W43 W48 W04 W06 W07: Time Scale (Week)Документ1 страницаW43 W48 W04 W06 W07: Time Scale (Week)Steve WanОценок пока нет

- Micro Turn Product (Blue Colour Tag) : RejectДокумент2 страницыMicro Turn Product (Blue Colour Tag) : RejectSahil WadhwaОценок пока нет

- 6 Team Feasibility STUDDYДокумент6 страниц6 Team Feasibility STUDDYkamalОценок пока нет

- Standard Work Chart: (NVA) (NVA) (NVA)Документ2 страницыStandard Work Chart: (NVA) (NVA) (NVA)Carlos Manuel ParionaОценок пока нет

- Competence Format ExampleДокумент10 страницCompetence Format ExampleAbraham GutierrezОценок пока нет

- 66 FM-TRD-05 Tool History CardДокумент2 страницы66 FM-TRD-05 Tool History CardUttrakhand Vibes- OriginalОценок пока нет

- Master TimingДокумент4 страницыMaster TimingPk NimiwalОценок пока нет

- Quality Plan (Incoming) : Assy / Sub-Assy Name: Format No: Assy / Sub-Assy No: Latest Drawing Reference DetailsДокумент5 страницQuality Plan (Incoming) : Assy / Sub-Assy Name: Format No: Assy / Sub-Assy No: Latest Drawing Reference DetailsScientific KingОценок пока нет

- Standard Operating Procedure / Work Instructions / Visual AidsДокумент3 страницыStandard Operating Procedure / Work Instructions / Visual AidsSwapnil BachhavОценок пока нет

- A3Документ1 страницаA3chavesierra20081 SierraОценок пока нет

- Audit MatrixДокумент1 страницаAudit MatrixsivamandoОценок пока нет

- Standard Operating ProcedureДокумент4 страницыStandard Operating ProcedureJana VinayaОценок пока нет

- 5S Audit - Task Force TeamДокумент7 страниц5S Audit - Task Force TeamRajaVeluОценок пока нет

- Packaging Details: Vendor Name & AddressДокумент4 страницыPackaging Details: Vendor Name & AddressPk NimiwalОценок пока нет

- HR-03 - Skill - Matrix NEWДокумент7 страницHR-03 - Skill - Matrix NEWVikin JainОценок пока нет

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsДокумент4 страницыControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- April 2021 Production SheetДокумент26 страницApril 2021 Production SheetPrakash kumarTripathiОценок пока нет

- 16 Major Losses in ProductionДокумент18 страниц16 Major Losses in ProductionAgung Chilmy FirdanaОценок пока нет

- 01.SOP - Center BezelДокумент2 страницы01.SOP - Center BezelRS MANIKANDANОценок пока нет

- Incident: What Was The Problem? (5W+2H)Документ3 страницыIncident: What Was The Problem? (5W+2H)Gyanveer SinghОценок пока нет

- D10414410A CP Rev 00Документ21 страницаD10414410A CP Rev 00Suraj RawatОценок пока нет

- Lean FormsДокумент103 страницыLean FormsWashington Fonseca100% (1)

- Quality ControlДокумент2 страницыQuality ControlKumar AshutoshОценок пока нет

- FEQ TemplateДокумент5 страницFEQ TemplateJackie van SchalkwykОценок пока нет

- Press Shop OEE Improvement PlanДокумент1 страницаPress Shop OEE Improvement PlanAmiya KumarОценок пока нет

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Документ10 страницNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmboreОценок пока нет

- Opr # Desc Location M/C Desc Cycle Time (Secs) Manpower Available # of Machines AvailableДокумент3 страницыOpr # Desc Location M/C Desc Cycle Time (Secs) Manpower Available # of Machines AvailableSudhaОценок пока нет

- O J T Check SheetДокумент1 страницаO J T Check SheetabhishekОценок пока нет

- Chintamani Metal Udhoy Pvt. Ltd. 4M Change BoardДокумент6 страницChintamani Metal Udhoy Pvt. Ltd. 4M Change Boardcmu qmsОценок пока нет

- GM 1927 31a PDCA Wall ScorecardДокумент10 страницGM 1927 31a PDCA Wall ScorecardMostafa Abd ElalemОценок пока нет

- OEE Calculation Example: Factors Number of Shifts Hours Per Shift TimeДокумент16 страницOEE Calculation Example: Factors Number of Shifts Hours Per Shift TimeMosfet AutomationОценок пока нет

- FIR-garments PDFДокумент4 страницыFIR-garments PDFTarun PariharОценок пока нет

- Part Packing Standard: Sidhi International - Metalloys PVT - LTDДокумент1 страницаPart Packing Standard: Sidhi International - Metalloys PVT - LTDpulkit gargОценок пока нет

- Anpqp 2.0Документ32 страницыAnpqp 2.0koalaboiОценок пока нет

- CAPA Incomplete Part MixДокумент16 страницCAPA Incomplete Part MixRohtash fastnerОценок пока нет

- Quality PlanДокумент1 страницаQuality PlanKumar AshutoshОценок пока нет

- Referance Number of QC DeptДокумент2 страницыReferance Number of QC Deptswapon kumar shillОценок пока нет

- In House PPM MonitoringДокумент2 страницыIn House PPM MonitoringSrinath NavadaОценок пока нет

- Project Planning Monitoring Tool MacroДокумент11 страницProject Planning Monitoring Tool MacroManoj R NairОценок пока нет

- Manufacturing Process Mapping (Overview) : Customer Requirement YESДокумент2 страницыManufacturing Process Mapping (Overview) : Customer Requirement YESJohn P. BandoquilloОценок пока нет

- Overall Equipment Effectiveness (O.E.E.) Monitoring Sheet: Shift 1Документ28 страницOverall Equipment Effectiveness (O.E.E.) Monitoring Sheet: Shift 1Sukhjot SinghОценок пока нет

- 8 D Report FormatДокумент9 страниц8 D Report FormatLukas LukasОценок пока нет

- Production KPI 22Документ3 страницыProduction KPI 22Senthilmani MuthuswamyОценок пока нет

- 8 D For ShrinkageДокумент6 страниц8 D For ShrinkageSachin KumbharОценок пока нет

- Improvement KaizenДокумент11 страницImprovement KaizenAnkur DhirОценок пока нет

- F-PD-11 Tool Development Plan (Micro Plan)Документ3 страницыF-PD-11 Tool Development Plan (Micro Plan)Trivesh SharmaОценок пока нет

- Single Machine - Multiple Parts (OEE Reporting)Документ2 страницыSingle Machine - Multiple Parts (OEE Reporting)Vergence Business Associates100% (1)

- KPI 40th To 48 Week Packing PlantДокумент18 страницKPI 40th To 48 Week Packing Plantsivareddy143Оценок пока нет

- 6W2H For Side Wrinkles MY17 - RearДокумент4 страницы6W2H For Side Wrinkles MY17 - RearVishvendra Pratap SinghОценок пока нет

- Quality Manual: Organization ChartДокумент2 страницыQuality Manual: Organization ChartmuthuselvanОценок пока нет

- Set-Up Approval Report-Separator LowerДокумент2 страницыSet-Up Approval Report-Separator Lowerswaran autoqaОценок пока нет

- Sidhi Alcast: Machine Maintenance RecordДокумент1 страницаSidhi Alcast: Machine Maintenance Recordpulkit gargОценок пока нет

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Документ13 страницWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerОценок пока нет

- Shree Spherotech PVT - LTD.: Control PlanДокумент33 страницыShree Spherotech PVT - LTD.: Control PlanSachin KumbharОценок пока нет

- Die Inward Inspection ReportДокумент2 страницыDie Inward Inspection ReportRahul DevkateОценок пока нет

- Control PlanДокумент9 страницControl Planjose antonioОценок пока нет

- Supplier Capability Self Assessment Form 2015 PROTECTEDДокумент24 страницыSupplier Capability Self Assessment Form 2015 PROTECTEDrgrao85Оценок пока нет

- Supplier Capability Self Assessment Form 2015 PROTECTEDДокумент24 страницыSupplier Capability Self Assessment Form 2015 PROTECTEDrgrao85Оценок пока нет

- Company Namebuhler: Deputy Manager - ProjectsДокумент1 страницаCompany Namebuhler: Deputy Manager - Projectsrgrao85Оценок пока нет

- Instructions: 'No' Answers Are To Be Resolved Immediately and DocumentedДокумент1 страницаInstructions: 'No' Answers Are To Be Resolved Immediately and Documentedrgrao85Оценок пока нет

- Green Belt Project Storyboard v2.0 TemplateДокумент27 страницGreen Belt Project Storyboard v2.0 Templatergrao85Оценок пока нет

- AVP Performance Head Stud Kit For 6.0L Power Stroke: Parts Included: Tools NeededДокумент2 страницыAVP Performance Head Stud Kit For 6.0L Power Stroke: Parts Included: Tools Neededrgrao85Оценок пока нет

- Starter Product RevenueДокумент5 страницStarter Product Revenuergrao85Оценок пока нет

- Apparel Pattern DesigningДокумент17 страницApparel Pattern Designingrgrao85Оценок пока нет

- ENG FRM 001 Ve 1Документ535 страницENG FRM 001 Ve 1rgrao85Оценок пока нет

- Procurement & LogisticДокумент1 страницаProcurement & Logisticrgrao85Оценок пока нет

- Auto and Auto Ancillaries Sector in IndiaДокумент13 страницAuto and Auto Ancillaries Sector in Indiargrao85Оценок пока нет

- Elements of Forecasting: LN Yr Logyr Actual Sales Estd - Sales-1 Est - Logsales Est - Lnsales LN Sales Log Sales Time PeriodДокумент10 страницElements of Forecasting: LN Yr Logyr Actual Sales Estd - Sales-1 Est - Logsales Est - Lnsales LN Sales Log Sales Time Periodrgrao85Оценок пока нет

- S20157enДокумент137 страницS20157enrgrao85Оценок пока нет

- Mold Design Fundamental Calculation BATTERY COVERДокумент7 страницMold Design Fundamental Calculation BATTERY COVERrgrao85Оценок пока нет

- Flexman QuestionДокумент2 страницыFlexman Questionrgrao85Оценок пока нет

- Element ListДокумент1 страницаElement Listrgrao85Оценок пока нет

- Marketing Research Tactical Plan: Scope Definition PhaseДокумент1 страницаMarketing Research Tactical Plan: Scope Definition Phasergrao85Оценок пока нет

- Financial StatementДокумент34 страницыFinancial Statementrgrao850% (2)

- LME Steel Rebar FactsheetДокумент2 страницыLME Steel Rebar Factsheetrgrao85Оценок пока нет

- New Production Dev TimelineДокумент2 страницыNew Production Dev Timelinergrao85Оценок пока нет

- 4.2 - Risk Assessment ProjectДокумент3 страницы4.2 - Risk Assessment ProjectMuhammad Nauman100% (1)

- Jet Aircraft PropulsionДокумент24 страницыJet Aircraft PropulsionashriveОценок пока нет

- NI Circuit Design Suite: Getting Started GuideДокумент72 страницыNI Circuit Design Suite: Getting Started GuideAlberto Manuel CarrilloОценок пока нет

- Regulate MM 166f eДокумент8 страницRegulate MM 166f eDrazen MakarovОценок пока нет

- Exhibition Material - Smart Energy ICT Solution Cases - V3.0Документ7 страницExhibition Material - Smart Energy ICT Solution Cases - V3.0Ahmed HadhoudОценок пока нет

- Yyy PDFДокумент15 страницYyy PDFaliОценок пока нет

- International Journal of Fatigue: C.M. Manjunatha, Ramesh Bojja, N. Jagannathan, A.J. Kinloch, A.C. TaylorДокумент7 страницInternational Journal of Fatigue: C.M. Manjunatha, Ramesh Bojja, N. Jagannathan, A.J. Kinloch, A.C. TaylorAnonymous 7hZOclОценок пока нет

- Newport Scout Group: Scout Hut Feasability Study March 2009Документ18 страницNewport Scout Group: Scout Hut Feasability Study March 2009jteppettОценок пока нет

- Error Codes E-FLY M25Документ1 страницаError Codes E-FLY M25pavlik1Оценок пока нет

- Shell Corena S4 R - TDSДокумент3 страницыShell Corena S4 R - TDSAnonymous oAbjbl4HОценок пока нет

- Product Information Bulletin: Handling ToolsДокумент7 страницProduct Information Bulletin: Handling ToolsghanОценок пока нет

- Escorts F15 Pick and Carry Cranes PDFДокумент2 страницыEscorts F15 Pick and Carry Cranes PDFVenugopal SriОценок пока нет

- Giudeca SocialДокумент36 страницGiudeca SocialCristiDuca-DamianОценок пока нет

- NCCI Design of Fixed Column Base JointsДокумент23 страницыNCCI Design of Fixed Column Base JointsVădan BogdanОценок пока нет

- SAR Factory Company ProfileДокумент20 страницSAR Factory Company ProfilePageduesca RouelОценок пока нет

- English Presentation .Документ16 страницEnglish Presentation .Joshua Tazeem100% (1)

- B.Tech ECE 028 05 DEC12Документ407 страницB.Tech ECE 028 05 DEC12Prateek GuptaОценок пока нет

- E2 Preventive Maintenance Manual1Документ68 страницE2 Preventive Maintenance Manual1Jeffry KarundengОценок пока нет

- Starting SystemДокумент84 страницыStarting SystemautoscanningОценок пока нет

- SOL ONE SpecificationДокумент10 страницSOL ONE SpecificationHenrry OchoaОценок пока нет

- Xylene SolubaleДокумент4 страницыXylene Solubale6850079Оценок пока нет

- SPP - Condensed NotesДокумент95 страницSPP - Condensed Notesu9099 powОценок пока нет

- Accelerometer Based Tilt Sensor For Controlling Wheel ChairДокумент23 страницыAccelerometer Based Tilt Sensor For Controlling Wheel ChairatulonwheelsОценок пока нет

- Hard Landscape Brochure PDFДокумент32 страницыHard Landscape Brochure PDFeromax1Оценок пока нет

- Osisense Xs & XT - xsdh603629Документ2 страницыOsisense Xs & XT - xsdh603629Hakim ArifОценок пока нет

- Install EquipmentДокумент8 страницInstall EquipmentDeyeck VergaОценок пока нет

- Alkorplan F InstallationДокумент68 страницAlkorplan F InstallationdracunciliasizОценок пока нет

- ARCH THESIS (Chapter 1)Документ10 страницARCH THESIS (Chapter 1)Clifford Jan Tabada AtigОценок пока нет

- Investment in PSX Project. Investment Portfolio Management.: Group Members. Rabee Shahzad Zahid Ch. Arslan WattooДокумент50 страницInvestment in PSX Project. Investment Portfolio Management.: Group Members. Rabee Shahzad Zahid Ch. Arslan WattooAhmad MalikОценок пока нет

- PCR-M30 M50 M80 OmДокумент124 страницыPCR-M30 M50 M80 OmmanolitoОценок пока нет