Академический Документы

Профессиональный Документы

Культура Документы

Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDF

Загружено:

christos032Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDF

Загружено:

christos032Авторское право:

Доступные форматы

DOCOL 420LA

DOCOL 420LA

General Product Description

A high-strength steel for modern production

The Docol 420LA steels are high-strength low-alloy steels, available both as hot rolled and cold rolled.

These steels are suitable for operations where higher strength is needed. It offers consistent properties for modern, rapid production

methods.

Dimension range

Docol 420LA / UC: thickness 0.40-3.00 mm, width up to 1527 mm, length up to 8500 mm.

Docol HR420LA / UC: thickness 2.00-6.00 mm, width up to 1610 mm, length up to 16000 mm.

Docol CR420LA / GI: thickness 0.80-2.00 mm, width up to 1500 mm, length up to 6000 mm.

Docol CR420LA / GA&ZA: thickness 0.80-2.00 mm, width up to 1500 mm, length up to 6000 mm. (upon request)

Docol HR420LA / GI: thickness 2.00-2.50 mm, width up to 1120 mm, length up to 6000 mm. (upon request)

Slitting to narrow coils and cutting to sheets are available upon request.

Mechanical Properties

Steelgrade Thickness Standards Coating Test direc- Yield Tensile Elongation n10-20/ Ag Min. inner

(mm) tion strength strength A80 (min) bending

Rp0,2 Rm (min %) radius for

(MPa) (MPa) 90 °

Docol 420 0.40 - 0.70 EN 10268 UC Transversal 420 - 5202) 470 - 590 15 - 0.25xt

LA

Docol 420 0.71 - 3.00 EN 10268 UC Transversal 420 - 5202) 470 - 590 17 - 0.25xt

LA

Docol HR 2.00 - 6.00 VDA 239- UC Longitud 420 - 520 480 - 600 18 - 0.5xt

420LA 100:2015 inal

Docol CR 0.80 - 2.00 VDA 239- GI, GA*, Longitud 420 - 520 480 - 590 17 0.11 1.0xt 1)

420LA 100:2015 ZA* inal

Docol HR 2.00 - 2.50 - GI Longitud 420 - 520 480 - 590 18 - 1.0xt 1)

420LA inal

1) The value apply to steel when bending angle is 90°. In some cases tight bending radius may cause micro-cracking of the coating in the bend area. Where

design permits, users are encouraged to employ larger radius.

2) If the yield strength is pronounced, the values apply to the lower yield point ReL.

* Available on request.

Data sheet 2136 Docol 420LA 2016-11-25

DOCOL 420LA

Chemical Composition

Steel- Product C Si Mn P S Al Ti Nb Cu

grade Type (max %) (max %) (max %) (max %) (max %) (min %) (max %) (max %) (max %)

Docol Uncoated 0.10 0.50 1.60 0.020 0.015 0.015 0.15 0.09 0.20

420 LA

Docol HR Uncoated 0.12 0.50 1.60 0.030 0.025 0.015 0.15 0.09 0.20

420LA

Docol CR Metal 0.12 0.50 1.65 0.030 0.025 0.015 0.15 0.09 0.20

420LA coated

Docol HR Metal 0.12 0.50 1.50 0.030 0.025 0.015 0.15 0.10 0.20

420LA coated

Tolerances

Cold-rolled (UC): Tolerances in accordance to EN10131.

Hot-dip metal coated: (GI, GA & ZA) Tolerances in accordance to EN10143.

Hot-rolled (UC): Tolerances in accordance to EN10051.

Customized dimensional and shape tolerances are available on request.

Coatings and surface treatments

Coatings

The metal coatings options for Docol products include:

Hot dip zinc coating (GI) consists almost entirely of zinc (>99%). It is lead free, resulting in a small zinc spangle size. The coating

provides good corrosion protection.

Galvannealed coating (GA) is a zinc-iron alloy coating having an iron content of approximately 10%. Galvannealed is produced by

post-heat treatment in continuous hot-dip coating process. Galvannealed provides excellent resistance weldability and corrosion

protection of painted products.

Galfan coating (ZA) is a zinc-aluminium alloy coating having the eutectic composition approximately of 95% Zn and 5% Al. Galfan is

produced in continuous hot-dip coating process. Galfan has better anticorrosive and forming properties than conventional hot dip

zinc coating (GI).

Grade specific availability of metal coated Docol products are given in the Mechanical properties table, coating column.

Data sheet 2136 Docol 420LA 2016-11-25

DOCOL 420LA

Type Coating class Standard Closest in Coating mass Thickness per Density Surface

EN10346, per side, Sin- side, informa- (g/cm3) quality

informative gle spot test tive (U = unex-

(g/m2) (μm) posed, E =

exposed

GI 40 VDA239-100 Z100 40 - 60 (1) 5,6 - 8,5 7,1 U

GI 50 VDA239-100 50 - 70 (1) 7,0 - 9,9 7,1 U

GI 60 VDA239-100 Z140 60 - 90 8,5 - 12,7 7,1 U

GI 70 VDA239-100 70 - 100 9,9 - 14,1 7,1 U

GI 85 VDA239-100 85 -115 12,0 - 16,2 7,1 U

GI 115 VDA239-100 Z275 115 -155 16,2 - 21,8 7,1 U

GA 40 VDA239-100 ZF100 40 - 60 (1) 5,6 - 8,5 7,1 U

GA 50 VDA239-100 ZF120 50 - 80 7,0 - 11,3 7,1 U

ZA 95 Upon request ZA95 7 6,6 U

ZA 130 Upon request ZA130 10 6,6 U

(1) For hot-dipped (GI, ZA, GA) hot rolled (HR) grades, the coating mass tolerance is increased to 30 g/m² by increasing the upper limit.

In addition to these coating masses, asymmetric coatings and OEM coating specifications are available upon request.

Surface treatments

All surface treatments are in accordance with RoHS directive (2011/65/EU) and do not contain Chromium VI (Cr6+). Surface

treatments provide only temporary surface protection during transportation and storage. In order to avoid corrosion damages, care

must be taken to keep the products dry during transportation and storage. If they become wet, they must be separated and situated

so that they are dried quickly.

Surface coating Available surface treatment

GI, ZA, GA Chemically passivated (C)

GI, ZA, GA Oiled (O)

GI, ZA, GA Chemically passivated and oiled (CO)

GI, ZA, GA Unprotected (U)

UC (Cold-rolled) Oiled

UC (Cold-rolled) Unprotected

UC (Hot-rolled) Oiled (Only for pickled steel)

UC (Hot-rolled) Unprotected

Data sheet 2136 Docol 420LA 2016-11-25

DOCOL 420LA

Fabrication and Other Recommendations

For information concerning fabrication, see SSAB’s brochures on www.ssab.com or consult Tech Support, techsupport@ssab.com.

Appropriate health and safety precautions must be taken when bending, welding, cutting, grinding or otherwise working on the

product.

The UK English version of this document shall prevail in case of discrepancy. Download the latest version of this document at www.ssab.com

Hardox, Strenx, Docol, Dogal, Domex, Toolox, Laser, Armox, Ramor, GreenCoat are trademarks of SSAB Technology AB, Sweden

www.ssab.com

Data sheet 2136 Docol 420LA 2016-11-25

Вам также может понравиться

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- SSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enДокумент4 страницыSSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enchristos032Оценок пока нет

- Materials Data for Cyclic Loading: Low-Alloy SteelsОт EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsРейтинг: 5 из 5 звезд5/5 (2)

- Eucaro Offshore CatalogДокумент36 страницEucaro Offshore CatalogSaulo Roseira100% (1)

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesОт EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesРейтинг: 4.5 из 5 звезд4.5/5 (7)

- Canada Culvert Non Woven Geotextile Spec Sheet 1Документ1 страницаCanada Culvert Non Woven Geotextile Spec Sheet 1VindireОценок пока нет

- Metal Coated HSLA Steels, EN10346:2015Документ3 страницыMetal Coated HSLA Steels, EN10346:2015ronakguptaОценок пока нет

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelДокумент4 страницыUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyОценок пока нет

- Modern Glass CharacterizationОт EverandModern Glass CharacterizationMario AffatigatoОценок пока нет

- 6060 PropertiesДокумент3 страницы6060 Propertiesinterpon07Оценок пока нет

- 03171344yzet PDFДокумент30 страниц03171344yzet PDFRobin LeeОценок пока нет

- Metal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesДокумент3 страницыMetal Coated Structural Steels, EN10346:2015: General Product Description Mechanical PropertiesSrikanth SrikantiОценок пока нет

- Docol 1300M: General Product DescriptionДокумент2 страницыDocol 1300M: General Product DescriptionAnonymous wR1jrmpYAОценок пока нет

- 27MG Ultrasonic Thickness GageДокумент3 страницы27MG Ultrasonic Thickness Gagevenu r sОценок пока нет

- HS-900B Technical Data SheetДокумент3 страницыHS-900B Technical Data SheetAji SetiawanОценок пока нет

- 1990 Siemens Discrete Semiconductors For Surface MountingДокумент952 страницы1990 Siemens Discrete Semiconductors For Surface MountingKannanDevanОценок пока нет

- Dogal LAD High Strength Low Alloy Steels For Cold Forming: GeneralДокумент2 страницыDogal LAD High Strength Low Alloy Steels For Cold Forming: Generalchristos032Оценок пока нет

- 308 - Dogal LAD PDFДокумент2 страницы308 - Dogal LAD PDFchristos032Оценок пока нет

- HS-900A Technical Data SheetДокумент3 страницыHS-900A Technical Data SheetAji SetiawanОценок пока нет

- h2066-HASTELLOY C-22 Welding DataДокумент4 страницыh2066-HASTELLOY C-22 Welding DataGovindarajalu PadmanabhanОценок пока нет

- Autrod 1264Документ2 страницыAutrod 1264Anonymous yL7oldKОценок пока нет

- Bergquist Gap Pad Comparison TableДокумент1 страницаBergquist Gap Pad Comparison TableMaike SongОценок пока нет

- Material Datea 2.4602Документ3 страницыMaterial Datea 2.4602Charwin XiaoОценок пока нет

- Chromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelДокумент2 страницыChromet 92: Mma All-Positional Electrode For Joining P92 Creep Resisting SteelVVan TanОценок пока нет

- Stalargo Stainless Steel I-Beams: For Demanding ApplicationsДокумент4 страницыStalargo Stainless Steel I-Beams: For Demanding ApplicationsTushar PatilОценок пока нет

- Datasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1Документ8 страницDatasheet-Saf-2205-En-V2021-10-07 13 - 05 Version 1simone.mauriОценок пока нет

- Yuken Valve DSG-01 Spec Ec-0402 PDFДокумент19 страницYuken Valve DSG-01 Spec Ec-0402 PDFgovindsrОценок пока нет

- HS-901D Technical Data SheetДокумент4 страницыHS-901D Technical Data SheetAji SetiawanОценок пока нет

- RG RM RGH Datasheet PDFДокумент3 страницыRG RM RGH Datasheet PDFNNMSAОценок пока нет

- RG RM RGH DatasheetДокумент3 страницыRG RM RGH DatasheetMomogi ForeverhappyОценок пока нет

- Tenax 35S (E 42 5 B 32 H5)Документ1 страницаTenax 35S (E 42 5 B 32 H5)brunizzaОценок пока нет

- Sidac: (95 - 330 Volts)Документ6 страницSidac: (95 - 330 Volts)Nithish NithiОценок пока нет

- Chemical Composition of Welding Wire % (Typical) StandardsДокумент1 страницаChemical Composition of Welding Wire % (Typical) StandardsAli KayaОценок пока нет

- LFBCW510L TN enДокумент4 страницыLFBCW510L TN endrgilleОценок пока нет

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Документ2 страницыProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourОценок пока нет

- A600 T E-2017Документ13 страницA600 T E-2017RezaYulisnaPNОценок пока нет

- PDF Toroids General InformationДокумент15 страницPDF Toroids General InformationThiếpОценок пока нет

- Bomba Weda D60Документ1 страницаBomba Weda D60CARLOS DAVILAОценок пока нет

- Inconel 112-DatasheetДокумент1 страницаInconel 112-DatasheetrobertОценок пока нет

- Vishay Dale ResistorsДокумент8 страницVishay Dale Resistorsalko123Оценок пока нет

- Adi Artech: DescriptionДокумент1 страницаAdi Artech: DescriptionkumarОценок пока нет

- Dual Phase High Ductility Steels Voestalpine EN 12062019Документ2 страницыDual Phase High Ductility Steels Voestalpine EN 12062019Willian FreireОценок пока нет

- Datasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Документ6 страницDatasheet Sandvik 3r65 For Medical Applications en v2020!12!10 06 - 47 Version 1Mohammed Saleem Syed KhaderОценок пока нет

- Dual Phase High Ductility Steels Voestalpine EN 12062019Документ2 страницыDual Phase High Ductility Steels Voestalpine EN 12062019RhushikeshОценок пока нет

- CLC4003 HardnessДокумент5 страницCLC4003 Hardnessarif.haddieОценок пока нет

- CZLLCW511L TN enДокумент4 страницыCZLLCW511L TN endrgilleОценок пока нет

- Bushings For PT MY2014Документ36 страницBushings For PT MY2014Shung Tak ChanОценок пока нет

- EMK 6 - DatasheetДокумент1 страницаEMK 6 - Datasheetronaldb322Оценок пока нет

- Stellite 12 Technical DataДокумент2 страницыStellite 12 Technical DataJakeTheSnake69Оценок пока нет

- 03 Bushing-Cedaspa Type FДокумент7 страниц03 Bushing-Cedaspa Type FKatherine SmithОценок пока нет

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesДокумент6 страниц2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobОценок пока нет

- Features: Finishing-Purpose of Negative Chip Breaker For Steel TurningДокумент4 страницыFeatures: Finishing-Purpose of Negative Chip Breaker For Steel TurningArdeleana TisaОценок пока нет

- Stellite 6 DS01-21708 (S R0808)Документ2 страницыStellite 6 DS01-21708 (S R0808)bwv1006Оценок пока нет

- SF-71 en EngДокумент2 страницыSF-71 en EngbvbarcОценок пока нет

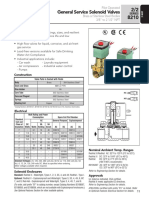

- General Service Solenoid Valves: FeaturesДокумент6 страницGeneral Service Solenoid Valves: FeaturesIgnacio FranОценок пока нет

- PSG Epoxy Glass PhenolicsДокумент1 страницаPSG Epoxy Glass PhenolicsmadhunnadigОценок пока нет

- Datasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Документ7 страницDatasheet-Sandvik-Saf-32760-En-V2020-12-10 07 - 47 Version 1Weipeng LvОценок пока нет

- Quenched and Tempered Alloyed Engineering Steel DINДокумент2 страницыQuenched and Tempered Alloyed Engineering Steel DINkazdoelahОценок пока нет

- Student WorkerIntern For Turbine Control, Siemens GamesaДокумент2 страницыStudent WorkerIntern For Turbine Control, Siemens Gamesachristos032Оценок пока нет

- Two-Dimensional Airfoil TheoryДокумент28 страницTwo-Dimensional Airfoil TheoryNavaneeth Krishnan BОценок пока нет

- AIAA Paper 2015 3296Документ23 страницыAIAA Paper 2015 3296christos032Оценок пока нет

- Assignment Fluid Mechanics 1st WeekДокумент3 страницыAssignment Fluid Mechanics 1st Weekchristos032Оценок пока нет

- Burington On The Use of Conformal Mapping in Shaping Wing ProfilesДокумент13 страницBurington On The Use of Conformal Mapping in Shaping Wing Profileschristos032Оценок пока нет

- Continuum PhysicsДокумент2 страницыContinuum Physicschristos032Оценок пока нет

- Assignment Fluid Mechanics 3rd WeekДокумент2 страницыAssignment Fluid Mechanics 3rd Weekchristos032Оценок пока нет

- (Reid, Et Al.,2006) - Detailed Tire Modelling For Crash Applications PDFДокумент11 страниц(Reid, Et Al.,2006) - Detailed Tire Modelling For Crash Applications PDFchristos032Оценок пока нет

- References: Continua, 2010, Cambridge University Press, New YorkДокумент1 страницаReferences: Continua, 2010, Cambridge University Press, New Yorkchristos032Оценок пока нет

- PavlidisDimakopoulosTsamopoulos 2009RheolActaДокумент19 страницPavlidisDimakopoulosTsamopoulos 2009RheolActachristos032Оценок пока нет

- Biotsavart PDFДокумент3 страницыBiotsavart PDFchristos032Оценок пока нет

- Partial Differential Equations: MST209 Mathematical Methods and ModelsДокумент32 страницыPartial Differential Equations: MST209 Mathematical Methods and Modelschristos032Оценок пока нет

- Dogal LAD High Strength Low Alloy Steels For Cold Forming: GeneralДокумент2 страницыDogal LAD High Strength Low Alloy Steels For Cold Forming: Generalchristos032Оценок пока нет

- 308 - Dogal LAD PDFДокумент2 страницы308 - Dogal LAD PDFchristos032Оценок пока нет

- Lug Analysis - MechaniCalc PDFДокумент20 страницLug Analysis - MechaniCalc PDFchristos032Оценок пока нет

- Analysis of Plates On Elastic Foundations PDFДокумент97 страницAnalysis of Plates On Elastic Foundations PDFchristos032Оценок пока нет

- 319 - Docol Product Program PDFДокумент2 страницы319 - Docol Product Program PDFchristos032Оценок пока нет

- SSAB - 912 en Bending of High Strength Steel PDFДокумент8 страницSSAB - 912 en Bending of High Strength Steel PDFchristos032Оценок пока нет

- 319 Docol Product ProgramДокумент2 страницы319 Docol Product Programchristos032Оценок пока нет

- (Tolbert, R. N., & R. M. Hackett, 1974) - Experimental Investigation of Lug Stresses and Failures PDFДокумент4 страницы(Tolbert, R. N., & R. M. Hackett, 1974) - Experimental Investigation of Lug Stresses and Failures PDFchristos032Оценок пока нет

- Plinth Beam and FoundationДокумент1 страницаPlinth Beam and FoundationSteny AbrahamОценок пока нет

- SANS1655ED1 1 - 04-10-22 - WP - TMДокумент15 страницSANS1655ED1 1 - 04-10-22 - WP - TMjohndupОценок пока нет

- SCC Containing Coal Fly Ash and Bottom AshДокумент9 страницSCC Containing Coal Fly Ash and Bottom AshGeorgeEdwardОценок пока нет

- Steam Trap FT450Документ3 страницыSteam Trap FT450joel angel Pinedo GamarraОценок пока нет

- Standard Penetration TestДокумент59 страницStandard Penetration TestcuervohijoguachoОценок пока нет

- Sentry Wellhead Catalog PDFДокумент129 страницSentry Wellhead Catalog PDFMuhammad TahirОценок пока нет

- Cib2010 - Design-Bid-Build Versus Design-Build - The Client's ChoiceДокумент14 страницCib2010 - Design-Bid-Build Versus Design-Build - The Client's ChoiceVan khuongОценок пока нет

- Tube-To-Tube Sheet Joint RequirementsДокумент2 страницыTube-To-Tube Sheet Joint RequirementsWaqas WaqasОценок пока нет

- PROBLEMASДокумент6 страницPROBLEMASAlejandro Claros100% (1)

- James StirlingДокумент30 страницJames StirlingRajniОценок пока нет

- University Forum: Item Description Qty Unit Rate (AED) Amount (AED) Drainage InstallationДокумент5 страницUniversity Forum: Item Description Qty Unit Rate (AED) Amount (AED) Drainage InstallationMohammed AzharОценок пока нет

- A Rehabilitation of RCC - PSC BridgesДокумент77 страницA Rehabilitation of RCC - PSC BridgesOneTech ManОценок пока нет

- Hollow SectionsДокумент199 страницHollow SectionsmandregomesОценок пока нет

- Design and Analysis of G+3 Building by Using Staad Pro: Mini ProjectДокумент10 страницDesign and Analysis of G+3 Building by Using Staad Pro: Mini ProjectsaikirankasivojjulaОценок пока нет

- A. Tes BQ StrukturДокумент1 страницаA. Tes BQ Strukturdian faniОценок пока нет

- Foundation For Civil EngineeringДокумент2 страницыFoundation For Civil Engineeringmudassir2640Оценок пока нет

- Sun Temple, GujratДокумент11 страницSun Temple, GujratSejal MengajiОценок пока нет

- Approximate BOQ For Limestone Crusher & Load CentreДокумент8 страницApproximate BOQ For Limestone Crusher & Load CentreSasanka SekharОценок пока нет

- Construction Claims Management Towards An Agent Based ApproachДокумент13 страницConstruction Claims Management Towards An Agent Based Approachringlove97Оценок пока нет

- Aci-305r 91 PDFДокумент20 страницAci-305r 91 PDFSiddharth Garg100% (1)

- What Is Corten SteelДокумент11 страницWhat Is Corten SteelNavneet SinghОценок пока нет

- Katalog Vers 2 ReprintДокумент52 страницыKatalog Vers 2 ReprintfernandoОценок пока нет

- Product Data Sheet Check Valve: General Arrangement DrawingДокумент2 страницыProduct Data Sheet Check Valve: General Arrangement DrawingArunОценок пока нет

- DanlyIEM Pins Bushings InchДокумент48 страницDanlyIEM Pins Bushings InchGustavo OrozcoОценок пока нет

- Elastisitas MaterialДокумент4 страницыElastisitas MaterialRantih FebriОценок пока нет

- Manual For Safety / Technical Audit of Power Distribution SystemДокумент44 страницыManual For Safety / Technical Audit of Power Distribution SystemAnand ShekharОценок пока нет

- 27 Jul 2018 Tenders Bids of Pakistan by Maven PKДокумент162 страницы27 Jul 2018 Tenders Bids of Pakistan by Maven PKMaven PKОценок пока нет

- Report Water Resources - Spillways, Crest Gates, and Outlet WorksДокумент13 страницReport Water Resources - Spillways, Crest Gates, and Outlet WorksChristian BaldoОценок пока нет

- Integrated Ventilation BrochureДокумент20 страницIntegrated Ventilation BrochureDhirendra Singh RathoreОценок пока нет

- MS Basement Slab Casting (Completed)Документ72 страницыMS Basement Slab Casting (Completed)Hafiz Kamarudin100% (2)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (242)

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationОт EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettРейтинг: 4 из 5 звезд4/5 (1)

- Real Life: Construction Management Guide from A-ZОт EverandReal Life: Construction Management Guide from A-ZРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyОт EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyРейтинг: 4 из 5 звезд4/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionОт EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionРейтинг: 4.5 из 5 звезд4.5/5 (2)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneОт EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОт EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesОценок пока нет

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tОт EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tРейтинг: 4.5 из 5 звезд4.5/5 (27)

- Building Construction Technology: A Useful Guide - Part 1От EverandBuilding Construction Technology: A Useful Guide - Part 1Рейтинг: 4 из 5 звезд4/5 (3)

- Civil Engineer's Handbook of Professional PracticeОт EverandCivil Engineer's Handbook of Professional PracticeРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyОт EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyРейтинг: 4 из 5 звезд4/5 (1)

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessОт EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessРейтинг: 5 из 5 звезд5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)