Академический Документы

Профессиональный Документы

Культура Документы

Scissor Lift Pre Delivery Inspection Report PDF

Загружено:

lanza206Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Scissor Lift Pre Delivery Inspection Report PDF

Загружено:

lanza206Авторское право:

Доступные форматы

JLG Industries, Inc.

SCISSOR LIFT

1 JLG Drive

McConnellsburg, PA 17233-9533 Pre-Delivery and Frequent Inspection Report

JLG Account Holder Name & Address Product Owner/User Name & Address

Serial Number: Customer No. : Owner User

Machine Model:

Hourmeter Reading:

INSPECTION TYPE: Pre-Delivery (Previous Inspection Date) Frequent (Previous Inspection Date)

PRE-DELIVERY . . . . . The Dealer/Owner must perform a Pre-Delivery Inspection of this machine prior to each delivery by sale, lease, or rental.

FREQUENT . . . . . . . . The Owner must perform, by a qualified mechanic, a Frequent Inspection of this machine every three months or 150 hours of operation, whichever comes first.

Check each item below. (Refer to Operators & Safety, Service & Maintenance Manuals for specific information regarding inspection procedures and criteria.) Indicate in the appropriate space as each item has been performed. If the item is

found to be not acceptable, describe each discrepancy in the comments space at the bottom of the form. Use additional paper if necessary. Immediate action must be taken to correct all discrepancies. The Owner shall not place the machine

in service until all discrepancies have been corrected.

Y=Yes (Passed) N=NO (Failed) C=Corrected NA=Not Applicable Y N C NA Y=Yes (Passed) N=NO (Failed) C=Corrected NA=Not Applicable Y N C NA Y=Yes (Passed) N=NO (Failed) C=Corrected NA=Not Applicable Y N C NA

FUNCTIONS & CONTROLS CHASSIS MANUALS & DECALS

1. Control levers, switches, gauges and instruments operate prop- 1. Wheel rim nuts torqued properly. 1. ANSI/SIA Manual of Responsibilities in manual storage box.

erly, including options (horn, lights, etc.).

2. Check tires for proper inflation, damage & wear. 2. Operators & Safety Manual in manual storage box.

2. Detents properly lock controls in place. Check condition of control

enclosures and protective boots/guards. 3. Steer, drive & axle components secure & undamaged. 3. AEM Handbook in manual storage box.

3. Emergency stop switches at the ground & platform control stations 4. Outriggers/stabilizers operate properly. 4. Capacity decals in place, secure & legible at both ground & plat-

operate properly, (shuts off controls & engine). form stations.

5. Hydraulic tray & battery/engine compartment covers open & latch

4. Lift, drive & speed cut-outs operate properly. properly. 5. All instruction & safety placards installed & legible.

5. Manual descent/auxiliary power system operates properly. 6. Static strap is in place. (If applicable) GENERAL

6. Function enable system if equipped, operates properly. (Disables POWER SYSTEM 1. Lift is free of unauthorized modifications or additions.

functions within 3 seconds).

1. Engine idle, throttle & RPM set properly. 2. Paint and overall appearance.

7. Brakes operate properly.

2. Fluid levels correct, hydraulic tank, engine oil, torque hubs, coolant 3. Applicable Safety Bulletins completed.

8. Machine functions operate properly at both ground & platform con- & batteries.

trols (lift, manual descent, etc..). 4. Inspect general structural condition including all welds.

3. Air & fuel filter clean.

PLATFORM ASSEMBLY 5. Grease and lubricate per Service & Maintenance Manual.

4. Fuel cap tight & vent open.

6. Is Annual Inspection due?

1. Platform installed & secure. 5. Exhaust system free of leaks. (Gas/diesel units only)

7. If machine ownership has changed complete attached Owner

2. Platform extension deck & related components secure & undam- 6. Pumps & motor secure, undamaged & free of leaks. Update form and return to JLG.

aged.

HYDRAULIC/ELECTRICAL SYSTEM COMMENTS:

3. Platform rails installed & secure, midrail chain/gate and bars

installed & latch properly.

1. All cylinders free of leaks and damage.

SCISSOR ARMS 2. Hydraulic filter clean.

1. Scissor arms free of damage, cracks and distortion. 3. Hydraulic oil level in tank correct.

2. Arm safety props operational. 4. Hydraulic tank cap tight & vent open.

3. Cylinder pins, pivot pins & attaching hardware secure & undam- 5. All hydraulic fittings & lines secure, free of damage, chafing &

aged. leaks.

4. Arm pins, wear pads & attaching hardware secure & undamaged. 6. All electrical connections tight, no corrosion or abrasions.

The undersigned certifies that this machine has been inspected, per each area of inspection, and any and all discrepancies have been brought to the attention of the Owner/User, and that all discrepancies have been corrected prior to any fur-

ther use of this machine.

JLG Account Holder: / / Owner/User: / /

Authorized Signature Printed Signature Date Authorized Signature Printed Signature Date

Copy to JLG Account Holder; Copy to Owner/User; Owner Update Form send to JLG Industries, Inc. as required Form No.- 3124128 - CGF484 - 3/16/2005

Вам также может понравиться

- Scissor Lift Annual Inspection Report AU PDFДокумент1 страницаScissor Lift Annual Inspection Report AU PDFMohd AidilОценок пока нет

- Item Description: From GroundДокумент16 страницItem Description: From GroundJhun Aquino100% (1)

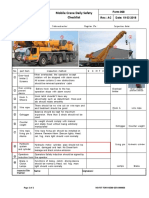

- Tower Crane Daily Inspection Form PDFДокумент1 страницаTower Crane Daily Inspection Form PDFMd Imteyaz AnsariОценок пока нет

- Telehandler ChecklistДокумент1 страницаTelehandler Checklistjapv_pasОценок пока нет

- Excavator Pre-Use InspectionДокумент1 страницаExcavator Pre-Use Inspectionshabban4uОценок пока нет

- Inspection ChecklistДокумент6 страницInspection Checklistmechman5Оценок пока нет

- Manlift 60-80 A PDFДокумент2 страницыManlift 60-80 A PDFvpizarro_23Оценок пока нет

- Concrete Pump (Static) ChecklistДокумент1 страницаConcrete Pump (Static) ChecklistKannan JaganОценок пока нет

- Forklift Service ReportДокумент1 страницаForklift Service ReportBarathОценок пока нет

- Daily Check List Wheel Loader R.001Документ2 страницыDaily Check List Wheel Loader R.001Maulana YusufОценок пока нет

- Hyster H1.5-3.5XT Operators ManualДокумент127 страницHyster H1.5-3.5XT Operators ManualAchmad WaluyoОценок пока нет

- Unlocked - F031 - Tower Crane Inspection Report - Rev 0Документ2 страницыUnlocked - F031 - Tower Crane Inspection Report - Rev 0Minami ChiengОценок пока нет

- M/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker ChecklistДокумент2 страницыM/S Kapoor Enterprises Vendor Code: K635: Mechanized Rock Breaker Checklistprojit basu100% (1)

- New Mobile Crawler Crane ChecklistДокумент2 страницыNew Mobile Crawler Crane ChecklistsunilОценок пока нет

- Crawler Crane Annual InspectionДокумент3 страницыCrawler Crane Annual InspectionMark SolmundsonОценок пока нет

- Excavator FormsДокумент5 страницExcavator FormsMarc ChuttooОценок пока нет

- Daily Pre-Operationla Check List (Tower Crane)Документ1 страницаDaily Pre-Operationla Check List (Tower Crane)Soufian BahmadОценок пока нет

- JAPL-F-HE-007-Concrete Pump ChecklistДокумент1 страницаJAPL-F-HE-007-Concrete Pump ChecklistFarrukh IjazОценок пока нет

- Safety & Maintenance Checklist Underground Trucks PDFДокумент1 страницаSafety & Maintenance Checklist Underground Trucks PDFGustavoОценок пока нет

- Excavator Pre-Use Inspection ChecklistДокумент1 страницаExcavator Pre-Use Inspection ChecklistFyan SaputraОценок пока нет

- Checklist BobcatДокумент1 страницаChecklist BobcatRajesh Kumar SinghОценок пока нет

- 8042 Parts Manual Serial Number 13197 and BeforeДокумент412 страниц8042 Parts Manual Serial Number 13197 and BeforeAlberth Mauricio Casteblanco GomezОценок пока нет

- 19-F13 Vehicle Mounted Crane Inspection ChecklistДокумент2 страницы19-F13 Vehicle Mounted Crane Inspection ChecklistSn Ahsan100% (1)

- Crane Daily Inspection Checklist-Sa 9466Документ1 страницаCrane Daily Inspection Checklist-Sa 9466Ricardo DalisayОценок пока нет

- Boom Placer Safety Inspection ChecklistДокумент1 страницаBoom Placer Safety Inspection ChecklistMyo LwinОценок пока нет

- Tower Cranes CommisioningДокумент15 страницTower Cranes Commisioningpammu18Оценок пока нет

- Welding Generator ChecklistДокумент1 страницаWelding Generator ChecklistAbdus SamadОценок пока нет

- Crane Assembling Check ListДокумент2 страницыCrane Assembling Check ListBaldev SinghОценок пока нет

- Excavator Inspection ChecklistДокумент1 страницаExcavator Inspection ChecklistArsalan Ahmad100% (2)

- 3 Mobile Crane ChecklistДокумент5 страниц3 Mobile Crane ChecklistEriq100% (1)

- Genie Z-60/34 Boom LiftДокумент2 страницыGenie Z-60/34 Boom LiftAnonymous arnc2g2NОценок пока нет

- Link Belt RTC8080tДокумент24 страницыLink Belt RTC8080tKreatif DesainОценок пока нет

- Form-068-Mobile Crane Daily Safety ChecklistДокумент1 страницаForm-068-Mobile Crane Daily Safety Checklistshamroz khan0% (1)

- Crane Inspection Form: Carry-In CertificateДокумент2 страницыCrane Inspection Form: Carry-In CertificateWisnu Suryo Andriyanto AndriyantoОценок пока нет

- Mobile Plant Checklist - Drum RollerДокумент1 страницаMobile Plant Checklist - Drum Rollerosama F. MohamedОценок пока нет

- Telehandler Daily Inspection ChecklistДокумент2 страницыTelehandler Daily Inspection ChecklisthoverОценок пока нет

- MANUAL DE PARTES AJ - 600A, 600AJ - JLG - Parts - EnglishДокумент344 страницыMANUAL DE PARTES AJ - 600A, 600AJ - JLG - Parts - Englishfercho_50Оценок пока нет

- Crawler Crane ACX750Документ11 страницCrawler Crane ACX750Joshua100% (1)

- Astra D.truck ChecklistДокумент9 страницAstra D.truck ChecklistEyobОценок пока нет

- Crawler Crane Checklist Rev 0Документ2 страницыCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- Backhoe-Rock Breaker Inspection ChecklistДокумент1 страницаBackhoe-Rock Breaker Inspection ChecklistAlok Singh100% (1)

- GD380A-L ListДокумент6 страницGD380A-L ListNam Won HongОценок пока нет

- Operator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsДокумент1 страницаOperator'S Pre-Operation Checklist Electric Pallet Jack: Have A Qualified Mechanic Correct All ProblemsPradeep ShindeОценок пока нет

- Operator Daily ChecklistДокумент5 страницOperator Daily ChecklistkrissregionОценок пока нет

- Palfinger PK 15500 Load ChartДокумент2 страницыPalfinger PK 15500 Load ChartD Chandra Sekhar100% (2)

- ChecklistДокумент24 страницыChecklistkalibrasi xray,kalibrasi x-ray,kalibrasi mesin x-ray,kalibrasi pesawat x ray,sop kalibrasi xray,Оценок пока нет

- Gr-500exl R S GДокумент16 страницGr-500exl R S GRizka RokhimОценок пока нет

- 4 2 Assembly (JT262.12)Документ20 страниц4 2 Assembly (JT262.12)mliugongОценок пока нет

- Fork ArmДокумент26 страницFork ArmtulogmulatОценок пока нет

- Form Check List Maintenance: Activity 250 500 1000 2000 RemarksДокумент1 страницаForm Check List Maintenance: Activity 250 500 1000 2000 Remarksferry saputra100% (2)

- DoosanCARE Maintenance Inspection - Wheel LoaderДокумент2 страницыDoosanCARE Maintenance Inspection - Wheel Loaderchady tanОценок пока нет

- 5878 en-GB Loadall RB 1Документ28 страниц5878 en-GB Loadall RB 1Daniel CringusОценок пока нет

- Ww6lhtwv6muUOvTZLink-Belt HTC-8690 90-Ton Telescopiv Boom Truck Crane NetworkДокумент48 страницWw6lhtwv6muUOvTZLink-Belt HTC-8690 90-Ton Telescopiv Boom Truck Crane NetworkKhawaja Arslan AhmedОценок пока нет

- TB145 BrochureДокумент4 страницыTB145 Brochurematej1992Оценок пока нет

- Crawler CraneДокумент2 страницыCrawler CraneFarukBasyoriОценок пока нет

- Saber Lube MSD Shears Users ManualДокумент117 страницSaber Lube MSD Shears Users ManualRaúl Appelgren AstorgaОценок пока нет

- Inspection Checklist Overhead Crane PDFДокумент2 страницыInspection Checklist Overhead Crane PDFMOST PASONОценок пока нет

- Tower Crane Daily Inspection Form PDFДокумент1 страницаTower Crane Daily Inspection Form PDFMd Imteyaz AnsariОценок пока нет

- Scissor Lift Annual Inspection Report PDFДокумент2 страницыScissor Lift Annual Inspection Report PDFdayana garvez contrerasОценок пока нет

- VP MSP MP Annual Inspection Report PDFДокумент1 страницаVP MSP MP Annual Inspection Report PDFlanza206Оценок пока нет

- Technical Information: Range-Free Controller FA-M3 System Upgrade GuideДокумент33 страницыTechnical Information: Range-Free Controller FA-M3 System Upgrade GuideAddaОценок пока нет

- DMDWLab Book AnswersДокумент44 страницыDMDWLab Book AnswersNarpat Makwana Pune100% (1)

- Indor Lighting DesignДокумент33 страницыIndor Lighting DesignRajesh MalikОценок пока нет

- Dusta ManaДокумент16 страницDusta ManamahaphalaОценок пока нет

- Dual Op Amp and Voltage Reference Ap4310/AДокумент12 страницDual Op Amp and Voltage Reference Ap4310/AМихаил ЯненкоОценок пока нет

- Keiilf: Training ManualДокумент53 страницыKeiilf: Training ManualGary GouveiaОценок пока нет

- The Light Fantastic by Sarah CombsДокумент34 страницыThe Light Fantastic by Sarah CombsCandlewick PressОценок пока нет

- Halfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PДокумент92 страницыHalfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PTulusОценок пока нет

- EN Manual Lenovo Ideapad S130-14igm S130-11igmДокумент33 страницыEN Manual Lenovo Ideapad S130-14igm S130-11igmDolgoffОценок пока нет

- G.S 5Документ2 страницыG.S 5Jamsher BalochОценок пока нет

- Sales 20: Years Advertising Expense (Millions) X Sales (Thousands) yДокумент8 страницSales 20: Years Advertising Expense (Millions) X Sales (Thousands) ybangОценок пока нет

- Midterm Exam Gor Grade 11Документ2 страницыMidterm Exam Gor Grade 11Algelle AbrantesОценок пока нет

- VBAC MCQsДокумент3 страницыVBAC MCQsHanaОценок пока нет

- Clevo W940tu Service ManualДокумент93 страницыClevo W940tu Service ManualBruno PaezОценок пока нет

- Harmonics PatternsДокумент4 страницыHarmonics PatternsIzzadAfif1990Оценок пока нет

- Managing Diabetic Foot Ulcers ReadingДокумент21 страницаManaging Diabetic Foot Ulcers Readinghimanshugupta811997Оценок пока нет

- Proefschrift T. Steenstra - tcm24-268767Документ181 страницаProefschrift T. Steenstra - tcm24-268767SLAMET PAMBUDIОценок пока нет

- 1762 Ob8 PDFДокумент16 страниц1762 Ob8 PDFRodríguez EdwardОценок пока нет

- 2022 Audi e Tron 22Документ318 страниц2022 Audi e Tron 22Alejandro Alberto Robalino MendezОценок пока нет

- SDHI18 - Komparativna Analiza Primene Vodostana I Sinhronih Regulatora TurbinaДокумент13 страницSDHI18 - Komparativna Analiza Primene Vodostana I Sinhronih Regulatora TurbinaAleksandar PetkovicОценок пока нет

- Fighting Techniques of The Early Modern World AD 1500-AD 1763 - Equipment Combat Skills Amp Amp TacticsДокумент258 страницFighting Techniques of The Early Modern World AD 1500-AD 1763 - Equipment Combat Skills Amp Amp Tacticslupoeva100% (3)

- H107en 201906 r4 Elcor Elcorplus 20200903 Red1Документ228 страницH107en 201906 r4 Elcor Elcorplus 20200903 Red1mokbelОценок пока нет

- Solutions GoldsteinДокумент10 страницSolutions GoldsteinAnyiОценок пока нет

- DR PDFДокумент252 страницыDR PDFa_ouchar0% (1)

- Presentation On 4G TechnologyДокумент23 страницыPresentation On 4G TechnologyFresh EpicОценок пока нет

- Electricity NotesДокумент35 страницElectricity Notesapi-277818647Оценок пока нет

- Recipes From The Perfect Scoop by David LebovitzДокумент10 страницRecipes From The Perfect Scoop by David LebovitzThe Recipe Club100% (7)

- Drilling & GroutingДокумент18 страницDrilling & GroutingSantosh Laxman PatilОценок пока нет

- Manual PipsДокумент5 страницManual PipsOzzyОценок пока нет

- Esteem 1999 2000 1.3L 1.6LДокумент45 страницEsteem 1999 2000 1.3L 1.6LArnold Hernández CarvajalОценок пока нет