Академический Документы

Профессиональный Документы

Культура Документы

11 Exprosoft+-+Integrated+well+integrity+&+reliability+management

Загружено:

LawОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

11 Exprosoft+-+Integrated+well+integrity+&+reliability+management

Загружено:

LawАвторское право:

Доступные форматы

INTEGRATED WELL INTEGRITY & RELIABILITY MANAGEMENT

How experience from well operations creates value in other areas

Well Integrity Management Well Equipment Reliability Well Life Simulator

Martin Relling, MSc

Well Integrity Consultant

INTEGRATED WELL INTEGRITY & RELIABILITY MANAGEMENT

How experience from well operations creates value in other areas

19%

TOP WELL INTEGRITY “Studies have shown that

OPERATIONAL CHALLENGE:

Gathering & Analyzing Data

760,000 wells

77%

SPE North Sea Well Integrity Forum,

2009/Drilling Engineering Association

Europe, 2010

globally are affected by well integrity

related problems

www.naturalgaswatch.org/wp-

of these wells being shut-

in - $1 billion/day lost.”

content/uploads/2011/09/well_integrity_failure_presentation.pdf

Martin Relling, MSc

Well Integrity Consultant

INTEGRATED WELL INTEGRITY & RELIABILITY MANAGEMENT

Well Integrity Well Reliability

RAM Simulations

Management Data

Monitoring & testing Pre-build models for

Equipment data

of barriers in place. simulation well and

field performance

Failure data

Keeping overview of based on reliability

failed barriers or data.

Operational data

equipment

Well Component Well System Installation/field

Martin Relling, MSc

Well Integrity Consultant

WELLMASTER INTEGRITY MANAGEMENT

Managing well integrity in operations

DETECT ANALYZE REACT

Failure Detection

Monitoring & wellhead/casing/tubing verification

Inflow Testing & Valve Function Verification

Martin Relling, MSc

Well Integrity Consultant

Failure Reporting Lift ga

pipe li

Testing & Monitoring is the basis Well Integrity management DHSV

for understanding the status of

ASV assembly

the well.

Action management

GLV

(not a well barrier elem

Deviation management Production packer

Martin Relling, MSc

Well Integrity Consultant

Operational Overview

Well overview & Trending & Analytics

Dashboards

OVERWIEV & CONTROL Reporting &

Exports

Martin Relling, MSc

Well Integrity Consultant

Experience from one Reduced number Transparent

operator implementing of shut in wells

performance

4% limits

Martin Relling, MSc

Well Integrity Consultant

How can we get more value out of test data?

Martin Relling, MSc

Well Integrity Consultant

WELLMASTER EQUIPMENT RELIABILITY

Storing test/failure data

for a more extensive use

WellMaster Data

Asset & Well Data

Operator, location, field,

operational conditions, fluids, etc.

Equipment Data

Vendor, model, serial no, dimensions,

metal type, etc.

Equipment History

Dates (installed, start operations, pulled),

service time, change of fluids, etc.

Failure Data

Failure type, mode & category, leak rate, intervention type, etc. Started collecting DHSV failures in 1983

Martin Relling, MSc 11

Well Integrity Consultant

Reliability Calculations for Components

Filter on:

• Country

• Failure mode

• Failure cause

• Fluid type

• Reservoir pressure &

temperature

• Installation period

• …and more

Example above: Benchmarking company (ExproSoft

Oil) with one particular field (Munkholm)

Example right: Failure rate per service year –

“bathtub curve”

Martin Relling, MSc

Well Integrity Consultant

Reliability Calculations for Components

Comparing failure rates between fluid types, for a specific component

(top). See the distribution of failure modes for each filter (bottom).

Martin Relling, MSc

Well Integrity Consultant

The WellMaster Program

Well equipment experience data

fed back to WellMaster RMS

Operat or 1

Operat or 2

Quality assurance Data anonymized in the Reports, benchmarking, Decisions made and

by ExproSoft WellMaster Program database and analysis based on a implemented in the field

larger data set

Operat or 3

Data Collection for 30+ Years from 20+ Operators

Martin Relling, MSc

Well Integrity Consultant

What integrity & performance failures is seen?

Scale

40%

Corrosion

Safety & other control systems

Annular Integrity

Tubulars - risk of uncontrolled discharge

0% 5% 10% 15% 20% 25% 30% 35% 40% 45%

OTM Consulting & Archer market survey 2010. Data shows relative distribution failures affecting well performance

encountered by survey participants. Based on global industry sample of 20 well performance experts

ExproSoft has done

Case: Robust well design

SAVING

~350

required for high impact wells.

expert studies for

Result: Zero downtime due to

DHSV failures for 7 years across all $200M

wells.

operators world-wide

Martin Relling, MSc

Well Integrity Consultant

WELLMASTER SIMULATOR

Predicting the future based on experience

Simulation types

Well System Simulations Field Simulations

Failure rate

Wing Valves

- Robust well design

- Remnant well life per well

- Leak to environment probability per well

Failure rate - Shut-in due to well integrity per well

Master Valves

Operational

Parameters

Failure rate - Predicting workover/intervention type &

DHSV

Failure rate frequency

Casing - Forecasting Production capacity

- Managing stock of spareparts

Failure rate

FIV/Screen etc.

Martin Relling, MSc

Well Integrity Consultant

Global WellMaster Operators

Global WellMaster Consultant Users

Martin Relling, MSc

Well Integrity Consultant

Martin Relling, MSc

Well Integrity Consultant

Вам также может понравиться

- Generator Condition Assessment Rev4Документ1 страницаGenerator Condition Assessment Rev4Ary SSОценок пока нет

- Reliaibility ToolsДокумент31 страницаReliaibility ToolsJose Alexander Peña BecerraОценок пока нет

- Vail PlantДокумент42 страницыVail PlantVelosiОценок пока нет

- RAM (Reliability, Availability and Maintainability) Analysis - Toyo Engineering CorporationДокумент3 страницыRAM (Reliability, Availability and Maintainability) Analysis - Toyo Engineering CorporationHafsa JalalОценок пока нет

- SM101 Life Expectancy Analysis Program (LEAP) Rev AДокумент2 страницыSM101 Life Expectancy Analysis Program (LEAP) Rev Aashish0011Оценок пока нет

- Testing and Diagnostics of Reclosers and Sectionalizers Brochure ENUДокумент16 страницTesting and Diagnostics of Reclosers and Sectionalizers Brochure ENUjagmcinquitosОценок пока нет

- Understanding The Elements of Operational Reliability A Key For Achieving High ReliabilityДокумент21 страницаUnderstanding The Elements of Operational Reliability A Key For Achieving High ReliabilitytohemaОценок пока нет

- Greg Jones, Ph.D. Configuration Aerodynamics Branch: Slide 1 of 21 June 7 - 11, 2015Документ26 страницGreg Jones, Ph.D. Configuration Aerodynamics Branch: Slide 1 of 21 June 7 - 11, 2015Tarık YılmazОценок пока нет

- Myremotecare: Introduction and Customer BenefitsДокумент44 страницыMyremotecare: Introduction and Customer Benefitsمحمد مОценок пока нет

- Stuart Wright Capability Feb 21Документ19 страницStuart Wright Capability Feb 21Julian Barrero MontalvoОценок пока нет

- Coating and Services: Interplan Asset IntegrityДокумент22 страницыCoating and Services: Interplan Asset IntegritynarmathaОценок пока нет

- CD-00519-002 Anh N en 2018-07-06Документ2 страницыCD-00519-002 Anh N en 2018-07-06Nicole de Castro RoveriОценок пока нет

- Reliability ToolsДокумент40 страницReliability ToolsgmitsutaОценок пока нет

- VAIL-Plant: Asset Integrity Management SoftwareДокумент40 страницVAIL-Plant: Asset Integrity Management SoftwareSyed Shiraz AliОценок пока нет

- Presentation of Mr. Sambasiva Rao UppalaДокумент27 страницPresentation of Mr. Sambasiva Rao UppalaRabindra RaiОценок пока нет

- The Failure Analysis and Troubleshooting System 1999Документ9 страницThe Failure Analysis and Troubleshooting System 1999Ridho Iqbal MaulanaОценок пока нет

- PRiSM 2.9.4 Predictive Asset AnalyticsДокумент19 страницPRiSM 2.9.4 Predictive Asset AnalyticsDeusdedit MottaОценок пока нет

- Module 3 Integrity Management PDFДокумент96 страницModule 3 Integrity Management PDFElias Jurado Teixeira100% (1)

- Automation and Integration Solutions For Electric Power SystemsДокумент16 страницAutomation and Integration Solutions For Electric Power SystemsMadhusudhan SrinivasanОценок пока нет

- Maintain Integrity and Increase Reliability: Safely Ensure More Up-Time Productivity by Increasing Asset ReliabilityДокумент2 страницыMaintain Integrity and Increase Reliability: Safely Ensure More Up-Time Productivity by Increasing Asset ReliabilityM AОценок пока нет

- Plant Wellness Way Book Process3-Numerate Your Options PDFДокумент30 страницPlant Wellness Way Book Process3-Numerate Your Options PDFrbdubey2020Оценок пока нет

- 04 Machine Learning Maintenance Predictive Cline2017Документ7 страниц04 Machine Learning Maintenance Predictive Cline2017Napoleón Hernandez VenegasОценок пока нет

- A347723 PDFДокумент48 страницA347723 PDFSanjay ParelkarОценок пока нет

- Gregg Schwartz 507-438-6703: ISO 18436-2 & ASNT Vibration Condition Monitoring CertificationsДокумент7 страницGregg Schwartz 507-438-6703: ISO 18436-2 & ASNT Vibration Condition Monitoring CertificationsGerardo RosalesОценок пока нет

- Sensitivity and Reliability of Commercial Drill-String Inspection ServicesДокумент8 страницSensitivity and Reliability of Commercial Drill-String Inspection ServicesFélix Gallo CruzОценок пока нет

- Kelompok 3 Keandalan, Ketersediaan Dan Keterpeliharaan AsetДокумент36 страницKelompok 3 Keandalan, Ketersediaan Dan Keterpeliharaan AsetMuhammad ArnezОценок пока нет

- 20 - CCD Iow RefineryДокумент2 страницы20 - CCD Iow RefineryRASHEED YUSUFОценок пока нет

- FR2 Asset ManagementДокумент49 страницFR2 Asset Managementjuan dela cruzОценок пока нет

- NERC Application of Power Line CarrierДокумент50 страницNERC Application of Power Line Carrierschaefer1015719Оценок пока нет

- Elec. AMNДокумент63 страницыElec. AMNAiman Al ArabОценок пока нет

- Assessment of Reliability and Maintenance of Motor Operated Valves at Finnish NppsДокумент9 страницAssessment of Reliability and Maintenance of Motor Operated Valves at Finnish NppsSuswantoro ToroОценок пока нет

- Implementing FDC in The Wafer Dicing Process - APC2017Документ17 страницImplementing FDC in The Wafer Dicing Process - APC2017Iain Alexander RossОценок пока нет

- Ongoing Challenges With IBRs Slide Deck 2Документ54 страницыOngoing Challenges With IBRs Slide Deck 2sulemankhalidОценок пока нет

- Paper RE - GAP AssessmentДокумент5 страницPaper RE - GAP AssessmentMiguelОценок пока нет

- Valve Ims PDFДокумент41 страницаValve Ims PDFnurul137Оценок пока нет

- Clinical Trial Management System: Investigator Portal Datasheet - CQДокумент7 страницClinical Trial Management System: Investigator Portal Datasheet - CQCompliance QuestОценок пока нет

- Psi Energy Infra Business Profile Update Nov 2017Документ21 страницаPsi Energy Infra Business Profile Update Nov 2017bhavesh shettyОценок пока нет

- TNM Wireless UMTS Summary Inspection Report - SummaryДокумент52 страницыTNM Wireless UMTS Summary Inspection Report - SummaryJoseph F ChikuseОценок пока нет

- NPRA Final PresentationДокумент34 страницыNPRA Final PresentationCarlos Araujo100% (1)

- Resiliency OrchestrationДокумент24 страницыResiliency OrchestrationNguyen Hai ToanОценок пока нет

- Partial Discharge Analysis and Asset Management: Experiences On Monitoring of Power ApparatusДокумент7 страницPartial Discharge Analysis and Asset Management: Experiences On Monitoring of Power Apparatusduong nguyenОценок пока нет

- Valve Advance DiagnosticДокумент18 страницValve Advance DiagnosticSohaibОценок пока нет

- Triple3 Aviation Company ProfileДокумент19 страницTriple3 Aviation Company ProfilebangkidsОценок пока нет

- Areva FatigueДокумент26 страницAreva Fatigueevo2005_2006Оценок пока нет

- BG - Well Integrity HandbookДокумент9 страницBG - Well Integrity Handbookwalter.tajuОценок пока нет

- Exfo Guide Key Testing Parameter For Dark Fiber enДокумент20 страницExfo Guide Key Testing Parameter For Dark Fiber enJose SanchezОценок пока нет

- 1LAB000613 Life ManagementДокумент2 страницы1LAB000613 Life ManagementAbdullah GhannamОценок пока нет

- Transformer Audits PDFДокумент2 страницыTransformer Audits PDFMuhammad KuncoroОценок пока нет

- DigiMoorX7 Software IntroductionДокумент24 страницыDigiMoorX7 Software IntroductionSachin SikkaОценок пока нет

- M 2 Prosper AideyanДокумент32 страницыM 2 Prosper AideyanJorgito AriasОценок пока нет

- Result Analysis Consulting BrochureДокумент3 страницыResult Analysis Consulting BrochureDennis MendozaОценок пока нет

- How To Analyze Gear FailuresДокумент7 страницHow To Analyze Gear Failuresphucdc095041Оценок пока нет

- Optimizing Maintenance Policies For A Yaw System Using Reliability-Centered Maintenance and Data-Driven Condition MonitoringДокумент9 страницOptimizing Maintenance Policies For A Yaw System Using Reliability-Centered Maintenance and Data-Driven Condition MonitoringclarkyeahОценок пока нет

- Condition Monitoring BlueprintДокумент4 страницыCondition Monitoring BlueprintYuber John Ccoa LabraОценок пока нет

- TESSA® APM - FunctionsДокумент15 страницTESSA® APM - FunctionsHiro ItoОценок пока нет

- Technical Materials: SeriesДокумент24 страницыTechnical Materials: SeriesMuhammad RahimsyahОценок пока нет

- Barringer SMRP Houston 5-7-09 Reliability ToolsДокумент16 страницBarringer SMRP Houston 5-7-09 Reliability ToolsIvan Elias GavidiaОценок пока нет

- Maintenance Product & BenefitsДокумент1 страницаMaintenance Product & Benefitsabhinay guptaОценок пока нет

- Ams Valvelink Snap On ApplicatioДокумент7 страницAms Valvelink Snap On ApplicatiofitasmounirОценок пока нет

- Earnings Highlight - DANGSUGAR PLC 9M 2016Документ1 страницаEarnings Highlight - DANGSUGAR PLC 9M 2016LawОценок пока нет

- The New BicycleДокумент1 страницаThe New BicycleLawОценок пока нет

- Earnings Highlight - Forte Oil Nigeria PLC Fy 2017Документ1 страницаEarnings Highlight - Forte Oil Nigeria PLC Fy 2017LawОценок пока нет

- Market Update For February 6, 2019Документ3 страницыMarket Update For February 6, 2019LawОценок пока нет

- Earnings Highlight - Stanbic IBTC Full Year 2017Документ1 страницаEarnings Highlight - Stanbic IBTC Full Year 2017LawОценок пока нет

- FORTE OIL NIGERIA PLC. FY:2016 Result - Financial Highlights (NGN Billion)Документ1 страницаFORTE OIL NIGERIA PLC. FY:2016 Result - Financial Highlights (NGN Billion)LawОценок пока нет

- Basics of Business ValuationДокумент24 страницыBasics of Business ValuationLawОценок пока нет

- IRP 22 Risk Register 2015Документ11 страницIRP 22 Risk Register 2015LawОценок пока нет

- LBSDecember2018 ProshareДокумент73 страницыLBSDecember2018 ProshareLawОценок пока нет

- Captain Extended Well Test Program - Project Management and ExecutionДокумент12 страницCaptain Extended Well Test Program - Project Management and ExecutionLawОценок пока нет

- SHL Test DocumentsДокумент71 страницаSHL Test DocumentsLaw100% (4)

- SPE-193424-MS Chevron 2018Документ17 страницSPE-193424-MS Chevron 2018LawОценок пока нет

- SPE-173759-MS Scale Modeling in ReservoirsДокумент10 страницSPE-173759-MS Scale Modeling in ReservoirsLawОценок пока нет

- Geomechanical Modeling To Assess Caprock Integrity in Oil SandsДокумент4 страницыGeomechanical Modeling To Assess Caprock Integrity in Oil SandsLawОценок пока нет

- Shell TestДокумент23 страницыShell TestLawОценок пока нет

- Investment TrackerДокумент8 страницInvestment TrackerLawОценок пока нет

- Google App EngineДокумент5 страницGoogle App EngineDinesh MudirajОценок пока нет

- GL 186400 Case DigestДокумент2 страницыGL 186400 Case DigestRuss TuazonОценок пока нет

- Group 1 Disaster Management Notes by D. Malleswari ReddyДокумент49 страницGroup 1 Disaster Management Notes by D. Malleswari Reddyraghu ramОценок пока нет

- Working Capital ManagementДокумент39 страницWorking Capital ManagementRebelliousRascalОценок пока нет

- Microsoft Word - Claimants Referral (Correct Dates)Документ15 страницMicrosoft Word - Claimants Referral (Correct Dates)Michael FourieОценок пока нет

- Engine Diesel PerfomanceДокумент32 страницыEngine Diesel PerfomancerizalОценок пока нет

- Peoria County Jail Booking Sheet For Oct. 7, 2016Документ6 страницPeoria County Jail Booking Sheet For Oct. 7, 2016Journal Star police documents50% (2)

- RevisionHistory APFIFF33 To V219Документ12 страницRevisionHistory APFIFF33 To V219younesОценок пока нет

- Securitron M38 Data SheetДокумент1 страницаSecuritron M38 Data SheetJMAC SupplyОценок пока нет

- Ingles Avanzado 1 Trabajo FinalДокумент4 страницыIngles Avanzado 1 Trabajo FinalFrancis GarciaОценок пока нет

- Instructions For Microsoft Teams Live Events: Plan and Schedule A Live Event in TeamsДокумент9 страницInstructions For Microsoft Teams Live Events: Plan and Schedule A Live Event in TeamsAnders LaursenОценок пока нет

- Specialty Arc Fusion Splicer: FSM-100 SeriesДокумент193 страницыSpecialty Arc Fusion Splicer: FSM-100 SeriesSFTB SoundsFromTheBirdsОценок пока нет

- Basics: Define The Task of Having Braking System in A VehicleДокумент27 страницBasics: Define The Task of Having Braking System in A VehiclearupОценок пока нет

- 5 Deming Principles That Help Healthcare Process ImprovementДокумент8 страниц5 Deming Principles That Help Healthcare Process Improvementdewi estariОценок пока нет

- BS 8541-1-2012Документ70 страницBS 8541-1-2012Johnny MongesОценок пока нет

- Building and Other Construction Workers Act 1996Документ151 страницаBuilding and Other Construction Workers Act 1996Rajesh KodavatiОценок пока нет

- ARUP Project UpdateДокумент5 страницARUP Project UpdateMark Erwin SalduaОценок пока нет

- 500 Logo Design Inspirations Download #1 (E-Book)Документ52 страницы500 Logo Design Inspirations Download #1 (E-Book)Detak Studio DesainОценок пока нет

- Use of EnglishДокумент4 страницыUse of EnglishBelén SalituriОценок пока нет

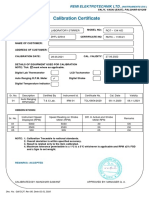

- Calibration CertificateДокумент1 страницаCalibration CertificateSales GoldClassОценок пока нет

- CSEC Jan 2011 Paper 1Документ8 страницCSEC Jan 2011 Paper 1R.D. KhanОценок пока нет

- Presentation Report On Customer Relationship Management On SubwayДокумент16 страницPresentation Report On Customer Relationship Management On SubwayVikrant KumarОценок пока нет

- BSCSE at UIUДокумент110 страницBSCSE at UIUshamir mahmudОценок пока нет

- 2016 066 RC - LuelcoДокумент11 страниц2016 066 RC - LuelcoJoshua GatumbatoОценок пока нет

- What Caused The Slave Trade Ruth LingardДокумент17 страницWhat Caused The Slave Trade Ruth LingardmahaОценок пока нет

- PeopleSoft Application Engine Program PDFДокумент17 страницPeopleSoft Application Engine Program PDFSaurabh MehtaОценок пока нет

- Separation PayДокумент3 страницыSeparation PayMalen Roque Saludes100% (1)

- Himachal Pradesh Important NumbersДокумент3 страницыHimachal Pradesh Important NumbersRaghav RahinwalОценок пока нет

- Government of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Документ2 страницыGovernment of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Satyaki Prasad MaitiОценок пока нет

- RENCANA KERJA Serious Inspeksi#3 Maret-April 2019Документ2 страницыRENCANA KERJA Serious Inspeksi#3 Maret-April 2019Nur Ali SaidОценок пока нет