Академический Документы

Профессиональный Документы

Культура Документы

Belt Rip

Загружено:

Christian Alberto DávilaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Belt Rip

Загружено:

Christian Alberto DávilaАвторское право:

Доступные форматы

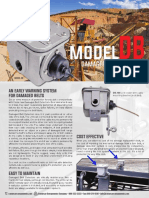

MODEL DAMAGED BELT DETECTOR

DB

MODEL DB

AN EARLY WARNING SYSTEM DB-100 unit shown with cable

FOR DAMAGED BELTS mounting bracket (included).

Get an extra measure of protection for valuable conveyor belts

with these new Damaged Belt Detectors. Economical and easy

to install, they warn supervisory personnel of impending belt

failures due to rips, punctures, splice failures, or sharp objects

protruding through the belt fabric.

Damaged Belt Detectors mount in pairs positioned on either

side of the belt. The units are connected by two spans of vinyl

coated aircraft cable. One end of the cable mounts permanently

to a support bracket and the other connects to a spring-loaded

ball located in the unit. The cables loop underneath the belt

from each side crossing at the midpoint. A belt problem is

detected when an object or a piece of damaged belt hangs

below the belt’s surface and sweeps away one or both cables.

As the cable is detached, it pulls a spring-loaded ball out of

a socket, causing two microswitches to sound an alarm or to COST EFFECTIVE

shut down the conveyor. One end of each cable is permanently When you consider the cost of the average replacement belt, or

affixed to the bracket preventing the loss of the cable. the cost of repairing the mechanical damage from a torn belt, a

damage detection system is very inexpensive by comparison.

It’s simple, effective, and it gives that extra warning of possible Other than internally wired belts (tears are electronically indicated),

belt failure. But, even though the idea is simple, these detectors there’s nothing like this system available in the U.S. It’s a lot of

are not lightweights. They’re rugged, heavy duty units that protection for very little cost.

are designed to work in any industrial environment including

hazardous locations.

So check out the cost/benefit ratio on this valuable detection

system. Like a good insurance policy, it’s protection you can’t

afford to be without.

EASY TO MAINTAIN

Damaged Belt Detectors are virtually maintenance free —

thanks to their simple, yet tough construction. The units can be

wired normally open or normally closed. Everything you need to

install your system is included, and accessory or replacement

items are always available for immediate shipment.

12 conveyorcomponents.com Conveyor Components Company • 800-233-3233 • Fax: 810-679-4510 • info@conveyorcomponents.com

HOW IT OPERATES INSTALLATION NOTES

The Damaged Belt Detector operates using a spring-loaded When installing a Damaged Belt Detection system on your

ball and socket connected to two plunger type microswitches. conveyor, the following points should be considered:

As an object hanging below the belt sweeps away the cable, • The force required to extract the ball end of the pull cable from a

it pulls the ball connector from its socket (only 4 lbs. of force detector unit increases proportionally with the distance from the

required). When this happens, a spring-loaded shaft is released detector. Therefore, the Cable extending beyond the midpoint of

the opposite side, is considered inactive for damaged detection

causing the plungers of the two microswitches to ride down

purposes. Thus, a second unit is mounted opposite the first to

cam surfaces machined on the shaft. This deactuates the effectively cover this inactive section. (See accompanying drawing.)

switches causing them to sound an alarm, turn on a warning

light, or shut down the system. To reactivate the detectors, all • A damaged portion of a belt may in certain instances be confined to

the top surface of the belt. This renders it undetectable by a system

that’s required is to snap the ball connector and cable back into

mounted between belt surfaces. However, this damaged section will

its socket. fall below the surface on the belt’s return run. In order to detect this

CROSS-SECTION OF CONVEYOR BELT type of damage to a belt, a second detection system can be installed

SHOWING INSTALLATION OF UNITS AND CABLE below the return belt’s surface. This will provide even more reliable

protection for your belt systems.

• Detection units must be mounted high enough for the cables to cover

the entire active area under the belt. In other words, the cables must

follow the contour of the belt closely enough to detect damaged

Max. 2” [51 mm]

below conveyor belt sections of the belt both at the center or near the edge.

SPECIFICATIONS

PART NUMBER DESCRIPTION 5-1/2”

[140 mm]

DB-100 General Purpose, 2 SP/DT microswitches

DBX-100 Explosion Proof, 2 SP/DT microswitches

6-1/8”

7-9/16” [456 mm] [156 mm]

DB-500 General Purpose, 2 DP/DT microswitches

6-7/8” [175 mm]

DBX-500 Explosion Proof, 2 DP/DT microswitches

2-1/4”

Note: Dual-Rated enclosures also available. Contact Sales for details. [57 mm]

Housing: Aluminum (Standard). Epoxy coating available.

6”

Conduit Opening: Two 1” NPT. Standard units and explosion proof [153 mm]

models have two conduit openings. 5”

[127 mm]

External Hardware: Stainless Steel

3-7/16” 2-1/2” 1-1/2”

Switches: SP/DT microswitch. Rated 20 amp at 125, 250 or 480V AC, [78 mm] [64 mm] [38 mm]

1/2 Amp 125 VDC; 1/4 Amp 250 VDC. Controls may be wired for single 1” NPT

throw operation, either normally open or normally closed as required. [26 mm]

DP/DT microswitches also available. Conduit Opening

TOP VIEW OF OPEN

DB-100 UNIT ACTUATION

MECHANISM

TWO MicroswitchES

MODEL DB SHOWN WITH PROTECTIVE RUBBER BOOT WHICH

SLIPS OFF WITH BALL AND CABLE WHEN UNIT IS ACTUATED.

MOUNTING BRACKET (not shown) INCLUDED.

Conveyor Components Company • 800-233-3233 • Fax: 810-679-4510 • info@conveyorcomponents.com • conveyorcomponents.com 13

Вам также может понравиться

- DB 100Документ3 страницыDB 100Jaime Valenzuela MarchantОценок пока нет

- Model DB Damaged Belt Detector: An Early Warning System For Damaged BeltsДокумент2 страницыModel DB Damaged Belt Detector: An Early Warning System For Damaged BeltsLiliana MedranoОценок пока нет

- DS20200117 - Conext Battery Fuse Combiner BoxДокумент2 страницыDS20200117 - Conext Battery Fuse Combiner BoxElectroventica ElectroventicaОценок пока нет

- TeSys fuse carriers protect low voltage equipmentДокумент4 страницыTeSys fuse carriers protect low voltage equipmentacarisimovicОценок пока нет

- Installation, Operation and Maintenance Instructions: Metalarm Series 6301 Ce Metal Detector SystemДокумент12 страницInstallation, Operation and Maintenance Instructions: Metalarm Series 6301 Ce Metal Detector SystemKarin AndersonОценок пока нет

- RBSS 7ML19985GX62Документ35 страницRBSS 7ML19985GX62Humberto Valentim MenegazОценок пока нет

- Detector Banda Dañada Bulk ProДокумент2 страницыDetector Banda Dañada Bulk ProANGEL BUENTELLO ESCAREÑOОценок пока нет

- Compact SureGround Grounding KitДокумент2 страницыCompact SureGround Grounding KitWesdi DОценок пока нет

- EX-A2X I/O Expansion Module Adapter GuideДокумент6 страницEX-A2X I/O Expansion Module Adapter GuiderosolareОценок пока нет

- Pix-H: Metal-Clad Switchgear Up To 17.5kVДокумент24 страницыPix-H: Metal-Clad Switchgear Up To 17.5kVCristian Martinez100% (1)

- Borneras SeccionableДокумент127 страницBorneras SeccionableSilvia De La CruzОценок пока нет

- Datum Electronics: Series 460 Bolt-On Strain Gauge SensorsДокумент7 страницDatum Electronics: Series 460 Bolt-On Strain Gauge Sensorsmuhammad taufik rahmanОценок пока нет

- Circuit Protection Solutions: CAM and SAFE BS88 Fuseholders Product GuideДокумент8 страницCircuit Protection Solutions: CAM and SAFE BS88 Fuseholders Product GuideJoseph TingОценок пока нет

- Pg05f05te PDFДокумент8 страницPg05f05te PDFa_salehiОценок пока нет

- Rsti 69 CCДокумент4 страницыRsti 69 CCGuilherme VillaçaОценок пока нет

- CDM Series 2 Operating GuideДокумент39 страницCDM Series 2 Operating Guide128BTC UnclebotОценок пока нет

- 000-0293 LL3 Probe Install Quick Reference GuideДокумент2 страницы000-0293 LL3 Probe Install Quick Reference GuideMohamed BoumedieneОценок пока нет

- Protect Fuse Switch Disconnector, XLBM 160-630AДокумент32 страницыProtect Fuse Switch Disconnector, XLBM 160-630Azg828Оценок пока нет

- Designing a Monorail System LoadДокумент62 страницыDesigning a Monorail System LoadHà Tiến ĐôngОценок пока нет

- MODIFICATION HISTORY AND SERVICE MANUALДокумент74 страницыMODIFICATION HISTORY AND SERVICE MANUALShahzadAhmed100% (1)

- Catalogo - IZM58 - Moeller 630-6300 AДокумент63 страницыCatalogo - IZM58 - Moeller 630-6300 Admeinhapim88% (8)

- Manhole Monitor PLUSSpec Sheet 2206 BДокумент2 страницыManhole Monitor PLUSSpec Sheet 2206 BTri NguyenОценок пока нет

- 对射光电开关 - VOICE OF STEVEДокумент4 страницы对射光电开关 - VOICE OF STEVEapi-19795268Оценок пока нет

- Logic Magnetic Pickups - : Super-Sensitive Magnetic Pickups With Current Sinking Output or Current Sourcing OutputДокумент2 страницыLogic Magnetic Pickups - : Super-Sensitive Magnetic Pickups With Current Sinking Output or Current Sourcing OutputNuc LeusОценок пока нет

- Control CableДокумент65 страницControl CableDeyoОценок пока нет

- HG351943Документ4 страницыHG351943Hayden LovettОценок пока нет

- The Future of Electrical Distribution TodayДокумент16 страницThe Future of Electrical Distribution TodayVishab FredОценок пока нет

- Magnum IEC - Product Specific InformationДокумент16 страницMagnum IEC - Product Specific Informationjehad azoozОценок пока нет

- GDM 5010PTДокумент52 страницыGDM 5010PTmarentОценок пока нет

- Vibrating Wire Pressure CellДокумент4 страницыVibrating Wire Pressure Cells pradhanОценок пока нет

- Data Sheet Ant2460npДокумент8 страницData Sheet Ant2460npp4i9e8r5Оценок пока нет

- BQ5477Документ10 страницBQ5477Helar Armejo VasquezОценок пока нет

- PDP42V18HAДокумент77 страницPDP42V18HAbobju14Оценок пока нет

- Raychem Screened, Separable Coupling System RSTI-CC-58 800 A Up To 24 KVДокумент4 страницыRaychem Screened, Separable Coupling System RSTI-CC-58 800 A Up To 24 KVgiovany_vq91Оценок пока нет

- Sony KLV-40X300A KLV-40X350A 46X 52X CH FIX2 LCDДокумент73 страницыSony KLV-40X300A KLV-40X350A 46X 52X CH FIX2 LCDkostelectronics switzerlandОценок пока нет

- RVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsДокумент12 страницRVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsKip ClayОценок пока нет

- CMP Triton July2014Документ6 страницCMP Triton July2014chinwe njokanmaОценок пока нет

- Scitronics - Metal - Detector - TMD1080 1Документ4 страницыScitronics - Metal - Detector - TMD1080 1Fernando BarrosОценок пока нет

- Slimline: Switch Disconnector Fuse, SR 63-630 AДокумент46 страницSlimline: Switch Disconnector Fuse, SR 63-630 AЕвгений МатвеевОценок пока нет

- Smartax Ma5800-X7 Quick Installation Guide: Issue: 04 Date: 2016-08-24Документ22 страницыSmartax Ma5800-X7 Quick Installation Guide: Issue: 04 Date: 2016-08-24Haider FiberОценок пока нет

- Read Service Manual Carefully Before ServicingДокумент21 страницаRead Service Manual Carefully Before Servicinganjan chatterjeeОценок пока нет

- Allen Bradley 800T-CatalogДокумент96 страницAllen Bradley 800T-CatalogChen LiuОценок пока нет

- Euromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionДокумент10 страницEuromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionMosa Elnaid ElnaidОценок пока нет

- Euromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionДокумент10 страницEuromold K158LR Separable Elbow Connectors Copper Wire Screen Cables Type A InstructionMosa Elnaid ElnaidОценок пока нет

- Espm 20-52-00Документ27 страницEspm 20-52-00Luis Enrique La Font FrancoОценок пока нет

- DrakaTechTipNo.1 CompensatingChain PDFДокумент2 страницыDrakaTechTipNo.1 CompensatingChain PDFKar Keong LewОценок пока нет

- Environmental Noise DisturbersДокумент6 страницEnvironmental Noise DisturbersjeswinchОценок пока нет

- Denon PMA255UK - IM (Engl)Документ8 страницDenon PMA255UK - IM (Engl)snshamiОценок пока нет

- REA101 - Sensor FiberДокумент18 страницREA101 - Sensor FiberLuan CotaОценок пока нет

- Modular Collator Base: ManualДокумент68 страницModular Collator Base: ManualRobot 3TОценок пока нет

- Belt Thickness Monitoring SystemДокумент8 страницBelt Thickness Monitoring SystemPrincepessa GaviОценок пока нет

- ST4 Vibrating Wire Embedment Strain GaugeДокумент4 страницыST4 Vibrating Wire Embedment Strain GaugeNurul BaizuraОценок пока нет

- 3m Cable Accessory Products 2013 Electrical Products CatalogДокумент28 страниц3m Cable Accessory Products 2013 Electrical Products CatalogAnil BoodhaiОценок пока нет

- Disabled Persons Toilet Alarm Kit: Single Zone Emergency Assistance AlarmДокумент13 страницDisabled Persons Toilet Alarm Kit: Single Zone Emergency Assistance AlarmCeban DumitruОценок пока нет

- Technical Information: Fiber Optic Pulling and Support GripsДокумент9 страницTechnical Information: Fiber Optic Pulling and Support GripssoayОценок пока нет

- B-S5A-5B Valve Status MonitorДокумент6 страницB-S5A-5B Valve Status Monitorsakura_jОценок пока нет

- Gladiator Microwave ManualДокумент49 страницGladiator Microwave ManualCardonettiОценок пока нет

- MG500 Extension Reel Training ManualДокумент18 страницMG500 Extension Reel Training ManualArtur ArturowskiОценок пока нет

- Breaker EnchufablesДокумент4 страницыBreaker EnchufablesChristian Alberto DávilaОценок пока нет

- NUEVO COLEGIO DEL PRADO Reinforces Science Topics for Grade 2Документ3 страницыNUEVO COLEGIO DEL PRADO Reinforces Science Topics for Grade 2Christian Alberto DávilaОценок пока нет

- Guía de Ciencias PDFДокумент3 страницыGuía de Ciencias PDFChristian Alberto DávilaОценок пока нет

- Guía de Español PDFДокумент3 страницыGuía de Español PDFChristian Alberto DávilaОценок пока нет

- Guía de MatemáticasДокумент3 страницыGuía de MatemáticasChristian Alberto DávilaОценок пока нет

- 45lms Um001 - en P PDFДокумент110 страниц45lms Um001 - en P PDFChristian Alberto DávilaОценок пока нет

- Logo Verification ReportДокумент1 страницаLogo Verification ReportAdrian AmzarОценок пока нет

- Codigos PeopleДокумент4 страницыCodigos PeopleChristian Alberto DávilaОценок пока нет

- Readme de ArduinoДокумент1 страницаReadme de ArduinoLuis SalgadoОценок пока нет

- 2N3819Документ8 страниц2N3819Pablo Napoleon Magne MendietaОценок пока нет

- Dataflex Service Manual PDFДокумент243 страницыDataflex Service Manual PDFRachiahi Tarik100% (2)

- InstrumentationДокумент84 страницыInstrumentationZulkernain Omer TariqОценок пока нет

- Parts List 950-960-985-995-988-998 PDFДокумент108 страницParts List 950-960-985-995-988-998 PDFkais rguiguiОценок пока нет

- CABLE GLAND SERIES PROVIDES FLAMEPROOF AND DUST PROTECTIONДокумент2 страницыCABLE GLAND SERIES PROVIDES FLAMEPROOF AND DUST PROTECTIONsedcОценок пока нет

- 971SmartRadarLTi ServMan 416716 Rev3Документ56 страниц971SmartRadarLTi ServMan 416716 Rev3HeshamEl-naggarОценок пока нет

- FPJ 320 Series Flameproof Lighting Junction BoxДокумент3 страницыFPJ 320 Series Flameproof Lighting Junction Boxdip461Оценок пока нет

- Masafety X20SC2212 Eng - V1141Документ54 страницыMasafety X20SC2212 Eng - V1141asmoosa_scribdОценок пока нет

- Sweco - ZS24 Manual PDFДокумент76 страницSweco - ZS24 Manual PDFdata493100% (1)

- Especificaciones - Transmisor DP-GTX00D-0100-17Документ24 страницыEspecificaciones - Transmisor DP-GTX00D-0100-17Jose Gustavo Robles MoralesОценок пока нет

- General Specifications: EJA110E Differential Pressure TransmitterДокумент14 страницGeneral Specifications: EJA110E Differential Pressure TransmitterHaryadi WirawanОценок пока нет

- SensoMatic Cataloge 2009Документ8 страницSensoMatic Cataloge 2009pradipiitgОценок пока нет

- Mototrbo Xir P6600I Series: You'Re More Productive, ConnectedДокумент4 страницыMototrbo Xir P6600I Series: You'Re More Productive, ConnectedAlbert Herrera GoquingcoОценок пока нет

- AADvance Especificacines TecnicasДокумент146 страницAADvance Especificacines TecnicasIsaac MendibleОценок пока нет

- PS 100 015 001 A4 Instrument General SpecificationДокумент73 страницыPS 100 015 001 A4 Instrument General SpecificationEdison BayazidОценок пока нет

- Catalogue ATB ExMot 14 GB Rev 01 PDFДокумент144 страницыCatalogue ATB ExMot 14 GB Rev 01 PDFRamy El GammalОценок пока нет

- Installation, Operation, and Maintenance ManualДокумент156 страницInstallation, Operation, and Maintenance ManualOmar SunasaraОценок пока нет

- Capeserve Energy - CoPC - BrochureДокумент9 страницCapeserve Energy - CoPC - BrochureGunawanОценок пока нет

- Bats DVMДокумент4 страницыBats DVMMuzammilОценок пока нет

- IM01C25B01-01EN Yokogawa DPДокумент65 страницIM01C25B01-01EN Yokogawa DPSikandar KhanОценок пока нет

- Directive 94/9/EC "ATEXДокумент23 страницыDirective 94/9/EC "ATEXMihai CiorbaruОценок пока нет

- Br323 ManualДокумент13 страницBr323 ManualFinnaSusantiОценок пока нет

- P105576 IC IDF 202 - Rev01Документ5 страницP105576 IC IDF 202 - Rev01bmanojkumar16Оценок пока нет

- GST C-9404 (Ex) SounderДокумент2 страницыGST C-9404 (Ex) SounderReinaldo SouzaОценок пока нет

- Abtech Junction Boxes and Enclosures - Industrial Hazardous Area High Voltage Catalogue 2012Документ242 страницыAbtech Junction Boxes and Enclosures - Industrial Hazardous Area High Voltage Catalogue 2012rocketvtОценок пока нет

- Etabloc Syt Operating InstructionsДокумент50 страницEtabloc Syt Operating InstructionsFayeez MukadamОценок пока нет

- Detect-A-Fire Detection and Release DevicesДокумент6 страницDetect-A-Fire Detection and Release DevicesAli HadiОценок пока нет

- Model 1456 Operations and Maintenance Manual With Parts ListДокумент132 страницыModel 1456 Operations and Maintenance Manual With Parts ListThang Vu0% (1)

- M0600 SiteSentinel 1 Controller ManualДокумент141 страницаM0600 SiteSentinel 1 Controller Manualnick nickОценок пока нет

- Ed P 11.06 I 01Документ15 страницEd P 11.06 I 01neymarronОценок пока нет

- C7061 Datasheet PDFДокумент12 страницC7061 Datasheet PDFMaxluthorОценок пока нет