Академический Документы

Профессиональный Документы

Культура Документы

US2253168 - Frictional Clutch, 1941 PDF

Загружено:

devheadbot0 оценок0% нашли этот документ полезным (0 голосов)

18 просмотров3 страницыОригинальное название

US2253168 - Frictional Clutch, 1941.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

18 просмотров3 страницыUS2253168 - Frictional Clutch, 1941 PDF

Загружено:

devheadbotАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

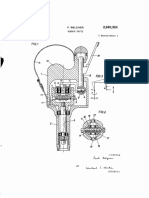

Aug. 19, 1941. J. R. BURBRIDGE 2,253,168

FRICTIONAL CLUTCH

Filed april 17, 19s

Snvonhor

creed John R-Bur bridge

re o™ Spi

* ay Cty, “iz

OMMorewer

Patented Aug. 19, 1941

2,253,168

UNITED STATES PATENT OFFICE

2,258,168,

FRICTIONAL CLUTCH

“Sohn R. Burbridge, Kenosha, Wis.

Application April 17, 1940, Serial No. 330,011

(cu 19244)

1 Claim.

‘This invention pertains generally to frictional

clutches, and more particularly to a reversible

cluteh for either intermittent or continuous drive

in opposite directions,

"The invention has primarily for its object to

provide an exceedingly simple and inexpensive

reversible frictional clutch, particularly -appii-

cable for intermittent operation, with minimum

lost: movement.

Tneldental to the foregoing, a more specific

object of the invention resides in the provision

of a frlotional clutch including a pair of spaced

rotatable clutch members interposed between a

driving and a driven member, to provide opera

tive connection between the two, and selectively

controlled by a cam interposed between the

clutch members.

‘With the above and other objects in view,

which will appear as the description proceeds,

the invention resides in the novel construction,

‘combination, and arrangement of parts, substan-

tially ag hereinafter described, and more par-

ticularly defined by the appended claims, it being

understood that such changes in the precise em-

bodiment of the herein disclosed invention may

be made as come within the scope of the claim.

In the accompanying drawing is illustrated

one complete example of the physical embodi-

ment of the present invention constructed ac-

cording to the best mode so far devised for the

practical application of the principles thereof.

In the drawing:

Figure 1 is an clevation of one form of the in-

vention, parts being broken away and in section;

‘igure 2 1s a vertical section, taken on the line

22 of Figure 1;

Figure 3 is a transverse section, taken on the

line 3—8 of Figure 1; and

‘igure 4 1s an exaggerated diagrammatic show-

ing of the elutch control mechanism in its var-

fous positions, the same being taken on substan-

tally the line é—4 of Figure 1.

“While the present invention bas many appli-

cations, such as in tools, machine tools, power

transmission, and the like, for the purpose of

explanation, ‘the same has been illustrated and

will be deseribed in connection with an inter-

mittent feed for @ shaper work table,

Referring now more particularly to the accom-

panying drawing, the numeral I designates @

Griven shaft which, in the present instance, may

tbe assumed to be the actuating shaft for a shaper

table feed that is intermittently operated. In

accordance with the primary object of the inven-

tion, the direction of rotation of the shaft may

10

25

30

35

40

6

50

55

be ‘reversed by selective setting of the clutch, as

‘will be hereinafter described.

‘One form of the mechanism incorporating the

principle of the present invention comprises an

arm_2 loosely journaled upon a sleeve 3, pinned

or otherwise secured upon the shaft {.. The lower

end of the arm ? is pivotally connected to a recip-

Socative link 4, which transmits oscillatory move-

ment to the arm 2 about the axis of the driven

shaft 1.

‘The rm 2 is provided with a recess § surround-

ing the sleeve 3, the same being closed by a cover

6 to house the clutch mechanism, and prevent

entrance of foreign mater, such as dust, metal

particles, and the like, and also retain necessary

lubricant within the clutch,

Positioned within the recess § is a flango 7

carried by the sleeve 3, Hero it is to be under-

stood that the sleeve and flange structure is pro-

vided merely for manufacturing reasons, inas-

much as the flange 1 may form an integral part

of the shaft 1 without departing from the prin-

ciple of the present invention. As will be best

noted in Figure 1, the upper edge 8 of the recess.

8 aiverges upon opposite sides of the vertical axis

of the shaft |, with relation to the diameter of

the flange.

Positioned within the recess 5, and disposed

between the periphery of the flange 7 of the

upper edge of the recess, is a pair of clutch rollers,

9, normally urged toward each other by an arcu-

ate leaf spring (0,

‘To control operative engagement of the clutch

zollers § between the periphery of the flange 7

and the upper edge 8 of the recess 6, a cam Ii

provided with a shank 12 is interposed between

the rollers. ‘The shank 12 of the cam is journaled

tn the upper end of the arm 2, and has secured

‘thereon a knurled thumb-piece 13, providing for

manual manipulation of the cam ‘Il. A spring-

urged ball Istch (4, positioned in ‘a recess 15

formed in the top of the arm (2 and engaging

indentations (6 formed in the bottom of the

thumb-plece 13, serves to frictionally hold the

thumb-piece and cam in thelr several selected

positions.

‘To assist the operator in adjustment of the

clutch mechanism, both the cover plate § and the

thumb-plece 13 may be provided with indicia I

to enable the operator to determine the setting

of the clutch.

Primarily, the present invention includes the

well known principle of elther ball or roller frie~

tional clutches, in which the clutch element pro-

‘vides operative engagement between a driving

2

and a driven member in one direction, and free,

relative movement in the opposite direction, In

the present invention the clutch elements 9 fune-

tion in a similar manner, but in opposite direc-

tions to each other.

‘To accomplish ‘the desired setting of the

eluteh, the cam (I is provided with a plurality

of surfaces, whereby both clutch rollers @ are

held in either operative or disengaged position,

‘Upon further selective setting of the cam II,

either roller may be held out of operative engage-

ment, permitting the driving member to inter~

mittently rotate the driven member in one di-

rection. Shifting of the cam allows intermittent

actuation of the driven member to be reversed,

When both rollers are operatively engaged, the

driven member may be oscillated in both direc-

tions. Obviously, the drive may be continuous

in either direction in certain applications of the

invention,

Referring more particularly to the schematic

showing of Figure 4, the cam {1 is shown in

adjusted position, in which the rollers 9 are

held out of operative engagement by the op-

Dositely disposed high points of the cam, indl-

cated by the lines a—a. A clockwise shift of

the cam will bring one of the faces b and the

opposite point c of the cam into engagement

with the rollers, whereby the roller 8 engaging

the face b assumes its operative position, while

the opposite roller 9 engaged by the point ¢ 1s

Tetained in operative position, A further elock-

‘wise movement of the cam allows the points d

and e to contact the opposite rollers, allowing

them both to assume operative positions. The

foregoing operation may be accomplished upon

reverse movement of the cam It in clockwise

direction, due to the conformity of the cam 11,

From the foregoing explanation, considered in

connection with the accompanying drawing, it

will be seen that an exceedingly simple, inex-

29

30

35

40

2,258,168

pensive and easily manipulated frictional clutch

mechanisin has been provided, capable of effect-

ing either intermittent or eontinuous érive in

either direction, or oscillatory action,

Without close machining, it has been deter-

mined that a clutch of the present type pro-

vides for operative engagement with minimum

lost movement, and, therefore, a high degree

of accuracy is obtained,

Housing of the clutch mechanism not only

provides against the entrance of forelgn matter,

such as metal, dust and the like, but also In

sures proper lubrication of the operative parts

of the clutch, and enables ready access to the

clutch elements for lubricating, cleaning, ot

replacement.

It Is also to be understood that the operative

faces of the clutch elements are substantially

smooth, as compared to toothed or seriated clutch

surfaces, which not only reduces cost of manu-

facture, but also provides for more minute con-

trol of the clutching operation,

T claim:

A reversible, frictional clutch comprising, an

annular driven member provided with a sub-

stantially smooth circumferential surface, an

oscillatory arm journaled about said driven

member and provided with recess surrounding

said member, a pair of rollers positioned in said

recess between said annular driven member and

the side wall of said recess, the longitudinal axes,

of said driven member and clutch members being

Parallel, a rotatable cam journaled in said arm

and disposed between said clutch members, the

axis of said cam being at right angles to the

longitudinal axes of said rollers, an arcuate flat

spring positioned in said recess and engaging

said rollers to normally urge them into operative

Position, and a cover for said recess,

JOHN R. BURBRIDGE,

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Pen TurningДокумент2 страницыPen TurningdevheadbotОценок пока нет

- Anodising - Aluminium Anodising DyesДокумент4 страницыAnodising - Aluminium Anodising DyesdevheadbotОценок пока нет

- US6953298 - Pinstripe Painting Device, 2005Документ8 страницUS6953298 - Pinstripe Painting Device, 2005devheadbotОценок пока нет

- @341 A É'Wqkammm: Filed July 28-, 1944Документ3 страницы@341 A É'Wqkammm: Filed July 28-, 1944devheadbotОценок пока нет

- US1994497 - Indicator - Winters For Gladwin, 1935Документ5 страницUS1994497 - Indicator - Winters For Gladwin, 1935devheadbotОценок пока нет

- US2466380 - Precision Centering Device - Leland Clark, 1949Документ5 страницUS2466380 - Precision Centering Device - Leland Clark, 1949devheadbotОценок пока нет

- US1157800 - Universal Test-Indicator - Oslund, 1915Документ3 страницыUS1157800 - Universal Test-Indicator - Oslund, 1915devheadbotОценок пока нет

- US2940324 - Wobble Mechanism (Scraper)Документ4 страницыUS2940324 - Wobble Mechanism (Scraper)devheadbotОценок пока нет

- US3230631 - Optical Center PunchДокумент6 страницUS3230631 - Optical Center PunchdevheadbotОценок пока нет

- @341 A É'Wqkammm: Filed July 28-, 1944Документ3 страницы@341 A É'Wqkammm: Filed July 28-, 1944devheadbotОценок пока нет

- US2579903 - Periscopic Sextant - Kollsman, 1951Документ9 страницUS2579903 - Periscopic Sextant - Kollsman, 1951devheadbot100% (1)