Академический Документы

Профессиональный Документы

Культура Документы

GM Cqi-23

Загружено:

Anonymous M4RGFF6YОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GM Cqi-23

Загружено:

Anonymous M4RGFF6YАвторское право:

Доступные форматы

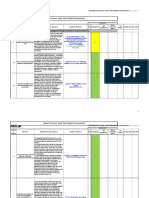

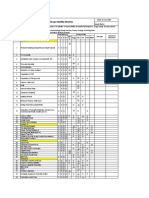

Special Process: Molding System Assessment (General Facility Overview)

Assessment

Question Not Needs Immediate

Question Requirements and Guidance Objective Evidence N/A Satisfactory

Number Satisfactory Action

Section 1 - Management Responsibility and Quality Planning

To ensure readily available expertise, there shall be a dedicated and qualified

molding person on the site. This individual shall be a full-time employee and

the position shall be reflected in the organization chart. A job description

shall exist identifying the qualifications for the position including chemical and

molding knowledge. The qualifications shall include a minimum of 5 years

Is there a dedicated and experience in molding operation or a combination of a minimum of 5 years of

qualified molding professional formal technical education and molding experience. / Para garantizar la

on-site? / ¿Hay un experiencia fácilmente disponible, debe haber una persona de

1.1 moldeado dedicada y calificada en el sitio. Este individuo debe ser un

profesional de moldeo

dedicado y calificado en el empleado de tiempo completo y el puesto debe reflejarse en el

sitio? organigrama. Deberá existir una descripción del trabajo que

identifique las calificaciones para el puesto, incluidos los

conocimientos químicos y de moldeo. Las calificaciones incluirán un

mínimo de 5 años de experiencia en la operación de moldeo o una

combinación de un mínimo de 5 años de educación formal técnica y

experiencia en moldeo.

The molder shall incorporate a documented advanced quality planning

procedure. A feasibility study shall be performed and internally approved for

each new part or process. Similar parts can be grouped into part families for

this effort as defined by the molder. After the part approval process is

approved by the customer, no process changes are allowed unless

approved by the customer. The molder shall contact the customer when

Does the molder perform clarification of process changes is required. This clarification of process

advanced quality planning? / changes shall be documented. / El moldeador deberá incorporar un

1.2 ¿El moldeador realiza una procedimiento documentado de planificación de calidad avanzada. Se

planificación de calidad realizará un estudio de viabilidad y se aprobará internamente para

avanzada? cada nueva parte o proceso. Partes similares pueden agruparse en

familias de partes para este esfuerzo según lo define el moldeador.

Después de que el cliente aprueba el proceso de aprobación de la

pieza, no se permiten cambios en el proceso a menos que el cliente lo

apruebe. El moldeador se pondrá en contacto con el cliente cuando se

requiera una aclaración de los cambios del proceso. Esta aclaración

de los cambios del proceso debe estar documentada.

The molder shall incorporate the use of a documented Failure Mode and

Are the molder's FMEA's up to Effects Analysis (FMEA) procedure and ensure the FMEAs are updated to

date and reflecting current reflect current part quality status. The FMEA shall be written for each part

or part family or they may be process-specific and written for each process.

processing? / ¿Están los

1.3 In any case, they shall address all process steps from part receipt to part

FMEA del moldeador

shipment and all key molding process parameters as defined by the molder.

actualizados y reflejan el

A cross-functional team shall be used in the development of the FMEA. All

procesamiento actual?

special characteristics, as defined by the molder and its customers, shall be

identified, defined, and addressed in the FMEA.

The molder shall incorporate the use of a documented Control Plan

procedure and ensure the Control Plans are updated to reflect current

controls. The Control Plans shall be written for each part or part family or

Are molding process Control they may be process-specific and written for each process. In any case,

Plans up to date and reflecting they shall address all process steps from part receipt to part shipment and

identify all equipment used and all key molding process parameters as

current processing? / ¿Los

defined by the molder. A cross-functional team, including a production

1.4 planes de control de

operator, shall be used in the development of Control Plans, which shall be

proceso de moldeo están

consistent with all associated documentation such as work instructions,

actualizados y reflejan el

shop travelers, and FMEAs. All special characteristics, as defined by the

procesamiento actual? molder and its customers, shall be identified, defined, and addressed in the

Control Plans. Sample sizes and frequencies for evaluation of process and

product characteristics shall also be addressed consistent with the minimum

requirements listed in the Process Tables.

To ensure all customer requirements are both understood and satisfied, the

Are all molding related and molder shall have all related molding and customer referenced standards

referenced specifications and specifications available for use and a method to ensure that they are

current and available? For current. Such standards and specifications include, but are not limited to,

example: SAE, AIAG, ASTM, those relevant documents published by SAE, AIAG, ASTM, General Motors,

General Motors, Ford, and Ford, and Chrysler. The molder shall have a process to ensure the timely

Chrysler. / ¿Están todas las review, distribution, and implementation of all customer and industry

1.5 especificaciones engineering standards and specifications and changes based on customer-

relacionadas y required schedule. This process shall be executed as soon as possible and

referenciadas de moldeo shall not exceed two weeks. The molder shall document this process of

actualizadas y disponibles? review and implementation, and it shall address how customer and industry

Por ejemplo: SAE, AIAG, documents are obtained, how they are maintained within the molder, how the

ASTM, General Motors, Ford current status is established, and how the relevant information is cascaded

y Chrysler. to the shop floor within the two-week period. The molder shall identify who is

responsible for performing these tasks.

Are all molding related internal

and external best practices

documented and maintained? /

¿Están todas las

especificaciones

The molder should have a documented process and system for maintaining

1.6 relacionadas y

best practices obtained through lessons learned or from industry knowledge.

referenciadas de moldeo

actualizadas y disponibles?

Por ejemplo: SAE, AIAG,

ASTM, General Motors, Ford

y Chrysler.

The molder shall have written process specifications for all active processes

Is there a written process and identify all steps of the process including relevant operating parameters.

specification for all active Examples of operating parameters include process temperatures, cycle

processes? / ¿Hay una times, etc. Such parameters shall not only be defined, they shall have

1.7

especificación de proceso operating tolerances as defined by the molder in order to maintain process

escrita para todos los control. All active processes should have a written process specification.

procesos activos? These process specifications may take the form of work instructions, job

card, start-up sheet, or other similar documents.

To demonstrate each process is capable of yielding acceptable product, the

molder shall perform product capability studies for the initial validation of

Has a valid product capability each process, after relocation of any process equipment, and after a major

study been performed initially rebuild of any equipment. The molder shall define what constitutes a major

and after process change? / rebuild. Initial product capability studies shall be conducted for all molding

processes per line as defined in scope of work and in accordance with

¿Se ha realizado un estudio

1.8 customer requirements. Capability study techniques shall be appropriate for

de capacidad de producto

the molding product characteristics, e.g., molding thickness, part weight,

válido inicialmente y

etc. Any specific customer requirements shall be met. In the absence of

después del cambio de

customer requirements, the molder shall establish acceptable ranges for

proceso? measures of capability. An action plan shall exist to address the steps to be

followed in case capability indices fall outside customer requirements or

established ranges.

Does the molder collect and

analyze data over time, and The analysis of products and processes over time can yield vital information

react to this data? Are records for defect prevention efforts. The molder shall have a system to collect,

analyze, and react to product or process data over time. Methods of

available? / ¿El moldeador

analysis shall include ongoing trend or historical data analysis of special

1.9 recopila y analiza datos a lo

product or process parameters/characteristics. The molder shall determine

largo del tiempo y reacciona

which parameters/characteristics to include in such analysis. All process

a estos datos? ¿Hay

control and testing records must be retained for a minimum of one calendar

registros disponibles? year after the year in which they were created.

Are internal assessments

being completed on an annual

basis, at a minimum,

incorporating AIAG Molding

The molder shall conduct internal assessments on an annual basis, at a

System Assessment? / ¿Las

1.10 minimum, using the AIAG Molding System Assessment. Concerns shall be

evaluaciones internas se

addressed in a timely manner.

completan anualmente,

como mínimo, incorporando

la evaluación del sistema de

moldeo AIAG?

The quality management system shall include a documented process for

Is there a system in place to reprocessing that shall include authorization from a designated individual.

authorize reprocessing and is The reprocessing procedure shall describe product characteristics for which

it documented? / ¿Hay un reprocessing is allowed as well as those characteristics for which

1.11 sistema en funcionamiento reprocessing is not permissible. All reprocessing activity shall require a new

para processing control sheet issued by qualified technical personnel denoting the

autoriza el reprocesamiento necessary molding modifications. Records shall clearly indicate when and

y está documentado? how any material has been reprocessed. The Quality Manager or a

designee shall authorize the release of reprocessed product.

Does the Quality Department

review, address, and

document customer and

The quality management system shall include a process for documenting,

internal concerns? / ¿El

1.12 reviewing, and addressing customer concerns and any other concerns

Departamento de Calidad

internal to the molder. A disciplined problem solving approach shall be used.

revisa, aborda y documenta

las inquietudes internas y de

los clientes?

Is there a continual

improvement plan applicable to The molder shall define a process for continual improvement for each

each process defined in the molding process identified in the scope of the Molding System Assessment.

scope of the assessment? / The process shall be designed to bring about continual improvement in

1.13

¿Existe un plan de mejora quality and productivity. Identified actions shall be prioritized and shall

continua aplicable a cada include timing (estimated completion dates). The molder shall show evidence

proceso definido en el of program effectiveness.

alcance de la evaluación?

Does the Quality Manager or

designee authorize the

disposition of material from

quarantine status? / ¿El The Quality Manager or designee is responsible for authorizing and

1.14

Gerente de Calidad o la documenting appropriate personnel to disposition quarantine material.

persona designada autoriza

la disposición del material

del estado de cuarentena?

Are there procedures or work

instructions available to There shall be procedures or work instructions available to molding

molding personnel that define personnel covering the molding process. These procedures or work

the molding process? / ¿Hay instructions shall include methods of addressing potential emergencies

1.15 procedimientos o (such as power failure), equipment start-up, equipment shut-down, product

instrucciones de trabajo segregation (See 2.8), product inspection, and general operating

disponibles para el personal procedures. These procedures or work instructions shall be accessible to

de moldeo que definen el shop floor personnel.

proceso de moldeo?

The molder shall provide employee training for applicable molding

Is management providing operations. All employees, including backup and temporary employees, shall

employee training for molding? be trained. Documented evidence shall be maintained showing the

1.16 / ¿La gerencia está employees trained and the evidence shall include an assessment of the

entrenando a los empleados effectiveness of the training. Management shall define the qualification

para moldear? requirements for each function, and ongoing or follow-up training shall also

be addressed.

Is there a responsibility matrix

to ensure that all key

management and supervisory

functions are performed by

qualified personnel? / ¿Existe The molder shall maintain a responsibility matrix identifying all key

management and supervisory functions and the qualified personnel who may

una matriz de

1.17 perform such functions. It shall identify both primary and secondary

responsabilidad para

(backup) personnel for the key functions (as defined by the molder). This

garantizar que todas las

matrix shall be readily available to management at all times.

funciones clave de gestión y

supervisión sean

desempeñadas por personal

calificado?

The molder shall have a documented preventive maintenance program for

key process equipment (as identified by the molder). The program shall be a

closed-loop process that tracks maintenance efforts from request to

completion to assessment of effectiveness. Equipment operators shall have

the opportunity to report problems, and problems shall also be handled in a

closed-loop manner. Company data, e.g., downtime, quality rejects, first

Is there a preventive time-through capability, recurring maintenance work orders, and operator-

maintenance program? Is reported problems, shall be used to improve the preventive maintenance

maintenance data being program. Maintenance data shall be collected and analyzed as part of a

utilized to form a predictive

predictive maintenance program. / El moldeador debe tener un programa

maintenance program? / ¿Hay

de mantenimiento preventivo documentado para el equipo clave del

un programa de

1.18 proceso (según lo identificado por el moldeador). El programa será un

mantenimiento preventivo?

proceso de ciclo cerrado que rastrea los esfuerzos de mantenimiento

¿Los datos de

desde la solicitud hasta la finalización hasta la evaluación de la

mantenimiento se utilizan

efectividad. Los operadores de los equipos tendrán la oportunidad de

para formar un programa de

informar los problemas, y los problemas también se manejarán de

mantenimiento predictivo?

manera cerrada. Los datos de la compañía, por ejemplo, tiempo de

inactividad, rechazos de calidad, capacidad de primera repetición,

órdenes de trabajo de mantenimiento recurrentes y problemas

informados por el operador se deben usar para mejorar el programa

de mantenimiento preventivo. Los datos de mantenimiento se deben

recopilar y analizar como parte de un programa de mantenimiento

predictivo.

Has the molder developed a

critical spare parts list, and are

the parts available to minimize

production disruptions? ¿Ha

desarrollado el moldeador The molder shall develop and maintain a critical spare parts list and shall

1.19

una lista crítica de piezas de ensure the availability of such parts to minimize production disruptions.

repuesto, y son las piezas

disponibles para minimizar

las interrupciones de la

producción?

Section 2 - Floor and Material Handling Responsibility

Does the facility ensure that

the data entered in the

receiving system matches the

information on the customer's

shipping documents? / ¿La Documented processes and evidence of compliance shall exist, e.g., shop

2.1 instalación se asegura de travelers, work orders, etc. The facility shall have a detailed process in place

que los datos ingresados en to resolve receiving discrepancies.

el sistema receptor

coincidan con la información

en los documentos de envío

del cliente?

Procedures for part and container identification help to avoid incorrect

processing or mixing of lots. Appropriate location and staging within the

Is product clearly identified and facility also help to ensure that orders are not shipped until all required

2.2 staged throughout the molding operations are performed. Customer product shall be clearly identified and

process? staged throughout the molding process. Non-molded, in-process, and

finished product shall be properly segregated and identified. All material shall

be staged in a dedicated and clearly defined area.

Is molder using adequate FIFO

2.3 system for material and There shall be a procedure that ensures a FIFO system is utilized.

product?

Is lot traceability and integrity Out-going lot(s) shall be traceable to the incoming lot(s). The discipline of

2.4 maintained throughout all precisely identifying lots and linking all pertinent information to them

processes? enhances the ability to do root cause analysis and continual improvement.

The control of suspect or non-conforming product is necessary to prevent

inadvertent shipment or contamination of other lots. Procedures shall be

Are procedures adequate to

adequate to prevent movement of non-conforming product into the

prevent movement of non-

2.5 production system. Procedures shall exist addressing proper disposition,

conforming product into the

product identification and tracking of material flow in and out of hold area.

production system?

Non-conforming hold area shall be clearly designated to maintain

segregation of such material.

Is there a system to identify

trap points in the entire

The molder shall have documented procedures to identify and monitor trap

process to reduce risk of

2.6 points for each process/equipment. Monitoring of potential trap points shall

mixed parts (inappropriate,

occur for every part changeover.

unfinished or improperly

molded parts)?

Containers handling customer product shall be free of inappropriate material.

After emptying and before re-using containers, containers shall be inspected

Are containers free of to ensure that all parts and inappropriate material have been removed. The

2.7

inappropriate material? source of inappropriate material shall be identified and addressed. This is to

ensure that no nonconforming molded parts or inappropriate material

contaminate the finished lot.

Unplanned or emergency downtime greatly raises the risk of improper

processing. Operators shall be trained in material handling, containment

action, and product segregation in the event of an equipment emergency

including power failure. Training shall be documented. Work instructions

Are operators trained in

specifically addressing potential types of equipment emergencies and

material handling, containment

failures shall be accessible to and understood by equipment operators.

action and product segregation

These instructions shall address containment/reaction plans related to all

in the event of an equipment

elements of the process. Evidence shall exist showing disposition and

emergency including power

traceability of affected product. / El tiempo de inactividad no planificado o

failure? / ¿Los operadores

de emergencia aumenta el riesgo de un procesamiento inadecuado.

2.8 están entrenados en el

Los operadores deben estar capacitados en el manejo de materiales,

manejo de materiales, la

la acción de contención y la segregación de productos en caso de una

acción de contención y la

emergencia del equipo, incluida la falla de energía. La capacitación

segregación de productos

debe estar documentada. Las instrucciones de trabajo que aborden

en caso de una emergencia

específicamente los posibles tipos de emergencias y fallas de los

del equipo, incluida la falla

equipos deben ser accesibles y entendidas por los operadores de los

de energía?

equipos. Estas instrucciones deben abordar los planes de contención /

reacción relacionados con todos los elementos del proceso. Deberá

existir evidencia que muestre la disposición y rastreabilidad del

producto afectado.

Is the handling, storage and

The molder's in-process handling and shipping process shall be assessed

2.9 packaging adequate to

for risk of part damage or other quality concerns.

preserve product quality?

Are plant cleanliness,

Plant cleanliness, housekeeping, environmental, and working conditions

housekeeping, environmental

shall be conducive to controlling and improving quality. The molder should

2.10 and working conditions

evaluate such conditions and their affect on quality. A housekeeping policy

conducive to control and

shall be clearly defined and executed.

improved quality?

Are process control Process control parameters shall be monitored per frequencies specified in

parameters monitored per Process Tables. Computer monitoring equipment with alarms and alarm logs

2.11

frequencies specified in satisfy the verification requirement. A designated floor person shall verify

Process Tables? the process parameters.

Are out of control/specification There are documented reaction plans to both out of control and out of

2.12 parameters reviewed and tolerance process parameters. There is documented evidence that reaction

reacted to? plans are followed.

Are Test Frequencies

Test Frequencies shall be performed as specified in Process Tables. Refer

2.13 performed as specified in

to Process Tables

Process Tables?

Test equipment shall be verified/calibrated per applicable customer specific

standard or per an applicable consensus standard, e.g., ASTM, SAE, ISO,

Is product test equipment NIST, etc. Verification/calibration results shall be internally reviewed,

2.14

verified? approved and documented.

Refer to Process Tables for frequency of checks.

Lighting in the inspection area shall be sufficient to allow the evaluation of all

part surfaces. The lighting shall be arranged to preclude spot lighting, glare

2.15 Lighting of inspection area

or shadows. There can be no moving or distracting reflections on the

surfaces to be evaluated.

Вам также может понравиться

- Assessment ResultsДокумент9 страницAssessment Resultsabid100% (1)

- Core Tool Self AssessmentДокумент1 страницаCore Tool Self AssessmentNagarajanОценок пока нет

- Check List For FMEA Evaluation SupplierДокумент7 страницCheck List For FMEA Evaluation SupplierMiroslaw OОценок пока нет

- Copia de CQI-23Документ79 страницCopia de CQI-23Ernesto Padilla100% (6)

- Matrix CSRДокумент6 страницMatrix CSRDiego Jordan Hernández100% (1)

- GM 1927-69 Drill Wide MatrixДокумент5 страницGM 1927-69 Drill Wide MatrixGeorge PetruОценок пока нет

- Cqi 11Документ73 страницыCqi 11dwimukh360Оценок пока нет

- Statement: Foundation AccountДокумент12 страницStatement: Foundation AccountJN Adingra0% (1)

- Exercises PDFДокумент5 страницExercises PDFOneОценок пока нет

- Special Processes: Molding System AssessmentДокумент54 страницыSpecial Processes: Molding System AssessmentisolongОценок пока нет

- AIAG-VDA DFMEA Final ExamДокумент10 страницAIAG-VDA DFMEA Final ExamMoham'medAlthafAs'lam100% (2)

- Special Process: Coating System Assessment Version 3 Issued 07/2020Документ10 страницSpecial Process: Coating System Assessment Version 3 Issued 07/2020r arumugamОценок пока нет

- BIQS 2017 Slide ShowДокумент202 страницыBIQS 2017 Slide Showismael cantuОценок пока нет

- Contigency Planning IATFДокумент1 страницаContigency Planning IATFDhananjay Patil100% (2)

- Gap Analysis Audit Checklist - IATF 16949Документ6 страницGap Analysis Audit Checklist - IATF 16949PaulaMagalhãesОценок пока нет

- CQI-14, How To Perfom The AssesmentДокумент4 страницыCQI-14, How To Perfom The AssesmentJose Cepeda50% (2)

- FMEA ExamДокумент4 страницыFMEA ExamPedroОценок пока нет

- IATF 16949 - 2016-Exam Paper With AnswersДокумент11 страницIATF 16949 - 2016-Exam Paper With Answersrashwin singhОценок пока нет

- System QSB First Step Fast Response PDFДокумент19 страницSystem QSB First Step Fast Response PDFPrabagarane RamachandranОценок пока нет

- CQI-11 AssessmentДокумент80 страницCQI-11 Assessmentaperezpi26606100% (1)

- Automotive Process Approach Audit For IATF 16949 - 2016Документ4 страницыAutomotive Process Approach Audit For IATF 16949 - 2016isolongОценок пока нет

- Sage ConverterДокумент4 страницыSage ConverterSergio DelgadoОценок пока нет

- Cqi 9Документ15 страницCqi 9sureshkumar silvernitzОценок пока нет

- Bureau Veritas India (Iatf 16949) (Page 3 of 6) OptionalДокумент9 страницBureau Veritas India (Iatf 16949) (Page 3 of 6) Optionalashish mehtaОценок пока нет

- Minimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFДокумент9 страницMinimum Automotive Quality Management System Requirements For Sub-Tier Suppliers - AUG 14 PDFFer Jesus Nieves UribeОценок пока нет

- AIAG-VDA PFMEA Template For Activity - (Delegate)Документ38 страницAIAG-VDA PFMEA Template For Activity - (Delegate)nadia_naaz90Оценок пока нет

- CQI-23 For Hitachi (Self Audit Submit 10-Mar-23)Документ24 страницыCQI-23 For Hitachi (Self Audit Submit 10-Mar-23)Jintara KaewrayaОценок пока нет

- 5.1.1.2 - Process Effectiveness EfficiencyДокумент1 страница5.1.1.2 - Process Effectiveness EfficiencyPrakash kumarTripathiОценок пока нет

- 4M ManagementДокумент5 страниц4M ManagementSachin YadavОценок пока нет

- Procedure - Special CharacteristicsДокумент13 страницProcedure - Special Characteristicsalexandru.ghiniaОценок пока нет

- Product Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementДокумент8 страницProduct Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDavid MorenoОценок пока нет

- PV 3347 Englisch CleanlinessДокумент12 страницPV 3347 Englisch CleanlinessAnonymous 7ZTcBn100% (1)

- IATF - Final 2Документ58 страницIATF - Final 2nelson.rodriguezm6142Оценок пока нет

- Gap Analysis IATF 16949Документ15 страницGap Analysis IATF 16949Elena BabinetchiОценок пока нет

- Austemper Inc. CQI - 9 4th Final DueDate 2.8.22Документ45 страницAustemper Inc. CQI - 9 4th Final DueDate 2.8.22NoonОценок пока нет

- Assessment Manual ExamДокумент19 страницAssessment Manual ExamSaurabhОценок пока нет

- GM SQD Bulletin 1927 36 2018Документ3 страницыGM SQD Bulletin 1927 36 2018Oscar DiazОценок пока нет

- 4th Edition Truck Industry PSW Edit2Документ1 страница4th Edition Truck Industry PSW Edit2befoaОценок пока нет

- Part Submission Warrant: Aimler HryslerДокумент1 страницаPart Submission Warrant: Aimler HryslerAlan GrajedaОценок пока нет

- Bliss Manufacturing Company Internal Lab Scope: Laboratory PersonnelДокумент2 страницыBliss Manufacturing Company Internal Lab Scope: Laboratory PersonnelsachОценок пока нет

- Excel Tool Prozessaudit VDA 6.3 2010 enДокумент29 страницExcel Tool Prozessaudit VDA 6.3 2010 enHokuto No KenОценок пока нет

- Field Failures Analysis: HeribertДокумент17 страницField Failures Analysis: Heribertmirosek100% (1)

- IATF 16949 - 2016 - Dec2016Документ66 страницIATF 16949 - 2016 - Dec2016anthony dunnОценок пока нет

- MBO CQI 11 2020 2nd EditionДокумент81 страницаMBO CQI 11 2020 2nd EditionHoang TanОценок пока нет

- Cqi 122014Документ28 страницCqi 122014Armando Flores Moreno100% (1)

- .013-00-Checking AidsДокумент3 страницы.013-00-Checking Aidsdaniel_sasikumarОценок пока нет

- Apqp Test.Документ2 страницыApqp Test.rajesh sharma100% (1)

- Layered Audit ChecklistДокумент4 страницыLayered Audit ChecklistNavnath TamhaneОценок пока нет

- Attribute MSA 4th EditionДокумент4 страницыAttribute MSA 4th EditionSachin RamdurgОценок пока нет

- P!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Документ14 страницP!. GM 1927-30 - BIQS Audit v.7.0 2017-04-05Duho ConsultoresОценок пока нет

- APQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionДокумент6 страницAPQP Chart With Responsibility Matrix: Development Categories Category Details A B C D E F Activity DescriptionParveen KumarОценок пока нет

- 6070634bea45a1f34b572c55 - CQI-9 4th Ed AMP 041021Документ30 страниц6070634bea45a1f34b572c55 - CQI-9 4th Ed AMP 041021harieduidОценок пока нет

- With What (Infrastructure) With Who (Personnel) Risk Assessment ModelДокумент3 страницыWith What (Infrastructure) With Who (Personnel) Risk Assessment Model80ALLA86i100% (2)

- Sample of PM DiagramДокумент1 страницаSample of PM DiagramKarim HakimОценок пока нет

- CQI-9Special Process: Heat Treat System AssessmentДокумент25 страницCQI-9Special Process: Heat Treat System AssessmentSaâdi Sahbi100% (1)

- Ford ApqpДокумент17 страницFord ApqpmageroteОценок пока нет

- MACE - Formats - 015 - APQP Matrix Sign OffДокумент3 страницыMACE - Formats - 015 - APQP Matrix Sign OffMohit KaushikОценок пока нет

- AIAG FMEA Heat TreatДокумент36 страницAIAG FMEA Heat TreatSoraida Ramirez100% (1)

- 8D Report 010510Документ4 страницы8D Report 010510Wellington SoaresОценок пока нет

- Control Plan 1st Edition - AnalysisДокумент9 страницControl Plan 1st Edition - AnalysisYassin Serhani100% (1)

- CQI 9 3rd Edition Errata SheetДокумент2 страницыCQI 9 3rd Edition Errata SheetANONIMOОценок пока нет

- Customer Specific Requirements MatrixДокумент4 страницыCustomer Specific Requirements Matrixjefry sitorusОценок пока нет

- Register Forum Home Page Post Attachment Files All Help Lost PasswordДокумент3 страницыRegister Forum Home Page Post Attachment Files All Help Lost PasswordKirthivasanОценок пока нет

- Reverse FMEAДокумент27 страницReverse FMEAJobs Steve100% (2)

- Lesson14 - DLP15 - While and Do While LoopДокумент3 страницыLesson14 - DLP15 - While and Do While LoopAlvaro QuemadoОценок пока нет

- 1.2D Viewing TransformationsДокумент127 страниц1.2D Viewing TransformationsAbhigyan HarshaОценок пока нет

- 18-Cellular Layout, Group Technology, Heuristic Approaches-08-11-2021 (08-Nov-2021) Material - II - 08-11-2021 - G.T - PDFДокумент24 страницы18-Cellular Layout, Group Technology, Heuristic Approaches-08-11-2021 (08-Nov-2021) Material - II - 08-11-2021 - G.T - PDFSahil KumarОценок пока нет

- Financial Intelligence Centre South AfricaДокумент1 страницаFinancial Intelligence Centre South AfricaShahab UllahОценок пока нет

- Four Dimensional ArtДокумент14 страницFour Dimensional ArtNoemi RenomeronОценок пока нет

- CS RecordДокумент97 страницCS RecordsharmikbkОценок пока нет

- Transistor DesignДокумент51 страницаTransistor DesignJohn GentileОценок пока нет

- Interpretability TcavДокумент5 страницInterpretability TcavTushar ChoudharyОценок пока нет

- Math 6 Plus Unit 7 Expressions and EquationsДокумент17 страницMath 6 Plus Unit 7 Expressions and EquationsridhaandeshpandeОценок пока нет

- Operations Management Homework 37 PDFДокумент3 страницыOperations Management Homework 37 PDFFerdinand MangaoangОценок пока нет

- A6V10444410 - Multi-Sensor Fire Detector - enДокумент8 страницA6V10444410 - Multi-Sensor Fire Detector - enRoman DebkovОценок пока нет

- Logistics & SCM SyllabusДокумент1 страницаLogistics & SCM SyllabusVignesh KhannaОценок пока нет

- FP-5500 Data Sheet Rev E-AlteraДокумент1 страницаFP-5500 Data Sheet Rev E-Alteravasece4537577Оценок пока нет

- L2VPN - SagheerДокумент83 страницыL2VPN - SagheerSaptarshi Bhattacharjee100% (1)

- CNC Turning Programming Exellent ExplainationДокумент29 страницCNC Turning Programming Exellent ExplainationschrienerОценок пока нет

- Anguttaranikaya 5Документ437 страницAnguttaranikaya 5Hansi ZhaiОценок пока нет

- Financial Accounting Assignment: Home Assignment by MehakДокумент3 страницыFinancial Accounting Assignment: Home Assignment by MehakAnam TahirОценок пока нет

- Power Electronics Homework SolutionsДокумент5 страницPower Electronics Homework Solutionsafnabzdmfiefxr100% (1)

- ZW3D CAD Tips How To Design A A Popular QQ DollДокумент10 страницZW3D CAD Tips How To Design A A Popular QQ DollAbu Mush'ab Putra HaltimОценок пока нет

- Basic Statistics Mcqs For Pcs ExamsДокумент4 страницыBasic Statistics Mcqs For Pcs ExamsSirajRahmdil100% (1)

- Store ManagerДокумент2 страницыStore Managerapi-78933101Оценок пока нет

- Heat IncroperaДокумент43 страницыHeat IncroperaAnonymous rEpAAK0iОценок пока нет

- Present Enrolment: Template For LRN Reactivation / Enrollment With Data Issues (Request Form 02)Документ4 страницыPresent Enrolment: Template For LRN Reactivation / Enrollment With Data Issues (Request Form 02)Daniel ManuelОценок пока нет

- Safetica Professional ServicesДокумент6 страницSafetica Professional ServicesMing LeОценок пока нет

- Epson FX 890 DatasheetДокумент2 страницыEpson FX 890 DatasheetMarcos ZamorioОценок пока нет

- Pentaho Report Designer User GuideДокумент248 страницPentaho Report Designer User GuidewawanknОценок пока нет