Академический Документы

Профессиональный Документы

Культура Документы

Sample Spiral Stair Assembly Drawing PDF

Загружено:

vna2971Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sample Spiral Stair Assembly Drawing PDF

Загружено:

vna2971Авторское право:

Доступные форматы

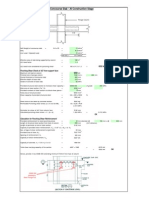

REVISIONS

REV. DESCRIPTION DATE

)

(Typ

23° p)

Tread support plates from 10mm THK plate, ribs (Ty

123 Finial detail and material to be

from 12mm THK plate. Both ribs and support confirmed. Dia 150 ball (from hardwood)

plates are fully welded to centre post shown for illustration purposes only.

NOTES:

1. All fabricated metal items from 304 Grade Stainless Steel finished to mirror polish.

2. Site welding and polishing required.

3. Stair Steelwork may need to be manufactured in 2 sections to allow installation on site.

4. Handrail welded to posts on site.

5. This drawing to be read in conjunction with XX.42.01 - In Situ Assembly

6. Stair designed in accordance with BS 5395: Part 2 : 1984, Category B Private Stair.

Handrail from dia 42.4 x2.6 CHS and

fitted with domed end caps

GENERAL STAIR DESIGN DATA

Total Rise : 3180

No. of treads : 14

DETAIL D

Individual Rise : 212mm

Centre Line Going : 194mm

SCALE 1 : 10

Nominal tread angle on plan : 23 degrees

Clear width : 828mm

VIEW FROM UNDERSIDE Baluster posts from dia 26.9 x3.2 CHS,

fitted with top end cap and dia 12 x70

handrail spigot. Posts secured to treads

using M10 stud rod screwed into

internal tread boss inside post and

secured under tread with 3mm oversize

washer and M10 Dome Nut.

97 mm gap between baluster posts

Note: top tread is 212mm lower than

predicted finish first floor level

13 No. Infill bars to prevent passage of dia

100 sphere. Manufactured from dia 12

round bar. Secured to treads with 2 No, M6

button head screws fitted from underside

212 (Typ)

4440

2756

14 Treads from select hardwood. 40mm THK.

All treads fitted with 3 no. 3mm wide aluminium anti -

slip bars rebated into tread and protruding

approxmately 1.5mm. Timber treads secured to tread

support plate using 8 No. size #8 (A2 SS) countersunk

wood screws from underside.

935

Center Post from dia 114.3 x 6.3 CHS

A A

372

200x200x 10 Base Plate

5

6 4

200 R950

3

7

Scale 1:10

114.30

200

2

8

23° (typ)

1

9

SECTION A-A

82

10

8

11 NOTE: THIS IS A SAMPLE DRAWING PREPARED BY SOLVE ENGINEERING

12

13

14 AND SHOULD NOT BE USED FOR MANUFACTURING PURPOSES.

NEXT USED ON: MATERIAL: PROJECT:

GENERAL TOLERANCES (U.N.O.)

FABRICATION / CUTTING TOLERANCE 1.5

FIRST ANGLE

PROJECTION DOMESTIC SPIRAL STAIR

solve

HOLE CENTRES ON FABRICATED PARTS 1.0

GENERAL NOTES (U.N.O.) FINISH: CLIENT:

- DEBUR AND BREAK SHARP EDGES PROFILED PLATES TOLERANCES

LASER CUTS 0.2

A N OTHER

- ALL HOLES NORMALLY DRILLED

- DIMENSIONS ARE IN MILLIMETERS FLAME CUTS 1.5

STATUS: TITLE:

PLAN VIEW - DO NOT SCALE DRAWING MACHINED PARTS TOLERANCES

LINEAR AND ANGULAR DIMS SAMPLE engineering MODIFIED MIXER 1

Mechanical Engineering Design

Copyright © Solve Engineering UP TO 100 0.1

and Draughting Services

100 TO 400 0.2

and/or their clients. This drawing OVER 400 0.5 NAME SIGNATURE DATE

and/or any part thereof must not DRAWN S. PAUL MAY 2012 e: sam@solveengineering.com DWG NO.

SAMPLE SPIRAL STAIR ASSEMBLY DRAWING

REVISION

be reproduced without the GEOMETRICAL TOLERANCES

CHK'D

t: 02825 882058

MACHINED PARTS ISO 2768-H w: www.solveengineering.com

permission of the owner. OTHERWISE ISO 2768-L WEIGHT: KG SCALE:1:20 SHEET 1 OF 1 SHEET SIZE: A1

Вам также может понравиться

- Genset Concrete Pad Detail-SignedДокумент1 страницаGenset Concrete Pad Detail-SignedJOSEPH ANTHONY VINCE MOICOОценок пока нет

- Handrail Coring Check (Calculation)Документ56 страницHandrail Coring Check (Calculation)Rey GonzalesОценок пока нет

- Design of SlabДокумент3 страницыDesign of SlabKetan Dhameliya100% (2)

- P13 Connection DetailДокумент1 страницаP13 Connection DetailreyhanОценок пока нет

- FRP Lighting PolesДокумент16 страницFRP Lighting PolesManish VaghelaОценок пока нет

- Earthquake Resistant Design by Seismic Base Isolation - Dr. R.S. JangidДокумент64 страницыEarthquake Resistant Design by Seismic Base Isolation - Dr. R.S. JangidAdrian Emmanuel ValeОценок пока нет

- Precast Concrete ConstructionДокумент28 страницPrecast Concrete ConstructionGirl in the CityОценок пока нет

- Structural Analysis TemplateДокумент1 страницаStructural Analysis TemplateChristian Noel YanesОценок пока нет

- Design Parameters For Longitudinal Bars (Beams - BS 8110)Документ4 страницыDesign Parameters For Longitudinal Bars (Beams - BS 8110)Lavanyan Satchithananthan100% (1)

- Footing Design According To BS8110 CodeДокумент4 страницыFooting Design According To BS8110 CodePre SheetОценок пока нет

- Strap Footing TheoryДокумент4 страницыStrap Footing TheorySwopnilOjhaОценок пока нет

- Anchorage To PedestalДокумент4 страницыAnchorage To Pedestaljorge01Оценок пока нет

- Potable Water Storage Tanks-Ring Beam Foundation DesignДокумент22 страницыPotable Water Storage Tanks-Ring Beam Foundation DesignAhmedОценок пока нет

- Annex-3 Vetogrout CG518Документ2 страницыAnnex-3 Vetogrout CG518MdShahbazAhmedОценок пока нет

- 1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandДокумент79 страниц1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandRianto FelissimoОценок пока нет

- Technical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFДокумент41 страницаTechnical Data Sheet For Hilti HIT HY 200 Injectable Mortar in Concrete Technical Information ASSET DOC 8258686 PDFiabdillahОценок пока нет

- Bolt Load Tables To BS5950 01.01.03 PDFДокумент1 страницаBolt Load Tables To BS5950 01.01.03 PDFjakeer7Оценок пока нет

- Bolt Depot - Bolt Grade Markings and Strength ChartДокумент2 страницыBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- RC Raft Foundation (Bs8110) : Project Job RefДокумент5 страницRC Raft Foundation (Bs8110) : Project Job RefsitheeqОценок пока нет

- 2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)Документ4 страницы2-Way Spanning Insitu Concrete Slabs To Bs 81101997 (Table 3.14)alialiОценок пока нет

- Types of Ties For and Placement of Reinforcing SteelДокумент8 страницTypes of Ties For and Placement of Reinforcing Steelइंजि कौस्तुभ पवार100% (1)

- Sign Board CalcsДокумент34 страницыSign Board CalcsMimi MoragnОценок пока нет

- Design Calculations For StructureДокумент3 страницыDesign Calculations For Structuremsiddiq1100% (3)

- Module-IV - Rectangular Water TanksДокумент61 страницаModule-IV - Rectangular Water TanksChinkuОценок пока нет

- Stair Hand Rail Connection Design Calculation-WPCДокумент12 страницStair Hand Rail Connection Design Calculation-WPCUmesh ChamaraОценок пока нет

- Spreadsheets To BS 8110etc: (Default Ult MT / Non-Factored MT.) ('+' Tension at Bottom Face)Документ1 страницаSpreadsheets To BS 8110etc: (Default Ult MT / Non-Factored MT.) ('+' Tension at Bottom Face)Anonymous mcHqIfbnV1100% (1)

- CHS Splice PDFДокумент5 страницCHS Splice PDFKintali VinodОценок пока нет

- How To Fix STAAD Warning WWW - UniquecivilДокумент5 страницHow To Fix STAAD Warning WWW - UniquecivilMohdDanishОценок пока нет

- General Notes & SpecificationsДокумент6 страницGeneral Notes & SpecificationsDon Santos100% (1)

- A&m BSR-2011Документ26 страницA&m BSR-2011Mukesh Jangid100% (1)

- Sample Calculations To Australian Standard AS1170 For Design Loads For A Post To A Barrier PDFДокумент24 страницыSample Calculations To Australian Standard AS1170 For Design Loads For A Post To A Barrier PDFRommel Angelo KirongОценок пока нет

- Design of Isolated Footing With Vertical Load Only - According To ACI 318M-99Документ1 страницаDesign of Isolated Footing With Vertical Load Only - According To ACI 318M-99mahmoud IbrahemОценок пока нет

- RECTBEAMДокумент20 страницRECTBEAMsalimanraharjoОценок пока нет

- Composite Slab Report For GIS AreaДокумент7 страницComposite Slab Report For GIS AreaMINОценок пока нет

- Calculation - Cainta 2 Storey Building - RetrofittingДокумент58 страницCalculation - Cainta 2 Storey Building - Retrofittingregino abuzoОценок пока нет

- Structural Analysis and Design: STAAD - Pro Steel Design (FAQ)Документ19 страницStructural Analysis and Design: STAAD - Pro Steel Design (FAQ)Suhas NatuОценок пока нет

- Beam 1st Floor - 1Документ1 страницаBeam 1st Floor - 1danokrayОценок пока нет

- Reference Description of Problem Values Units: Infomile SolutionsДокумент3 страницыReference Description of Problem Values Units: Infomile SolutionsdhawanaxitОценок пока нет

- Inverted Beams Not A Good ChoiceДокумент4 страницыInverted Beams Not A Good ChoicefmalameerОценок пока нет

- Determination of Lateral LoadsДокумент11 страницDetermination of Lateral LoadschamilcjОценок пока нет

- Guy AnchorДокумент1 страницаGuy AnchorVijay KumarОценок пока нет

- Smartdek 51Документ12 страницSmartdek 51Fairly InsurgentОценок пока нет

- Building Inspection ReportДокумент8 страницBuilding Inspection ReportA DubeyОценок пока нет

- Slab Designer As Per IS 456-2000Документ7 страницSlab Designer As Per IS 456-2000mofizahmed64% (11)

- Street Light PoleДокумент2 страницыStreet Light Polejagdish prabhuОценок пока нет

- Beam DesignДокумент7 страницBeam DesignKasi ViswanathanОценок пока нет

- Structural Calculation TemplateДокумент19 страницStructural Calculation TemplateMelecio Magbuhos IIОценок пока нет

- Zamil Steel Panel Chart PDFДокумент1 страницаZamil Steel Panel Chart PDFFerdie TolosaОценок пока нет

- 2 HoardingДокумент1 страница2 HoardingAkhilesh KajarekarОценок пока нет

- AU Datacentre Structural Ceiling Grid 60CM DatasheetДокумент9 страницAU Datacentre Structural Ceiling Grid 60CM Datasheetguillote_666Оценок пока нет

- Mathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2Документ15 страницMathcad - Tank Foundation Design Actions - 2611-501 & 502 - Rougher WMS Feed Tank 1 & 2shashank sharmaОценок пока нет

- Punching Shear Check For SlabДокумент2 страницыPunching Shear Check For SlabArnab Sur50% (2)

- Design CriteriaДокумент7 страницDesign CriteriaKhaled Abdel SalamОценок пока нет

- Minimum & Maximum SteelДокумент3 страницыMinimum & Maximum SteelSathishОценок пока нет

- Hexagon Socket Set Screws, Flat Type Hexagon BoltsДокумент1 страницаHexagon Socket Set Screws, Flat Type Hexagon BoltsVarun VaruОценок пока нет

- Mv-22 Details 02Документ1 страницаMv-22 Details 02riyazОценок пока нет

- Las Tuercas TiposДокумент1 страницаLas Tuercas TiposJhoel CastilloОценок пока нет

- ISO-5167 Table 3Документ1 страницаISO-5167 Table 3Prasad RamanОценок пока нет

- Conaire Standard Construction: Revision History REV Description Date ApprovedДокумент1 страницаConaire Standard Construction: Revision History REV Description Date ApprovedShabbir AliОценок пока нет

- Val2 Art HLS SHD SST 40 2 Cov 002 AДокумент24 страницыVal2 Art HLS SHD SST 40 2 Cov 002 AAnh KyОценок пока нет

- Elevators & Escalators - Mitsubishi ElectricДокумент3 страницыElevators & Escalators - Mitsubishi Electricvna2971Оценок пока нет

- Labour Contractors in CoimbatoreДокумент8 страницLabour Contractors in Coimbatorevna2971Оценок пока нет

- Schindler IntroductionДокумент30 страницSchindler Introductionvna2971Оценок пока нет

- Pensioners BpsДокумент8 страницPensioners Bpsvna2971Оценок пока нет

- Law FirmsДокумент2 страницыLaw Firmsvna2971Оценок пока нет

- WB-Mech 120 Ch05 ModalДокумент16 страницWB-Mech 120 Ch05 ModalhebiyongОценок пока нет

- Interdisciplinary Project 1Документ11 страницInterdisciplinary Project 1api-424250570Оценок пока нет

- Rural Marketing MergedДокумент146 страницRural Marketing MergedRishabh HemaniОценок пока нет

- Cues Nursing Diagnosis Background Knowledge Goal and Objectives Nursing Interventions and Rationale Evaluation Subjective: Noc: NIC: Fluid ManagementДокумент10 страницCues Nursing Diagnosis Background Knowledge Goal and Objectives Nursing Interventions and Rationale Evaluation Subjective: Noc: NIC: Fluid ManagementSkyla FiestaОценок пока нет

- Centiloquium of PtolemyДокумент37 страницCentiloquium of PtolemyNatasa Karalic Koprivica100% (9)

- Comparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese CompaniesДокумент7 страницComparison of The EC-GMP Guide Part I With The SFDA-GMP Guideline For Chinese Companiesrambabukomati472Оценок пока нет

- Symbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenДокумент3 страницыSymbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenIgor Dutra BaptistaОценок пока нет

- PE 12 Q3 WK1-2 Understanding On Health Related FitnessДокумент8 страницPE 12 Q3 WK1-2 Understanding On Health Related FitnessEmarkzkie Mosra OrecrebОценок пока нет

- Tasha Giles: WebsiteДокумент1 страницаTasha Giles: Websiteapi-395325861Оценок пока нет

- Ostrich RacingДокумент4 страницыOstrich RacingalexmadoareОценок пока нет

- Nursing Care Plan Diabetes Mellitus Type 1Документ2 страницыNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- Circuit Breaker - Ground & Test Device Type VR Electrically OperatedДокумент24 страницыCircuit Breaker - Ground & Test Device Type VR Electrically OperatedcadtilОценок пока нет

- Introduction To Hydraulic System in The Construction Machinery - Copy ALIДокумент2 страницыIntroduction To Hydraulic System in The Construction Machinery - Copy ALImahadОценок пока нет

- Bruner, Jerome - The Growth of MindДокумент11 страницBruner, Jerome - The Growth of MindTalia Tijero100% (1)

- Umihara Et Al-2017-Chemistry - A European JournalДокумент3 страницыUmihara Et Al-2017-Chemistry - A European JournalNathalia MojicaОценок пока нет

- Declaration of Absence of Conflict of InterestДокумент1 страницаDeclaration of Absence of Conflict of InterestJvhelcoronacondat CondatОценок пока нет

- Unit 2 Talents: Phrasal Verbs: TurnДокумент5 страницUnit 2 Talents: Phrasal Verbs: TurnwhysignupagainОценок пока нет

- Infoblatt Skischulen Trends Port eДокумент18 страницInfoblatt Skischulen Trends Port eAustrian National Tourism BoardОценок пока нет

- 06 Renr5908 08 01 All PDFДокумент108 страниц06 Renr5908 08 01 All PDFFrancisco Ospino Arrieta100% (2)

- Sponsor and Principal Investigator: Responsibilities of The SponsorДокумент10 страницSponsor and Principal Investigator: Responsibilities of The SponsorNoriОценок пока нет

- Paula Moraga (Author) - Geospatial Health Data-Modeling and Visualization With R-InLA and Shiny-Chapman and Hall - CRC (2019)Документ295 страницPaula Moraga (Author) - Geospatial Health Data-Modeling and Visualization With R-InLA and Shiny-Chapman and Hall - CRC (2019)M Khahfi ZuhandaОценок пока нет

- CE - 441 - Environmental Engineering II Lecture # 11 11-Nov-106, IEER, UET LahoreДокумент8 страницCE - 441 - Environmental Engineering II Lecture # 11 11-Nov-106, IEER, UET LahoreWasif RiazОценок пока нет

- Emergency Floatation Helicoptero PDFДокумент14 страницEmergency Floatation Helicoptero PDFterrywhizardhotmail.com The Best Of The Best.Оценок пока нет

- Jazz - Installing LED DRLsДокумент16 страницJazz - Installing LED DRLsKrishnaОценок пока нет

- 1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineДокумент1 страница1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineVINEET GAIROLAОценок пока нет

- 6 1 Maxima and MinimaДокумент10 страниц6 1 Maxima and MinimaSebastian GarciaОценок пока нет

- Concordance C Index - 2 PDFДокумент8 страницConcordance C Index - 2 PDFnuriyesanОценок пока нет

- Cosmology Questions and Answers - SanfoundryДокумент9 страницCosmology Questions and Answers - SanfoundryGopinathan MОценок пока нет

- 1) About The Pandemic COVID-19Документ2 страницы1) About The Pandemic COVID-19محسين اشيكОценок пока нет

- Mechanical Energy Storage: Created by Nick StroudДокумент24 страницыMechanical Energy Storage: Created by Nick StroudAli ShazanОценок пока нет