Академический Документы

Профессиональный Документы

Культура Документы

Sabre en Lo 4pp v2

Загружено:

UliAlejandroRodriguezCoriangaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sabre en Lo 4pp v2

Загружено:

UliAlejandroRodriguezCoriangaАвторское право:

Доступные форматы

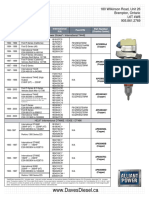

Sabre CRi Master

Compact All Makes

Common Rail Injector Tester

Advanced Common Rail Injector Testing

Key features overview

• Fast - typically 1 minute per test step

• High flow delivery output

• Highly accurate testing and stability

• Simplified and fast injector clampling/changeover

• Advanced magmah user interface

• Very easy installation

Ultimate user flexibility

Simple fixturing Central to the Sabre’s design are exceptional levels of user-control, enabling the

full customisation of test conditions and parameters.

Tests can be run in fully automatic or manual mode and existing test plans can be

modified as easily as new ones can be created.

When generating a new test plan the operator is able to intervene at all stages.

Even percentage tolerances for each step can be assigned individually, enabling

the magmah software to automatically assign limits according to the parameters

set.

Be an expert

The intuitive 10” TFT touchscreen and user-friendly interface enables workshops at

all levels to fully utilise the Sabre’s highly advanced software functionality.

The Sabre is as comprehensive or as simple as you want it to be, whether your

requirement is for a fast and accurate function tester, or for a repair-quality

evaluation of injector performance.

Whatever your needs, the Sabre CRi Master ensures the highest standards of

Common Rail injector testing capability are achieved.

Anywhere, anytime, anyplace

Eyelets The Sabre CRi Master is ready to be used as soon as it has been filled with ISO4113

calibration fluid and plugged in to a domestic power socket. There is no need to

connect to a compressed air supply or a water supply.

It can be easily positioned on a worktop with the help of its eyelets and retractable

roller balls.

Retractable roller balls on rear All machines are delivered fully calibrated and loaded with popular test plans.

feet

Sabre CRi Master

Advanced cooling

The Sabre utilises 3 air-to-oil heat exchangers to regulate and stabilise

temperatures ensuring test-to-test and machine-to-machine repeatability. This

superior cooling performance enables injectors to run for extended test periods.

Patented technology

Tank level indicator

By utilising an internal Common Rail pump along with a patented closed loop

control system, the Sabre is able to generate an impressive level of flow, even at

high pressures. It does this despite running on domestic power connections and

without having to rely on an external compressed air supply.

Windows 10 magmahsharp touchscreen application

The new magmahsharp interface seamlessly integrates in to the Windows 10 plat-

form to enable absolute control and flexibility through the 10” TFT touchscreen.

To print off the colour reports, users can connect a printer to the Sabre front

mounted USB ports or print, email, transfer them via Wifi.

Main test screen Diagnostic screen

The Sabre CRi Master is fast, accurate and easy to use.

Sabre CRi Master

Installation requirements

• Two domestic mains electrical connections required

- High voltage: 1 of 200-240 Vac (10 amps) and 1 of 200-240 Vac (16 amps)

- Low voltage: 1 of 100-120 Vac (10 amps) and 1 of 200-240 Vac (16 amps)*

* with step-up transformer included

• 160kg fully loaded (145kg dry)

240 Vac domestic electrical • Dimensions 610mm (W), 610mm (D), 110mm (H)

connection • Uses ISO4113 calibration fluid

Injector measurements

• Coil resistance 0 - 200 Ω

• Inductance (coil injectors only) 0 - 20 mH

• Capacitance (piezo injectors) 0 - 12 µF

• Response time measurements 0 - 999 µS

• Backleak flow measurements 0 - 290 mL/min

• Delivery measurements 0 - 400 mm3/str

• Backleak temperature 0 - 180°

Technical specification

• Rail Pressure 0 - 1800 bar

• Injection Speed 120 - 3000 ipm

Contact your

• Pulse Width 0 - 400 0 µS

local Hartridge™

• Time Delay 0 - 600 seconds

distributor for

• Tank Capacity 10 litres

more detailed

information or visit • Tank Filtration 2 µm

hartridge.com • Metering Unit Filtration 60 µm

• Backleak Filtration 60 µm

• High Pressure Flow 600 - 250 cc/min

• Fluid Cooling Air to oil heat exchangers

Hartridge. The Hartridge Building. Network 421, Radclive Road, Buckingham MK18 4FD. United Kingdom

Tel: +44 (0)1280 825600 Fax: +44 (0)1280 825601 Email: sales@hartridge.com www.hartridge.com

Continuous development is taking place. Hartridge reserves the right to alter the design and/or specification without prior notice.

© Hartridge 2017 / Sabre CRi Master EN 03/17 v2.0

Вам также может понравиться

- Stegner WeldingДокумент12 страницStegner Weldinguriac86Оценок пока нет

- D 2060 Product Data Sheet EnglishДокумент2 страницыD 2060 Product Data Sheet English杜文欽Оценок пока нет

- Portable Shaker Table: Vibration Field TestingДокумент2 страницыPortable Shaker Table: Vibration Field TestingvikryaОценок пока нет

- ADH 2045 Product Data Sheet EnglishДокумент2 страницыADH 2045 Product Data Sheet Englishkarthikeyan1992Оценок пока нет

- AD Product Brochure-EnДокумент4 страницыAD Product Brochure-EnMohamed AlkharashyОценок пока нет

- Universal WE - Product Data SheetДокумент2 страницыUniversal WE - Product Data SheetVishal ChudasamaОценок пока нет

- 3400 Series SeniorSonic JuniorSonic Data Sheet PDFДокумент16 страниц3400 Series SeniorSonic JuniorSonic Data Sheet PDFprihartono_dias100% (1)

- Technical Brochure: Submersible 4" Non-Clog Sewage PumpДокумент4 страницыTechnical Brochure: Submersible 4" Non-Clog Sewage PumpLisandro Torrealba MedranoОценок пока нет

- Portable Particle Counter For The Use in Harsh Environment: Pamas S40 GoДокумент2 страницыPortable Particle Counter For The Use in Harsh Environment: Pamas S40 Godaya vashishtОценок пока нет

- Rosemount 2160 Wireless Vibrating Fork Liquid Level SwitchДокумент18 страницRosemount 2160 Wireless Vibrating Fork Liquid Level SwitchCristian Rene Orozco PerezОценок пока нет

- Icon 5000 Series 1 CommercialДокумент2 страницыIcon 5000 Series 1 Commercialpedzisai tokweОценок пока нет

- Water-Powered Oscillating Unit and Oscillating Monitor AssembliesДокумент4 страницыWater-Powered Oscillating Unit and Oscillating Monitor AssembliessridharanОценок пока нет

- Sabre Expert Brochure PDFДокумент6 страницSabre Expert Brochure PDFayaz100% (1)

- May Nen IntermechДокумент2 страницыMay Nen IntermechUchiha SaitamaОценок пока нет

- Sabre CRI Master BrochureДокумент3 страницыSabre CRI Master BrochureJason ArellanoОценок пока нет

- SpeedLoader - Automatic Electromechanical Variable Speed 50kN TesterДокумент2 страницыSpeedLoader - Automatic Electromechanical Variable Speed 50kN TesterKhalil SalehОценок пока нет

- M3600 BrochureДокумент1 страницаM3600 BrochureLina Espitia TorresОценок пока нет

- RoMat PGSДокумент2 страницыRoMat PGSRodni POОценок пока нет

- Dti 600Документ2 страницыDti 600UMESH CHAUHANОценок пока нет

- Series 400 Cavitation-Free Flange-Mounted Hydraulic DynamometersДокумент2 страницыSeries 400 Cavitation-Free Flange-Mounted Hydraulic Dynamometers唐波Оценок пока нет

- Product Introduction: LMP633-NCN Capacitive Ceramic Submersible Level TransmitterДокумент10 страницProduct Introduction: LMP633-NCN Capacitive Ceramic Submersible Level TransmitterAbdul KurniadiОценок пока нет

- CG 2020004 01 CHEMGUARD OscillatingMonitorsДокумент4 страницыCG 2020004 01 CHEMGUARD OscillatingMonitorsbhima irabattiОценок пока нет

- Portable Dynamometers For Testing Aerospace Turbines: Kahn SeriesДокумент4 страницыPortable Dynamometers For Testing Aerospace Turbines: Kahn SeriesEsteban Alejandro Méndez WebarОценок пока нет

- Viscopro 2000: Monitoring and Control For Single-Line Process EnvironmentsДокумент4 страницыViscopro 2000: Monitoring and Control For Single-Line Process EnvironmentsLuz Stella Calixto GomezОценок пока нет

- Portable Vibration Calibrator: Lab Accuracy To The FieldДокумент2 страницыPortable Vibration Calibrator: Lab Accuracy To The Fieldenghemo89Оценок пока нет

- Series 100 Flange Mounted Hydraulic Dynamometers For Load Testing Aerospace EnginesДокумент2 страницыSeries 100 Flange Mounted Hydraulic Dynamometers For Load Testing Aerospace Engines唐波Оценок пока нет

- Baker-St 112eДокумент2 страницыBaker-St 112eDenis MoreschiОценок пока нет

- Industrial Robot Controller: Key BenefitsДокумент2 страницыIndustrial Robot Controller: Key BenefitsPhúc Lê HoàngОценок пока нет

- M 110yДокумент2 страницыM 110yjawadОценок пока нет

- 1/8 To 25 HP NEMA 1 Current Vector Microdrive: A World of Power in The Palm of Your Hand!Документ2 страницы1/8 To 25 HP NEMA 1 Current Vector Microdrive: A World of Power in The Palm of Your Hand!Jeimy Rafael Zacarias RodriguezОценок пока нет

- Market Leading Portfolio of Actuation TechnologiesДокумент20 страницMarket Leading Portfolio of Actuation Technologieskamala 123Оценок пока нет

- Brochure Bettis Product Selection Guide Us en 83876 PDFДокумент6 страницBrochure Bettis Product Selection Guide Us en 83876 PDFIsidro RODRIGUEZ VILLEGASОценок пока нет

- Oxygen Sensors Line Guide: FeaturesДокумент4 страницыOxygen Sensors Line Guide: FeaturesResaKandhyОценок пока нет

- Características Técnicas Probador Hastings 6799Документ1 страницаCaracterísticas Técnicas Probador Hastings 6799Henry Diaz Parada100% (1)

- Vitrek 4670BДокумент2 страницыVitrek 4670BJorge Cardona GilОценок пока нет

- AL Brochure - EmailДокумент8 страницAL Brochure - EmailrolandoОценок пока нет

- CPCL Transformer Rectifier Brochure 2022 1Документ6 страницCPCL Transformer Rectifier Brochure 2022 1Taiwo AdenipekunОценок пока нет

- Komax Alpha 550 1 30 T Fully Automatic Wire Processing MachineДокумент12 страницKomax Alpha 550 1 30 T Fully Automatic Wire Processing MachineZayene KhmaisОценок пока нет

- GCTS Rock Catalog 2022Документ40 страницGCTS Rock Catalog 2022ofentse lefadolaОценок пока нет

- Sensata-20ps Series-Pressure Switches-DatasheetДокумент4 страницыSensata-20ps Series-Pressure Switches-DatasheetWILLIAMCAОценок пока нет

- Pv16-30C-0-U-12Er: The Hydraforce Hyperformance™ Valve AdvantageДокумент1 страницаPv16-30C-0-U-12Er: The Hydraforce Hyperformance™ Valve AdvantageMiguel VlntìnОценок пока нет

- Lmp633 NLN (GP)Документ10 страницLmp633 NLN (GP)Edén Paz TadeoОценок пока нет

- Power Transformer Testing ProceduresДокумент2 страницыPower Transformer Testing ProceduresbharathОценок пока нет

- Actuator Capacity Controller: Technical SpecificationsДокумент5 страницActuator Capacity Controller: Technical SpecificationsMiguel Ángel SánchezОценок пока нет

- Compact Prover 8in-40in 166KBДокумент4 страницыCompact Prover 8in-40in 166KBLuis BobadillaОценок пока нет

- 9 PRO Alpha550 ENДокумент12 страниц9 PRO Alpha550 ENZayene KhmaisОценок пока нет

- Industrial Robot Controller: Key BenefitsДокумент2 страницыIndustrial Robot Controller: Key BenefitsAdarsh SinghОценок пока нет

- Digital Winding Tester: Advanced Test Equipment RentalsДокумент2 страницыDigital Winding Tester: Advanced Test Equipment RentalsDavid PolitoОценок пока нет

- Gas Turbin Meter CatalogДокумент16 страницGas Turbin Meter CatalogAlvaro Joel Quinteros RochaОценок пока нет

- 9110D Portable Vibration Calibrator Datasheet DS 0103Документ2 страницы9110D Portable Vibration Calibrator Datasheet DS 0103Adhitya ReОценок пока нет

- Cat Engine c23Документ15 страницCat Engine c23wuub wuugfgОценок пока нет

- Αναδευτήρες CAT - Overhead Stirrers - ΙΓΕ 2014b1,2Документ8 страницΑναδευτήρες CAT - Overhead Stirrers - ΙΓΕ 2014b1,2katerinaОценок пока нет

- Brochure HQ Vertical Pump enДокумент4 страницыBrochure HQ Vertical Pump enabdeslem mouloudjОценок пока нет

- 2013 Esi CatalogДокумент16 страниц2013 Esi Catalogtotoymola8Оценок пока нет

- 2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-MetersДокумент7 страниц2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-Metersichi ezzahraОценок пока нет

- VACON 100 Product PresentationДокумент100 страницVACON 100 Product PresentationJuan Paulo Fernandez VallejosОценок пока нет

- Medium Voltage Fire Pump Controller, ULFM Listed, FiretrolДокумент2 страницыMedium Voltage Fire Pump Controller, ULFM Listed, FiretrolitskittylimОценок пока нет

- Automatic Straightening Machine From Coil: The History of InnovationДокумент5 страницAutomatic Straightening Machine From Coil: The History of InnovationLuiz HenriqueОценок пока нет

- 9851 3607 01 - Simba E6-W - WL Technical Specification - EnglishДокумент8 страниц9851 3607 01 - Simba E6-W - WL Technical Specification - EnglishMiguel Angel Otiniano ParedesОценок пока нет

- Injection Pump Specification ©: All Degrees Are in Pump Degrees Unless Otherwise NotedДокумент3 страницыInjection Pump Specification ©: All Degrees Are in Pump Degrees Unless Otherwise NotedUliAlejandroRodriguezCoriangaОценок пока нет

- Bosch Injector Caracteristics PDFДокумент14 страницBosch Injector Caracteristics PDFSutiknoОценок пока нет

- MR453X7913B000 PDFДокумент202 страницыMR453X7913B000 PDFmilerk100% (2)

- Service Light ResetДокумент55 страницService Light ResetJulio Juarez100% (1)

- Informacion de Toberas Precion y Bar.Документ36 страницInformacion de Toberas Precion y Bar.Jorge Rodolfo Yanez Escudero100% (1)

- Notas de Listas de Despieces Bombas EPIC HSDIДокумент2 страницыNotas de Listas de Despieces Bombas EPIC HSDIUliAlejandroRodriguezCoriangaОценок пока нет

- Stanadyne CorporationДокумент1 страницаStanadyne CorporationUliAlejandroRodriguezCoriangaОценок пока нет

- 03 228e 05 PDFДокумент171 страница03 228e 05 PDFHữuLộcÂuОценок пока нет

- MR453X7913B000 PDFДокумент202 страницыMR453X7913B000 PDFmilerk100% (2)

- Hino Common Rail J05d-J08eДокумент50 страницHino Common Rail J05d-J08eJusto Paniagua Champa94% (50)

- Case Study On Cummins PDFДокумент18 страницCase Study On Cummins PDFUliAlejandroRodriguezCorianga100% (1)

- Service Light ResetДокумент55 страницService Light ResetJulio Juarez100% (1)

- EДокумент23 страницыEUliAlejandroRodriguezCorianga100% (2)

- EbДокумент62 страницыEbUliAlejandroRodriguezCorianga100% (1)

- Multitronic 01JДокумент100 страницMultitronic 01JAlex DosofteiОценок пока нет

- HLN03 7Документ4 страницыHLN03 7UliAlejandroRodriguezCoriangaОценок пока нет

- Bulletin 1243 John Deere Injectors PDFДокумент3 страницыBulletin 1243 John Deere Injectors PDFUliAlejandroRodriguezCoriangaОценок пока нет

- Service Light ResetДокумент55 страницService Light ResetJulio Juarez100% (1)

- Service Light ResetДокумент55 страницService Light ResetJulio Juarez100% (1)

- 3208 Pump Install Timing InstructionsДокумент4 страницы3208 Pump Install Timing InstructionsUliAlejandroRodriguezCorianga100% (1)

- 1.okay DieselДокумент34 страницы1.okay DieselUliAlejandroRodriguezCorianga100% (2)

- Stanadyne Inyectores y ToberasДокумент70 страницStanadyne Inyectores y ToberasMas Inyeccion Electronica100% (1)

- Alliant Power HEUI Injector Application GuideДокумент4 страницыAlliant Power HEUI Injector Application GuideUliAlejandroRodriguezCorianga100% (1)

- Bulletin 1243 John Deere Injectors PDFДокумент3 страницыBulletin 1243 John Deere Injectors PDFUliAlejandroRodriguezCoriangaОценок пока нет

- DSRM 2015.01Документ156 страницDSRM 2015.01Ventas CCORESОценок пока нет

- 2RZ 3RZ SC PDFДокумент21 страница2RZ 3RZ SC PDFUliAlejandroRodriguezCoriangaОценок пока нет

- 64L Overview PDFДокумент16 страниц64L Overview PDFrusynОценок пока нет

- Informacion de Toberas Precion y Bar.Документ36 страницInformacion de Toberas Precion y Bar.Jorge Rodolfo Yanez Escudero100% (1)

- Test Data Sheets For DPCN Pumps PDFДокумент78 страницTest Data Sheets For DPCN Pumps PDFUliAlejandroRodriguezCorianga100% (4)

- Us 3871298Документ13 страницUs 3871298Phúc DuyОценок пока нет

- IC EnginesДокумент17 страницIC EnginesJames ContiОценок пока нет

- Enerpac - Hydraulic Tool..Документ3 страницыEnerpac - Hydraulic Tool..luluОценок пока нет

- Bangui Wind FarmДокумент5 страницBangui Wind FarmChristopher YsitОценок пока нет

- Corken ManualДокумент24 страницыCorken Manualطارق سويد100% (1)

- Esas 12Документ8 страницEsas 12Marche SebastianОценок пока нет

- Copia de 2946074102 ABB ACS800 Spare PartsДокумент22 страницыCopia de 2946074102 ABB ACS800 Spare PartsNatan Hernandez100% (1)

- TM 9-1651 Data Transmission System m3, January 1942Документ78 страницTM 9-1651 Data Transmission System m3, January 1942Advocate100% (1)

- Giz BR Esof Product 3Документ686 страницGiz BR Esof Product 3Cintia KagueyamaОценок пока нет

- L1 ML Waves IДокумент67 страницL1 ML Waves ISadiq QocayevОценок пока нет

- Testing & Commissioning of Chilled Water PumpsДокумент3 страницыTesting & Commissioning of Chilled Water Pumpsamg00733% (3)

- Engine Block ReportДокумент11 страницEngine Block ReportLouis Fernandez100% (1)

- DOCUMENT: Electrical Standard Specification: Of: 1 Standard No. EPD - A.19Документ5 страницDOCUMENT: Electrical Standard Specification: Of: 1 Standard No. EPD - A.19Ahitworld 21Оценок пока нет

- SOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSДокумент159 страницSOP-14 AGEL-P02-SP02-Module Mounting Structure - Installation of MMSVikas SinghОценок пока нет

- HMD01 Instruction ManualДокумент72 страницыHMD01 Instruction ManualLevonYeghyanОценок пока нет

- Coal 2021Документ127 страницCoal 2021Thiago Presa100% (1)

- Types of NoiseДокумент12 страницTypes of NoiseSajith Chandran ReoОценок пока нет

- Benefits of Solar EnergyДокумент22 страницыBenefits of Solar EnergyVinith GopalakrishnanОценок пока нет

- KI1101-2012-KD Lec07 IntermolecularAttractionsДокумент128 страницKI1101-2012-KD Lec07 IntermolecularAttractionsAchmad RochliadiОценок пока нет

- SyllabusДокумент8 страницSyllabusSameer SolankiОценок пока нет

- HERAcell 150i 240i With Decontamination Routine PDFДокумент156 страницHERAcell 150i 240i With Decontamination Routine PDFdeepthiОценок пока нет

- Chevron CorporationДокумент32 страницыChevron CorporationEdmond Dantès100% (1)

- Argus European ProductsДокумент14 страницArgus European ProductsMihaElla_07Оценок пока нет

- Cutera GIS-HP Cooling FFA Data Capture - Rev AДокумент3 страницыCutera GIS-HP Cooling FFA Data Capture - Rev AMickey A CouvertierОценок пока нет

- 4045HMC85Документ2 страницы4045HMC85فتحي الجمل فتحي الجملОценок пока нет

- Bab 3 StoikiometriДокумент28 страницBab 3 StoikiometriM Nur M. Mahmud0% (1)

- Contents Electronic Circuits For AllДокумент8 страницContents Electronic Circuits For AllmoiОценок пока нет

- ChE ThermodynamicsДокумент49 страницChE ThermodynamicsMiguel FelisildaОценок пока нет

- Shell Turbo Oil T32: Performance, Features & BenefitsДокумент2 страницыShell Turbo Oil T32: Performance, Features & BenefitsElias GabrielОценок пока нет

- Conceptual Design of Planetary Gearbox System ForДокумент11 страницConceptual Design of Planetary Gearbox System ForAthoriq Dias MuyasarОценок пока нет