Академический Документы

Профессиональный Документы

Культура Документы

p103-Stts-gec-Asi-ms-ele-007 - Method Statement For Installation of Cable Tray & Trunking

Загружено:

Anandu AshokanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

p103-Stts-gec-Asi-ms-ele-007 - Method Statement For Installation of Cable Tray & Trunking

Загружено:

Anandu AshokanАвторское право:

Доступные форматы

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF CABLE TRAY & TRUNKING

METHOD STATEMENT FOR INSTALLATION OF CABLE TRAY & TRUNKING

Document No: P103-STTS-GEC-ASI-MS-ELE-007

REV. DATE DESCRIPTION GENFOCUS ASI/WSP

PREPARED APPROVED

00 27-05-18 Issued for Approval QA/QC PM

DOCUMENT No. REV DATE

Page 1 of7

P103-STTS-GEC-ASI-MS-ELE-007 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF CABLE TRAY & TRUNKING

1.0 PURPOSE

1.1 The purpose of this Method Statement is to describe in details the method for installation of Cable

Tray & Trunking

2.0 SCOPE

2.1 The purpose of this Method statement is to define the procedure on installation of cable tray

and Trunking for the arrangements of various Power, Lighting and Control Cables.

3.0 TOOLS AND RESOURCES

3.1 Touch-up material

3.2 Hand tools

3.3 Hand Drilling machine

4.0 RESPONSIBILITIES

4.1 PROJECT MANAGER

4.1.1 Is responsible for ensuring that all works are carried out as per the specifications,

drawing/shop drawings and method statement as per the manufacturer instructions,

coordinated with other works and will plan for the required manpower and tools for all

activities.

4.2 SITE ENGINEER/ SUPERVISOR

4.2.1 Ensure the foreman is aware of cable installation procedures & splicing procedures.

4.2.2 Check periodically that the job is executed safely and following the standards.

4.2.3 Ensure that the installation complies with the approved shop drawings/specifications.

4.2.4 Maintain records of work done and submit the progress report to the authorities concerned.

4.2.5 Follow the ITP procedures and co-ordinate with the QA/QC team for inspections.

DOCUMENT No. REV DATE

Page 2 of7

P103-STTS-GEC-ASI-MS-ELE-007 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF CABLE TRAY & TRUNKING

4.3 QA/QC ENGINEER

4.3.1 Carry out the material inspection to ensure that materials received on site are approved

materials.

4.3.2 Monitoring the installation works according to the approved drawings and method statement.

4.3.3 Coordinate with the ENGINEERS and EMPLOYERS REPRESENTATIVE to carry out

inspection/testing of the completed works.

4.3.4 Monitoring the work and ensure all installation or construction work will be carried out in

accordance with specification requirements and good engineering practice.

4.4 HSE OFFICER

4.4.1 Ensure that all installation or construction works will be carried out in accordance with the

ENGINEERS safety manual and EMPLOYERS REPRESENTATIVE standard regulations

and practices.

4.4.2 Ensure that all necessary permits shall be obtained from AUTHORITIES/MAIN

CONTRACTOR/ENGINEER/EMPLOYER REPRESENTATIVE wherever necessary.

4.4.3 Ensure that good housekeeping at work site is implemented.

4.4.4 Ensure that all necessary personnel protective equipment is being provided as per the

requirement of the job.

4.4.5 Ensure that usage of cranes, lifting items and working platforms will be used in accordance

with the ENGINEERS and EMPLOYERS REPRESENTATIVE Safety Manual.

5 PROCEDURE

5.1 Check and verify whether drawings and materials are approved for site execution.

5.2 Approved schedules to verify the site progress with architectural section to properly coordinate

the site execution of schedule.

5.3 Proper coordination with civil architectural works for the erection of tray supports in

trench/wall/ceilings and Mechanical works for the pipeline & other service routings.

DOCUMENT No. REV DATE

Page 3 of7

P103-STTS-GEC-ASI-MS-ELE-007 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF CABLE TRAY & TRUNKING

5.4 All Approvals shall be obtained for the installation of tray and supports on the truss/

cladding/floor slab etc. prior to commencement of work

5.5 Submit material inspection request of materials delivered to site.

5.6 Attach delivery receipt of materials and complete description to show the compliance of material

s according to approved technical submittals.

5.7 If materials are not being used immediately, manufacturer’s recommended storage procedure

shall be followed to protect materials from damage.

5.8 Wherever trays are going along the overhead pipes separate supports are used as the tray

supports.

5.9 Wherever pipe racks are not there the overhead tray / Trunking layout is supported by the C

channels fixed in Tie rods anchor fastened to the ceiling or welded to the Flush plate, I beam as

per the approved shop drawing.

5.10 Supports must be located so that splice joints between horizontal runs fall between the support

point and the quarter point of the span.

5.11 The Tray accessories like Bends, Tee, and Cross etc. shall be supported in line with cable bending

radius as per manufacturer recommendation.

5.12 The cable ladder system is used for heavy weight power cables as approved.

5.13 The cables to be laid in each tray are determined and the size of the cable tray required is

determined, accordingly a tray layout is also prepared to be as per specification

5.14 As per the prepared tray schedule, the required number and size of cantilever support is fixed in

the concrete or wall

5.15 The bends and trays are coupled using the coupling plate / Fishplate.

5.16 For connections from higher width to lower width appropriate Right / left hand reducers are used.

5.17 Wherever tray cutting is done, the cut end shall be well grinded to avoid sharp edges and zinc rich

corrosion resistant paint shall be applied with primer.

DOCUMENT No. REV DATE

Page 4 of7

P103-STTS-GEC-ASI-MS-ELE-007 000 27-05-2018

STTS WIDEBODY AIRCRAFT FACILITY

METHOD STATEMENT FOR INSTALLATION OF CABLE TRAY & TRUNKING

5.18 The inside of cable tray system shall present no sharp edges; burrs or projections that can damage

cable insulation.

5.19 Install the cable support system such that it does not interfere with the lift-out feature if lay-in

grating or floor plate panels and so that there is adequate access for the installation of all cable

and wiring.

5.20 Provide rubber or plastic edges protectors to assure that the conductors/cabling will not abrade

directly on any exposed tray edges.

5.21 Secure the cables to the tray with cable ties at intervals

5.22 To prevent damage to cable tray, never pull cable tray from truck trailer by chaining to bottom

rung and dragging out of trailer. Always observe common safety practices when assembling tray

and fittings in the field.

5.23 Personnel should wear safety goggles, dust mask, coveralls, or a shop coat when sawing,

machining, and/or sanding.

5.24 Deliver products in their original packaging with legible manufacturer’s identification.

5.25 Continuous Earthing of Cable Tray / Trunking are done with braided earth strip the ends shall be

earthed at equipotential Bus Bar.

DOCUMENT No. REV DATE

Page 5 of7

P103-STTS-GEC-ASI-MS-ELE-007 000 27-05-2018

Вам также может понравиться

- Risk Assessment For Installation of Drainage PipesДокумент17 страницRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Fire Fighting SystemДокумент20 страницRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan91% (32)

- Risk Assessment For Installation of Water Supply PipeДокумент18 страницRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Ducts and AccessoriesДокумент17 страницRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan85% (13)

- Method Statement For Structured Cabling System InstallationДокумент9 страницMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Risk Assessment For Installation of Grill, Diffuser and LouversДокумент13 страницRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Risk Assessment For Installation of Fan Coil UnitsДокумент18 страницRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation of Sanitary WaresДокумент14 страницRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Toilet Exhaust FanДокумент11 страницRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Method Statement For Cable Tray and Truncking InstallationДокумент9 страницMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanОценок пока нет

- Method Statement For Cable Tray and Truncking InstallationДокумент9 страницMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanОценок пока нет

- Method Statement For Water Heaters InstallationДокумент9 страницMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- p103-Stts-gec-Asi-ms-ele-005 - Method Statement For Cable Termination & Joint For HV SystemДокумент10 страницp103-Stts-gec-Asi-ms-ele-005 - Method Statement For Cable Termination & Joint For HV SystemAnandu AshokanОценок пока нет

- MS For Installation of Grills, Diffuser & LouversДокумент21 страницаMS For Installation of Grills, Diffuser & LouversAnandu AshokanОценок пока нет

- Method Statement For Installation of Power Factor Correction CapacitorsДокумент6 страницMethod Statement For Installation of Power Factor Correction CapacitorsDuel TimeОценок пока нет

- MS For Installation of SMDB, DB PanelsДокумент20 страницMS For Installation of SMDB, DB PanelsAnandu AshokanОценок пока нет

- Method Statement For Testing and Commissioning of MATVДокумент7 страницMethod Statement For Testing and Commissioning of MATVDong Vanra100% (1)

- Method Statement For Wiring Accessories InstallationДокумент9 страницMethod Statement For Wiring Accessories InstallationAnandu AshokanОценок пока нет

- MOS For Electrical Conduit InstallationДокумент8 страницMOS For Electrical Conduit Installationanas BieОценок пока нет

- Method Statement For Installation of Feeder Panels PDFДокумент6 страницMethod Statement For Installation of Feeder Panels PDFAjayThakurОценок пока нет

- Method Statement-Conduiting WorkДокумент10 страницMethod Statement-Conduiting WorkEesha ThakreОценок пока нет

- Method Statement For Installation of Wiring DevicesДокумент6 страницMethod Statement For Installation of Wiring DevicesMohammed Mujeeb Ali Fathaan100% (2)

- Method Statement For Electrical WorksДокумент14 страницMethod Statement For Electrical WorksWaqas Muhammad Sadi1100% (1)

- MSRA Installation of Firefighting SystemДокумент28 страницMSRA Installation of Firefighting Systemadnan hanif100% (1)

- Method Statement Earthing, Bonding and Lightning Protection LatestДокумент11 страницMethod Statement Earthing, Bonding and Lightning Protection Latestasombrado_jeraldОценок пока нет

- Method Statement - Concealed ConduitДокумент4 страницыMethod Statement - Concealed Conduitjoo2585Оценок пока нет

- Method Statement For Installation of BMS M Tower PDFДокумент16 страницMethod Statement For Installation of BMS M Tower PDFAndrew HivОценок пока нет

- Method Statement - SCSДокумент9 страницMethod Statement - SCSYazan ZahalqaОценок пока нет

- Method Statement For Earthing and Lightning ProtectionДокумент12 страницMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Drainage Pipes InstallationДокумент11 страницMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For Wiring Accessories InstallationДокумент9 страницMethod Statement For Wiring Accessories InstallationAnandu AshokanОценок пока нет

- RAMS EvaluationДокумент3 страницыRAMS EvaluationAnandu AshokanОценок пока нет

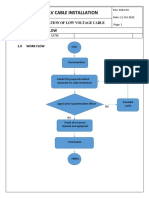

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationДокумент11 страницMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method Statement LV Distribution Boards InstallationДокумент9 страницMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- MS For Installation of Grills, Diffuser & LouversДокумент21 страницаMS For Installation of Grills, Diffuser & LouversAnandu AshokanОценок пока нет

- Spaghetti Bridge Construction HintsДокумент23 страницыSpaghetti Bridge Construction HintsRonny Antonio Quispe SuniОценок пока нет

- p103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionДокумент7 страницp103-Stts-gec-Asi-ms-ele-008 - Method Statement For Installation of Earthing & Lightning ProtectionAnandu AshokanОценок пока нет

- p103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesДокумент6 страницp103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesAnandu AshokanОценок пока нет

- p103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureДокумент5 страницp103-Stts-gec-Asi-ms-ele-009 - Method Statement For Installation of Light Fitting FixtureAnandu AshokanОценок пока нет

- p103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayДокумент6 страницp103-Stts-gec-Asi-ms-ele-004 - Method Statement For Cable Laying On Cable TrayAnandu AshokanОценок пока нет

- p103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemДокумент5 страницp103-Stts-gec-Asi-ms-ele-013 - Method Statement For Installation of Access Control SystemAnandu AshokanОценок пока нет

- p103 Stts Gec Asi Ms Ele 014 - Method Statement For Installation of CCTV SystemДокумент7 страницp103 Stts Gec Asi Ms Ele 014 - Method Statement For Installation of CCTV SystemAnandu AshokanОценок пока нет

- DX SplitДокумент29 страницDX Splitsiva_nagesh_2Оценок пока нет

- p103-Stts-gec-Asi-ms-hvac-009 Method Statement For Installation of Grills and DiffusersДокумент6 страницp103-Stts-gec-Asi-ms-hvac-009 Method Statement For Installation of Grills and DiffusersAnandu AshokanОценок пока нет

- p103-Stts-gec-Asi-ms-ele-015 - Method Statement For Installation, Termination and Testing of Structured Cabling SystemДокумент9 страницp103-Stts-gec-Asi-ms-ele-015 - Method Statement For Installation, Termination and Testing of Structured Cabling SystemAnandu AshokanОценок пока нет

- p103-Stts-gec-Asi-ms-hvac-003method Statement For Installation of Air Handling UnitsДокумент6 страницp103-Stts-gec-Asi-ms-hvac-003method Statement For Installation of Air Handling UnitsAnandu AshokanОценок пока нет

- p103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Документ6 страницp103-Stts-gec-Asi-ms-ele-003 - Method Statement For Installation of LV Distribution Panels (MDB, Capacitor Bank, VFD, SMDB, DB)Anandu AshokanОценок пока нет

- p103-Stts-gec-Asi-ms-hvac-002 Method Statemenr For Installation of Chemical Dosing, Chilled Water Pump Pressurization UnitsДокумент8 страницp103-Stts-gec-Asi-ms-hvac-002 Method Statemenr For Installation of Chemical Dosing, Chilled Water Pump Pressurization UnitsAnandu AshokanОценок пока нет

- Method Statement For Installation of LV Power, Control and Low Current System Cables, Glands and AccessoriesДокумент5 страницMethod Statement For Installation of LV Power, Control and Low Current System Cables, Glands and Accessoriesmidhun muraliОценок пока нет

- 2-Method of Statment WiringДокумент15 страниц2-Method of Statment WiringSyed AtherОценок пока нет

- 4-Method of Statment FixturesДокумент17 страниц4-Method of Statment FixturesSyed AtherОценок пока нет

- DWA-00-HS-MS - 0002 - Rev000 - MS&RA For MV FO Cable Laying, Jointing, Termination and TestingДокумент22 страницыDWA-00-HS-MS - 0002 - Rev000 - MS&RA For MV FO Cable Laying, Jointing, Termination and TestingAnandu AshokanОценок пока нет

- Metallic Raceways & Boxes Method StatementДокумент15 страницMetallic Raceways & Boxes Method StatementRahil Tasawar67% (3)

- DWA-A1-HS-MS-GNF-0003-00A WMSRA For LV DC AC Cable Laying Works Rev-00AДокумент22 страницыDWA-A1-HS-MS-GNF-0003-00A WMSRA For LV DC AC Cable Laying Works Rev-00AAnandu AshokanОценок пока нет

- Method Statement - Earthing & Lightning ProtectionДокумент9 страницMethod Statement - Earthing & Lightning ProtectionKamal Deo Shah100% (1)

- Cgk063-Rfa-mos-m-xxx - Underground Domestic Water Pipe Installation (r.1)Документ34 страницыCgk063-Rfa-mos-m-xxx - Underground Domestic Water Pipe Installation (r.1)diki anggriawanОценок пока нет

- Light FittingsДокумент35 страницLight FittingsAnandu AshokanОценок пока нет

- Method Statement Elect Pipe UndergroundДокумент67 страницMethod Statement Elect Pipe Undergroundمقاول تكييف كهرباء وصحيОценок пока нет

- Bus Duct Installation - Method of StatementДокумент13 страницBus Duct Installation - Method of StatementTalha Altaf100% (1)

- Method Statement For MEP & Internal FinishingДокумент6 страницMethod Statement For MEP & Internal FinishingNaveed Ahmed KhanОценок пока нет

- Method Statement - Cable ConduitДокумент3 страницыMethod Statement - Cable Conduitjoo2585100% (1)

- Method of Statement PartДокумент3 страницыMethod of Statement PartAl Manar PetroleumОценок пока нет

- Cable Ladder Method of Statement.Документ4 страницыCable Ladder Method of Statement.Ahmad DagamsehОценок пока нет

- METHODOLOGY EE-Embedded Conduits (IMC) InstallationДокумент5 страницMETHODOLOGY EE-Embedded Conduits (IMC) Installationjerrick raulОценок пока нет

- Method Statement For Installation of MATV Distribution SystemДокумент7 страницMethod Statement For Installation of MATV Distribution SystemDong VanraОценок пока нет

- KP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSДокумент22 страницыKP-00+++-MQ758-V0018-Rev 0-METHOD OF STATEMENT FOR EARTHING INSTALLATION WORKSUtku Can KılıçОценок пока нет

- CBS Method Statement GeneralДокумент7 страницCBS Method Statement Generalnawazeee2840Оценок пока нет

- Method Statement For Installation of Electric PVC Conduits and AccessoriesДокумент6 страницMethod Statement For Installation of Electric PVC Conduits and AccessoriessamsungloverОценок пока нет

- Method Statement For Electrical ServicesДокумент6 страницMethod Statement For Electrical ServicesUmaira ZainalОценок пока нет

- Ms For Facade Light InstallationДокумент14 страницMs For Facade Light InstallationAdnan AbdulОценок пока нет

- 1.0 Method Statement Above Ground - Drainage SystemДокумент19 страниц1.0 Method Statement Above Ground - Drainage Systemمقاول تكييف كهرباء وصحيОценок пока нет

- Rev02-Work Method Statement For Conduit InstallationДокумент25 страницRev02-Work Method Statement For Conduit InstallationMahaboob PashaОценок пока нет

- Mos T&C EarthingДокумент20 страницMos T&C EarthingAhanaf TahmidОценок пока нет

- Method Statement Cable TerminationДокумент3 страницыMethod Statement Cable TerminationfaizbukhariОценок пока нет

- Rev - 06 - Ms - Installation of Electric Galvanized ConduitsДокумент8 страницRev - 06 - Ms - Installation of Electric Galvanized Conduitsanon_534254691Оценок пока нет

- MOS For Electrical UG Ducts (PVC Pipes) InstallationДокумент3 страницыMOS For Electrical UG Ducts (PVC Pipes) Installationmagdi badran100% (1)

- MS For Testing and Commissioning of Electrical SystemДокумент21 страницаMS For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (2)

- MOS AG Drainage SystemДокумент22 страницыMOS AG Drainage SystemAdrianaChivuОценок пока нет

- Method Statement For Installation of Emt Conduit-OldДокумент13 страницMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinОценок пока нет

- Method Statement For GI Conduits InstallationДокумент9 страницMethod Statement For GI Conduits InstallationAnandu AshokanОценок пока нет

- Method Statement For PEX Pipes and Fittings InstallationДокумент9 страницMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanОценок пока нет

- Method Statement For PPR Pipes and Fittings InstallationДокумент9 страницMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanОценок пока нет

- Method Statement For PVC Conduits InstallationДокумент9 страницMethod Statement For PVC Conduits InstallationAnandu AshokanОценок пока нет

- Method Statement For Fire Alarm and Emergency System InstallationДокумент9 страницMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- MS For Installation of Drainage PipesДокумент20 страницMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of Duct & AccessariesДокумент21 страницаMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS For Installation of Sanitary WaresДокумент22 страницыMS For Installation of Sanitary WaresAnandu AshokanОценок пока нет

- MS For Installation of Toilet Exhaust FanДокумент20 страницMS For Installation of Toilet Exhaust FanAnandu AshokanОценок пока нет

- MS For Installation of FCUДокумент20 страницMS For Installation of FCUAnandu AshokanОценок пока нет

- MS - Installation of Water Supply PipeДокумент20 страницMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS For Installation of FF Pipes FittingsДокумент23 страницыMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- Ew412 - Ew512Документ2 страницыEw412 - Ew512Carlos PosadaОценок пока нет

- Apollo: Model SL30 Installation ManualДокумент88 страницApollo: Model SL30 Installation Manualxwe7Оценок пока нет

- Dvorak 8 Vla Fingering and BowingsДокумент15 страницDvorak 8 Vla Fingering and BowingsTimothy EngОценок пока нет

- AirworpaДокумент96 страницAirworpaMd. Pabel AhmedОценок пока нет

- Why Do Vortices Generate Sound-Alan PowellДокумент9 страницWhy Do Vortices Generate Sound-Alan Powellila_368684492Оценок пока нет

- Steel Hardness ConversionДокумент10 страницSteel Hardness ConversionJewel Maxwell KohОценок пока нет

- Aircraft Instruments: Learning ObjectivesДокумент88 страницAircraft Instruments: Learning ObjectivesjhОценок пока нет

- European Military Aviation Requirements:: Who Should Be The Military Type Certificate Holder?Документ12 страницEuropean Military Aviation Requirements:: Who Should Be The Military Type Certificate Holder?TAN WEI HANОценок пока нет

- New Glenn Payload Users Guide Rev CДокумент124 страницыNew Glenn Payload Users Guide Rev CSudarsan RОценок пока нет

- Stokes' Law and The Coffee Filters: A ProblemДокумент3 страницыStokes' Law and The Coffee Filters: A Problemabdul_azemiОценок пока нет

- Long Report (Ueberlingen)Документ12 страницLong Report (Ueberlingen)csue_1Оценок пока нет

- 206B3FM206B3FM01S01Документ20 страниц206B3FM206B3FM01S01javierОценок пока нет

- Tcds Atr Easa A 084 Issue-11Документ45 страницTcds Atr Easa A 084 Issue-11Alejandro BarradasОценок пока нет

- RadioNavigation QB 1Документ64 страницыRadioNavigation QB 1Vishwadeep Barge100% (1)

- Report of TrussДокумент13 страницReport of TrussShara Haues100% (1)

- Master's Degree in Airports and Air NavigationДокумент2 страницыMaster's Degree in Airports and Air NavigationEETACОценок пока нет

- Fundamentals of Airliner Performance Part 6 The EngineДокумент9 страницFundamentals of Airliner Performance Part 6 The EngineupsasaОценок пока нет

- UFO Files From The UK Government DEFE 24/2024Документ295 страницUFO Files From The UK Government DEFE 24/2024Exit ExitОценок пока нет

- Pemetaan Kompetensi DasarДокумент30 страницPemetaan Kompetensi DasarRangga Bhakty IskandarОценок пока нет

- Aerospace BlocksetДокумент4 страницыAerospace BlocksetMuhammed NayeemОценок пока нет

- Training Course: Aviation Law ObjectivesДокумент4 страницыTraining Course: Aviation Law ObjectivesDawood waheedОценок пока нет

- Design and Analysis of PropellantДокумент7 страницDesign and Analysis of PropellantMarhendraОценок пока нет

- Ship Geometry Lecture NotesДокумент46 страницShip Geometry Lecture NotespothirajkalyanОценок пока нет

- FL 861 Medium Intensity Elevated Lights MIELДокумент2 страницыFL 861 Medium Intensity Elevated Lights MIELBrunoCarrielloОценок пока нет

- Helicopter Flying Handbook Helicopter Flying Handbook: FAA-H-8083-21BДокумент8 страницHelicopter Flying Handbook Helicopter Flying Handbook: FAA-H-8083-21BRumah Bali 67Оценок пока нет

- Review of Propeller-Wing Aerodynamic InterferenceДокумент21 страницаReview of Propeller-Wing Aerodynamic Interferencekrishnamoorthy_krishОценок пока нет

- Fuel Cells in Aviation Hamburg PrintnewДокумент30 страницFuel Cells in Aviation Hamburg PrintnewMarina LenzaОценок пока нет

- UdddДокумент8 страницUdddİ. Çağlar YILDIRIMОценок пока нет

- Strategic Missile ZarchanДокумент75 страницStrategic Missile ZarchanPritam Kumar PratihariОценок пока нет