Академический Документы

Профессиональный Документы

Культура Документы

Fill Stop Fill Valve

Загружено:

Denier RubianoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fill Stop Fill Valve

Загружено:

Denier RubianoАвторское право:

Доступные форматы

Fill/Stop Fill Valve

Applications

• Partial cushion TCP perforating

• Permanent completions

• Drillstem Testing (DST)

Features

• Underbalance can be quantified before deploying gun system

• High precision shear pins guarantee actuation at required pressure

Benefits

• Tubing does not need to be filled joint by joint while running in hole

1

• Required underbalance will ensure proper perforation cleanup

potentially improving productivity or injectivity

• No wireline or slickline tools required saving rig time

2

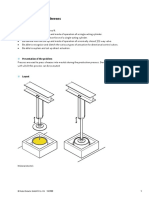

Fill/Stop Fill Valves are used to establish a predetermined fluid level in

the tubing while running in hole or as circulating valves to displace well

fluid prior to setting a plug or packer.

Partial cushions are commonly used for underbalance TCP perforating. 3

Surging cleans the perforation tunnels which in turn reduces

perforation skin and can potentially improve productivity or injectivity.

The amount of fluid that can build up in the tubing (required hydrostatic

pressure) is determined by the number of precision shear pins used.

4

This will vary from job to job depending on well conditions.

The valve will remain open until the precision shear pins fail within ±5%

of the calculated hydrostatic pressure. This causes the piston sleeve to

move closing the valve. The valve will remain closed as long as there is

5

hydrostatic pressure acting upon it.

Fill/Stop Fill Valve Hardware Specifications

Tubing Size (in)[mm] 2-3/8 [60] EUE 2-7/8 [68] EUE

Assembly Part Number FV-338-238-200** FV-380-288-200**

O.D. (in)[mm] 3.38 [86] 3.80 [97]

I.D. (in)[mm] 1.94 [49] 2.38 [60]

Flow Area of Ports (in2)[cm2] 3.14 [20.26] 4.71 [30.39]

Makeup Length (ft)[m] 2.09 [0.64] 2.03 [0.62]

Max. 100 Hour Temperature Rating (oF)[oC]† 400 [204] 400 [204]

Min. Operating Pressure (psi)[MPa] 500 [3] 500 [3]

Max. Operating Pressure (psi)[MPa]‡ 9,000 [62] 10,000 [69]

C_TCP-Catalog-2012-2013_092720130620

Max. Differential Pressure (psi)[MPa] 7,500 [52] 6,000 [41]

Precision Shear Pins 1. Brass Shear Pin

500psi/pin [3.4MPa/pin] SPIN-0076-250 SPIN-0076-250

900psi/pin [6.2MPa/pin] SPIN-0100-250 SPIN-0100-250 2. Flow Ports

Max. Tension (lbf)[kN] 185,000 [823] 185,000 [823] 3. Piston Sleeve

Redress Kit Part Number FV-338-238-200**-KIT FV-380-288-200**-KIT

4. Air Chamber

** Use “HT” for high temperature operations (above 325oF (163oC))

†

Hardware only. Viton O-rings need to be used above 325oF (163oC) 5. Precision Shear Pins

20 Right Tools. Right Location. Right Time.

Copyright © 2013 Hunting Energy Services. All Rights Reserved.

Вам также может понравиться

- FS4-3 - Installation Instructions (MM-601J)Документ8 страницFS4-3 - Installation Instructions (MM-601J)mendozaОценок пока нет

- Drilling Fluids Processing HandbookОт EverandDrilling Fluids Processing HandbookРейтинг: 4.5 из 5 звезд4.5/5 (4)

- Strainer Type 305Документ5 страницStrainer Type 305alexiel1806Оценок пока нет

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversОт EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversРейтинг: 5 из 5 звезд5/5 (2)

- Annular Pressure Packer BypassДокумент1 страницаAnnular Pressure Packer BypassDenier RubianoОценок пока нет

- Block and Bleed Gauge Valves - M25 and M251: Product OverviewДокумент5 страницBlock and Bleed Gauge Valves - M25 and M251: Product OverviewFercomil S.A.SОценок пока нет

- DB - c50 - 51 - 57hpw - GB - GEMU Diaphragm Globe ValveДокумент8 страницDB - c50 - 51 - 57hpw - GB - GEMU Diaphragm Globe ValveKrisОценок пока нет

- Downhole Vantage Logging Head PsДокумент2 страницыDownhole Vantage Logging Head PsLuisОценок пока нет

- SJD (CEP) Vertical Multistage Can Pump For Condensate ExtractionДокумент5 страницSJD (CEP) Vertical Multistage Can Pump For Condensate ExtractionClke OGОценок пока нет

- Válvulas Modelo CTДокумент5 страницVálvulas Modelo CTOdlanier José MendozaОценок пока нет

- Pipeweld Esab Case StudyДокумент2 страницыPipeweld Esab Case StudyLuis Chiara LoayzaОценок пока нет

- KWIK-Brochure 15Документ5 страницKWIK-Brochure 15marketingОценок пока нет

- 860LTB BrochureДокумент4 страницы860LTB BrochureMachani OmkarОценок пока нет

- WFT Tubing Conveyed Perforating SystemsДокумент8 страницWFT Tubing Conveyed Perforating SystemsDenier RubianoОценок пока нет

- Hydralics Aeroquip - Swivle - JointsДокумент20 страницHydralics Aeroquip - Swivle - JointssunnyartboyОценок пока нет

- FS 21"-500 Psi Marine Riser Diverter: Gas Diversion Made Simple For SafetyДокумент2 страницыFS 21"-500 Psi Marine Riser Diverter: Gas Diversion Made Simple For Safetymehmet sait öztürkОценок пока нет

- VT IPH 21 BDI 90115 enДокумент16 страницVT IPH 21 BDI 90115 enwag008Оценок пока нет

- LEWA Ecoflow Variable Eccentric Pump Drive Type LDF: PerformanceДокумент2 страницыLEWA Ecoflow Variable Eccentric Pump Drive Type LDF: PerformanceNguyễn NgọcОценок пока нет

- Vacuum Pump ManualДокумент29 страницVacuum Pump ManualAnonymous Qy5TzR1fОценок пока нет

- Tools Install PDFДокумент20 страницTools Install PDFmfj79607555Оценок пока нет

- Switch Flujo DHDДокумент6 страницSwitch Flujo DHDAF VMОценок пока нет

- Design RSS Lined Globe ValveДокумент12 страницDesign RSS Lined Globe Valveyenifer garciaОценок пока нет

- NF-200 Tech DataДокумент2 страницыNF-200 Tech DataAndres Pinilla TorresОценок пока нет

- Moldeadora PDFДокумент12 страницMoldeadora PDFAmirAmiriОценок пока нет

- Manual BOOK AR SERIESДокумент4 страницыManual BOOK AR SERIESchandra atmaОценок пока нет

- High-Pressure Internal Gear Pumps Technical Data SheetДокумент14 страницHigh-Pressure Internal Gear Pumps Technical Data Sheetabdelhanin bouzianeОценок пока нет

- Features - PVC, CPVC & PP: Needle ValvesДокумент2 страницыFeatures - PVC, CPVC & PP: Needle ValvesKunming WangОценок пока нет

- SerialДокумент17 страницSerialJesus BolivarОценок пока нет

- Autoseal Ii Fill-Up and Circulation Tools: ApplicationsДокумент6 страницAutoseal Ii Fill-Up and Circulation Tools: ApplicationsAli mohammadОценок пока нет

- Specification For Double Pipes: Rev. Date Revision Description Issued by Checked by Approved byДокумент11 страницSpecification For Double Pipes: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreОценок пока нет

- RacorVMT AquaPro Pumps BulletinДокумент2 страницыRacorVMT AquaPro Pumps BulletinAzril DahariОценок пока нет

- Type 369 Data SheetДокумент2 страницыType 369 Data Sheetmanoj_sitecОценок пока нет

- Data Sheets Series 60 80 Direct Spring Operated Pressure Relief Valves Anderson Greenwood en en 5198028Документ71 страницаData Sheets Series 60 80 Direct Spring Operated Pressure Relief Valves Anderson Greenwood en en 5198028Alexander Charry GiraldoОценок пока нет

- Chemical Injection Quills Nozzle: FeaturesДокумент1 страницаChemical Injection Quills Nozzle: FeaturesAmjad HaniОценок пока нет

- Well Intervention PDFДокумент54 страницыWell Intervention PDFCARLOSELSOARESОценок пока нет

- Lndian Standard: Penstock and Turbine Inlet Butterfly Valves For Hydropower Stations and SystemsДокумент12 страницLndian Standard: Penstock and Turbine Inlet Butterfly Valves For Hydropower Stations and SystemsGREYHOUND ENGINEERS INDIA INDIA PVT.LTDОценок пока нет

- Fixed Cone ValveДокумент11 страницFixed Cone ValveRofi Trianto SОценок пока нет

- Ipvp 6-80 101 Voith PumpДокумент24 страницыIpvp 6-80 101 Voith Pumppapinaidu2Оценок пока нет

- Material No 462190Документ12 страницMaterial No 462190Yelena ObyazovaОценок пока нет

- VC Series: 2 - Way, Balanced Hydronic ValvesДокумент4 страницыVC Series: 2 - Way, Balanced Hydronic ValvesArun SivaОценок пока нет

- PumpsДокумент106 страницPumpsBobeelleeОценок пока нет

- Grundfosliterature 1891259Документ4 страницыGrundfosliterature 1891259Mohammad ZeeshanОценок пока нет

- FC81081Документ2 страницыFC81081Khalid ZaeemОценок пока нет

- ECP External Casing Packer - PIS 200730Документ4 страницыECP External Casing Packer - PIS 200730Игорь КачалинОценок пока нет

- Agitator Handbook 2005Документ22 страницыAgitator Handbook 2005casda73Оценок пока нет

- Design and Performance Curve Generation by CFD Analysis of Centrifugal PumpДокумент10 страницDesign and Performance Curve Generation by CFD Analysis of Centrifugal Pumpبلال بن عميرهОценок пока нет

- Tomoe Valve-ManualДокумент2 страницыTomoe Valve-Manualphuc nguyenОценок пока нет

- Water Treatment Plant - UPG - Specs.Документ4 страницыWater Treatment Plant - UPG - Specs.ashokjj26Оценок пока нет

- WPT 50 WPT 70 / WPT 95: Truck Mounted Concrete PumpДокумент2 страницыWPT 50 WPT 70 / WPT 95: Truck Mounted Concrete PumpIvan D. RiveraОценок пока нет

- Hydra Stroke Bumper SubДокумент1 страницаHydra Stroke Bumper SubradiciptaОценок пока нет

- Valv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsДокумент10 страницValv-Powr® Series VPVL Model D Double-Acting and Spring-Return Rack-And-Pinion Compact Pneumatic ActuatorsibharОценок пока нет

- TRSCSSV ValvulaДокумент4 страницыTRSCSSV ValvulaTharsila Chaves MauricioОценок пока нет

- DiffuserДокумент41 страницаDiffuserViet LeОценок пока нет

- 7356 1 PDFДокумент12 страниц7356 1 PDFvishnumani3011Оценок пока нет

- Nozzles For Spray Drying: BETE Introduces The New Twist & Dry, A Breakthrough in Spray Dryer Nozzle MaintenanceДокумент11 страницNozzles For Spray Drying: BETE Introduces The New Twist & Dry, A Breakthrough in Spray Dryer Nozzle MaintenanceuvsarathiОценок пока нет

- Installation Instructions: Durametallic MW-200 SeriesДокумент8 страницInstallation Instructions: Durametallic MW-200 SeriesEli Emmanuel Cárcamo Rodríguez100% (1)

- DV Centerfeed Brochure 2013 PDFДокумент16 страницDV Centerfeed Brochure 2013 PDFAnonymous nw5AXJqjdОценок пока нет

- Dosificador Electromagnetico Seko Apg 803Документ8 страницDosificador Electromagnetico Seko Apg 803Niko OlnicasaОценок пока нет

- Blower and Compressor Sizing and SelectionДокумент42 страницыBlower and Compressor Sizing and SelectionSuryaprakashОценок пока нет

- Baker Style 20 Setting Tool PDFДокумент1 страницаBaker Style 20 Setting Tool PDFDenier RubianoОценок пока нет

- X-Span & Setting ToolsДокумент18 страницX-Span & Setting ToolsDenier RubianoОценок пока нет

- Baker Style 20 Setting Tool PDFДокумент1 страницаBaker Style 20 Setting Tool PDFDenier RubianoОценок пока нет

- WFT Tubing Conveyed Perforating SystemsДокумент8 страницWFT Tubing Conveyed Perforating SystemsDenier RubianoОценок пока нет

- Scalloped Gun System 4.5 12Spf 135°-45° Spiral Sgs - S45-1201-CДокумент2 страницыScalloped Gun System 4.5 12Spf 135°-45° Spiral Sgs - S45-1201-CDenier RubianoОценок пока нет

- 34 Model AD-1 Tension PackerДокумент2 страницы34 Model AD-1 Tension PackerDenier RubianoОценок пока нет

- Annular Pressure Operated Production VentДокумент1 страницаAnnular Pressure Operated Production VentDenier RubianoОценок пока нет

- Mechanical Gun ReleaseДокумент1 страницаMechanical Gun ReleaseDenier RubianoОценок пока нет

- Omega: Wireline Sample / Drive Down BailerДокумент2 страницыOmega: Wireline Sample / Drive Down BailerDenier RubianoОценок пока нет

- Gamma Ray - Gamma GunДокумент1 страницаGamma Ray - Gamma GunDenier RubianoОценок пока нет

- Drilling Practices: Drill Stem TestingДокумент37 страницDrilling Practices: Drill Stem TestingDenier Rubiano100% (2)

- GASGUN Online BrochureДокумент41 страницаGASGUN Online BrochureDenier RubianoОценок пока нет

- TCP Loading Procedure - Gas Gun - 06-13-2012Документ4 страницыTCP Loading Procedure - Gas Gun - 06-13-2012Denier RubianoОценок пока нет

- The Positrieive Packer Is A FullboreДокумент1 страницаThe Positrieive Packer Is A FullboreDenier RubianoОценок пока нет

- Drill Stem Testing RD Sampler: SmartstarДокумент1 страницаDrill Stem Testing RD Sampler: SmartstarDenier RubianoОценок пока нет

- Shock AbsorberДокумент1 страницаShock AbsorberDenier RubianoОценок пока нет

- Tubing Conveyed Gauge Carriers Datasheet PDFДокумент3 страницыTubing Conveyed Gauge Carriers Datasheet PDFDenier RubianoОценок пока нет

- 400 Slick LineДокумент1 страница400 Slick LineDenier RubianoОценок пока нет

- SNG From Pet CokeДокумент6 страницSNG From Pet CokeSarath Jose KОценок пока нет

- LPCB Sprinkler Pump Testing Procedure PDFДокумент19 страницLPCB Sprinkler Pump Testing Procedure PDFAkmal Hazuan SulaimanОценок пока нет

- STUCOR - ME8595-TJ (1) - WatermarkДокумент14 страницSTUCOR - ME8595-TJ (1) - WatermarkMr PerfectОценок пока нет

- JPE CO2 Transportation by Pipeline Special IssueДокумент94 страницыJPE CO2 Transportation by Pipeline Special Issueargentino_ar01Оценок пока нет

- Section 8 - Control Valve Flow CharacteristicsДокумент6 страницSection 8 - Control Valve Flow CharacteristicshammamiОценок пока нет

- Unit Operation: (KG Water / KG Solid)Документ4 страницыUnit Operation: (KG Water / KG Solid)عبداللە عمر ابراهیمОценок пока нет

- Air Compressor Lab PDFДокумент4 страницыAir Compressor Lab PDFbernabas100% (2)

- Coal GasificationДокумент37 страницCoal GasificationSadam BalochОценок пока нет

- Exercise 1: Pressing Cheeses: Cheese ProductionДокумент8 страницExercise 1: Pressing Cheeses: Cheese ProductionAhmed HusseinОценок пока нет

- Enhancing Pipeline Integrity With Early Detection of Internal CorrosionДокумент29 страницEnhancing Pipeline Integrity With Early Detection of Internal CorrosionRumi Kai RekaОценок пока нет

- Busch Instruction Manual Mink MM 1324-1320 AV Us 0870132194Документ24 страницыBusch Instruction Manual Mink MM 1324-1320 AV Us 0870132194JORGE OTALORAОценок пока нет

- Tarea 1 TermodinamicaДокумент3 страницыTarea 1 TermodinamicaMario Gonzalez100% (1)

- Quick Reference CardДокумент3 страницыQuick Reference Cardaslam.ambОценок пока нет

- 03.SOP For Air CompressorДокумент4 страницы03.SOP For Air CompressorThangella Vijayaramaraju100% (2)

- Case StudyДокумент33 страницыCase StudyMir Hasib Ul LatifОценок пока нет

- Design and Numerical Analysis of Rocket NozzleДокумент30 страницDesign and Numerical Analysis of Rocket NozzleMathan rajОценок пока нет

- Design of Hydrokinetic Turbine Blades Considering CavitationДокумент6 страницDesign of Hydrokinetic Turbine Blades Considering CavitationChristopher Lennon Dela CruzОценок пока нет

- Unit 2 Part A 1. Write Short Notes On A) Deliver Ratio B) Trapping Efficiency C) Charging EfficiencyДокумент22 страницыUnit 2 Part A 1. Write Short Notes On A) Deliver Ratio B) Trapping Efficiency C) Charging EfficiencyJVCОценок пока нет

- Iran Gas ProjectsДокумент37 страницIran Gas ProjectsAnusuya SwamyОценок пока нет

- Final BookДокумент479 страницFinal Bookmohamed352100% (1)

- HGV Power Box SC Data Sheet v1 0Документ8 страницHGV Power Box SC Data Sheet v1 0Miguel CОценок пока нет

- Experiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Документ11 страницExperiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Safi Ullah WarraichОценок пока нет

- Reservoir Engineering I: Barham S. Mahmood E-Mail: Petroleum Engineering DepartmentДокумент33 страницыReservoir Engineering I: Barham S. Mahmood E-Mail: Petroleum Engineering DepartmentAbdulla MohammadОценок пока нет

- Steam Boiler - Hydrostatic Test in Steam BoilerДокумент2 страницыSteam Boiler - Hydrostatic Test in Steam BoilerRoland NicolasОценок пока нет

- Water Distribution Manual PDFДокумент96 страницWater Distribution Manual PDFgalca_stefanОценок пока нет

- Heat Exchanger Design - ProcessДокумент42 страницыHeat Exchanger Design - Processalokbdas100% (1)

- 623-09 - Compressor Airflow ControlДокумент36 страниц623-09 - Compressor Airflow ControlA ENGENHARIA DAS COISASОценок пока нет

- F.O. Lines Steam BlowingДокумент9 страницF.O. Lines Steam Blowingsrigirisetty208Оценок пока нет

- Fluid and BMCДокумент3 страницыFluid and BMChitkcivilОценок пока нет

- AFT BrochureДокумент4 страницыAFT BrochurenkouhiОценок пока нет