Академический Документы

Профессиональный Документы

Культура Документы

Belt Design Assngmnt

Загружено:

MohammedAminShaikhАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Belt Design Assngmnt

Загружено:

MohammedAminShaikhАвторское право:

Доступные форматы

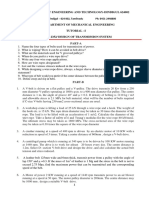

Design of Machine Elements – 2151907 (5th Semester)

Assignment for Belt Design.

Milap M. Madhikar, Assistant Professor, Mechanical. GEC Surat.

1 Explain in brief the design procedure for v-belt drives.

2 Derive the expression of a ratio of driving tensions for the flat belt drive. Explain the effect of

centrifugal tension on ratio of driving tensions in brief.

3 A pulley of 0.9m diameter transmits 7.5 kW power at 200 rpm. Find the width of a leather

belt if maximum tension is not to exceed 14.5 N per mm width. The tension in the tight side is

twice that in the slack side. Also determine the dimensions of the various parts of the flat belt

pulley, assuming it to have six arms. The arms are of C.I. for which tensile stress may be taken

as 15 N/mm2. The diameter of the shaft is 35 mm.

4 Design a V belt drive from the following data.

Motor Power = 3.75 kw, Belt width = 17 mm, Speed of Motor = 1440 rpm, Belt thickness = 11

mm, Speed reduction = 4 , Belt area = 140 mm2, Density of belt = 1.5×10-5 N/mm3,

Endurance limit for belt is 10N/mm2.

5 Design a 10 mm thick rubber belt to drive a dynamo generating 20 KW at 2250 R.P.M. and

fitted with a pulley 200 mm diameter. The dynamo efficiency to be 85%. Allowable stress for

belt = 2.1 MPa, Density of rubber = 1000 kg/m3, Angle of contact for dynamo pulley = 1650,

Coefficient of friction between belt and pulley = 0.3

6 A compressor, requiring 90 KW, is to run at about 250 R.P.M. The drive is by V-belts from an

electric motor running at 750 R.P.M. The diameter of pulley on compressor shaft must not be

greater than 1 meter while the centre distance between the pulleys is limited to 1.75 meter.

The belt speed should not exceed 1600 meters/min. Determine the number of V-belts

required to transmit the power if each belt has a cross-sectional area of 375 mm2, density

1000 kg / m3 and an allowable tensile stress of 2.5 MPa. The groove angle of the pulleys is

350. The coefficient of friction between the belt and the pulley is 0.25. Calculate also the

length required of each belt.

7 Two V Belts of section B are transmitting power on grooved pulleys. Angle of Groove is 350.

Belt angle is 400.The driver pulley of 300 mm runs at 1500 rpm and driven pulley is 600 mm

diameter. The coefficient of friction between belt and pulley is 0.3. If the power transmitted is

150 kW, determine (i) Centrifugal tension (ii) maximum tension, (iii) length of the belt for

open drive. (iv) designation of the belt, (v) the speed at which maximum power can be

transmitted The mass of the belt is 0.193 kg per m length For Section B Belt. Assume centre

distance between pulleys is 900 mm.

8 A flat belt drive transmits 50 kW at 25 m/s. The mass of the belt is 1.75 kg per meter of belt

length and width the belt is 180 mm. The belt drive is cross belt drive having driver pulley of

350 mm and driven pulley of 1050 mm. The centre distance between two pulleys is 5 m.

Calculate the length of belt; angle of contact; belt tensions and thickness of belt. Take mass

density of belt= 1000 kg/m3 and coefficient of friction between belt and pulley surface=0.35.

Вам также может понравиться

- Dme-II Question BankДокумент4 страницыDme-II Question BankenggsantuОценок пока нет

- Topics - Clutches, Belts and Ropes: Part - AДокумент3 страницыTopics - Clutches, Belts and Ropes: Part - AramОценок пока нет

- DTS Question BankДокумент21 страницаDTS Question BankSam TirshathОценок пока нет

- ME-311 Belt 2018Документ2 страницыME-311 Belt 2018VishnuОценок пока нет

- Me1036 Dts Tutorial Note BookДокумент176 страницMe1036 Dts Tutorial Note BookSachi DhanandamОценок пока нет

- Dme-II Question BankДокумент7 страницDme-II Question BankenggsantuОценок пока нет

- Belt Drives ExamplesДокумент3 страницыBelt Drives ExamplesMuhd Afiq AzmirОценок пока нет

- Assignment For Belt DriveДокумент2 страницыAssignment For Belt DriveNevil ModiОценок пока нет

- Module 1 Belt Drive 2018 PDFДокумент3 страницыModule 1 Belt Drive 2018 PDFKerr GenebraldoОценок пока нет

- Design of Transmission Systems Question Bank 1Документ27 страницDesign of Transmission Systems Question Bank 1shivesh rockesОценок пока нет

- Friction Belt Drive ProblemsДокумент4 страницыFriction Belt Drive ProblemsKenta Hirohata100% (1)

- A. Flat Belt & Pulleys: Unit I Design of Transmission Systems For Flexible ElementsДокумент3 страницыA. Flat Belt & Pulleys: Unit I Design of Transmission Systems For Flexible ElementsVijaya Prabhu KumarasamyОценок пока нет

- Chapter Wise Questions Bank MD-iiДокумент6 страницChapter Wise Questions Bank MD-iiinderpreet singhОценок пока нет

- Assignment 1B - Belt Drive PDFДокумент2 страницыAssignment 1B - Belt Drive PDFFattihiEkhmal0% (2)

- Unit-I Design of Transmission Systems For Flexible Elements - Part-A Belt DrivesДокумент15 страницUnit-I Design of Transmission Systems For Flexible Elements - Part-A Belt DrivesM Rasyid RidhoОценок пока нет

- Machine Design I TutorialДокумент3 страницыMachine Design I TutorialbngelotrОценок пока нет

- Me4C03 - Kinematics of MachineryДокумент2 страницыMe4C03 - Kinematics of Machineryshishirganesh 1109Оценок пока нет

- Design of Transmission Systems-Question BankДокумент28 страницDesign of Transmission Systems-Question BankAlfred Franklin V100% (1)

- Possible Exercise On Machine Element Two Flat BeltДокумент4 страницыPossible Exercise On Machine Element Two Flat BeltAbebaw AyeleОценок пока нет

- Dts Tutorial - IДокумент1 страницаDts Tutorial - IRama SamyОценок пока нет

- KDM Portion - Design of Belt DrivesДокумент3 страницыKDM Portion - Design of Belt DrivesAadrika UmashankarОценок пока нет

- 3.1.belt and Belt DrivesДокумент17 страниц3.1.belt and Belt DrivesVignesh ShenoyОценок пока нет

- Belt DriveДокумент12 страницBelt DriveBISHAL AdhikariОценок пока нет

- V DriveДокумент7 страницV Drivedilshadabdullah786Оценок пока нет

- DMM 2Документ6 страницDMM 2Shubham MahajanОценок пока нет

- Design of Transmission Systems Question BankДокумент26 страницDesign of Transmission Systems Question BankJennifer WilsonОценок пока нет

- gupta PG - No:176) Exercise 9Документ3 страницыgupta PG - No:176) Exercise 9mahendra babu mekalaОценок пока нет

- cp0053 25-Jul-2011 rm01Документ2 страницыcp0053 25-Jul-2011 rm01stalinkbcОценок пока нет

- DTS University Question BankДокумент11 страницDTS University Question BankMURUGANОценок пока нет

- Tutorial 3 (Kom)Документ2 страницыTutorial 3 (Kom)patelsandip1990Оценок пока нет

- UNIT-5 SpringsДокумент6 страницUNIT-5 SpringsUday Narasimha100% (2)

- Design of Transmission Systems Question BankДокумент27 страницDesign of Transmission Systems Question BankbalajimetturОценок пока нет

- Assignment - IIДокумент3 страницыAssignment - IIRamaswamy SubbiahОценок пока нет

- Tutorial 5&6 Mechanics of Machine (Q)Документ1 страницаTutorial 5&6 Mechanics of Machine (Q)Raiham EffendyОценок пока нет

- A. Belt Drive Option: Design Alternatives and Selection of The Design ApproachДокумент2 страницыA. Belt Drive Option: Design Alternatives and Selection of The Design ApproachAgung RiyadiОценок пока нет

- Dme-2 2013Документ3 страницыDme-2 2013Mohammed YunusОценок пока нет

- V Belt Drive-ProblemsДокумент1 страницаV Belt Drive-ProblemsLightОценок пока нет

- Dynamics of Machines 4 Units New Question BankДокумент4 страницыDynamics of Machines 4 Units New Question BankgbharathreddysОценок пока нет

- MDlab FinalsДокумент18 страницMDlab FinalsNarry StrummerОценок пока нет

- MD1 and MD2 Compilation 1Документ50 страницMD1 and MD2 Compilation 1boj VillanuevaОценок пока нет

- Mechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Документ4 страницыMechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Harpinder GotraaОценок пока нет

- Mechanical Engineering Department Institute of Technology Nirma University Kinematics - 2ME301 Belt Rope and Chain DriveДокумент2 страницыMechanical Engineering Department Institute of Technology Nirma University Kinematics - 2ME301 Belt Rope and Chain DriveMutegi Jack100% (1)

- DTS ME 6601 - University Tutorial Problem.Документ1 страницаDTS ME 6601 - University Tutorial Problem.Vishnu Viki Pranav BОценок пока нет

- Assignment 3 KomДокумент2 страницыAssignment 3 Komrana singhОценок пока нет

- mODULE #3. Machine Elements .FinalsДокумент21 страницаmODULE #3. Machine Elements .FinalsRocsОценок пока нет

- ME2352-DTS Question BankДокумент8 страницME2352-DTS Question BankNaresh015Оценок пока нет

- A1. Examples: Belt Drives Examples and WorksheetДокумент3 страницыA1. Examples: Belt Drives Examples and WorksheetAb_AlizadehОценок пока нет

- Simple Mechanisms: (2 Marks) 1. What Are The Materials Used For Making Ropes?Документ3 страницыSimple Mechanisms: (2 Marks) 1. What Are The Materials Used For Making Ropes?RahulОценок пока нет

- Sheet Belt 1Документ2 страницыSheet Belt 1omar dahabОценок пока нет

- ME 424B Quiz 4Документ2 страницыME 424B Quiz 4Grido FinoОценок пока нет

- Me 2352 Design of Transmission Systems: III Year MechanicalДокумент14 страницMe 2352 Design of Transmission Systems: III Year MechanicalAravinthan VijayanОценок пока нет

- Automobile Design Rev2015Документ6 страницAutomobile Design Rev2015Rithik Raj RanjuОценок пока нет

- University Questions: Unit-I Design If Transmission Sustems For Flenible ElementsДокумент5 страницUniversity Questions: Unit-I Design If Transmission Sustems For Flenible ElementsMalik Al TurkiОценок пока нет

- Tutorial1 B+ Belt+Drive+SystemДокумент6 страницTutorial1 B+ Belt+Drive+Systemnornadiah93Оценок пока нет

- D MДокумент9 страницD MMuthu KumarОценок пока нет

- Assignment 01Документ2 страницыAssignment 01Ratan Sadanandan O MОценок пока нет

- Study of a reluctance magnetic gearbox for energy storage system applicationОт EverandStudy of a reluctance magnetic gearbox for energy storage system applicationРейтинг: 1 из 5 звезд1/5 (1)

- A Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsОт EverandA Guide to Making a Leather Belt - A Collection of Historical Articles on Designs and Methods for Making BeltsРейтинг: 3 из 5 звезд3/5 (1)

- Hip NormДокумент35 страницHip NormAiman ArifinОценок пока нет

- IdM11gR2 Sizing WP LatestДокумент31 страницаIdM11gR2 Sizing WP Latesttranhieu5959Оценок пока нет

- L1 L2 Highway and Railroad EngineeringДокумент7 страницL1 L2 Highway and Railroad Engineeringeutikol69Оценок пока нет

- A Novel Adoption of LSTM in Customer Touchpoint Prediction Problems Presentation 1Документ73 страницыA Novel Adoption of LSTM in Customer Touchpoint Prediction Problems Presentation 1Os MОценок пока нет

- Assignment - 2: Fundamentals of Management Science For Built EnvironmentДокумент23 страницыAssignment - 2: Fundamentals of Management Science For Built EnvironmentVarma LakkamrajuОценок пока нет

- DC Servo MotorДокумент6 страницDC Servo MotortaindiОценок пока нет

- PCДокумент4 страницыPCHrithik AryaОценок пока нет

- Activity Description Predecessor Time (Days) Activity Description Predecessor AДокумент4 страницыActivity Description Predecessor Time (Days) Activity Description Predecessor AAlvin LuisaОценок пока нет

- COOKERY10 Q2W4 10p LATOJA SPTVEДокумент10 страницCOOKERY10 Q2W4 10p LATOJA SPTVECritt GogolinОценок пока нет

- PC210 8M0Документ8 страницPC210 8M0Vamshidhar Reddy KundurОценок пока нет

- Edita's Opertionalization StrategyДокумент13 страницEdita's Opertionalization StrategyMaryОценок пока нет

- Fake PDFДокумент2 страницыFake PDFJessicaОценок пока нет

- 23 Things You Should Know About Excel Pivot Tables - Exceljet PDFДокумент21 страница23 Things You Should Know About Excel Pivot Tables - Exceljet PDFRishavKrishna0% (1)

- Sustainable Urban Mobility Final ReportДокумент141 страницаSustainable Urban Mobility Final ReportMaria ClapaОценок пока нет

- Ajp Project (1) MergedДокумент22 страницыAjp Project (1) MergedRohit GhoshtekarОценок пока нет

- Peoria County Jail Booking Sheet For Oct. 7, 2016Документ6 страницPeoria County Jail Booking Sheet For Oct. 7, 2016Journal Star police documents50% (2)

- Building and Other Construction Workers Act 1996Документ151 страницаBuilding and Other Construction Workers Act 1996Rajesh KodavatiОценок пока нет

- Efs151 Parts ManualДокумент78 страницEfs151 Parts ManualRafael VanegasОценок пока нет

- Presentation Report On Customer Relationship Management On SubwayДокумент16 страницPresentation Report On Customer Relationship Management On SubwayVikrant KumarОценок пока нет

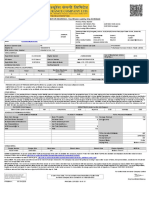

- MOTOR INSURANCE - Two Wheeler Liability Only SCHEDULEДокумент1 страницаMOTOR INSURANCE - Two Wheeler Liability Only SCHEDULESuhail V VОценок пока нет

- Kaitlyn LabrecqueДокумент15 страницKaitlyn LabrecqueAmanda SimpsonОценок пока нет

- Dissertation On Indian Constitutional LawДокумент6 страницDissertation On Indian Constitutional LawCustomPaperWritingAnnArbor100% (1)

- Analysis of Material Nonlinear Problems Using Pseudo-Elastic Finite Element MethodДокумент5 страницAnalysis of Material Nonlinear Problems Using Pseudo-Elastic Finite Element MethodleksremeshОценок пока нет

- Star Link SafetyДокумент2 страницыStar Link SafetyJeronimo FernandezОценок пока нет

- Use of EnglishДокумент4 страницыUse of EnglishBelén SalituriОценок пока нет

- BS 8541-1-2012Документ70 страницBS 8541-1-2012Johnny MongesОценок пока нет

- ACIS - Auditing Computer Information SystemДокумент10 страницACIS - Auditing Computer Information SystemErwin Labayog MedinaОценок пока нет

- Aluminum 3003-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyДокумент2 страницыAluminum 3003-H112: Metal Nonferrous Metal Aluminum Alloy 3000 Series Aluminum AlloyJoachim MausolfОценок пока нет

- Difference Between Mountain Bike and BMXДокумент3 страницыDifference Between Mountain Bike and BMXShakirОценок пока нет

- Office Storage GuideДокумент7 страницOffice Storage Guidebob bobОценок пока нет