Академический Документы

Профессиональный Документы

Культура Документы

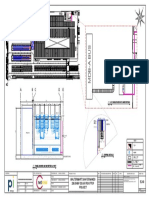

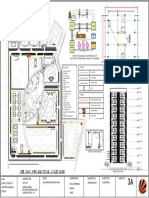

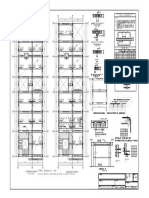

HANDRAIL TYPICAL CROSS SECTION AND ELEVATION

Загружено:

TrươngPhiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HANDRAIL TYPICAL CROSS SECTION AND ELEVATION

Загружено:

TrươngPhiАвторское право:

Доступные форматы

HANDRAIL TYPICAL CROSS SECTION HANDRAIL TYPICAL ELEVATION - SPAN U-GRIDER - STRAIGHT ALIGNMENT CROSS SECTION I - I

Pipe D70x5 PIPE D70x5 SPANS INTERFACE

30 150 30

2A, 2B, 2C, 2D 2A, 2B

210

A 200 100

64

I I PLATE D70x5

-

-

BM3

R3

17

36 185 61

70

4 Base plate 282x210x20 282 19

Plate 80x17x5 7 BM2

90

BM1 R2 TUBE 90x2.8

1 TUBE 30x30x3 PLATE 40x3x650

186

Plate D90x5 3D BM4 Pipe D70x5

749

BM5 2A, 2B, 2C, 2D

Base plate of cable tray (CP02)

150

150

Tube 90x2.8

1

3A, 3B, 3C, 3D

TUBE 30x30x3

150

150

90

3A

1100

1100

Detail "E"

600

1500

559

2

150

150

BM6

D80x3

D80x3

BM6 Detail "B"

150

150

604 5 312

380

380

50

Tube 30x30x3

Foot path on concrete parapet

244

244

749

R9

Plate D90x5 R1 90 90 155 100 155 90

90

BM5

0

80 282 19

Steel plate 282x210x20 BM5 Plate D90x5 36 185 61

282 19 BM2

30 150 30

Detail "A"

210

A 200 EXPANSION JOINT Tube 90x2.8

BL 4 Post drilling bolts M16 1

DETAIL "A" CROSS SECTION II - II

SCALE: 1/50 SCALE: 1/50 90

Tube 90x2.8 Plate 80x17x5

15 60 15 I Joint connection D58x4 BM1

227 19 Tube 90x2.8 Pipe D70x5 -

50 5 282 19 80 Plate D90x5

BM5

II II

-

4 Post drilling bolts M16 36 185 61

Detail "C" BL

6

20

58

70

Base plate 282x210x20 Detail "D"

BM2

Tube 30x30x3 Tube 30x30x3

6

30

5 1 50 1 5

749 2 749 4 58 4

2.8 84.2 2.8

192

16 16 1500

210

150

90 70 17

Tube 90x2.8

Tube 90x2.8

Tube 90x2.8

30

BL 227

1 -

50 19

I

36 185 61 5

282 19 BM2 Base plate 282x210x20

18

1 16 1

DETAIL "C" DETAIL OF WASHER, NUT OF BOLT

3

9

1. All dimension are in mm.

R9

SCALE: NA SCALE: NA 2. Steel of handrail structure manufactured by steel SS400 (TCVN 5575:2012) approved follow to letter no.PIC-MLT-04043-16-E dated 15/12/2016

30

20 33

6.5 17 6.5 3. Fabricated segments in factory. Transport & install segments at site. Segments are connected by internal joint connection D58x4 and welded at site.

22

22

16

4

Base plate 282x210x20

4. All metal elements shall be galvanized including all accessories such as bolts, nuts, washer and workshop welding.

Hollow section elements must be closed for air tighness. Site welding must be avoided. If use it shall be protected

Emin=26.8

from corrosion by zinc coat galvanization at the site.

250

9

192

Chemical bolt

3

5. If there is conflict with girder rebar and anchor bolt, allow to adjust the pole position one times of rebar diameter.

Injection motar 6. Anchorage bolts using chemical bolts. Bolt embeddment length in concrete is 192mm for chemical.

5

13 Smax=24

2.5

1 16 1 7. This drawing is to be read in conjunction with drawings no.DLM-IMP-GAD-WVO-J00-17819~17822-B

18 6.5 17 6.5 8. Detail of bolt, nut, washer referred to Proposal of chemical bolt material approved follow to letter no.PIC-MLT-04043-16-E dated 15/12/2016.

30 9. Arrangement detail for base plate of cable tray (CP02) shown at drawing no. DLM-IMP-GAD-WVO-J00-17822-B

DLM-IMP-GAD-WVO-J00-17841-B-.dwg

DAELIM

A3 15/4/2017

This drawing must not be either loaned, copied or otherwise reproduced TYPICAL DETAIL DESIGN OF HANDRAIL (1/2)

2A N.T.Anh P.M.Tuan in whole or in part or used for any prupose without the prior written

permission of MRB.

1A N.T.Anh P.V.Hung

Oh Seung Jong DLM-IMP-GAD-WVO-J00-17841-B-.dwg 2A

Вам также может понравиться

- 3D BBE Tone Control Bass Boost: Sheet - 1Документ1 страница3D BBE Tone Control Bass Boost: Sheet - 1Daniel OfoeОценок пока нет

- BBS BorpileДокумент1 страницаBBS BorpileSurya Bintang RamadhanaОценок пока нет

- A102-R7 Ground Floor Plan-A102-r7 Revised Ground Floor PlanДокумент1 страницаA102-R7 Ground Floor Plan-A102-r7 Revised Ground Floor Planzubair khanОценок пока нет

- Review of Ramps and Stairs Drawings Shop DrawingДокумент1 страницаReview of Ramps and Stairs Drawings Shop DrawingPhạm Quốc ViệtОценок пока нет

- Color Diagram Basic Schematic TV (14"-21"/130V-260V) /Belson/Dpto - Tecnico/Ed.01Документ1 страницаColor Diagram Basic Schematic TV (14"-21"/130V-260V) /Belson/Dpto - Tecnico/Ed.01nikko hinostrozaОценок пока нет

- Showroom - 2021-RC-01-02-FOUNDATION DRG - R0-16.11.2021-ModelДокумент1 страницаShowroom - 2021-RC-01-02-FOUNDATION DRG - R0-16.11.2021-Modelswapnil bokadeОценок пока нет

- Electrical room layout and detailsДокумент1 страницаElectrical room layout and detailsharold de guzmanОценок пока нет

- AngkurДокумент1 страницаAngkurJundiОценок пока нет

- XPROG-m - Schematic DiagramДокумент2 страницыXPROG-m - Schematic DiagramAndrei67% (3)

- 1310 GEIC TEN AR SS1 100 - Substation AR SS1 100Документ1 страница1310 GEIC TEN AR SS1 100 - Substation AR SS1 100Mohd AkkiОценок пока нет

- 39 Gfc-P2c3-Tu02-Crp-Dr-Btn-73112-01-AДокумент1 страница39 Gfc-P2c3-Tu02-Crp-Dr-Btn-73112-01-ASUBHASH KUMARОценок пока нет

- Power supply circuit analysisДокумент2 страницыPower supply circuit analysisIliescu Cristian100% (2)

- Peavey 6505PLUS 112 SchematicДокумент9 страницPeavey 6505PLUS 112 SchematicR .GОценок пока нет

- Diagrams TDS820Документ42 страницыDiagrams TDS820Waldemar JęczewskiОценок пока нет

- Country House 1605201Документ3 страницыCountry House 1605201David KisaluОценок пока нет

- For Approval: Ceiling Space To Be Airtight by OthersДокумент1 страницаFor Approval: Ceiling Space To Be Airtight by Othersavinash3479Оценок пока нет

- Bore Hole DiametersДокумент1 страницаBore Hole DiametersVladislavОценок пока нет

- PR139 - B1 Layout PDFДокумент1 страницаPR139 - B1 Layout PDFshazril93Оценок пока нет

- Dash Display Communication Port ConnectionsДокумент2 страницыDash Display Communication Port ConnectionsChristian BedoyaОценок пока нет

- SMW 3 0Документ1 страницаSMW 3 0Zoran Poštin0% (1)

- 3408E and 3412E Engines Electrical System PDFДокумент2 страницы3408E and 3412E Engines Electrical System PDFssinokrot100% (2)

- Audio amplifier circuit diagramДокумент1 страницаAudio amplifier circuit diagramMarco Pedrosa100% (3)

- Alto+Ps4ha Amp+DiagramДокумент1 страницаAlto+Ps4ha Amp+DiagramBial SatosОценок пока нет

- Balcont DetailsДокумент1 страницаBalcont DetailsBharani MadamanchiОценок пока нет

- Circuit board assembly replacement guideДокумент1 страницаCircuit board assembly replacement guidedareka darezouОценок пока нет

- Prancha 04Документ1 страницаPrancha 04ALFA Consultoria Agronômica e AmbientalОценок пока нет

- Asf 607 02 Ad 535 Rev.bДокумент1 страницаAsf 607 02 Ad 535 Rev.bHaseeb RazviОценок пока нет

- Prestressed Girder Elevation (Type V, L 33.00M) : Back of Backwall End of Girder 3 2 End of GirderДокумент1 страницаPrestressed Girder Elevation (Type V, L 33.00M) : Back of Backwall End of Girder 3 2 End of GirderErika Faye GutierrezОценок пока нет

- OUTLET G3/8": Confidentiality Class Acc. To 1102 KДокумент1 страницаOUTLET G3/8": Confidentiality Class Acc. To 1102 Krogerroman24Оценок пока нет

- ARCH راشد المزروعي PDFДокумент4 страницыARCH راشد المزروعي PDFIvanna GlonОценок пока нет

- 308 Hyd PDFДокумент1 страница308 Hyd PDFchanlin100% (2)

- A01 Osmar PDFДокумент1 страницаA01 Osmar PDFOsmar BarriosОценок пока нет

- Bauer Spezialtiefbau GMBH: NotesДокумент1 страницаBauer Spezialtiefbau GMBH: NotesVignesh VenkatasubramanianОценок пока нет

- Elevation of Tower - 2 (Facing North) Part 3 of 3: Section L-LДокумент1 страницаElevation of Tower - 2 (Facing North) Part 3 of 3: Section L-LHozien OnofreОценок пока нет

- Low Level Plan - Area E - Mass Notification System: A B C D E F G HДокумент1 страницаLow Level Plan - Area E - Mass Notification System: A B C D E F G HrajaОценок пока нет

- Pdf 檔案使用 "Pdffactory Pro" 試用版本建立: Pth 1 Ee10 NДокумент2 страницыPdf 檔案使用 "Pdffactory Pro" 試用版本建立: Pth 1 Ee10 NZlatko Mrki HrncicОценок пока нет

- Approval by NCRTC QR Code: National Capital Region Transport CorporationДокумент1 страницаApproval by NCRTC QR Code: National Capital Region Transport CorporationZaid HussainОценок пока нет

- Group 2 Electrical Circuit: 25L/30L/33L (LC) - 7MДокумент7 страницGroup 2 Electrical Circuit: 25L/30L/33L (LC) - 7MCamilo TorresОценок пока нет

- Vintage Rosewood Guitar ElectronicsДокумент1 страницаVintage Rosewood Guitar ElectronicsJorgeLuisОценок пока нет

- Floor Plan - 1420Документ5 страницFloor Plan - 1420rutujaОценок пока нет

- Manual operation mechanism dimensionsДокумент2 страницыManual operation mechanism dimensionsxuanloc214Оценок пока нет

- 3 Guest Elevations and Stair DetailsДокумент1 страница3 Guest Elevations and Stair Detailstouati benОценок пока нет

- Liz and The Blue Bird-BassoonДокумент6 страницLiz and The Blue Bird-BassoonPooPooОценок пока нет

- Wet H2S Service Amine Service: 3D ViewДокумент1 страницаWet H2S Service Amine Service: 3D ViewMohamed SamirОценок пока нет

- Dźwigar GOTOWY-ModelДокумент1 страницаDźwigar GOTOWY-Modelanes beckОценок пока нет

- Denah Lantai 5-15Документ1 страницаDenah Lantai 5-15WA ODE SITTI AISYAH AОценок пока нет

- ST 1Документ1 страницаST 1ktm nirvanaОценок пока нет

- MRCN Map Ward No: 4: LegendДокумент6 страницMRCN Map Ward No: 4: LegendShekhar ChapagainОценок пока нет

- Bill of Material: Section A-AДокумент1 страницаBill of Material: Section A-APinak ProjectsОценок пока нет

- General Sheet Notes - Floor Plans: Ecopark Daesung International SchoolДокумент1 страницаGeneral Sheet Notes - Floor Plans: Ecopark Daesung International SchoolVũ Việt DũngОценок пока нет

- U/S D/S: Sectional ElevationДокумент2 страницыU/S D/S: Sectional ElevationRajender Reddy ParneОценок пока нет

- S4 PDFДокумент1 страницаS4 PDFSowmya ShreeОценок пока нет

- Audio 600Документ3 страницыAudio 600rea sonerОценок пока нет

- Schematic - Design Mock Up - Main PCB Copy - 20200327153258Документ1 страницаSchematic - Design Mock Up - Main PCB Copy - 20200327153258Yoshua M FAОценок пока нет

- Gato Del MandolínДокумент1 страницаGato Del MandolínEnzo LunaОценок пока нет

- Simplified Diagram of Distributuion of Electricity From Power Station To ConsumerДокумент1 страницаSimplified Diagram of Distributuion of Electricity From Power Station To ConsumerDivija PampanaОценок пока нет

- Primera Planta Segunda Planta: Detalle: Doblado de Estribos en Columnas Y VigasДокумент1 страницаPrimera Planta Segunda Planta: Detalle: Doblado de Estribos en Columnas Y VigasDiego CervantesОценок пока нет

- Dam MauДокумент1 страницаDam MauTrươngPhiОценок пока нет

- khám skДокумент4 страницыkhám skTrươngPhiОценок пока нет

- SMR 59 - U Bolt M16 For Handrail Structure at Ramp To DepoДокумент27 страницSMR 59 - U Bolt M16 For Handrail Structure at Ramp To DepoTrươngPhiОценок пока нет

- BJTY-PZ-364-2016 - Chap Thuan Ho So Phuong An Thi Cong Ket Cau Tuong Chong OnДокумент2 страницыBJTY-PZ-364-2016 - Chap Thuan Ho So Phuong An Thi Cong Ket Cau Tuong Chong OnTrươngPhiОценок пока нет

- Arrange Bolt - Left SideДокумент6 страницArrange Bolt - Left SideTrươngPhiОценок пока нет

- Foundation Engineering Handbook, H.Y. FangДокумент942 страницыFoundation Engineering Handbook, H.Y. FangFranco0492% (37)

- Crane ATF-1000XL PDFДокумент8 страницCrane ATF-1000XL PDFTrươngPhiОценок пока нет

- BG Tieng Anh Chuyen Nganh XdungДокумент41 страницаBG Tieng Anh Chuyen Nganh XdungTrươngPhiОценок пока нет

- Graduate Civil Engineer ResumeДокумент3 страницыGraduate Civil Engineer ResumeIsaacОценок пока нет

- Horizontal & Extended Reach WellsДокумент18 страницHorizontal & Extended Reach WellsRachid Touati100% (6)

- Underwing Nozzles: 3 Inch Unisex CouplingsДокумент12 страницUnderwing Nozzles: 3 Inch Unisex CouplingsHenryОценок пока нет

- Pipe's Minor LossesДокумент95 страницPipe's Minor LossesJosept RevueltaОценок пока нет

- Salberg A4 Catalogue RevisedДокумент28 страницSalberg A4 Catalogue RevisedSinenhlanhlaОценок пока нет

- Fencing, Compound Wall and Gate: by Ar. Pranoti LadДокумент49 страницFencing, Compound Wall and Gate: by Ar. Pranoti Ladbishal dasОценок пока нет

- Green ConstructionДокумент19 страницGreen ConstructionJohn ChristopherОценок пока нет

- Presentation On Reinforcing Detailing of R.CДокумент16 страницPresentation On Reinforcing Detailing of R.CbertazcorpОценок пока нет

- 3 - Precast Frame Analysis - Connections DesignДокумент35 страниц3 - Precast Frame Analysis - Connections DesignFatima rafiqОценок пока нет

- Stress and Strain - Axial Loading2Документ33 страницыStress and Strain - Axial Loading2Clackfuik12Оценок пока нет

- Akpark: Cover Sheet - ElectricalДокумент10 страницAkpark: Cover Sheet - ElectricalEngr M.Arshad KhalidОценок пока нет

- HPV135 - 2650002536 - Control Piston Valves and Add-On Pieces Equipamento CATERPILLAR 938KДокумент4 страницыHPV135 - 2650002536 - Control Piston Valves and Add-On Pieces Equipamento CATERPILLAR 938KRodrigues de OliveiraОценок пока нет

- Pile Design CalculationДокумент69 страницPile Design Calculationhessian123Оценок пока нет

- EML e BrochureДокумент21 страницаEML e BrochureECCSОценок пока нет

- Commercial Split System Installation Chart: Typical Piping and Wiring 3) Install Refrigerant PipingДокумент2 страницыCommercial Split System Installation Chart: Typical Piping and Wiring 3) Install Refrigerant PipingcarlosorizabaОценок пока нет

- Oil and gas processing equipment; Valve manufacturers and suppliers in IndonesiaДокумент3 страницыOil and gas processing equipment; Valve manufacturers and suppliers in IndonesiaKopi Soe SPBU MargahayuОценок пока нет

- Main Seawater Pump Overhaul ReportДокумент7 страницMain Seawater Pump Overhaul ReportPrakhyati RautОценок пока нет

- SC20 Sample Cooler PDFДокумент2 страницыSC20 Sample Cooler PDFjdanastasОценок пока нет

- IIT Madras Research Park Substation LayoutДокумент13 страницIIT Madras Research Park Substation Layoutnakul4491_88890127Оценок пока нет

- Affordable Housing in DhakaДокумент4 страницыAffordable Housing in DhakaNazmulОценок пока нет

- Designing A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Документ15 страницDesigning A Simply Supported Reinforced Concrete One Way Slab Per ACI Code 318-11Jigar100% (1)

- FLOW CONTROL VALVESДокумент6 страницFLOW CONTROL VALVESkulkarni278Оценок пока нет

- UntitledДокумент19 страницUntitledRene Constantine AvilaОценок пока нет

- SB Brace Frame For Single Sided Walls Instructions For Assembly and UseДокумент84 страницыSB Brace Frame For Single Sided Walls Instructions For Assembly and UseYaser IsmailОценок пока нет

- Luminaire Schedule-Exterior Facade Rev.02Документ2 страницыLuminaire Schedule-Exterior Facade Rev.02NATHANОценок пока нет

- Free Green: ArchitecturalДокумент14 страницFree Green: ArchitecturalPaola DiazОценок пока нет

- Ce 208 PDFДокумент87 страницCe 208 PDFanku4frenzОценок пока нет

- 13-Adv Materials Technologies - 2018 - Goh - Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer CompositeДокумент22 страницы13-Adv Materials Technologies - 2018 - Goh - Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer CompositeMuhammad TouheedОценок пока нет

- BOQ For Dubti Dam-GeotecДокумент4 страницыBOQ For Dubti Dam-GeotecMehari GebremeskelОценок пока нет

- Diversion Head WorksДокумент8 страницDiversion Head WorksMrinmoy SahaОценок пока нет