Академический Документы

Профессиональный Документы

Культура Документы

Oracle Inventory Management Cloud

Загружено:

j0nygrОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Oracle Inventory Management Cloud

Загружено:

j0nygrАвторское право:

Доступные форматы

ORACLE DAT A SHEET

ORACLE INVENTORY

MANAGEMENT CLOUD

Inventory is a major asset for many organizations, and effectively managing

inventory, including the related inventory movement transactions, can impact

your bottom line. Oracle Inventory Management Cloud Service offers a

complete materials management solution that enables companies to

successfully manage the flow of goods: inbound, within the warehouse and

outbound. Oracle Cost Management allows

s cost professionals to capture,

track, and analyze costs associated with inventory items as they move

through the supply chain. Oracle Supply Chain Orchestration is a powerful

rules based engine that manages more complex supply and fulfillment flows.

Oracle

acle Supply Chain Financial Orchestration automates the financial flow

execution for internal trade between parties independently from the physical

movement of goods and fulfillment of services.

KEY BUSINESS BENEFITS

Complete Materials Management Solution in the Cloud

• Global inventory visibility

Oracle Inventory Management Cloud offers an integrated inventory, advanced

• Reduce inventory levels and cycle

times fulfillment, cost and financial trade management suite that is designed to automate,

• Reduce fulfillment cost of on-time streamline, and control inventory, manage complex demand and supply scenarios, cost

fulfillment using partner capabilities processes and internal trade end-to-end

end without expensive hardware and system

• Gain better insight into product costs management overhead costs.

and margins

The Oracle Cloud offers self-service

service business applications delivered on an integrated

• Flexibly manage trade between

internal parties development and deployment platform with tools to rapidly extend and

a create new

services. The Oracle Cloud is ideal for customers seeking subscription-based

subscription access to

leading Oracle applications, middleware and database services, all hosted and expertly

managed by Oracle. The application services are designed for ease-of-use,

ease enabling

business users to manage the solution directly with no IT involvement.

ORACLE DAT A SHEET

KEY FEATURES

• Proactive management of inbound, on-

hand and outbound operations

• End-to-end supplier consigned Comprehensive Materials Management Visibility and Control

inventory support

Oracle Inventory Management helps organizations ensure that material is effectively

• Advanced fulfillment processes –

Internal Material Transfer, Dropship, managed from receipt through the point of consumption in stock rooms, warehouses

Back-to-Back Support and manufacturing plants.

• Third party and advanced warehouse The flow of inbound materials is streamlined by providing centralized, proactive

management integration support

monitoring mechanisms that efficiently manage both expected receipts, in-transit and

• Internal and external manufacturing

support received lines by supplier, internal location or customer. Receiving agents are guided

through prescribed receiving, inspection and put-away tasks ensuring receipts are

• Standard and configured Product

support processed quickly and easily, and exceptions are promptly identified and resolved.

• Dedicated cost transaction workbench Access to inventory, replenishment and counting tasks are arranged in a central

• Business intelligence dashboard for inventory work area to simplify management of materials within and across facilities.

cost analysis From the centralized view of balances, users can easily see and manage different

• Multiple simultaneous cost material statuses, lots and serial numbers enabling proper stocking and handling of

representations

different types of materials. Additionally, users can initiate issue, receipt, count and

• Flexible, configurable cost calculation transfer of material within a facility and across facilities.

levels

• Model physical flow and financial flow Classification of materials is simplified by offering a variety of ABC valuation methods

independently allowing for effective counting of different types of materials. Based upon flexible

• Landed cost support approvals and controls, managers can identify problem products or handling within the

facility.

Stock-outs can be costly to your business. Oracle Inventory Management offers robust

Min/Max planning capabilities to replenish from your suppliers, manufacturing plants,

from other internal organizations or from bulk stocking locations.

Consigning inventory from suppliers allows you to only pay for the inventory you use.

This is great for controlling your inventory costs, but adds additional complexity and

overhead to the procure-to-pay process because taking ownership of inventory needs to

be decoupled from the physical receipt of inventory, and the actual ownership change

and associated payments triggered by a later, separate process.

The consigned inventory from supplier solution addresses these requirements with

functionality built-into the procure-to-pay process. Oracle Inventory Management

provides full visibility to materials consigned internally from your suppliers and externally

to your suppliers. As you consume goods a new document, called a consumption

advice, is communicated to your supplier via multiple communication methods. This

flexible solution allows you to consign goods from multiple suppliers, provides the ability

to return “owned” goods to consigned or vice-versa as well as returned back to the

supplier.

Throughout the various material management flows, Oracle Inventory Management

provides user friendly transactional and analytical reporting for business users to create,

modify and publish reports and alerts tailored to the business needs and the audience.

2 | ORACLE FUSION INVENTORY MANAGEMENT CLOUD SERVICE

ORACLE DAT A SHEET

Support Simple and Advanced Fulfillment Flows

Whether your locations are fulfilling orders for internal or external customers, Oracle

Inventory Management provides flexible capabilities to manage orders shipped from on-

on

hand or from supply specifically created for these orders.

Picking and Shipping work

ork areas provide intuitive analytics enabling managers and

operators to see the state

tate of fulfillment operations at a glance,

glance work completed, work to

be done, problems and potential problems. From there, users can drill into orders, lines

and shipments.

Flexible release rules allow for orders to be released to warehouse operators for picking

by a variety of attributes such as carrier, priority, customer, date and type of order to

name a few. Shipments

hipments can then be packed and confirmed or interfaced to manifesting

systems.

Figure 1 - Shipping Work Area

Advanced fulfillment techniques ensure on-time

time fulfillment and extend your product

offering without carrying excess inventory. The supported flows are: Internal Material

Transfers (IMT); Drop-shipment; Back-to-Back

Back purchase, make, and transfer; and

Supplier Consigned Inventory.

Support for Configured to Order (CTO) products blends the best of multiple worlds.

Items representing each unique configuration are automatically created and re-used

re

from prior orders to facilitate warehouse handling, promising and full forecasting and

supply planning capabilities. Fulfillment of these products leverage the same advanced

fulfillment processes of drop ship and back-to-back

back as other types of non-configurable

non

items providing the same level of flexibility and change management for all types of

items. Visibility to the details of each unique configuration is tailored to the type of user

or trading partner ensuring simple and effective fulfillment, procurement and production

and better communication with customers, transportation providers and suppliers.

IMTs are a fully-integrated flow that supports intra-organization,

organization, inter-organization,

inter and

inter-company transfers. Execution

xecution rules determine if the transfer will be executed as an

a

3 | ORACLE FUSION INVENTORY MANAGEMENT CLOUD SERVICE

ORACLE DAT A SHEET

Inventory Transfer Order or a Procurement Purchase Order to buy/sell between the

organizations.

Transfer Orders are a single document managing both demand in the source location

and supply in the destination integrated into the standard fulfillment and receiving

processes. Transfer Orders provide options to transfer supplier consigned goods as

consigned or owned and provide full returns capabilities.

Using drop-shipment, orders for items can be filled from an external (your supplier’s)

warehouse. This process maintains full visibility into the material movement process and

ensures supplier collaboration when changes to orders occur.

Order-specific supplies can be created using the fully integrated

ntegrated back-to-back

back process

that supports buying of products

ducts from a supplier, making them in-house (or at a contract

manufacturer’s facility), or transferring products between a distribution center and the

fulfillment warehouse. Supply is reserved to the

he demand until fulfillment and automated

change management procedures ensures perfect order fulfillment.

Figure 2 - Supply Chain Orchestration Workbench

Advanced and/or Extended Inventory Operations

Many companies outsource warehouse operations to third parties to take advantage of

their expertise and save on operational costs. Oracle Inventory Management provides

tools to enable full visibility and control of warehousing operations managed by third

parties such as third-party logistics (3PL) providers or contract manufacturers.

manufacturers These

same tools can be used to fully integrate with your own advanced warehouse

management systems.

4 | ORACLE FUSION INVENTORY MANAGEMENT CLOUD SERVICE

ORACLE DAT A SHEET

Manage Global Inter Company Transactions

Automate the financial flow execution for internal trade between parties independently

from the physical movement of goods and fulfillment of services with Oracle Supply

Chain Financial Orchestration. This configurable application manages all the financial

relationships resulting from

m trade between internal parties. The framework provides

modeling of flexible financial flows that define the parties involved, the nature of trade

relationships and business rules for documentation and accounting. Model and

automate multiple ownership changes

nges for a single movement of goods so that you can

account for supply chain functions that are centralized without sacrificing supply chain

speed. In addition, the framework supports the ability to define and configure transfer

pricing rules with markups and markdowns. There is a dedicated work area for the

supply chain controller to monitor execution and manage exceptions.

Figure 3 - Physical vs. Financial Flow

Single Solution for GAAP, Management

anagement and Statutory Cost

Reporting

Oracle Cost Management is an advanced cost accounting solution that helps

companies effectively manage their product costing and inventory accounting business

flows. The solution allows companies to maintain multiple cost books and financial

ledgers to better meet external regulatory and internal management reporting needs.

The solution increases product cost accuracy by providing a flexible cost infrastructure

that allows cost accountants to define the level of cost calculations. It greatly reduces

manual cost maintenance tasks by providing automated rules-based

rules engines and

efficient fault-tolerant

tolerant cost processors tuned for high volume transaction environments.

Adding to the regulatory and managerial needs for full visibility of product cost across

the entire global supply chain, market-based

based product pricing and sales deal quoting

requires an accurate and full understanding of variable versus fully absorbed cost

factors in order to maximize all sales opportunities.

5 | ORACLE FUSION INVENTORY MANAGEMENT CLOUD SERVICE

ORACLE DAT A SHEET

Graphical Views of Product Costs

Oracle Cost Management’s graphical user interfaces provide time-based,

time graphical

views of product costs using line, bar and pie charts to show product costs over time

and in comparison to other products or other organizations.. Cost professionals and

operations personnel can visually identify cost trend problems in their products

facilitating the determination of root causes and timely corrective actions.

Figure 4 - Review Item Costs

CONTACT US

For more information about [insert product name], visit oracle.com or call +1.800.ORACLE1 to speak to

an Oracle representative.

CONNECT W ITH US

blogs.oracle.com/oracle

Copyright © 2012016,, Oracle and/or its affiliates. All rights reserved. This document is provided for information purposes only, and the

contents hereof are subject to change without notice. This document is not warranted to be error-free,error nor subject to any other

facebook.com/oracle warranties or conditions, whether expressed orally or implied in law, including implied warranties and conditions of merchantability or

fitness for a particular purpose. We specifically disclaim any liability with respect to this document, and no contractual obligations

ob are

twitter.com/oracle formed either directly or indirectly by this document. This document may not be reproduced or transmitted in any form or by any

means, electronic or mechanical, for any purpose, without our prior written permission.

oracle.com Oracle and Java are registere

registered

d trademarks of Oracle and/or its affiliates. Other names may be trademarks of their respective owners.

Intel and Intel Xeon are trademarks or registered trademarks of Intel Corporation. All SPARC trademarks are used under license

licens and

are trademarks or re

registered

gistered trademarks of SPARC International, Inc. AMD, Opteron, the AMD logo, and the AMD Opteron logo are

trademarks or registered trademarks of Advanced Micro Devices. UNIX is a registered trademark of The Open Group. 0316

6 | ORACLE FUSION INVENTORY MANAGEMENT CLOUD SERVICE

Вам также может понравиться

- Oracle Inventory and Costing Cloud EbookДокумент11 страницOracle Inventory and Costing Cloud Ebooksingh_indrajeetkumarОценок пока нет

- Oracle Information Integration, Migration, and ConsolidationОт EverandOracle Information Integration, Migration, and ConsolidationОценок пока нет

- Quality Inspection Management Implementation - R19A - Student Guide PDFДокумент97 страницQuality Inspection Management Implementation - R19A - Student Guide PDFNeha9_scribd100% (1)

- Oracle® Fusion Procurement, Supplier Contracts and Agreements GuideДокумент195 страницOracle® Fusion Procurement, Supplier Contracts and Agreements GuideRammohan Pushadapu100% (1)

- Evosys Fso Fusion Procurement v1.4Документ26 страницEvosys Fso Fusion Procurement v1.4venvimal1Оценок пока нет

- Oracle Service ContractДокумент12 страницOracle Service Contractfernando_salazar_27100% (1)

- Setup Steps in Oracle Property ManagerДокумент43 страницыSetup Steps in Oracle Property ManagerAhmed Elhendawy100% (1)

- Fusion Procurement Applications Guide PDFДокумент244 страницыFusion Procurement Applications Guide PDFRammohan PushadapuОценок пока нет

- Overvieww of AIM Methodology OracleДокумент3 страницыOvervieww of AIM Methodology OracletsurendarОценок пока нет

- Purchasing Presentation OAДокумент39 страницPurchasing Presentation OASanthosh Kumar PathaОценок пока нет

- Oracle 1z0 963Документ38 страницOracle 1z0 963otherjumper100% (1)

- Oracle SourcingДокумент158 страницOracle SourcingPJ190290% (10)

- Ahmad Kamal, ,: MSC Oracle Ebs R12 Scm/P2P/O2C and Fusion SCM ConsultantДокумент5 страницAhmad Kamal, ,: MSC Oracle Ebs R12 Scm/P2P/O2C and Fusion SCM ConsultantzafernaseerОценок пока нет

- Evosys Fixed Scope Offering For Oracle Fusion Procurement Cloud ServiceДокумент12 страницEvosys Fixed Scope Offering For Oracle Fusion Procurement Cloud ServiceMunir AhmedОценок пока нет

- 15 SourcingДокумент34 страницы15 SourcingRodolfo BassettoОценок пока нет

- Oracle Procurement Cloud Using ProcuremeДокумент348 страницOracle Procurement Cloud Using ProcuremesiddharthkaulОценок пока нет

- What Is Oracle Shopfloor ManagementДокумент7 страницWhat Is Oracle Shopfloor ManagementRamesh GarikapatiОценок пока нет

- Oracle Isupplier Sit SessionsДокумент13 страницOracle Isupplier Sit SessionsNaveen Shankar MauwalaОценок пока нет

- SCM - Manufacturing Cloud: Update 21B OverviewДокумент26 страницSCM - Manufacturing Cloud: Update 21B OverviewSAINTJOE100% (1)

- Oracle Procurement ContractsДокумент7 страницOracle Procurement ContractsGopinath GoudОценок пока нет

- Manufacturing Foundation R19A Student GuideДокумент276 страницManufacturing Foundation R19A Student Guidedreamsky702243Оценок пока нет

- OM - What Is Modifiers and QualifiersДокумент4 страницыOM - What Is Modifiers and QualifiersAhmedОценок пока нет

- Fusion Allocation ManagerДокумент29 страницFusion Allocation ManagerRahul Jain100% (2)

- Oracle Project Accounting - R12 New Functionalities v1.1Документ11 страницOracle Project Accounting - R12 New Functionalities v1.1siva_lordОценок пока нет

- OAUG Oracle WMS ManagementДокумент42 страницыOAUG Oracle WMS ManagementmobakОценок пока нет

- Oracle 1Z0-347 Cloud Exam Practice MaterialДокумент6 страницOracle 1Z0-347 Cloud Exam Practice MaterialPass4leads ExamОценок пока нет

- Oracle R12 Complex ProcurementДокумент13 страницOracle R12 Complex ProcurementAli xОценок пока нет

- Oracle Depot Repair Features 1Документ22 страницыOracle Depot Repair Features 1Brajesh KumarОценок пока нет

- Introduction To Oracle R12 Application Training ManualДокумент160 страницIntroduction To Oracle R12 Application Training ManualAsmita ChatterjeeОценок пока нет

- Practice Guide OPMДокумент19 страницPractice Guide OPMAsad SoomroОценок пока нет

- R11 MSCA Setup Flow (Including Profile)Документ58 страницR11 MSCA Setup Flow (Including Profile)Babu ChalamalasettiОценок пока нет

- PRC SettingUpApprovals Whitepaper Rel13Документ95 страницPRC SettingUpApprovals Whitepaper Rel13Adity MathurОценок пока нет

- Interview Questions Oracle Apps Functional and TechnicalДокумент41 страницаInterview Questions Oracle Apps Functional and Technicalcrecyken@gmail.comОценок пока нет

- A Guide To Oracle Process Manufacturing System SetupДокумент39 страницA Guide To Oracle Process Manufacturing System SetupMegha Vijay100% (1)

- Oracle Apps Isourcing Process FlowДокумент4 страницыOracle Apps Isourcing Process FlowRamesh GarikapatiОценок пока нет

- Oracle Install Base OverviewДокумент18 страницOracle Install Base OverviewmallikarjunОценок пока нет

- Oracle Applications Inventory Training ManualДокумент171 страницаOracle Applications Inventory Training ManualLaxminarayanaОценок пока нет

- PRC SettingUpApprovals Whitepaper Rel13-20DДокумент112 страницPRC SettingUpApprovals Whitepaper Rel13-20DRajasekharОценок пока нет

- Procurement Impl Rel10 Activity GuideДокумент257 страницProcurement Impl Rel10 Activity GuideabhayasarangiОценок пока нет

- BR100 Service Contract Ver1.0Документ44 страницыBR100 Service Contract Ver1.0Sri Nithya AmritanandaОценок пока нет

- Oracle Isupplier Portal: Introduction To Isupplier Portal For Suppliers To American LafranceДокумент39 страницOracle Isupplier Portal: Introduction To Isupplier Portal For Suppliers To American Lafranceajit0706Оценок пока нет

- Oracle Fusion SCM GoodДокумент21 страницаOracle Fusion SCM GoodR50% (4)

- Oracle Fusion Functional Setup Manager (FSM) : Security ConsoleДокумент9 страницOracle Fusion Functional Setup Manager (FSM) : Security ConsoleAmitfusion R13Оценок пока нет

- TAB Whitepaper R13 18 05Документ49 страницTAB Whitepaper R13 18 05Kishan Bussa100% (1)

- Oracle SCM Functional Online Training With ProjectДокумент8 страницOracle SCM Functional Online Training With ProjectIshaac Newton0% (1)

- Demand Management Course Rel 18C - Student GuideДокумент172 страницыDemand Management Course Rel 18C - Student GuideVictor MillanОценок пока нет

- Inventory TransactionsДокумент38 страницInventory TransactionsStacey BrooksОценок пока нет

- Fixed AssetsДокумент353 страницыFixed Assetssrinivasta1973Оценок пока нет

- Oracle SCM - Inventory - Management - TrainingДокумент61 страницаOracle SCM - Inventory - Management - Trainingdheeraj007_nitk3164100% (3)

- 19D ActivityGuideДокумент466 страниц19D ActivityGuideحسين عبدالرحمنОценок пока нет

- Oracle Procurement Cloud-Rel-13 PDFДокумент472 страницыOracle Procurement Cloud-Rel-13 PDFVishal Bhanudas PatilОценок пока нет

- Oracle Diiference Between Asset and Expense ItemsДокумент5 страницOracle Diiference Between Asset and Expense ItemsmogaОценок пока нет

- BR.100. Cost ManagementДокумент17 страницBR.100. Cost ManagementjinfaherОценок пока нет

- Oracle Unified Method (OUM) : Oracle's Full Lifecycle Method For Deploying Oracle - Based Business SolutionsДокумент16 страницOracle Unified Method (OUM) : Oracle's Full Lifecycle Method For Deploying Oracle - Based Business SolutionsshrinawОценок пока нет

- Oracle Sales CloudДокумент225 страницOracle Sales Cloudj0nygrОценок пока нет

- Oracle® Supplier ManagementДокумент136 страницOracle® Supplier Managementj0nygrОценок пока нет

- Label Review David WertheimerДокумент32 страницыLabel Review David Wertheimerj0nygrОценок пока нет

- Sample Questions For Itb Modular ExamДокумент4 страницыSample Questions For Itb Modular Exam_23100% (2)

- Planning and Working Capital ManagementДокумент4 страницыPlanning and Working Capital ManagementSheena Mari Uy ElleveraОценок пока нет

- Analysis of Brand Loyalty of Cosmetics in Thanjavur DistrictДокумент7 страницAnalysis of Brand Loyalty of Cosmetics in Thanjavur Districtkavita_nОценок пока нет

- EY Further Expansion On Per 22 in New Transfer Pricing Audit GuidanceДокумент4 страницыEY Further Expansion On Per 22 in New Transfer Pricing Audit GuidanceRizky Hd-rОценок пока нет

- Marketing - Module 9 The Marketing Mix - PROMOTIONДокумент12 страницMarketing - Module 9 The Marketing Mix - PROMOTIONKJ Jones100% (3)

- Chapter 5 - External AuditДокумент11 страницChapter 5 - External AuditJesus ObligaОценок пока нет

- Explain in Detail All Types of Trademarks With Related Case LawsДокумент5 страницExplain in Detail All Types of Trademarks With Related Case LawsPiku NaikОценок пока нет

- Pitch - Investor Pitch ToolkitДокумент35 страницPitch - Investor Pitch Toolkitapritul3539100% (2)

- Peel Mining LTD Investor SheetДокумент2 страницыPeel Mining LTD Investor SheetkaiselkОценок пока нет

- E-Tendering Srs 5 JulyДокумент9 страницE-Tendering Srs 5 Julyanon-510114100% (2)

- KGN-GDD-033-2018 - Tender For Supply Installation Construction Commissioning of Kengen Detergent Plant - 0Документ127 страницKGN-GDD-033-2018 - Tender For Supply Installation Construction Commissioning of Kengen Detergent Plant - 0Eric MuyaОценок пока нет

- Assignment 2Документ27 страницAssignment 2Amisha SinghОценок пока нет

- Assistant Manager - CSR (Mumbai)Документ2 страницыAssistant Manager - CSR (Mumbai)Kumar GauravОценок пока нет

- Personal Financial Statement Template: General Rates Workcover Insurance Other OtherДокумент2 страницыPersonal Financial Statement Template: General Rates Workcover Insurance Other OtherBenjiОценок пока нет

- Gr11 ACC P2 (ENG) June 2022 Possible AnswersДокумент9 страницGr11 ACC P2 (ENG) June 2022 Possible Answersora mashaОценок пока нет

- Robinhood Case StudyДокумент3 страницыRobinhood Case StudyXnort G. XwestОценок пока нет

- Introduction To Banking: Basics, Savings, Current, CCOD, Remittance, CashДокумент54 страницыIntroduction To Banking: Basics, Savings, Current, CCOD, Remittance, CashcutesunyОценок пока нет

- Glucon-D: Its Gives Us. - . - Instant Energy Replenishes Lost EnergyДокумент19 страницGlucon-D: Its Gives Us. - . - Instant Energy Replenishes Lost EnergyBalreddy KompallyОценок пока нет

- 2 Chapter 2 - Purchasing StrategyДокумент52 страницы2 Chapter 2 - Purchasing StrategyMuhammad Arif FarhanОценок пока нет

- Wing Cloud Data Summit DescriptionДокумент16 страницWing Cloud Data Summit DescriptionKOMATSU SHOVELОценок пока нет

- The 2010 Standards of Professional Practice (SPP)Документ204 страницыThe 2010 Standards of Professional Practice (SPP)JP MacatdonОценок пока нет

- A Balanced Scorecard For Small BusinessДокумент8 страницA Balanced Scorecard For Small BusinessmoussumiiОценок пока нет

- Analysis of Logistic Department Through Supply Chain ManagementДокумент6 страницAnalysis of Logistic Department Through Supply Chain ManagementGRD JournalsОценок пока нет

- Internal Audit Checklist 2008: What To Look For QuestionsДокумент14 страницInternal Audit Checklist 2008: What To Look For QuestionsEhab SaadОценок пока нет

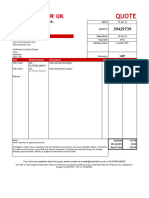

- Maximator Quote No 39429739Документ1 страницаMaximator Quote No 39429739William EvansОценок пока нет

- BX2011 Topic01 Tutorial Solutions 2020Документ15 страницBX2011 Topic01 Tutorial Solutions 2020Shi Pyeit Sone Kyaw0% (1)

- FA GP5 Assignment 1Документ4 страницыFA GP5 Assignment 1saurabhОценок пока нет

- Roll No . Sushant University, Gurgaon End Term Examination, Jan 2022Документ2 страницыRoll No . Sushant University, Gurgaon End Term Examination, Jan 2022Kartik ChoudharyОценок пока нет

- Abbott Laboratories (ABT)Документ8 страницAbbott Laboratories (ABT)Riffat Al ImamОценок пока нет

- Citizen-Charter-15-Lfo-05-Issuance of Standards Compliance Certificate (SCC) For LPG Retail OutletsДокумент4 страницыCitizen-Charter-15-Lfo-05-Issuance of Standards Compliance Certificate (SCC) For LPG Retail OutletsGenesis AdarloОценок пока нет