Академический Документы

Профессиональный Документы

Культура Документы

Features: 110Mhz, High Slew Rate, High Output Current Buffer

Загружено:

Pepe ChorizoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Features: 110Mhz, High Slew Rate, High Output Current Buffer

Загружено:

Pepe ChorizoАвторское право:

Доступные форматы

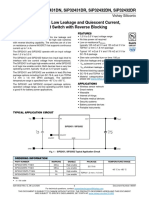

DATASHEET

HA-5002 FN2921

110MHz, High Slew Rate, High Output Current Buffer Rev 12.00

October 18, 2013

The HA-5002 is a monolithic, wideband, high slew rate, high Features

output current, buffer amplifier.

• Voltage gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.995

Utilizing the advantages of the Intersil D.I. technologies, the

• High input impedance . . . . . . . . . . . . . . . . . . . . . .3000k

HA-5002 current buffer offers 1300V/s slew rate with

110MHz of bandwidth. The 200mA output current capability • Low output impedance . . . . . . . . . . . . . . . . . . . . . . . . . 3

is enhanced by a 3 output impedance. • Very high slew rate. . . . . . . . . . . . . . . . . . . . . . . 1300V/s

The monolithic HA-5002 will replace the hybrid LH0002 with • Very wide bandwidth . . . . . . . . . . . . . . . . . . . . . . 110MHz

corresponding performance increases. These characteristics • High output current 200mA

range from the 3000k input impedance to the increased • Pulsed output current . . . . . . . . . . . . . . . . . . . . . . . 400mA

output voltage swing. Monolithic design technologies have

• Monolithic construction

allowed a more precise buffer to be developed with more than

an order of magnitude smaller gain error. • Pb-Free available (RoHS Compliant)

The HA-5002 will provide many present hybrid users with a Applications

higher degree of reliability and at the same time increase • Line driver

overall circuit performance. • Data acquisition

For the military grade product, refer to the HA-5002/883 • 110MHz buffer

datasheet. • Radar cable driver

• High power current booster

• High power current source

• Sample and holds

• Video products

Ordering Information

TEMP. PKG.

PART NUMBER PART MARKING RANGE (°C) PACKAGE DWG. #

HA2-5002-2 HA2- 5002-2 -55 to +125 8 Pin Metal Can T8.C

HA4P5002-5Z (Note 1) HA4P 5002-5Z 0 to +75 20 Ld PLCC (Pb-free) N20.35

HA9P5002-5Z (Note 1) 5002 5Z 0 to +75 8 Ld SOIC (Pb-free) M8.15

HA9P5002-9Z (Note 1) 5002 9Z -40 to +85 8 Ld SOIC (Pb-free) M8.15

NOTE:

1. These Intersil Pb-free plastic packaged products employ special Pb-free material sets, molding compounds/die attach materials, and 100% matte

tin plate plus anneal (e3 termination finish, which is RoHS compliant and compatible with both SnPb and Pb-free soldering operations). Intersil

Pb-free products are MSL classified at Pb-free peak reflow temperatures that meet or exceed the Pb-free requirements of IPC/JEDEC J STD-

020.

FN2921 Rev 12.00 Page 1 of 12

October 18, 2013

HA-5002

Pinouts

HA-5002 HA-5002 HA-5002

(8 LD SOIC) (20 LD PLCC) (8 PIN METAL CAN)

TOP VIEW TOP VIEW TOP VIEW

OUT

V1+

IN

NC

NC

NC

V1+ 1 8 OUT 8

3 2 1 20 19

V1+ 1 7 V1-

V2- 2 7 V2+

NC 4 18 NC

NC 3 6 NC V2+ 2 6 V2-

V2- 5 17 V2+

IN 4 5 V1- NC 6 16 NC

3 5

NC NC

NC 7 15 NC 4

NC 8 14 NC OUT

NOTE: Case Voltage = Floating

9 10 11 12 13

NC

IN

NC

V1-

NC

FN2921 Rev 12.00 Page 2 of 12

October 18, 2013

HA-5002

Absolute Maximum Ratings Thermal Information

Voltage Between V+ and V- Terminals . . . . . . . . . . . . . . . . . . . 44V Thermal Resistance JA (°C/W) JC (°C/W)

Input Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V1+ to V1- Metal Can Package (Notes 3, 4) . . . . . 155 67

Output Current (Continuous) . . . . . . . . . . . . . . . . . . . . . . . . 200mA PLCC Package (Note 3). . . . . . . . . . . . 74 N/A

Output Current (50ms On, 1s Off) . . . . . . . . . . . . . . . . . . . . 400mA SOIC Package (Note 3) . . . . . . . . . . . . 157 N/A

Max Junction Temperature (Hermetic Packages, Note 2). . . . . +175°C

Operating Conditions Max Junction Temperature (Plastic Packages, Note 2). . . . . . . +150°C

Max Storage Temperature Range . . . . . . . . . . . . . -65°C to +150°C

Temperature Range

HA-5002-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -55°C to +125°C Max Lead Temperature (Soldering 10s) . . . . . . . . . . . . . . . +300°C

(PLCC and SOIC - Lead Tips Only)

HA-5002-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0°C to +75°C

HA-5002-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -40°C to +85°C

CAUTION: Do not operate at or near the maximum ratings listed for extended periods of time. Exposure to such conditions may adversely impact product reliability and

result in failures not covered by warranty.

2. Maximum power dissipation, including load conditions, must be designed to maintain the maximum junction temperature below +175°C for the

can packages, and below +150°C for the plastic packages.

3. For JA is measured with the component mounted on an evaluation PC board in free air.

4. ForJC, the “case temp” location is the center of the exposed metal pad on the package underside.

Electrical Specifications VSUPPLY = 12V to 15V, RS = 50, RL = 1k CL = 10pF, Unless Otherwise Specified

TEST TEMP HA-5002-2 HA-5002-5, -9

PARAMETER CONDITIONS (°C) MIN TYP MAX MIN TYP MAX UNITS

INPUT CHARACTERISTICS

Offset Voltage 25 - 5 20 - 5 20 mV

Full - 10 30 - 10 30 mV

Average Offset Voltage Drift Full - 30 - - 30 - V/°C

Bias Current 25 - 2 7 - 2 7 A

Full - 3.4 10 - 2.4 10 A

Input Resistance Full 1.5 3 - 1.5 3 - M

Input Noise Voltage 10Hz-1MHz 25 - 18 - - 18 - VP-P

TRANSFER CHARACTERISTICS

Voltage Gain RL = 50 25 - 0.900 - - 0.900 - V/V

(VOUT = 10V) RL = 100 25 - 0.971 - - 0.971 - V/V

RL = 1k 25 - 0.995 - - 0.995 - V/V

RL = 1k Full 0.980 - - 0.980 - - V/V

-3dB Bandwidth VIN = 1VP-P 25 - 110 - - 110 - MHz

AC Current Gain 25 - 40 - - 40 - A/mA

OUTPUT CHARACTERISTICS

Output Voltage Swing RL = 100 25 10 10.7 - 10 11.2 - V

RL = 1k, VS = 15V Full 10 13.5 - 10 13.9 - V

RL = 1k, VS = 12V Full 10 10.5 - 10 10.5 - V

Output Current VIN = 10V, RL = 40 25 - 220 - - 220 - mA

Output Resistance Full - 3 10 - 3 10

Harmonic Distortion VIN = 1VRMS, f = 10kHz 25 - <0.005 - - <0.005 - %

TRANSIENT RESPONSE

Full Power Bandwidth (Note 5) 25 - 20.7 - - 20.7 - MHz

Rise Time 25 - 3.6 - - 3.6 - ns

Propagation Delay 25 - 2 - - 2 - ns

Overshoot 25 - 30 - - 30 - %

Slew Rate 25 1.0 1.3 - 1.0 1.3 - V/ns

Settling Time To 0.1% 25 - 50 - - 50 - ns

Differential Gain RL = 500 25 - 0.06 - - 0.06 - %

Differential Phase RL = 500 25 - 0.22 - - 0.22 - °

FN2921 Rev 12.00 Page 3 of 12

October 18, 2013

HA-5002

Electrical Specifications VSUPPLY = 12V to 15V, RS = 50, RL = 1k CL = 10pF, Unless Otherwise Specified (Continued)

TEST TEMP HA-5002-2 HA-5002-5, -9

PARAMETER CONDITIONS (°C) MIN TYP MAX MIN TYP MAX UNITS

POWER REQUIREMENTS

Supply Current 25 - 8.3 - - 8.3 - mA

Full - - 10 - - 10 mA

Power Supply Rejection Ratio AV = 10V Full 54 64 - 54 64 - dB

NOTE:

Slew Rate

- ; V = 10V

5. FPBW = --------------------------

2V P EAK P

Test Circuit and Waveforms

+15V

V1+ V2+

RS

IN OUT

V1- V2-

-15V RL

FIGURE 1. LARGE AND SMALL SIGNAL RESPONSE

VIN VIN

VOUT VOUT

RS = 50, RL = 100 RS = 50, RL = 1k

SMALL SIGNAL WAVEFORMS SMALL SIGNAL WAVEFORMS

VIN VIN

VOUT VOUT

RS = 50, RL = 100 RS = 50, RL = 1k

LARGE SIGNAL WAVEFORMS LARGE SIGNAL WAVEFORMS

FN2921 Rev 12.00 Page 4 of 12

October 18, 2013

HA-5002

Schematic Diagram

V1+

R8

R9 RN1

Q19

R4 R1 V2+

Q25 Q26 Q20 Q18

Q12

R10 Q3

Q9 Q27 Q1

Q6

Q10

R11

Q7 Q4

R5 IN OUT

RN2

Q21

Q5

Q11 Q2

Q22

Q15 Q8

Q23 Q24

R6 V2-

Q17

Q13

Q16 Q14

R7

R2 RN3

R12 R3

V1-

Application Information Short Circuit Protection

Layout Considerations The output current can be limited by using the following circuit:

V+ V- V+ IOUTMAX = 200mA

The wide bandwidth of the HA-5002 necessitates that high R LIM = -------------------------- = --------------------------

I OUTMAX I OUTMAX (CONTINUOUS)

frequency circuit layout procedures be followed. Failure to

follow these guidelines can result in marginal performance. V1+ RLIM

Probably the most crucial of the RF/video layout rules is the V2+

OUT

use of a ground plane. A ground plane provides isolation and IN V2-

V1-

minimizes distributed circuit capacitance and inductance which RLIM

will degrade high frequency performance.

Other considerations are proper power supply bypassing and

V-

keeping the input and output connections as short as possible

which minimizes distributed capacitance and reduces board Capacitive Loading

space. The HA-5002 will drive large capacitive loads without oscillation

but peak current limits should not be exceeded. Following the

Power Supply Decoupling

formula I = Cdv/dt implies that the slew rate or the capacitive load

For optimal device performance, it is recommended that the must be controlled to keep peak current below the maximum or

positive and negative power supplies be bypassed with use the current limiting approach as shown. The HA-5002 can

capacitors to ground. Ceramic capacitors ranging in value from become unstable with small capacitive loads (50pF) if certain

0.01 to 0.1F will minimize high frequency variations in supply precautions are not taken. Stability is enhanced by any one of the

voltage, while low frequency bypassing requires larger valued following: a source resistance in series with the input of 50 to

capacitors since the impedance of the capacitor is dependent 1k; increasing capacitive load to 150pF or greater; decreasing

on frequency. CLOAD to 20pF or less; adding an output resistor of 10 to 50;

It is also recommended that the bypass capacitors be or adding feedback capacitance of 50pF or greater. Adding

connected close to the HA-5002 (preferably directly to the source resistance generally yields the best results.

supply pins).

Operation at Reduced Supply Levels

The HA-5002 can operate at supply voltage levels as low as

5V and lower. Output swing is directly affected as well as

slight reductions in slew rate and bandwidth.

FN2921 Rev 12.00 Page 5 of 12

October 18, 2013

HA-5002

1.8

1.6

MAXIMUM POWER DISSIPATION (W)

1.4 T JMAX – T A

PLCC P DMAX = --------------------------------------------

JC + CS + SA

1.2

Where: TJMAX = Maximum Junction Temperature of the

1.0 CAN Device

TA = Ambient

0.8

JC = Junction to Case Thermal Resistance

0.6 SOIC

CS = Case to Heat Sink Thermal Resistance

0.4

SA = Heat Sink to Ambient Thermal Resistance

QUIESCENT POWER DISSIPATION T JMAX – T A

0.2 Graph is based on: P DMAX = --------------------------------

AT 15V SUPPLIES JA

0.0

25 45 65 85 105 125

TEMPERATURE (°C)

FIGURE 2. MAXIMUM POWER DISSIPATION vs TEMPERATURE

Typical Application

+12V

V1+ V2+

RS VIN

RM RG -58

VOUT

50 50

VIN RL 50

V1- V2-

-12V

VOUT

FIGURE 3. COAXIAL CABLE DRIVER - 50 SYSTEM

Typical Performance Curves

9 9

VS = 15V, RS = 50 VS = 15V, RS = 50

6 6

3 3

VOLTAGE GAIN (dB)

VOLTAGE GAIN (dB)

GAIN

0 GAIN

0

-3 -3

PHASE PHASE

-6 0° -6 0°

PHASE SHIFT

PHASE SHIFT

-9 45° -9 45°

-12 90° -12 90°

-15 135° -15 135°

-18 180° -18 180°

1 10 100 1 10 100

FREQUENCY (MHz) FREQUENCY (MHz)

FIGURE 4. GAIN/PHASE vs FREQUENCY (RL = 1k) FIGURE 5. GAIN/PHASE vs FREQUENCY (RL = 50)

FN2921 Rev 12.00 Page 6 of 12

October 18, 2013

HA-5002

Typical Performance Curves (Continued)

0.994 0.998

VS = 15V VS = 15V

0.992

0.997

0.990

VOUT = 0 TO +10V

VOLTAGE GAIN (V/V)

VOLTAGE GAIN (V/V)

0.988 0.996

VOUT = -10V TO +10V

0.986

0.995

0.984

0.994

0.982

VOUT = 0 TO -10V

0.980 0.993

0.978

0.992

0.976

0.974 0.991

-60 -40 -20 0 20 40 60 80 100 120 -60 -40 -20 0 20 40 60 80 100 120

TEMPERATURE (°C) TEMPERATURE (°C)

FIGURE 6. VOLTAGE GAIN vs TEMPERATURE (RL = 100) FIGURE 7. VOLTAGE GAIN vs TEMPERATURE (RL = 1k)

3 7

2 VS = 15V VS = 15V

1 6

0

OFFSET VOLTAGE (mV)

BIAS CURRENT (A)

-1 5

-2

-3 4

-4

-5 3

-6

-7 2

-8

-9 1

-10

-11 0

-60 -40 -20 0 20 40 60 80 100 120 -60 -40 -20 0 20 40 60 80 100 120

TEMPERATURE (°C) TEMPERATURE (°C)

FIGURE 8. OFFSET VOLTAGE vs TEMPERATURE FIGURE 9. BIAS CURRENT vs TEMPERATURE

15 10

VS = 15V, RLOAD = 100 VS = 15V, IOUT = 0mA

9

SUPPLY CURRENT (mA)

OUTPUT VOLTAGE (V)

14

+VOUT 8

7

-VOUT

13

6

5

12

11 3

-60 -40 -20 0 20 40 60 80 100 120 -60 -40 -20 0 20 40 60 80 100 120

TEMPERATURE (°C) TEMPERATURE (°C)

FIGURE 10. MAXIMUM OUTPUT VOLTAGE vs TEMPERATURE FIGURE 11. SUPPLY CURRENT vs TEMPERATURE

FN2921 Rev 12.00 Page 7 of 12

October 18, 2013

HA-5002

Typical Performance Curves (Continued)

10

IOUT = 0mA VS = 15V

125°C, 25°C

8 100K

SUPPLY CURRENT (mA)

ZIN

-55°C 10K

IMPEDANCE ()

6

1000

4

100

2

10 ZOUT

0

0 2 4 6 8 10 12 14 16 18 1

100K 1M 10M 100M

SUPPLY VOLTAGE (V)

FREQUENCY (Hz)

FIGURE 12. SUPPLY CURRENT vs SUPPLY VOLTAGE FIGURE 13. INPUT/OUTPUT IMPEDANCE vs FREQUENCY

23 80

22 RLOAD = 100

21 70

20

VOUT MAX, VP-P AT 100kHz

19 60

18

17 50

PSRR (dB)

16 TA = 25°C

15 40

14 TA = 125°C,

13 30

TA = -55°C

12

11 20

10

9 10

8

7 0

15 12 8 5 10K 100K 1M 10M 100M

SUPPLY VOLTAGE (V) FREQUENCY (Hz)

FIGURE 14. VOUT MAXIMUM vs VSUPPLY FIGURE 15. PSRR vs FREQUENCY

1500 150

VS = 15V

TA = 25°C

1400 100

RL = 100

SLEW RATE (V/s)

VOUT - VIN (mV)

1300 50

RL = 1K

1200 0

1100 -50

RL = 600

1000 -100

900 -150

6 8 10 12 14 16 18 -10 -8 -6 -4 -2 0 2 4 6 8 10

SUPPLY VOLTAGE (V) INPUT VOLTAGE (VOLTS)

FIGURE 16. SLEW RATE vs SUPPLY VOLTAGE FIGURE 17. GAIN ERROR vs INPUT VOLTAGE

FN2921 Rev 12.00 Page 8 of 12

October 18, 2013

HA-5002

Die Characteristics TRANSISTOR COUNT:

27

SUBSTRATE POTENTIAL (POWERED UP):

V1- PROCESS:

Bipolar Dielectric Isolation

Metallization Mask Layout

HA-5002

V1- IN

V1- (ALT)

V1+ (ALT)

V2+

V2-

V1+

OUT

© Copyright Intersil Americas LLC 2003-2013. All Rights Reserved.

All trademarks and registered trademarks are the property of their respective owners.

For additional products, see www.intersil.com/en/products.html

Intersil products are manufactured, assembled and tested utilizing ISO9001 quality systems as noted

in the quality certifications found at www.intersil.com/en/support/qualandreliability.html

Intersil products are sold by description only. Intersil may modify the circuit design and/or specifications of products at any time without notice, provided that such

modification does not, in Intersil's sole judgment, affect the form, fit or function of the product. Accordingly, the reader is cautioned to verify that datasheets are

current before placing orders. Information furnished by Intersil is believed to be accurate and reliable. However, no responsibility is assumed by Intersil or its

subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see www.intersil.com

FN2921 Rev 12.00 Page 9 of 12

October 18, 2013

HA-5002

Metal Can Packages (Can)

REFERENCE PLANE T8.C MIL-STD-1835 MACY1-X8 (A1)

A e1 8 LEAD METAL CAN PACKAGE

L

INCHES MILLIMETERS

L2

L1 SYMBOL MIN MAX MIN MAX NOTES

ØD2 A 0.165 0.185 4.19 4.70 -

A

Øb 0.016 0.019 0.41 0.48 1

A

ØD ØD1 Øe k1 Øb1 0.016 0.021 0.41 0.53 1

2 N Øb2 0.016 0.024 0.41 0.61 -

1 ØD 0.335 0.375 8.51 9.40 -

ØD1 0.305 0.335 7.75 8.51 -

Øb1

C

L ØD2 0.110 0.160 2.79 4.06 -

F Øb k

e 0.200 BSC 5.08 BSC -

Q BASE AND

SEATING PLANE e1 0.100 BSC 2.54 BSC -

F - 0.040 - 1.02 -

BASE METAL LEAD FINISH

k 0.027 0.034 0.69 0.86 -

k1 0.027 0.045 0.69 1.14 2

Øb1 Øb2

L 0.500 0.750 12.70 19.05 1

L1 - 0.050 - 1.27 1

SECTION A-A L2 0.250 - 6.35 - 1

NOTES: Q 0.010 0.045 0.25 1.14 -

1. (All leads) Øb applies between L1 and L2. Øb1 applies between L2 45o BSC 45o BSC 3

and 0.500 from the reference plane. Diameter is uncontrolled in L1 45o BSC 45o BSC 3

and beyond 0.500 from the reference plane.

N 8 8 4

2. Measured from maximum diameter of the product.

Rev. 0 5/18/94

3. is the basic spacing from the centerline of the tab to terminal 1 and

is the basic spacing of each lead or lead position (N -1 places)

from looking at the bottom of the package.

4. N is the maximum number of terminal positions.

5. Dimensioning and tolerancing per ANSI Y14.5M - 1982.

6. Controlling dimension: INCH.

FN2921 Rev 12.00 Page 10 of 12

October 18, 2013

HA-5002

Plastic Leaded Chip Carrier Packages (PLCC)

0.042 (1.07)

0.042 (1.07) N20.35 (JEDEC MS-018AA ISSUE A)

0.048 (1.22) 0.004 (0.10) C 20 LEAD PLASTIC LEADED CHIP CARRIER PACKAGE

0.056 (1.42)

PIN (1) IDENTIFIER

0.050 (1.27) TP 0.025 (0.64) INCHES MILLIMETERS

R

C 0.045 (1.14)

L SYMBOL MIN MAX MIN MAX NOTES

A 0.165 0.180 4.20 4.57 -

A1 0.090 0.120 2.29 3.04 -

D2/E2

D 0.385 0.395 9.78 10.03 -

C

L D1 0.350 0.356 8.89 9.04 3

E1 E

D2 0.141 0.169 3.59 4.29 4, 5

D2/E2

E 0.385 0.395 9.78 10.03 -

VIEW “A”

E1 0.350 0.356 8.89 9.04 3

E2 0.141 0.169 3.59 4.29 4, 5

0.020 (0.51)

MIN N 20 20 6

D1 A1

D A Rev. 2 11/97

0.020 (0.51) MAX SEATING

-C- PLANE

3 PLCS 0.026 (0.66)

0.032 (0.81) 0.013 (0.33)

0.021 (0.53)

0.025 (0.64)

0.045 (1.14) MIN

MIN

VIEW “A” TYP.

NOTES:

1. Controlling dimension: INCH. Converted millimeter dimensions are

not necessarily exact.

2. Dimensions and tolerancing per ANSI Y14.5M-1982.

3. Dimensions D1 and E1 do not include mold protrusions. Allowable

mold protrusion is 0.010 inch (0.25mm) per side. Dimensions D1

and E1 include mold mismatch and are measured at the extreme

material condition at the body parting line.

4. To be measured at seating plane -C- contact point.

5. Centerline to be determined where center leads exit plastic body.

6. “N” is the number of terminal positions.

FN2921 Rev 12.00 Page 11 of 12

October 18, 2013

HA-5002

Package Outline Drawing

M8.15

8 LEAD NARROW BODY SMALL OUTLINE PLASTIC PACKAGE

Rev 4, 1/12

DETAIL "A"

1.27 (0.050)

0.40 (0.016)

INDEX 6.20 (0.244)

AREA 5.80 (0.228)

0.50 (0.20)

x 45°

4.00 (0.157) 0.25 (0.01)

3.80 (0.150)

8°

1 2 3 0°

0.25 (0.010)

0.19 (0.008)

TOP VIEW SIDE VIEW “B”

2.20 (0.087)

1 8

SEATING PLANE

1.75 (0.069) 0.60 (0.023)

5.00 (0.197) 2 7

4.80 (0.189) 1.35 (0.053)

1.27 (0.050)

3 6

-C-

4 5

1.27 (0.050) 0.25(0.010)

0.10(0.004)

0.51(0.020)

0.33(0.013) 5.20(0.205)

SIDE VIEW “A TYPICAL RECOMMENDED LAND PATTERN

NOTES:

1. Dimensioning and tolerancing per ANSI Y14.5M-1994.

2. Package length does not include mold flash, protrusions or gate burrs.

Mold flash, protrusion and gate burrs shall not exceed 0.15mm (0.006

inch) per side.

3. Package width does not include interlead flash or protrusions. Interlead

flash and protrusions shall not exceed 0.25mm (0.010 inch) per side.

4. The chamfer on the body is optional. If it is not present, a visual index

feature must be located within the crosshatched area.

5. Terminal numbers are shown for reference only.

6. The lead width as measured 0.36mm (0.014 inch) or greater above the

seating plane, shall not exceed a maximum value of 0.61mm (0.024 inch).

7. Controlling dimension: MILLIMETER. Converted inch dimensions are not

necessarily exact.

8. This outline conforms to JEDEC publication MS-012-AA ISSUE C.

FN2921 Rev 12.00 Page 12 of 12

October 18, 2013

Вам также может понравиться

- DatasheetДокумент12 страницDatasheetAsad AhmedОценок пока нет

- Features: Dual, Low Power CMOS Operational AmplifiersДокумент9 страницFeatures: Dual, Low Power CMOS Operational AmplifiersDibya DeyОценок пока нет

- 100V/2A Peak, Low Cost, High Frequency Half Bridge Driver FeaturesДокумент13 страниц100V/2A Peak, Low Cost, High Frequency Half Bridge Driver FeaturescarcavaОценок пока нет

- NE/SA/SE5532/5532A: Internally-Compensated Dual Low Noise Operational AmplifierДокумент12 страницNE/SA/SE5532/5532A: Internally-Compensated Dual Low Noise Operational Amplifiersaul camposОценок пока нет

- NE/SA/SE5532/5532A: Internally-Compensated Dual Low Noise Operational AmplifierДокумент13 страницNE/SA/SE5532/5532A: Internally-Compensated Dual Low Noise Operational AmplifierOmar QuintanillaОценок пока нет

- Features: 0.5Mhz, Low Supply Voltage, Low Input Current Bimos Operational AmplifierДокумент5 страницFeatures: 0.5Mhz, Low Supply Voltage, Low Input Current Bimos Operational AmplifierAlexandre Correa100% (1)

- Icl7650s Cba-1zДокумент13 страницIcl7650s Cba-1zmarcodlcruz94Оценок пока нет

- Ha 2542Документ12 страницHa 2542Charbel TadrosОценок пока нет

- ICL7611-1.4MHz, Low Power CMOS Operational AmplifiersДокумент13 страницICL7611-1.4MHz, Low Power CMOS Operational Amplifiersy0956880Оценок пока нет

- REN Hip2101 DST 20010410Документ15 страницREN Hip2101 DST 20010410Yenidir TeknoОценок пока нет

- High Speed Transistor Optocouplers - HP2530Документ14 страницHigh Speed Transistor Optocouplers - HP2530Lucía MitchellОценок пока нет

- Single-Channel: 6N138, 6N139 Dual-Channel: HCPL-2730, HCPL-2731 Low Input Current High Gain Split Darlington OptocouplersДокумент15 страницSingle-Channel: 6N138, 6N139 Dual-Channel: HCPL-2730, HCPL-2731 Low Input Current High Gain Split Darlington Optocouplersdevrim.kosalОценок пока нет

- TDA2822Документ6 страницTDA2822josetantonioОценок пока нет

- 2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetДокумент5 страниц2N7002DWQ Product Summary Features and Benefits: Dual N-Channel Enhancement Mode MosfetErkanОценок пока нет

- BA6208Документ4 страницыBA6208jcsg2007Оценок пока нет

- LH0002CH HF Signal BufferДокумент6 страницLH0002CH HF Signal BufferPaul PaciniОценок пока нет

- DG401, DG403, DG405: Vishay SiliconixДокумент15 страницDG401, DG403, DG405: Vishay SiliconixytnateОценок пока нет

- Features: EL5202, EL5203Документ14 страницFeatures: EL5202, EL5203Евгений ИвановОценок пока нет

- Icl 7667Документ11 страницIcl 7667De JeanОценок пока нет

- Macom Pa Maap-010168Документ9 страницMacom Pa Maap-010168Alejandro PopovskyОценок пока нет

- DG201B, DG202B: Vishay SiliconixДокумент16 страницDG201B, DG202B: Vishay SiliconixPhong DoОценок пока нет

- DG408, DG409: Single 8-Channel/Differential 4-Channel, CMOS Analog Multiplexers FeaturesДокумент17 страницDG408, DG409: Single 8-Channel/Differential 4-Channel, CMOS Analog Multiplexers FeaturesmikigabriОценок пока нет

- IXDD409PI / 409SI / 409YI / 409CI IXDI409PI / 409SI / 409YI / 409CI IXDN409PI / 409SI / 409YI / 409CI 9 Ampere Low-Side Ultrafast MOSFET DriverДокумент10 страницIXDD409PI / 409SI / 409YI / 409CI IXDI409PI / 409SI / 409YI / 409CI IXDN409PI / 409SI / 409YI / 409CI 9 Ampere Low-Side Ultrafast MOSFET Drivernhatnam06dt1Оценок пока нет

- V02 0409en - DS - HCPL 7860 - 2015 03 061 908727Документ18 страницV02 0409en - DS - HCPL 7860 - 2015 03 061 908727Shirley CastañedaОценок пока нет

- HCPL 7710 300 AvagoДокумент19 страницHCPL 7710 300 Avagohanif khanОценок пока нет

- HCPL 7710 300 AvagoДокумент19 страницHCPL 7710 300 Avagohanif khanОценок пока нет

- 6 N 136Документ12 страниц6 N 136acruwerОценок пока нет

- ON Semiconductor-MC78L05ACDG-datasheetДокумент18 страницON Semiconductor-MC78L05ACDG-datasheetGamal SalehОценок пока нет

- Tda7265 (30W+30W)Документ18 страницTda7265 (30W+30W)ShiguMiku TheyОценок пока нет

- Positive Voltage Regulators MC78L00A Series, NCV78L00A: TO 92 P Suffix CASE 29 10Документ20 страницPositive Voltage Regulators MC78L00A Series, NCV78L00A: TO 92 P Suffix CASE 29 10Rodrigo VelaОценок пока нет

- Sip 32431Документ15 страницSip 32431Remy MendozaОценок пока нет

- MC34119Документ17 страницMC34119Joe ErdeОценок пока нет

- HTC Korea TAEJIN Tech MAX485ED - C481667Документ10 страницHTC Korea TAEJIN Tech MAX485ED - C481667PhátTrầnОценок пока нет

- 6 N 139Документ15 страниц6 N 1391867468Оценок пока нет

- TDA7294 Stereo Power Amplifier Ver 2.0Документ8 страницTDA7294 Stereo Power Amplifier Ver 2.0Sentimental SagОценок пока нет

- Datasheet - HK hcpl-2731 92412Документ13 страницDatasheet - HK hcpl-2731 92412Anonymous aP1FSUPoОценок пока нет

- Ba00dd0w eДокумент20 страницBa00dd0w emarius tanjalaОценок пока нет

- Isl6545 A PDFДокумент17 страницIsl6545 A PDFdragoblaztrОценок пока нет

- TLO72CNДокумент10 страницTLO72CNx3roОценок пока нет

- General Description Features: 12A-Peak Low-Side MOSFET Driver Bipolar/CMOS/DMOS ProcessДокумент14 страницGeneral Description Features: 12A-Peak Low-Side MOSFET Driver Bipolar/CMOS/DMOS ProcessNikhil SharmaОценок пока нет

- Suggested Magnetics: General DescriptionДокумент10 страницSuggested Magnetics: General DescriptionLarbi BelazizОценок пока нет

- Opa2333 HTДокумент18 страницOpa2333 HTananthadigaОценок пока нет

- DG641, DG642, DG643: Vishay SiliconixДокумент17 страницDG641, DG642, DG643: Vishay SiliconixHiền Nguyễn VănОценок пока нет

- CA5260, CA5260A: FeaturesДокумент7 страницCA5260, CA5260A: FeaturesCharbel TadrosОценок пока нет

- 500ma Variable/Fixed Output LDO Regulators: DatasheetДокумент18 страниц500ma Variable/Fixed Output LDO Regulators: DatasheetDiego OliveiraОценок пока нет

- Tsop 752 WДокумент13 страницTsop 752 WMatias RendonОценок пока нет

- Ciber Af4500 MC024-020Документ4 страницыCiber Af4500 MC024-020Jhecko BalbinotОценок пока нет

- DG 441Документ13 страницDG 441melquicedecОценок пока нет

- DG506A, DG507A, DG508A, DG509A: CMOS Analog Multiplexers FeaturesДокумент19 страницDG506A, DG507A, DG508A, DG509A: CMOS Analog Multiplexers FeaturesahmedОценок пока нет

- 6N135-136, HCNW135-136, HCPL-2502-0500-0501Документ16 страниц6N135-136, HCNW135-136, HCPL-2502-0500-0501robert_lascuОценок пока нет

- Evaluates: DS28E01/DS28CN01/DS2460 Secure Authentication Starter KitДокумент15 страницEvaluates: DS28E01/DS28CN01/DS2460 Secure Authentication Starter KitWilman LealОценок пока нет

- Sic780, Sic780A: Vishay SiliconixДокумент14 страницSic780, Sic780A: Vishay SiliconixBoris ȚepeșОценок пока нет

- Intermediate Bus PWM Controller Features: ISL6744AДокумент18 страницIntermediate Bus PWM Controller Features: ISL6744AaliolleikОценок пока нет

- AS358 DiodesДокумент19 страницAS358 DiodesdanielОценок пока нет

- El 7104Документ7 страницEl 7104Oscar FernandezОценок пока нет

- Icl7667 1528911Документ12 страницIcl7667 1528911Trung Nguyên VõОценок пока нет

- Listado Detarjetas PLC Honeywell PDFДокумент4 страницыListado Detarjetas PLC Honeywell PDFSebastian TorresОценок пока нет

- 4.5-V To 65-V Input, Compact Bias Supply With Power Stage Reference Design For Igbt/Sic Gate DriversДокумент44 страницы4.5-V To 65-V Input, Compact Bias Supply With Power Stage Reference Design For Igbt/Sic Gate DriversDebasish MishraОценок пока нет

- Scanner para Hc900 de I o Remotas Honeywell 231Документ5 страницScanner para Hc900 de I o Remotas Honeywell 231thanh_cdt01Оценок пока нет

- Arlon 85N: High Performance Polyimide / E-Glass Exceptional Thermal Performance Superior ReliabilityДокумент2 страницыArlon 85N: High Performance Polyimide / E-Glass Exceptional Thermal Performance Superior ReliabilityPepe ChorizoОценок пока нет

- Qualification of Class Y Flip Chip Cga Package Technology For SpaceДокумент8 страницQualification of Class Y Flip Chip Cga Package Technology For SpacePepe ChorizoОценок пока нет

- 1Gb DDR2Документ133 страницы1Gb DDR2Pepe ChorizoОценок пока нет

- Microsemi CN19009 RTG4 PLL Lock StabilityДокумент4 страницыMicrosemi CN19009 RTG4 PLL Lock StabilityPepe ChorizoОценок пока нет

- Closing Dumpsite Report Spreads HR CompressedДокумент31 страницаClosing Dumpsite Report Spreads HR CompressedPepe ChorizoОценок пока нет

- Shengyi S1000 2M DSДокумент1 страницаShengyi S1000 2M DSPepe ChorizoОценок пока нет

- WhitePaper Top 8 Reasons OscillatorДокумент8 страницWhitePaper Top 8 Reasons OscillatorPepe ChorizoОценок пока нет

- AN10002 Single Ended Clock TerminationДокумент17 страницAN10002 Single Ended Clock TerminationPepe ChorizoОценок пока нет

- PV2R Series Single PumpДокумент14 страницPV2R Series Single PumpBagus setiawanОценок пока нет

- Key ScientificДокумент4 страницыKey ScientificGarrettОценок пока нет

- 3 Ways To Take Isabgol - WikiHowДокумент6 страниц3 Ways To Take Isabgol - WikiHownasirОценок пока нет

- Beckhoff Service Tool - USB StickДокумент7 страницBeckhoff Service Tool - USB StickGustavo VélizОценок пока нет

- MPERSДокумент1 страницаMPERSKen ChiaОценок пока нет

- An Energy Saving Guide For Plastic Injection Molding MachinesДокумент16 страницAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoОценок пока нет

- RMP ContractДокумент181 страницаRMP ContractHillary AmistosoОценок пока нет

- Hospital - Data Collection & Literature StudyДокумент42 страницыHospital - Data Collection & Literature StudyNagateja MallelaОценок пока нет

- Glycolysis Krebscycle Practice Questions SCДокумент2 страницыGlycolysis Krebscycle Practice Questions SCapi-323720899Оценок пока нет

- The Impact Behaviour of Composite MaterialsДокумент6 страницThe Impact Behaviour of Composite MaterialsVíctor Fer100% (1)

- Paterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013Документ45 страницPaterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013The Morning CallОценок пока нет

- CARBOWAX™ Polyethylene Glycol (PEG) 1000Документ2 страницыCARBOWAX™ Polyethylene Glycol (PEG) 1000Anonymous vJPniV7Оценок пока нет

- Inked CultureДокумент90 страницInked Culturemar phisОценок пока нет

- FennelДокумент2 страницыFennelAlesam44bОценок пока нет

- IB Final ShellДокумент25 страницIB Final ShellsnehakopadeОценок пока нет

- Astm d2729Документ2 страницыAstm d2729Shan AdriasОценок пока нет

- Form 28 Attendence RegisterДокумент1 страницаForm 28 Attendence RegisterSanjeet SinghОценок пока нет

- Onuaguluchi1996 1Документ10 страницOnuaguluchi1996 1IkaSugihartatikОценок пока нет

- Formulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersДокумент5 страницFormulation and Evaluation of Mefenamic Acid Ointment Using Penetration EnhancersIndradewiОценок пока нет

- Hemostatic AgentsДокумент18 страницHemostatic AgentshariОценок пока нет

- 7 Fuel Failure in Water Reactors - Causes and MitigationДокумент165 страниц7 Fuel Failure in Water Reactors - Causes and MitigationLauri RubertiОценок пока нет

- BKM 10e Ch07 Two Security ModelДокумент2 страницыBKM 10e Ch07 Two Security ModelJoe IammarinoОценок пока нет

- SA 8000 Audit Check List VeeraДокумент6 страницSA 8000 Audit Check List Veeranallasivam v92% (12)

- Vital Statistics: Presented by Mrs - Arockia Mary Associate ProfДокумент17 страницVital Statistics: Presented by Mrs - Arockia Mary Associate ProfraghumscnОценок пока нет

- Handout Module6Документ69 страницHandout Module6Oana MirceaОценок пока нет

- Online Games and Academic AchievementДокумент25 страницOnline Games and Academic AchievementJasmine GamoraОценок пока нет

- Remote Control Unit Manual BookДокумент21 страницаRemote Control Unit Manual BookIgor Ungur100% (1)

- Waste Heat Recovery UnitДокумент15 страницWaste Heat Recovery UnitEDUARDOОценок пока нет

- 24.2 The Core Assumptions of MindfulnessДокумент9 страниц24.2 The Core Assumptions of Mindfulnessale alvarezОценок пока нет

- PPC Production PlantДокумент106 страницPPC Production PlantAljay Neeson Imperial100% (1)