Академический Документы

Профессиональный Документы

Культура Документы

Technical Data Sheet For Temperature Transmitter

Загружено:

alinor_tnОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Technical Data Sheet For Temperature Transmitter

Загружено:

alinor_tnАвторское право:

Доступные форматы

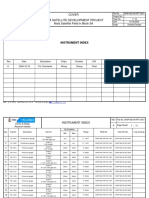

Contractor: Engineering: Project: Client:

NAWARA PROJECT

(PIPELINE)

Contract n°: OTP/PP/189 OMV/BIMS EPCC PPL

Job n° : P13IT02472

Contractor doc. n°: Engineering doc. n°: Sheet Class Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 1 of 37 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

NOTE:

Document revised to incorporate modifications of 6" GAS BUY-BACK PIPELINE.

Modification depicted with this clouds

BBG

002 15/06/2017 Issue for Use/Construction FPA MBO BFU

001 24/06/2015 Issue for Use/Construction FPA MBO BFU

000 27/02/2015 Issue for Use/Construction FPA MBO BFU

C01 19/12/2014 Issue for Information FPA MBO BFU D

Rev. Date REVISION TITLE PREPARED CHECKED APPROVED Rev. Status

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File Name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 2 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

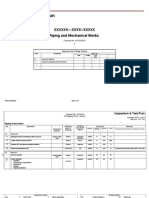

INDEX FOR SHEETS AND REVISIONS

SHEET

DENOMINATION DATE OF LAST REV. REVISION

N°

1 Cover 24/06/2015 C01 000 001

2 Index 24/06/2015 C01 000 001

3 General Notes BBG

24/06/2015 C01 000 001

4 NP0-321-TT-0392 - Temperature Transmitter - 6" BBG pipeline - gas Heater 15/06/2017 002

5 NP0-321-TT-0100 - Temperature Transmitter - Nawara raw gas export pig launcher 24/06/2015 C01 000 001

6 NP0-321-TT-0390 - Temperature Transmitter - Gabes GTP raw gas export pipeline pig receiver 24/06/2015 C01 000 001

7 NP0-310-TT-0100 - Temperature Transmitter - Export Condensate pig launcher 24/06/2015 C01 000 001

8 NP0-310-TT-0101 - Temperature Transmitter - Export Condensate pig receiver 24/06/2015 C01 000 001

9 NG0-320-TT-0501 - Temperature Transmitter - Gabes GTP sales gas export pipeline pig launcher 24/06/2015 C01 000 001

10 NG0-320-TT-0503 - Temperature Transmitter - Gabes GTP sales gas export pipeline pig receiver 24/06/2015 C01 000 001

11 NG0-324-TT-0601 - Temperature Transmitter - Gabes GTP propane export pipeline pig launcher 24/06/2015 C01 000 001

12 NG0-324-TT-0603 - Temperature Transmitter - Gabes GTP propane export pipeline pig receiver 24/06/2015 C01 000 001

13 NG0-323-TT-0701 - Temperature Transmitter - Gabes GTP butane export pipeline pig launcher 24/06/2015 C01 000 001

14 NG0-323-TT-0703 - Temperature Transmitter - Gabes GTP butane export pipeline pig receiver 24/06/2015 C01 000 001

15 NP0-321-TT-0110A - Temperature Transmitter - LVS1 - upstream temperature 24/06/2015 C01 000 001

16 NP0-321-TT-0110B - Temperature Transmitter - LVS1 - downstream temperature 24/06/2015 C01 000 001

17 NP0-321-TT-0120A - Temperature Transmitter - LVS2 - upstream temperature 24/06/2015 C01 000 001

18 NP0-321-TT-0120B - Temperature Transmitter - LVS2 - downstream temperature 24/06/2015 C01 000 001

19 NP0-321-TT-0130A - Temperature Transmitter - LVS3 - upstream temperature 24/06/2015 C01 000 001

20 NP0-321-TT-0130B - Temperature Transmitter - LVS3 - downstream temperature 24/06/2015 C01 000 001

21 NP0-321-TT-0140A - Temperature Transmitter - LVS4 - upstream temperature 24/06/2015 C01 000 001

22 NP0-321-TT-0140B - Temperature Transmitter - LVS4 - downstream temperature 24/06/2015 C01 000 001

23 NP0-321-TT-0150A - Temperature Transmitter - LVS5 - upstream temperature 24/06/2015 C01 000 001

24 NP0-321-TT-0150B - Temperature Transmitter - LVS5 - downstream temperature 24/06/2015 C01 000 001

25 NP0-321-TT-0160A - Temperature Transmitter - LVS6 - upstream temperature 24/06/2015 C01 000 001

26 NP0-321-TT-0160B - Temperature Transmitter - LVS6 - downstream temperature 24/06/2015 C01 000 001

27 NP0-321-TT-0170A - Temperature Transmitter - LVS7 - upstream temperature 24/06/2015 C01 000 001

28 NP0-321-TT-0170B - Temperature Transmitter - LVS7 - downstream temperature 24/06/2015 C01 000 001

29 NP0-321-TT-0180A - Temperature Transmitter - LVS8 - upstream temperature 24/06/2015 C01 000 001

30 NP0-321-TT-0180B - Temperature Transmitter - LVS8 - downstream temperature 24/06/2015 C01 000 001

31 NP0-321-TT-0190A - Temperature Transmitter - LVS9 - upstream temperature 24/06/2015 C01 000 001

32 NP0-321-TT-0190B - Temperature Transmitter - LVS9 - downstream temperature 24/06/2015 C01 000 001

33 NP0-321-TT-0200A - Temperature Transmitter - LVS10 - upstream temperature 24/06/2015 C01 000 001

34 NP0-321-TT-0200B - Temperature Transmitter - LVS10 - downstream temperature 24/06/2015 C01 000 001

35 NP0-321-TT-0210A - Temperature Transmitter - LVS11 - upstream temperature 24/06/2015 C01 000 001

36 NP0-321-TT-0210B - Temperature Transmitter - LVS11 - downstream temperature 24/06/2015 C01 000 001

37 NP0-321-TT-0220A - Temperature Transmitter - LVS12 - upstream temperature 24/06/2015 C01 000 001

38 NP0-321-TT-0220B - Temperature Transmitter - LVS12 - downstream temperature 24/06/2015 C01 000 001

39

40

41

42

43

44

45

46

47

48

49

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 3 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL NOTES

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: 002 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 4 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

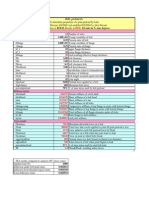

GENERAL

01 Instrument tag no. : NP0-321-TT-0392 05 Weight : (*) BBG

02 P & ID : NAWPPL-BIMS-0F03-320-PR-PID-00004 06 Mfr. /Mfr. model no. : (*)

03 Service : 6" BBG pipeline- Heater downstream temp. 07 Purchase order no. : TBA

04 Line/equipement no. : NP0-6"-EG-321-0304-C41Y-V 08

PROCESS AND PIPING DATA:

Ambient temperature limits : -0.2 / +46.2 °C 12 Fluid/Phase : Sales Gas / gas

INSTALLATION OPERATING CONDITIONS

09

10 Design pressure/temperature : 92.0 barg / -10 °C / +85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 250320

16 Flow velocity : m/s 1.7 4.7

17 Temperature : °C 10 50

18 Pressure : barg 35

19 Viscosity : cP 0.0125 0.0137

20 Density : kg/m3 26.9 61.6

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 6" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 8.74 mm 30 Flange class : ANSI #600

24 Pipe internal diameter : 150.82 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 170 mm 32 Flange material : A 694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell

59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

Type : 38 Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

Design standard : 39 (*) 62 Min/Max span : (*)

Sensor operating limits : 40 Class A (IEC 60751) 63 Zero/span adjustement : required

Wire configuration : 41 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

Stem diameter : 42 (*) (to suit relevant thermowell) 65 Dimension : (*)

Stem lenght : 43 (*) to suit relevant thermowell 66 Material : Aluminium

Sensitive portion lenght : 44 (*) 67 Cable connection : screwed terminals

Stem material : 45 AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

Sensitive portion material :

46 AISI 316SS 69 Enclosure protection : IP 66

Sensor assemblies : 47 spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

Extension fittings : 48 required (*) 71 Protective coating : epoxy coating

Extension fittings lenght :49 (*) 72 Tropicalization : -

Connection size/type : 50 ½" NPT-M / adjust. insertion lenght 73

Connection material : 51 AISI 316SS 74

Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

52

Output signal : 53 4-20 mA (2-wires) 76

Comunication : 54 Smart /HART protocol 77

Supply voltage 55 24 VDC (loop powered) 78

Consumption : 56 (*) 79

Load limitation : 57 (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #600 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 245 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 4 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0100 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00002 06 Mfr. /Mfr. model no. : (*)

03 Service : raw gas from export gas metering skid 07 Purchase order no. : TBA

04 NP0-24"-EG-321-0201-D41Y-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Raw Gas / gas

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : m/s 0.8 2.8 3.9

17 Temperature : °C 28 51.6 55

18 Pressure : barg 34.5 44 104

19 Viscosity : cP 0.009 0.01

20 Density : kg/m3 27 107

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 24" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 17.48 mm 30 Flange class : ANSI #1500

24 Pipe internal diameter : 574.64 mm 31 Flange facing : RJ

25 Nozzle or Threadolet height (H) : 200 mm 32 Flange material : A694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #1500 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 500 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RJ 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 5 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0390 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00003 06 Mfr. /Mfr. model no. : (*)

03 Service : raw gas to slug catcher 07 Purchase order no. : TBA

04 NP0-24"-EG-321-0301-D41Y-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -0.2 / +46.2 °C 12 Fluid/Phase : Raw Gas / gas

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : m/s 0.8 3 11

17 Temperature : °C 1.7 27 55

18 Pressure : barg 35 35 35

19 Viscosity : cP 0.009 0.009

20 Density : kg/m3 30 37

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 24" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 17.48 mm 30 Flange class : ANSI #1500

24 Pipe internal diameter : 574.64 mm 31 Flange facing : RJ

25 Nozzle or Threadolet height (H) : 200 mm 32 Flange material : A694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #1500 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 500 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RJ 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 6 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-310-TT-0100 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F02-310-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : condensate from metering package 07 Purchase order no. : TBA

04 NP0-6"-HC-310-0002-06CA3SY-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Condensate / liquid

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 94.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : SIL 2 14

Minimum Normal Maximum

15 Flow rate : SBPD 7000 10000

16 Flow velocity : m/s 0.72 1

17 Temperature : °C 64 64 64

18 Pressure : barg 76 76 80

19 Viscosity : cP 3.5 4.2

20 Density : kg/m3 727 731

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 6" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 7.92 mm 30 Flange class : ANSI #600

24 Pipe internal diameter : 152.44 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 170 mm 32 Flange material : A 694 F 52

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #600 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 250 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 7 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-310-TT-0101 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F02-310-PR-PID-00002 06 Mfr. /Mfr. model no. : (*)

03 Service : condensate to TRAPSA pipeline 07 Purchase order no. : TBA

04 NP0-6"-HC-310-0012-06CA3SY-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Condensate / liquid

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 94.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : SBPD 7000 10000

16 Flow velocity : m/s 0.7 1

17 Temperature : °C 23.0 41 64

18 Pressure : barg 70 70 70

19 Viscosity : cP 4.3 6.4

20 Density : kg/m3 744 762

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 6" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 7.92 mm 30 Flange class : ANSI #600

24 Pipe internal diameter : 152.44 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 170 mm 32 Flange material : A 694 F 52

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #600 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 250 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 8 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NG0-320-TT-0501 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F03-320-PR-PID-00002 06 Mfr. /Mfr. model no. : (*)

03 Service : sales gas from Gas treatment plant 07 Purchase order no. : TBA

04 NG0-20"-EG-320-0401-C41Y-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -0.2 / +46.2 °C 12 Fluid/Phase : Sales Gas / gas

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 92.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : MSCMD 0.4 2.4 10

16 Flow velocity : m/s 0.3 12.6

17 Temperature : °C 50 52

18 Pressure : barg 51.8 75.1

19 Viscosity : cP 0.01 0.01

20 Density : kg/m3 37.9 68.1

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 20" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 12.7 mm 30 Flange class : ANSI #600

24 Pipe internal diameter : 482.6 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 170 mm 32 Flange material : A694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #600 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 420 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 9 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NG0-320-TT-0503 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F03-320-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : sales gas to fiscal metering 07 Purchase order no. : TBA

04 NG0-20"-EG-3200-501-C41Y-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -0.2 / +46.2 °C 12 Fluid/Phase : Sales Gas / gas

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 92.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : MSCMD 0.4 2.4 10

16 Flow velocity : m/s 0.3 12.6

17 Temperature : °C 45 50

18 Pressure : barg 50 75

19 Viscosity : cP 0.01 0.01

20 Density : kg/m3 38 60

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 20" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 12.7 mm 30 Flange class : ANSI #600

24 Pipe internal diameter : 482.6 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 170 mm 32 Flange material : A694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #600 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 420 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 10 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NG0-324-TT-0601 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F04-324-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : propane from Gabes gas treat. plant 07 Purchase order no. : TBA

04 NG0-6"-LP-324-0002-B51X-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -0.2 / +46.2 °C 12 Fluid/Phase : Propane / liquid

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 44.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : kg/h 20020 20030 58000

16 Flow velocity : m/s 0.6 1.6

17 Temperature : °C 13 50

18 Pressure : barg 25 33.7 33.7

19 Viscosity : cP 0.11 0.11

20 Density : kg/m3 515.5 516.5

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 6" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 6.35 mm 30 Flange class : ANSI #300

24 Pipe internal diameter : 155.58 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 160 mm 32 Flange material : A694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #300 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 240 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 11 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NG0-324-TT-0603 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F04-324-PR-PID-00002 06 Mfr. /Mfr. model no. : (*)

03 Service : propane to fiscal metering 07 Purchase order no. : TBA

04 NG0-6"-LP-324-0012-B51X-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -0.2 / +46.2 °C 12 Fluid/Phase : Propane / liquid

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 44.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : kg/h 20020 20030 58000

16 Flow velocity : m/s 0.6 1.6

17 Temperature : °C 12 13 50

18 Pressure : barg 25 33 34

19 Viscosity : cP 0.11 0.11

20 Density : kg/m3 515 517

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 6" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 6.35 mm 30 Flange class : ANSI #300

24 Pipe internal diameter : 155.58 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 160 mm 32 Flange material : A694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #300 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 240 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 12 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NG0-323-TT-0701 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F05-323-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : butane from Gabes gas treat. plant 07 Purchase order no. : TBA

04 NG0-4"-LB-323-0002-B41X-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -0.2 / +46.2 °C 12 Fluid/Phase : Butane / liquid

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 44.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : kg/h 11600 11610 28000

16 Flow velocity : m/s 0.7 1.6

17 Temperature : °C 12.6 50

18 Pressure : barg 16.5 33.7 33.7

19 Viscosity : cP 0.19 0.19

20 Density : kg/m3 582 583

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 4" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 5.56 mm 30 Flange class : ANSI #300

24 Pipe internal diameter : 103.18 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 160 mm 32 Flange material : A694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #300 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 210 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 13 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NG0-323-TT-0703 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F05-323-PR-PID-00002 06 Mfr. /Mfr. model no. : (*)

03 Service : butane to fiscal metering 07 Purchase order no. : TBA

04 NG0-4"-LB-323-0012-B41X-V

Line/equipement no. : 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -0.2 / +46.2 °C 12 Fluid/Phase : Butane / liquid

INSTALLATION OPERATING CONDITIONS

10 Design pressure/temperature : 44.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : kg/h 11600 11610 28000

16 Flow velocity : m/s 0.7 1.6

17 Temperature : °C 12 12 50

18 Pressure : barg 16.5 32 34

19 Viscosity : cP 0.19 0.19

20 Density : kg/m3 583 584

21 Pipe or Vessel : Pipe 28 Flange code or Std. : ASME B 16.5

22 Pipe size : 4" 29 Flange size : 2"

23 Pipe or Vessel wall thickness : 5.56 mm 30 Flange class : ANSI #300

24 Pipe internal diameter : 103.18 mm 31 Flange facing : RF

25 Nozzle or Threadolet height (H) : 160 mm 32 Flange material : A694 F65

26 Threadolet internal size/type : n.a. 33 Pipe or Vessel insulat. Thickness : -

27 Nozzle internal diameter : 49.25 mm 34

TEMPERATURE TRANSMITTER DATA :

35 Type : RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : on thermowell 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) (to suit relevant thermowell) 65 Dimension : (*)

43 Stem lenght : (*) to suit relevant thermowell 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : AISI 316SS 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings : required (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) 72 Tropicalization : -

50 Connection size/type : ½" NPT-M / adjust. insertion lenght 73

51 Connection material : AISI 316SS 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76

54 Comunication : Smart /HART protocol 77

55 Supply voltage 24 VDC (loop powered) 78

56 Consumption : (*) 79

57 Load limitation : (*) 80

THERMOWELL DATA :

81 Type : flanged 95 Type : tapered

THREADED GEN.

82 Construction : drilled from bar stock 96 Material : AISI 316SS

83 Pressure rating : ANSI #300 97 Shank diameter at tip (QT) : (*)

84 Hexagon nut size : n.a. 98 Max. allow. shank diam. Q : 45 mm

n.a.

STEM

85 External thread size/type : 99 Insertion lenght U : 210 mm (*) (note 1)

86 100 Thermowell total lenght T : (*)

87 101 Internal thread size/type : ½" NPT-F

88 Flange code or Std. : ASME B 16.5 102 Bore diameter B : to suit rel. temp. tr.

89 Flange size : 2" 103 Stem lenght A : to suit relevant temp. tr.

FLANGED

90 Flange facing : RF 104

91 Flange material : AISI 316SS 105 Plug and chain : required

ACCESS.

92 106 Plug and chain material : AISI 316SS

93 107 Tag/data plate material : required / SS

94 108 Wake freq. calc. (ASME PTC 19.3) : required

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to confirm/revise this value according to

API RP 551 (ASME PTC 19.3)

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 14 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0110A 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : LVS1 upstream temperature 07 Purchase order no. : TBA

04 Line/equipement no. : NP0-24"-EG-321-0010-D41Y-V 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Raw gas / gas

OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : 0.7 2.5 3.8

17 Temperature : 10 31 55

18 Pressure : 35 44 100

19 Viscosity : 0.009 0.01

20 Density : 27 37 107

21 Pipe size : 24" 28

INSTALLATION

22 Pipe wall thickness : 17.48 mm 29

23 Pipe insulat. Thickness : 3 mm 30

24 31

25 32

26 33

27 34

TEMPERATURE TRANSMITTER DATA :

35 Type : non intrusive RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : clamped on underground pipe 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) 65 Dimension : (*)

43 Stem lenght : (*) 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS (*) 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : Silver tip (*) 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings/type : required / (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) (note 1) 72 Tropicalization : -

50 73

51 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76 Pipe Clamp : required

54 Comunication : Smart /HART protocol 77 Pipe Clamp size : (*)

55 Supply voltage 24 VDC (loop powered) 78 Pipe clamp material : SS

56 Consumption : (*) 79

57 Load limitation : (*) 80

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to indicate if any particular support is deemed

necessary for the extension. If yes, the support shall be adequately qualified

during bid phase and included in the supply.

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 15 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0110B 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : LVS1 downstream temperature 07 Purchase order no. : TBA

04 Line/equipement no. : NP0-24"-EG-3210-010-D41Y-V 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Raw gas / gas

OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : 0.7 2.5 3.8

17 Temperature : 10 31 55

18 Pressure : 35 44 100

19 Viscosity : 0.009 0.01

20 Density : 27 37 107

21 Pipe size : 24" 28

INSTALLATION

22 Pipe wall thickness : 17.48 mm 29

23 Pipe insulat. Thickness : 3 mm 30

24 31

25 32

26 33

27 34

TEMPERATURE TRANSMITTER DATA :

35 Type : non intrusive RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : clamped on underground pipe 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) 65 Dimension : (*)

43 Stem lenght : (*) 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS (*) 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : Silver tip (*) 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings/type : required / (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) (note 1) 72 Tropicalization : -

50 73

51 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76 Pipe Clamp : required

54 Comunication : Smart /HART protocol 77 Pipe Clamp size : (*)

55 Supply voltage 24 VDC (loop powered) 78 Pipe clamp material : SS

56 Consumption : (*) 79

57 Load limitation : (*) 80

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to indicate if any particular support is deemed

necessary for the extension. If yes, the support shall be adequately qualified

during bid phase and included in the supply.

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 16 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0120A 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : LVS2 upstream temperature 07 Purchase order no. : TBA

04 Line/equipement no. : NP0-24"-EG-321-0020-D41Y-V 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Raw gas / gas

OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : 0.8 2.3 3.9

17 Temperature : 10 27 55

18 Pressure : 35 43 95

19 Viscosity : 0.009 0.01

20 Density : 27 37 107

21 Pipe size : 24" 28

INSTALLATION

22 Pipe wall thickness : 17.48 mm 29

23 Pipe insulat. Thickness : 3 mm 30

24 31

25 32

26 33

27 34

TEMPERATURE TRANSMITTER DATA :

35 Type : non intrusive RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : clamped on underground pipe 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) 65 Dimension : (*)

43 Stem lenght : (*) 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS (*) 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : Silver tip (*) 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings/type : required / (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) (note 1) 72 Tropicalization : -

50 73

51 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76 Pipe Clamp : required

54 Comunication : Smart /HART protocol 77 Pipe Clamp size : (*)

55 Supply voltage 24 VDC (loop powered) 78 Pipe clamp material : SS

56 Consumption : (*) 79

57 Load limitation : (*) 80

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to indicate if any particular support is deemed

necessary for the extension. If yes, the support shall be adequately qualified

during bid phase and included in the supply.

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 17 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0120B 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : LVS2 downstream temperature 07 Purchase order no. : TBA

04 Line/equipement no. : NP0-24"-EG-321-0020-D41Y-V 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Raw gas / gas

OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : 0.8 2.3 3.9

17 Temperature : 10 27 55

18 Pressure : 35 43 95

19 Viscosity : 0.009 0.01

20 Density : 27 37 107

21 Pipe size : 24" 28

INSTALLATION

22 Pipe wall thickness : 17.48 mm 29

23 Pipe insulat. Thickness : 3 mm 30

24 31

25 32

26 33

27 34

TEMPERATURE TRANSMITTER DATA :

35 Type : non intrusive RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : clamped on underground pipe 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) 65 Dimension : (*)

43 Stem lenght : (*) 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS (*) 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : Silver tip (*) 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings/type : required / (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) (note 1) 72 Tropicalization : -

50 73

51 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76 Pipe Clamp : required

54 Comunication : Smart /HART protocol 77 Pipe Clamp size : (*)

55 Supply voltage 24 VDC (loop powered) 78 Pipe clamp material : SS

56 Consumption : (*) 79

57 Load limitation : (*) 80

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to indicate if any particular support is deemed

necessary for the extension. If yes, the support shall be adequately qualified

during bid phase and included in the supply.

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 18 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0130A 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : LVS3 upstream temperature 07 Purchase order no. : TBA

04 Line/equipement no. : NP0-24"-EG-321-0030-D41Y-V 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Raw gas / gas

OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : 0.8 2.5 3.9

17 Temperature : 10 27 55

18 Pressure : 35 43 93

19 Viscosity : 0.009 0.01

20 Density : 27 37 107

21 Pipe size : 24" 28

INSTALLATION

22 Pipe wall thickness : 17.48 mm 29

23 Pipe insulat. Thickness : 3 mm 30

24 31

25 32

26 33

27 34

TEMPERATURE TRANSMITTER DATA :

35 Type : non intrusive RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : clamped on underground pipe 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) 65 Dimension : (*)

43 Stem lenght : (*) 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS (*) 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : Silver tip (*) 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings/type : required / (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) (note 1) 72 Tropicalization : -

50 73

51 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76 Pipe Clamp : required

54 Comunication : Smart /HART protocol 77 Pipe Clamp size : (*)

55 Supply voltage 24 VDC (loop powered) 78 Pipe clamp material : SS

56 Consumption : (*) 79

57 Load limitation : (*) 80

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to indicate if any particular support is deemed

necessary for the extension. If yes, the support shall be adequately qualified

during bid phase and included in the supply.

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 19 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0130B 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : LVS3 downstream temperature 07 Purchase order no. : TBA

04 Line/equipement no. : NP0-24"-EG-321-0030-D41Y-V 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Raw gas / gas

OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : 0.8 2.5 3.9

17 Temperature : 10 27 55

18 Pressure : 35 43 93

19 Viscosity : 0.009 0.01

20 Density : 27 37 107

21 Pipe size : 24" 28

INSTALLATION

22 Pipe wall thickness : 17.48 mm 29

23 Pipe insulat. Thickness : 3 mm 30

24 31

25 32

26 33

27 34

TEMPERATURE TRANSMITTER DATA :

35 Type : non intrusive RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : clamped on underground pipe 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)

40 Sensor operating limits : Class A (IEC 60751) 63 Zero/span adjustement : required

41 Wire configuration : 3 wires 64 Mounting : directly to the sensor head

ELEMENT/SENSOR

42 Stem diameter : (*) 65 Dimension : (*)

43 Stem lenght : (*) 66 Material : Aluminium

44 Sensitive portion lenght : (*) 67 Cable connection : screwed terminals

45 Stem material : AISI 316SS (*) 68 Cable entry n°/type : n°1 / ISO M20x1.5mm

CASE

46 Sensitive portion material : Silver tip (*) 69 Enclosure protection : IP 66

47 Sensor assemblies : spring loaded 70 Ex. Classification : Zone 2, Ex-ia IIB T3 (as a min)

48 Extension fittings/type : required / (*) 71 Protective coating : epoxy coating

49 Extension fittings lenght : (*) (note 1) 72 Tropicalization : -

50 73

51 74

52 Indicator : Digital LCD local display 75 Tag/data plate material : required / SS

ACCESSORIES

TRANSMITTER

53 Output signal : 4-20 mA (2-wires) 76 Pipe Clamp : required

54 Comunication : Smart /HART protocol 77 Pipe Clamp size : (*)

55 Supply voltage 24 VDC (loop powered) 78 Pipe clamp material : SS

56 Consumption : (*) 79

57 Load limitation : (*) 80

NOTES

(*) Information supplied and/or confirmed by Manufacturer.

(1) Supplier is required to indicate if any particular support is deemed

necessary for the extension. If yes, the support shall be adequately qualified

during bid phase and included in the supply.

This document is the property of ETAP and OMV. It shall not be copied, reproduced and circulated without the Authorization of ETAP and OMV.

File name: NAWPPL-BIMS-NPPL-000-CI-DAT-00007-002.xlsx

NAWARA PROJECT (PIPELINE)

TECHNICAL DATA SHEET FOR TEMPERATURE TRANSMITTER

Contractor doc. n°: Engineering doc. n°: Rev: C01 000 001 Client doc. n°:

NAWPPL-BIMS-NPPL-000-CI-DAT-00007 P13IT02472-ICT-DS-000-0044 Sheet: 20 of 37 Class: 3 NAWPPL-BIMS-NPPL-000-CI-DAT-00007

GENERAL

01 Instrument tag no. : NP0-321-TT-0140A 05 Weight : (*)

02 P & ID : NAWPPL-BIMS-0F01-321-PR-PID-00001 06 Mfr. /Mfr. model no. : (*)

03 Service : LVS4 upstream temperature 07 Purchase order no. : TBA

04 Line/equipement no. : NP0-24"-EG-321-0040-D41Y-V 08

PROCESS AND PIPING DATA:

09 Ambient temperature limits : -3.6 / +50 °C 12 Fluid/Phase : Raw gas / gas

OPERATING CONDITIONS

10 Design pressure/temperature : 111.0 barg / 85°C 13 Sour service spec. : -

11 SIL requirement : - 14

Minimum Normal Maximum

15 Flow rate : Sm3/d 0.6 2.7 10

16 Flow velocity : 0.8 2.8 4

17 Temperature : 9 27 55

18 Pressure : 35 42 88

19 Viscosity : 0.009 0.01

20 Density : 27 37 107

21 Pipe size : 24" 28

INSTALLATION

22 Pipe wall thickness : 17.48 mm 29

23 Pipe insulat. Thickness : 3 mm 30

24 31

25 32

26 33

27 34

TEMPERATURE TRANSMITTER DATA :

35 Type : non intrusive RTD 58 Calibrated range : 0÷100 °C

GEN.

INST. CHAR.

36 Mounting : clamped on underground pipe 59 Characteristic/Accuracy : linear / ± 0.1% of span (*)

37 60 Overrange protection : required

38 Type : Pt 100 ohm @ 0°C, single element 61 Lower/upper range limits : (*)

39 Design standard : (*) 62 Min/Max span : (*)