Академический Документы

Профессиональный Документы

Культура Документы

HD 247 Alarm Valve Model-H

Загружено:

Vinoth PАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HD 247 Alarm Valve Model-H

Загружено:

Vinoth PАвторское право:

Доступные форматы

ALARM VALVE

MODEL-H

TECHNICAL DATA

MODEL H

END CONNECTION Flange X Flange

Flange X Groove

Groove X Groove

NOMINAL SIZE 200, 150, 100 & 80 NB

MAXIMUM SERVICE 17.5 Bar (250 PSI)*

PRESSURE

THREADED OPENING BSPT

MOUNTING Vertical

FLANGE CONNECTION ANSI B16.42 #150

(Flange drilling matching to LISTED

ANSI B 16.5 # 150) 3S38

TRIM Galvanised fitting with DESCRIPTION

Brass Valves

Alarm Valve is a double seated clapper check valve

FACTORY 35Kg./Sq.Cm. (500PSI) with grooved seat design, which ensures positive

HYDROSTATIC TEST water flow for alarm operation and is designed for

PRESSURE installation in wet pipe sprinkler system. External

FRICTIONAL LOSS 200 NB - 7.50 Mtrs. bypass prevents false alarm under all supply pressure

IN TERMS OF 150 NB - 7 Mtrs. condition. In the event of variable pressure condition,

EQUIVALENT LENGTH 100 NB - 6.1 Mtrs. false alarm is prevented with the provision of retard

OF PIPE ( C-120 ) 80 NB - 4.7 Mtrs. chamber, thus the design allows for installation under

both variable and constant supply pressure condition.

FINISH Red RAL 3000

Operation of one or more automatic fire sprinklers

APPROVAL UL Listed & FM Approved causes the water to flow into the sprinkler system

ORDERING Specify Size of valve, causing the alarm valve to open, allowing continuous

INFORMATION Trim details, End Connection flow of water into the system and transmittal of

& PIPE OD alarm, both electrical and mechanical.

REFERENCE NFPA 13 and NFPA 25 OPERATION

* For 200 NB, FM approval is rated upto 200 PSI (14 Bar)

The fire protection system initially when being

pressurized, will allow water to flow into the system

WEIGHT IN KG until the water supply and system pressure is

equalized and the clapper closes the waterway. Once

Valve Size Flange X Flange Flange X Groove Groove X Groove the pressure is stabilized, the fire protection system

200 65 54.0 44.0 is ready to be placed in service and then the alarm

150 42 35.8 28.0 control valve must be opened. Under normal condition,

100 27 22.1 17.30 the water pressure gauge connected to the system

80 18 15.0 12.10 side of the alarm valve would show a higher or equal

pressure reading than the water pressure gauge

GROOVE PIPE SIZE connected to the supply side of the valve. This occurs

because of the bypass line connecting downstream

NORMAL SIZE Pipe OD in MM and upstream side of the alarm valve, which allows

3” (80 NB) 89 water pressure surge to pass without lifting the valve

4” (100 NB) 114.3 clapper off its seat, thereby causing excessive high

pressure surge entrapped in the system side due to

6” (150 NB) 165.1

presence of a check valve, which generally prevents

6” (150 NB) 168.3 false alarm.

8” (200 NB) 219.1

Sudden high pressure surge, as might be encountered

NOTE: FOR 6” (150 NB) STANDARD SUPPLY IS 168.3 MM OD PIPE by the start-up of a large fire pump may lead the valve

GROOVE. FOR 165.1MM SPECIFY IN ORDER clapper to lift momentarily, allowing water to

OCTOBER, 2013 PAGE 1 OF 16 HD 247

flow through grooves in the valve seat to the retard 9. All the newly installed system pipes must be

chamber. The water in the alarm line is automatically flushed properly before alarm valve is put

drained out, which helps to prevent false alarm due into service.

to successive transient surge in supply pressure.

Restriction assembly located beneath the retard INSPECTION AND MAINTENANCE

chamber consists of inlet and drain restriction A qualified and trained person must commission

orifices, which are established by considering the the system. After few initial successful tests an

volume of the retard chamber to meet the listing authorised person must be trained to perform

and approval requirement with regard to time-to- inspection and testing of the system.

alarm. These requirements represent a balancing of

the need to reduce the possible false alarm due to It is recommended to carry out physical inspection

a transient surge in supply pressure and to achieve of the system at least twice a week. The inspection

desired minimum time- to- alarm following a sprinkler should verify that all the control valves are in proper

operation. position as per the requirement of the system and no

damage has taken place to any component.

In constant pressure installation, the retard chamber

is not required and the water passing through the It is recommended that the alarm valve and its

groove in the alarm valve seat flows directly through accessories should be examined and performed

restriction nozzle assembly to activate the mechanical for following at least quarterly or as demanded by

and electrical alarm. local authorities to ensure reliable and trouble free

operation and service.

INSTALLATION

1. Inspection and testing is to be carried out only by

1. HD Sprinkler alarm valve, Model-H must be an authorized person. DO NOT TURN OFF the

installed vertically. water supply valve to undertake repair work or to

test the valve, without placing a roving fire patrol

2. The alarm valve must be installed in a readily

in the area covered by the system. The patrol

visible and accessible location and provision to be

should continue until the system is back into

made in such a way that alarm line drain is visible

service. Also do inform the local security personnel

and accessible.

and alarm control station, so that a false alarm

3. Where water pressure fluctuates, the variable is not signaled.

pressure trim with retard chamber must be used.

2. Open the alarm test valve. Verify that the sprinkler

Under non-fluctuating water pressure condition,

alarm bell and/or the pressure alarm switch/

the constant pressure trim, which does not

electric alarm properly actuate. Close the alarm

include retard chamber, may be used.

test valve and verify that water has ceased

4. The valve must be installed with trim in accordance to flow from the alarm line drain.

with the trim data. Failure to follow the

3. Clean the 20 NB (3/4”) strainer provided on the

appropriate trim connection guidelines may

sprinkler alarm bell line.

prevent the device from functioning properly as

well as void listing, approval and the manufacturer’s 4. Clean the strainer of restriction assembly.

warranty.

5. Inspect the check valve clapper located on

5. Care must be exercised while installing the the bypass line.

check valve in the trim to ascertain that they are

located with the arrow mark on the check valve FALSE ALARM

body and pointed in proper direction. 1. Inspect the valve rubber clapper face. If worn

6. The contraction and expansion associated with or damaged, replace it. Be certain that dirt, stone

an excessive volume of trapped air could cause or any other foreign object have not accumulated

the waterway clapper to cycle open and shut. This under the clapper face and lodged in the groove

may result in false alarm or an intermittent alarm. or holes. Clean the clapper face thoroughly. If the

To avoid these, it is recommended to have breather seat ring surface is nicked or scoured, it might be

valve in the system piping network and a vent valve possible to repair the same using lapping

at the extreme end of the system to bleed-off compound. If not, replace the complete valve or

the air. return it to the manufacturer’s works for repair.

7. The ball valve provided on the alarm line must 2. If sprinkler alarm bell is not functioning or the

be kept open and strapped in set position. impeller is jammed, please follow the maintenance

guideline provided in the catalogue for sprinkler

8. Pipe connecting the retard chamber and alarm bell.

sprinkler alarm bell must be supported

properly to avoid loading on the retard chamber.

OCTOBER, 2013 PAGE 2 OF 16 HD 247

3. If pressure alarm switch gives a steady signal,

but sprinkler alarm generates an intermittent

alarm, check sprinkler alarm bell shaft. If both

the sprinkler alarm bell and pressure alarm

switch are generating intermittent alarm then

check for the possible air which is trapped within

the sprinkler system. Trapped air is to be bled off.

Also the intermittent alarm may occur due to

sudden pressure drop and increase in the system.

These problems can be corrected by maintaining

a steady supply.

CAUTION

1. The UL Listing,FM Approval and manufacturer’s

warranty are valid only when the alarm

valve is installed with HD trim set and installed

as per installation guidelines.

2. Pressure relief valve is required with wet pipe

system, when a rise in ambient temperature can

cause system pressure to exceed 17.5 Bar

(250 PSI). A 17.7 Bar relief valve setting should

be used.

3. For proper operation of the wet system and to

minimize unwanted false alarm, it is important to

remove trapped air from the system. The air

trapped in the system may also cause intermittent

operation of the Water Motor Alarm during

sustained flow of water.

OCTOBER, 2013 PAGE 3 OF 16 HD 247

Nominal Pressure Loss vs Flow - Alarm Valve (Model H)

Nominal Pressure Loss vs Flow - Alarm Valve AV-H

Flow Rate - Gallons Per Minute (GPM)

70 100 200 300 500 700 1000 2000 3000 5000

3 0.2

Nominal Pressure Loss in KG/SQCM

2

Nominla Pressure Loss in PSI

0.1

1 0.07

0.7 0.05

0.04

0.5

0.4 0.03

0.3 0.02

0.2

0.01

0.1

200 300 500 700 1000 2000 3000 5000 7000 10000 20000

Flow Rate - Liters Per Minute (LPM)

OCTOBER, 2013 PAGE 4 OF 16 HD 247

ALARM VALVE, MODEL – H SIZE 200 / 150 / 100 / 80 NB

FLANGE X GROOVE 2

1

1

7

11 3

GROOVE X GROOVE 6

9

5

9 12

4

8 FLANGE X FLANGE

13

11

10

PART LIST

MATERIAL

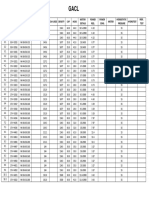

ITEM 200 150 100 80 DESCRIPTION 200 150 100 80 SPECIFICATION

NB NB NB NB NB NB NB NB

1 2630 2601 2614 2650 HOUSING (FLANGE X FLANGE) 1 1 1 1 DUCTILE IRON

1 2478 2471 2469 2468 HOUSING (FLANGE X GROOVE) 1 1 1 1 DUCTILE IRON

1 2485 2482 2480 2479 HOUSING (GROOVE X GROOVE) 1 1 1 1 DUCTILE IRON

2 2632 2607 2616 2652 SEAT 1 1 1 1 BRONZE

3 2600 2600 2600 2600 CLAPPER BUSH 2 2 2 2 BRASS

4 9102 9101 9101 9101 HEX. HEAD BOLT 4 1 1 1 STAINLESS STEEL

5 2636 2628 2619 2656 RUBBER CLAMP 1 1 1 1 STAINLESS STEEL

6 2635 2606 2618 2655 RUBBER SEAT 1 1 1 1 NEOPRENE RUBBER

7 2634 2603 2617 2654 CLAPPER 1 1 1 1 DUCTILE IRON

8 2638 2608 2258 2658 HINGE PIN 1 1 1 1 STAINLESS STEEL

9 2599 2599 2599 2599 BODY BUSH 2 2 2 2 BRASS

10 9004 9004 9004 8373 HEX. HEAD BOLT 6 6 4 4 STEEL

11 9430 9430 9430 9430 SQ. HEAD PLUG 2 2 2 2 FORGED STEEL

12 2637 2611 2620 2657 COVER GASKET 1 1 1 1 NEOPRENE RUBBER

13 2631 2604 2615 2651 COVER 1 1 1 1 DUCTILE IRON

OCTOBER, 2013 PAGE 5 OF 16 HD 247

CONSTANT PRESSURE TRIM FOR ALARM VALVE MODEL - H

200 / 150 / 100 / 80 NB

GROOVE X GROOVE FLANGE X GROOVE

17 17

25

NO 16

14 15 NO 24

14 D

15 18

16

13

FLANGE X FLANGE

2

29

28

30

1

#

NC 12

# 2 2

2,29

10

22 1

# 19 11 9

28 28 8 4

NO

2 5 7

*

21 10 1,28 3

6 1,28

# 26

23 27 1 19

2

29 3

26

20

D

D

#

D

*

WHEN PRESSURE SWITCH IS SUPPLIED THEN SL.NO.22 PLUG NOT REQUIRED.

OCTOBER, 2013 PAGE 6 OF 16 HD 247

CONSTANT PRESSURE TRIM FOR ALARM VALVE MODEL - H

200 / 150 / 100 / 80 NB

QUANTITY

ITEM CODE

DESCRIPTION SIZE PER ALARM VALVE SIZE

NO. NO.

200NB 150NB 100NB 80NB

1 8625 HEX NIPPLE 3/4” 4 4 5 2

2 8620 TEE 3/4” 3 3 3 2

3 8617 ELBOW 3/4” 2 2 2 -

3 8616 ELBOW 1/2” - - - 2

4 8951 PIPE NIPPLE 3/4” X 150 MM LONG 1 - - -

4 9407 PIPE NIPPLE 3/4” X 130 MM LONG - 1 - -

4 9406 PIPE NIPPLE 3/4” X 100 MM LONG - - 1 -

4 9397 PIPE NIPPLE 1/2” X 100 MM LONG - - - 1

5 9406 PIPE NIPPLE 3/4” X 100 MM LONG 1 - - -

5 9441 PIPE NIPPLE 3/4” X 80 MM LONG - 1 - -

6 9397 PIPE NIPPLE 1/2” X 100 MM LONG 1 - - 1

6 9480 PIPE NIPPLE 1/2” X 80 MM LONG - 1 1 -

7 8628 UNION 3/4” 1 1 1 -

7 8627 UNION 1/2” - - - 1

8 9421 SWING CHECK VALVE 3/4” 1 1 1

8 9455 SWING CHECK VALVE 1/2” - - - 1

9 8663 PIPE NIPPLE 3/4” X 70MM LONG 1 1 - -

9 9426 PIPE NIPPLE 3/4” X 60MM LONG - - 1 -

9 9893 PIPE NIPPLE 1/2” X 70MM LONG - - - 1

10 9423 BALL VALVE 1/2” 2 2 2 2

11 8633 REDUCING HEX NIPPLE 3/4” X 1/2” - - - 1

12 8632 REDUCING HEX NIPPLE 3/4” X 1/4” 1 1 1 1

13 8631 REDUCING HEX NIPPLE 1/2” X 1/4” 1 1 1 1

14 9477 BALL VALVE 1/4” 2 2 2 2

15 8698 HEX NIPPLE 1/4” 2 2 2 2

16 8357 ELBOW 1/4” 2 2 2 2

17 9526 PRESSURE GUAGE 1/4” 2 2 2 2

18 2301 ALARM TEST LINE ASSEMBLY 1/2” - - - 1

18 2302 ALARM TEST LINE ASSEMBLY 1/2” - - 1 -

18 2303 ALARM TEST LINE ASSEMBLY 1/2” - 1 - -

18 2304 ALARM TEST LINE ASSEMBLY 1/2” 1 - - -

19 8355 REDUCING BUSH 3/4” X 1/2” 2 2 2 1

20 1027 RESTRICTION NOZZLE ASSEMBLY ‘HD’ MAKE 1 1 1 1

21 9382 ‘Y‘ TYPE STRAINER 3/4” 1 1 1 1

22 8629 PLUG 1/2” 1 1 1 1

23 1416 SPRINKLER ALARM ‘HD’ MAKE TYPE ‘A’ 1 1 1 1

23 1417 SPRINKLER ALARM ‘HD’ MAKE TYPE ‘B’ 1 1 1 1

24 8359 HEX NIPPLE 2” 1 1 1 -

24 8360 HEX NIPPLE 1-1/4” - - - 1

25 9394 ANGLE VALVE 2” 1 1 1 -

25 9392 ANGLE VALVE 1-1/4” - - - 1

26 9561 PIPE NIPPLE 1/2” X 60MM LONG 2 2 2 2

27 9441 PIPE NIPPLE 3/4” X 80MM LONG 1 1 1 1

28 8624 HEX NIPPLE 1/2” 3 3 3 5

29 8619 TEE 1/2” 2 2 2 3

30 - PRESSURE SWITCH (OPTIONAL) 1/2” END CONNECTION 1 1 1 1

OCTOBER, 2013 PAGE 7 OF 16 HD 247

VARIABLE PRESSURE TRIM FOR ALARM VALVE MODEL - H

200 / 150 / 100 / 80 NB

GROOVE X GROOVE FLANGE X GROOVE

17 17

25

30 NO 16

14

# 15 NO 24

14 D

# 15 18

16

13

@ FLANGE X FLANGE

22

19 2

29

#

2 28

*

21 1

1 #

27 NC 12

# 23

2 2,29

# 10

1

11 9

28 28 8 4

NO

5 7

31

10 1,28 3

6 1,28

D

D 26

32 # 2

29

19

3

# 26

20

D

#

D

*

WHEN PRESSURE SWITCH IS SUPPLIED THEN SL.NO.22 PLUG NOT REQUIRED.

OCTOBER, 2013 PAGE 8 OF 16 HD 247

VARIABLE PRESSURE TRIM FOR ALARM VALVE MODEL - H

200 / 150 / 100 / 80 NB

QUANTITY

ITEM CODE

DESCRIPTION SIZE PER ALARM VALVE SIZE

NO. NO.

200NB 150NB 100NB 80NB

1 8625 HEX NIPPLE 3/4” 4 4 5 2

2 8620 TEE 3/4” 3 3 3 2

3 8617 ELBOW 3/4” 2 2 2 -

3 8616 ELBOW 1/2” - - - 2

4 8951 PIPE NIPPLE 3/4” X 150 MM LONG 1 - - -

4 9407 PIPE NIPPLE 3/4” X 130 MM LONG - 1 - -

4 9406 PIPE NIPPLE 3/4” X 100 MM LONG - - 1 -

4 9397 PIPE NIPPLE 1/2” X 100 MM LONG - - - 1

5 9406 PIPE NIPPLE 3/4” X 100 MM LONG 1 - - -

5 9441 PIPE NIPPLE 3/4” X 80 MM LONG - 1 - -

6 9397 PIPE NIPPLE 1/2” X 100 MM LONG 1 - - 1

6 9480 PIPE NIPPLE 1/2” X 80 MM LONG - 1 1 -

7 8628 UNION 3/4” 1 1 1 -

7 8627 UNION 1/2” - - - 1

8 9421 SWING CHECK VALVE 3/4” 1 1 1

8 9455 SWING CHECK VALVE 1/2” - - - 1

9 8663 PIPE NIPPLE 3/4” X 70MM LONG 1 1 - -

9 9426 PIPE NIPPLE 3/4” X 60MM LONG - - 1 -

9 9893 PIPE NIPPLE 1/2” X 70MM LONG - - - 1

10 9423 BALL VALVE 1/2” 2 2 2 2

11 8633 REDUCING HEX NIPPLE 3/4” X 1/2” - - - 1

12 8632 REDUCING HEX NIPPLE 3/4” X 1/4” 1 1 1 1

13 8631 REDUCING HEX NIPPLE 1/2” X 1/4” 1 1 1 1

14 9477 BALL VALVE 1/4” 2 2 2 2

15 8698 HEX NIPPLE 1/4” 2 2 2 2

16 8357 ELBOW 1/4” 2 2 2 2

17 9526 PRESSURE GUAGE 1/4” 2 2 2 2

18 2301 ALARM TEST LINE ASSEMBLY 1/2” - - - 1

18 2302 ALARM TEST LINE ASSEMBLY 1/2” - - 1 -

18 2303 ALARM TEST LINE ASSEMBLY 1/2” - 1 - -

18 2304 ALARM TEST LINE ASSEMBLY 1/2” 1 - - -

19 8355 REDUCING BUSH 3/4” X 1/2” 2 2 2 1

20 1027 RESTRICTION NOZZLE ASSEMBLY ‘HD’ MAKE 1 1 1 1

21 9382 ‘Y‘ TYPE STRAINER 3/4” 1 1 1 1

22 8629 PLUG 1/2” 1 1 1 1

23 1416 SPRINKLER ALARM ‘HD’ MAKE TYPE ‘A’ 1 1 1 1

23 1417 SPRINKLER ALARM ‘HD’ MAKE TYPE ‘B’ 1 1 1 1

24 8359 HEX NIPPLE 2” 1 1 1 -

24 8360 HEX NIPPLE 1-1/4” - - - 1

25 9394 ANGLE VALVE 2” 1 1 1 -

25 9392 ANGLE VALVE 1-1/4” - - - 1

26 9561 PIPE NIPPLE 1/2” X 60MM LONG 2 2 2 2

27 9441 PIPE NIPPLE 3/4” X 80MM LONG 1 1 1 1

28 8624 HEX NIPPLE 1/2” 3 3 3 5

29 8619 TEE 1/2” 2 2 2 3

30 - PRESSURE SWITCH (OPTIONAL) 1/2” END CONNECTION 1 1 1 1

31 2300 RETARD CHAMBER, MODEL - RC9 ‘HD’ MAKE 1 1 1 1

32 8625 HEX NIPPLE 3/4” 1 1 1 1

OCTOBER, 2013 PAGE 9 OF 16 HD 247

CONSTANT PRESSURE TRIM - SCHEMATIC

ALARM VALVE MODEL - H FLANGE X FLANGE 200 / 150 / 100 / 80 NB

DOWNSTREAM.

(TO SYSTEM) SYSTEM SUPPLY

PRESSURE PRESSURE

PG PG

PS *

*G

AT

~

TO DRAIN

AC

TO DRAIN

UPSTREAM.

(FROM SUPPLY)

VARIABLE PRESSURE TRIM - SCHEMATIC

ALARM VALVE MODEL - H FLANGE X FLANGE 200 / 150 / 100 / 80 NB

DOWNSTREAM.

(TO SYSTEM) SYSTEM SUPPLY

PRESSURE PRESSURE

PG PG

PS *

*G

AT RC

~

TO DRAIN

AC

TO DRAIN

UPSTREAM.

(FROM SUPPLY)

ABBREVIATION & SYMBOLS

NON RETURN VALVE RESTRICTION NOZZLE ASSEMBLY AV ALARM VALVE

VALVE * OPTIONAL G SPRINKLER ALARM

ANGLE VALVE NO NORMALLY OPEN PS PRESSURE SWITCH

STRAINER OD OPEN DRAIN RC RETARD CHAMBER

NC NORMALLY CLOSED PG PRESSURE GUAGE AT SPRINKLER ALARM TEST VALVE

AC SPRINKLER ALARM CONTROL VALVE --- BY USER (NOT IN ‘HD’ SCOPE OF SUPPLY)

NOTE :-

1) SPRINKLER ALARM CONTROL VALVE MUST BE KEPT NORMALLY OPEN IF THIS VALVE IS KEPT CLOSED

THE SPRINKLER ALARM BELL/ ELECTRIC ALARM WILL NOT SIGNAL.

2) SPRINKLER ALARM TEST VALVE MUST BE KEPT NORMALLY CLOSED CONDITION. VALVE IS OPENED TO

TEST THE SPRINKLER ALARM BELL / ELECTRIC ALARM.

OCTOBER, 2013 PAGE 10 OF 16 HD 247

CONSTANT PRESSURE TRIM - SCHEMATIC

ALARM VALVE MODEL - H FLANGE X GROOVE 200 / 150 / 100 / 80 NB

DOWNSTREAM.

(TO SYSTEM) SYSTEM SUPPLY

PRESSURE PRESSURE

PG PG

PS *

*G

AT

~

TO DRAIN

AC

TO DRAIN

UPSTREAM.

(FROM SUPPLY)

VARIABLE PRESSURE TRIM - SCHEMATIC

ALARM VALVE MODEL - H FLANGE X GROOVE 200 / 150 / 100 / 80 NB

SYSTEM SUPPLY

PRESSURE PRESSURE

PG PG

PS *

*G

AT RC

~

TO DRAIN

AC

TO DRAIN

ABBREVIATION & SYMBOLS

NON RETURN VALVE RESTRICTION NOZZLE ASSEMBLY AV ALARM VALVE

VALVE * OPTIONAL G SPRINKLER ALARM

ANGLE VALVE NO NORMALLY OPEN PS PRESSURE SWITCH

STRAINER OD OPEN DRAIN RC RETARD CHAMBER

NC NORMALLY CLOSED PG PRESSURE GUAGE AT SPRINKLER ALARM TEST VALVE

AC SPRINKLER ALARM CONTROL VALVE --- BY USER (NOT IN ‘HD’ SCOPE OF SUPPLY)

NOTE :-

1) SPRINKLER ALARM CONTROL VALVE MUST BE KEPT NORMALLY OPEN IF THIS VALVE IS KEPT CLOSED

THE SPRINKLER ALARM BELL/ ELECTRIC ALARM WILL NOT SIGNAL.

2) SPRINKLER ALARM TEST VALVE MUST BE KEPT NORMALLY CLOSED CONDITION. VALVE IS OPENED TO

TEST THE SPRINKLER ALARM BELL / ELECTRIC ALARM.

OCTOBER, 2013 PAGE 11 OF 16 HD 247

CONSTANT PRESSURE TRIM - SCHEMATIC

ALARM VALVE MODEL - H GROOVE X GROOVE 200 / 150 / 100 / 80 NB

DOWNSTREAM.

(TO SYSTEM) SYSTEM SUPPLY

PRESSURE PRESSURE

PG PG

PS *

*G

AT

~

TO DRAIN

AC

TO DRAIN

UPSTREAM.

(FROM SUPPLY)

VARIABLE PRESSURE TRIM - SCHEMATIC

ALARM VALVE MODEL - H GROOVE X GROOVE 200 / 150 / 100 / 80 NB

DOWNSTREAM.

(TO SYSTEM) SYSTEM SUPPLY

PRESSURE PRESSURE

PG PG

PS *

*G

AT RC

~

TO DRAIN

AC

TO DRAIN

UPSTREAM.

(FROM SUPPLY)

ABBREVIATION & SYMBOLS

NON RETURN VALVE RESTRICTION NOZZLE ASSEMBLY AV ALARM VALVE

VALVE * OPTIONAL G SPRINKLER ALARM

ANGLE VALVE NO NORMALLY OPEN PS PRESSURE SWITCH

STRAINER OD OPEN DRAIN RC RETARD CHAMBER

NC NORMALLY CLOSED PG PRESSURE GUAGE AT SPRINKLER ALARM TEST VALVE

AC SPRINKLER ALARM CONTROL VALVE --- BY USER (NOT IN ‘HD’ SCOPE OF SUPPLY)

NOTE :-

1) SPRINKLER ALARM CONTROL VALVE MUST BE KEPT NORMALLY OPEN IF THIS VALVE IS KEPT CLOSED

THE SPRINKLER ALARM BELL/ ELECTRIC ALARM WILL NOT SIGNAL.

2) SPRINKLER ALARM TEST VALVE MUST BE KEPT NORMALLY CLOSED CONDITION. VALVE IS OPENED TO

TEST THE SPRINKLER ALARM BELL / ELECTRIC ALARM.

OCTOBER, 2013 PAGE 12 OF 16 HD 247

INSTALLATION DIMENSION WITH TRIM

ALARM VALVE MODEL - H FLANGE X FLANGE 200 / 150 / 100 / 80 NB

A) CONSTANT PRESSURE TRIM WITH CONSTANT PRESSURE TRIM

SIZE 80NB 100NB 150NB 200NB

A 279 312 331 350

B 457 464 486 527

E

C 434 434 434 443

D 127 140 173 192

E 201 219 234 269

F 262 274 315 378

D

DIMENSIONS are approx. and in millimeters

C

F

A B

B) VARIABLE PRESSURE TRIM WITH VARIABLE PRESSURE TRIM

SIZE 80NB 100NB 150NB 200NB

A 279 312 331 350

B 482 488 510 551

E

C 588 588 588 597

D 127 140 173 192

E 201 219 234 269

F 262 274 315 378

D

DIMENSIONS are approx. and in millimeters

C

F

A B

OCTOBER, 2013 PAGE 13 OF 16 HD 247

INSTALLATION DIMENSION WITH TRIM

ALARM VALVE MODEL - H FLANGE X GROOVE 200 / 150 / 100 / 80 NB

A) CONSTANT PRESSURE TRIM WITH CONSTANT PRESSURE TRIM

SIZE 80NB 100NB 150NB 200NB

A 279 312 331 350

E

B 457 464 486 527

C 434 434 434 443

D 127 140 173 204

E 201 219 234 269

D

F 275 291.3 316.8 395.2

DIMENSIONS are approx. and in millimeters

C

F

A B

B) VARIABLE PRESSURE TRIM WITH VARIABLE PRESSURE TRIM

SIZE 80NB 100NB 150NB 200NB

A 279 312 331 350

B 482 488 510 551

E

C 588 588 588 597

D 127 140 173 204

E 201 219 234 269

D

F 275 291.3 316.8 395.2

DIMENSIONS are approx. and in millimeters

C

F

A B

OCTOBER, 2013 PAGE 14 OF 16 HD 247

INSTALLATION DIMENSION WITH TRIM

ALARM VALVE MODEL - H GROOVE X GROOVE 200 / 150 / 100 / 80 NB

A) CONSTANT PRESSURE TRIM WITH CONSTANT PRESSURE TRIM

SIZE 80NB 100NB 150NB 200NB

A 279 312 331 350

B 457 464 486 527

E

C 439 443 442 443

D 127 140 173 204

E 201 219 234 269

D

F 280 300 324 405

DIMENSIONS are approx. and in millimeters

C

F

A B

B) VARIABLE PRESSURE TRIM WITH VARIABLE PRESSURE TRIM

SIZE 80NB 100NB 150NB 200NB

A 279 312 331 350

B 482 488 510 551

E

C 593 596 596 607

D 127 140 173 204

E 201 219 234 269

D

F 280 300 324 405

DIMENSIONS are approx. and in millimeters

C

F

A B

OCTOBER, 2013 PAGE 15 OF 16 HD 247

LIMITED WARRANTY

HD FIRE PROTECT PVT. LTD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person

to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of

shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty.

No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair, alteration or un-maintained.

HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.

HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is

found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly

or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured

by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any

damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.

The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited

to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with

the provision of government codes or ordinances wherever applicable.

The information provided by us are to the best of our knowledge and belief, and are general guidelines only. Site handling and installation control is beyond our reach.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation or

damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

C-3/6, THE NANDANVAN IND. ESTATE, L.B.S. MARG, THANE 400 604., INDIA.

HD FIRE PROTECT PVT. LTD. • PHONES : + (91) 22 2583 5434 • 2582 6958 • 2582 6793

Protecting What Matters Most to You • FAX : +(91) 22 2581 2524 • 6796 9049

• EMAIL : info@hdfire.com WEBSITE : www.hdfire.com

OCTOBER, 2013 PAGE 16 OF 16 HD 247

Вам также может понравиться

- GST Fire Alarm System Version 202102Документ44 страницыGST Fire Alarm System Version 202102Vinoth PОценок пока нет

- Inertia Base CalculationДокумент2 страницыInertia Base CalculationVinoth PОценок пока нет

- GST UL System Submittal GuideДокумент48 страницGST UL System Submittal GuideVinoth PОценок пока нет

- Beam Sensors: Key FeaturesДокумент2 страницыBeam Sensors: Key FeaturesVinoth PОценок пока нет

- HD 196 Foam Branch PipeДокумент1 страницаHD 196 Foam Branch PipeVinoth PОценок пока нет

- IS Standard 8329 - DI Pipes K 9Документ26 страницIS Standard 8329 - DI Pipes K 9Pradeep Kanwar89% (18)

- Is 10221Документ31 страницаIs 10221Vinoth P50% (2)

- Is 14846Документ24 страницыIs 14846rinabiswas100% (1)

- 2189 Fire Detection Alarm SystemДокумент25 страниц2189 Fire Detection Alarm Systemchatakondu sudhakar40% (5)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Break Down IPAL Packed ATS 100.100Документ5 страницBreak Down IPAL Packed ATS 100.100yayanОценок пока нет

- 28 27 - Bell - Gossett - HistoricalДокумент7 страниц28 27 - Bell - Gossett - HistoricalthepimpoОценок пока нет

- Rumus Afinitas Otk-2Документ1 страницаRumus Afinitas Otk-2Intan PuspitariniОценок пока нет

- 3K Pump 26.2.2015Документ65 страниц3K Pump 26.2.2015TamОценок пока нет

- Valve Selection 900-PHI-MP-0001 - B01Документ18 страницValve Selection 900-PHI-MP-0001 - B01saebani sbnОценок пока нет

- Check Valve DescriptionДокумент1 страницаCheck Valve DescriptionmoodydoodyОценок пока нет

- Schedule 40 Pipes & Fittings: Reducer Bushing (Flush Style) (Spgxsoc)Документ3 страницыSchedule 40 Pipes & Fittings: Reducer Bushing (Flush Style) (Spgxsoc)1075SYBPATEL DHRUVОценок пока нет

- Sanyi Gate Valve Spare PartsДокумент18 страницSanyi Gate Valve Spare PartsAnonymous MxwCc4Оценок пока нет

- Hydraulic Systems VI Handout PDFДокумент39 страницHydraulic Systems VI Handout PDFMalik ForbesОценок пока нет

- Gacl Testing Data SheetДокумент2 страницыGacl Testing Data SheetVIKASH RAIОценок пока нет

- E5 SteeringunitДокумент57 страницE5 SteeringunitSam JacobОценок пока нет

- Am-06 Vacuum Toilet SystemДокумент125 страницAm-06 Vacuum Toilet SystemMustafa YıldırımОценок пока нет

- Husco PDFДокумент70 страницHusco PDFhamdaОценок пока нет

- 966H 972H Hydraulic Schematic RENR8828Документ2 страницы966H 972H Hydraulic Schematic RENR8828Freddy Quispe100% (1)

- Hydarulic and Pneumatics SystemДокумент18 страницHydarulic and Pneumatics SystemjaigemukОценок пока нет

- QR 1211 Main Drain TestДокумент1 страницаQR 1211 Main Drain TestDec DmcОценок пока нет

- Check Valve Koganei C250Документ1 страницаCheck Valve Koganei C250Riki HermansyahОценок пока нет

- Pid Symbols PDFДокумент16 страницPid Symbols PDFJosé Antônio CardosoОценок пока нет

- EN ControlValves HR PDFДокумент28 страницEN ControlValves HR PDFioan cristian cotorobai100% (1)

- Spare Parts Book: Ity. Mped. OriginalДокумент108 страницSpare Parts Book: Ity. Mped. OriginalSergey MylnikovОценок пока нет

- Section 5: Hydraulic SystemsДокумент14 страницSection 5: Hydraulic SystemsrobbertmdОценок пока нет

- Basic Training HydralicДокумент56 страницBasic Training HydralicAneliese Enache100% (5)

- Pipe Data: Mason Industries, IncДокумент1 страницаPipe Data: Mason Industries, IncselisenОценок пока нет

- Table of ContentsДокумент27 страницTable of ContentsEng-Mohammed SalemОценок пока нет

- Valve Selection & Specification Guide For Building Services: Ahead of The FlowДокумент20 страницValve Selection & Specification Guide For Building Services: Ahead of The FlowGreg FarzettaОценок пока нет

- Pro PDF p27Документ1 страницаPro PDF p27Андрей НавОценок пока нет

- A320 HydraulicsystemДокумент2 страницыA320 HydraulicsystemMinh NguyễnОценок пока нет

- 1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Документ1 страница1 Gala Ci Gate Valve Resilient Seated Nrs NRGV 3243Non Etabas GadnatamОценок пока нет

- 43 - Southern Cross - Iso Pump - 125 X 100 - 400 - 1470 RPMДокумент1 страница43 - Southern Cross - Iso Pump - 125 X 100 - 400 - 1470 RPMBayuОценок пока нет

- Bangalore's Impending Water Crisis Deccan Herald 02 January, 2011Документ1 страницаBangalore's Impending Water Crisis Deccan Herald 02 January, 2011Dr Vidya S SharmaОценок пока нет