Академический Документы

Профессиональный Документы

Культура Документы

Absco Shed 23141R Domestic 20 04 11 PDF

Загружено:

AlejandroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Absco Shed 23141R Domestic 20 04 11 PDF

Загружено:

AlejandroАвторское право:

Доступные форматы

Absco Regent Shed

Assembly Instructions

Model: 23141R

FRONT: 2.26m

SIDE: 1.44m

HEIGHT: 1.96m

SLAB

CONCRETE

15

40m

m 2360mm

WHEN LAYING YOUR CONCRETE

SLAB, CHAMFER THE 50mm EDGES

DOWNWARDS BY 10mm.

50mm

10mm

THIS WILL ENSURE THAT

50

mm WATER RUN OFF IS KEPT

CLEAR FROM YOUR SHED

We thank you for choosing an Australian Made Shed. For further assistance please

visit our detailed instructional video library at http://www.absco.com.au/videos.php

At ABSCO Industries we are always looking to be number ONE, so please let us

know what you think of our instructions. Feedback makes us better.

feedback@absco.com.au.

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 1

Absco Regent Shed - Model: 23141R

GENERAL INSTRUCTIONS

Before commencing any assembly, read through these instructions in

detail to gain a thorough understanding of assembly methods and

associated details.

Unpack the carton and carefully identify and check off all the parts

against the parts described and illustrated on pages three and four.

SITE PREPARATION

The site for the shed must be level.

It is recommended that the shed be set on a 100mm concrete slab and

anchored down appropriately (refer page 15 for details).

Anchor sets are not supplied as standard items with this product.

TOOLS REQUIRED

3mm

4mm OPTIONAL

A NOTE ON SAFETY

Some parts may have sharp edges. It is advisable to wear gloves when

handling these items and safety glasses if drilling holes. Sensible shoes

are highly recommended.

Do not erect your shed in windy conditions, ensure that the shed is

securely anchored to a solid foundation immediately after construction is

completed.

It is highly recommended to erect the shed with two or more people.

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 2

Absco Regent Shed - Model: 23141R

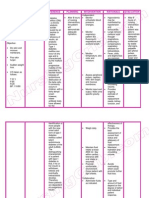

COMPONENTS PACKING LIST - CHECK OFF ALL COMPONENTS

COMPONENT PART COMPONENT PART

QTY CHECK QTY CHECK

DESCRIPTION No. DESCRIPTION No.

STEEL SHEET

2 1785mm X 773mm 30A 1 CHANNEL

76A

L = 2253mm

STEEL SHEET

1 1785mm X 773mm 31A 1 CHANNEL

54C

L = 2253mm

STEEL SHEET

2 1170mm X 773mm 48L 1 CHANNEL

76B

L = 2253mm

STEEL SHEET

2 1170mm X 773mm 48R 1 CHANNEL

81D

L = 2253mm

STEEL SHEET

6 1785mm X 731mm 32A 2 CHANNEL

81E

L = 1513mm

STEEL SHEET

1 1725mm X 773mm A 2 CHANNEL

59C

L = 1439

GABLE L/H

L=1105mm

2 17L 2 CHANNEL

81I

L = 1439

GABLE R/H

L=1105

2 17R 2 CHANNEL

78C

L = 1513

BRACE

2 L: 350mm 13B 1 CHANNEL

79B

L = 788mm

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 3

Absco Regent Shed - Model: 23141R

COMPONENTS PACKING LIST - (CONT.) CHECK OFF ALL COMPONENTS

COMPONENT PART COMPONENT PART

QTY CHECK QTY CHECK

DESCRIPTION No. DESCRIPTION No.

1 CHANNEL WITH HINGES

58A 1 89A

JAMB L= 1785mm

L = 1725mm

1 CHANNEL

58B 1 90B

L = 1725mm JAMB L= 788mm

2 CHANNEL

58C 2 91A

L = 773mm JAMB L= 1120mm

RIDGE

1 BEAM 97C 4 86B

L = 1513 LIP TRIM L= 1170mm

1 89B

JAMB L= 1785mm

CONTENTS OF FITTINGS PACKET

220 SELF TAPPING

SCREWS

1 DOOR

PADBOLT

22A

4mm CSK SCREW & DOOR

PADBOLT

6 NUT SECURE HINGES

TO DOOR

1 HASP

3mm POP RIVETS SECURE

ASSEMBLY

1 INSTRUCTIONS 6 HINGES TO DOOR

(ALTERNATIVE FIXING

METHOD)

DOOR

CAP GABLE

2 L: 170mm 14A 1 STRAP

L: 165mm

12A

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 4

Absco Regent Shed - Model: 23141R

VIEW OF ROOF COMPONENTS

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 5

Absco Regent Shed

Model: 23141R

VIEW OF WALL COMPONENTS

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 6

Absco Regent Shed - Model: 23141R

ABSCO ASSEMBLY INTRODUCTION

The snap-tite assembly system locks all perimeter channels to all roof and wall

sheets without the need for tools and fasteners .

To pre-assemble the four wall panels

and two roof panels, the perimeter

channels are secured to the top and

bottom of each panel using the

snaptite system, as detailed on the

following pages wherever you see

the symbol. SNAP

T iTE

HIGH SIDE

E

HIGH SIDE

HIGH SID

HIGH SIDE

PUSH

PUSH After joining sheets together,

position channel over one end of the

sheets, gently tapping it over the

snaptite lugs, working along the

sheets to the other end.

PUSH

Each perimeter channel must finish flush

with the edges of the sheets. the snap-tite

Position sheets on timbers,

system allows adjustment for this

trestles or partly over edge of

process by simply tapping the channel

concrete slab. HIG

HS

along the sheets until each end is neatly

IDE

flush.

FASTENING SYMBOLS

Join components together with one screw at this 3mm POP RIVETS

location only, as some channel sections have extra

holes that are not required for this model of garden 4mm NUT & BOLT SET

shed

Do not join components together at this location yet,

as the screw may obstruct further assembly of other

components

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 7

Absco Regent Shed - Model: 23141R

DOOR PANEL ASSEMBLY

58C

58A

B

58B

12A

58C

20mm FLANGE

15mm FLANGE

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 8

Absco Regent Shed - Model: 23141R

REAR PANEL ASSEMBLY

30A

76B

31A

30A

81D

SIDE PANEL ASSEMBLY

(2 Required)

32A

32A

SMALL PAN

59C

81I

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 9

Absco Regent Shed - Model: 23141R

ROOF PANEL ASSEMBLY

(2 Required)

48R

48L

2 x PRE-PUNCHED

HOLES TO THIS

END OF EACH

SHEET WITH PART

86B NO. 81E FITTED

78C

81E

86B

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 10

Absco Regent Shed - Model: 23141R

FRONT PANEL ASSEMBLY 89A

89B

32A

32A

76A

90B

79B

54C

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 11

Absco Regent Shed - Model: 23141R

91A

91A

B

NOTE: NUTS AND BOLTS (SUPPLIED) MAY BE USED

INSTEAD OF POP RIVETS (SUPPLIED) BY SIMPLY

ENLARGING THE HINGE HOLE SETS IN THE JAMB

USING A 4MM DRILL BIT

NOTE: The two holes required to connect the padbolt hasp for each door have not been pre-punched, to allow for

proper alignment. position each hasp centrally over the padbolt shaft, and drill 3mm holes and secure with screws

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 12

Absco Regent Shed - Model: 23141R

PANEL CONSTRUCTION Note: Take care to ensure that all wall panels

are not positioned upside down. The top

channel of each panel is pre-punched for

attaching to roof sheets or gable sections.

The bottom channels are not pre-punched.

SIDE WALL PANEL CHANNELS FIT

INTO THE NOTCHED FRONT AND

REAR WALL PANEL CHANNELS 97C

CHANNEL TYPE

78C THIS END

CHANNEL TYPE

81E THIS END

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 13

Absco Regent Shed - Model: 23141R

ROOF CONSTRUCTION

OUTSIDE VIEW INSIDE VIEW

ROOR OVERHANGS SECURE RIDGE BEAM TO

ALL WALL PANELS GABLE SECTIONS WITH

BY 37mm TWO SCREWS AT EACH

END. SECURE EACH ROOF

PANEL WITH ONE SCREW

37mm IN EACH CORNER ONLY

AT THIS STAGE

INSIDE VIEW

AFTER ATTACHING BOTH ROOF

PANELS TO WALLS AS SHOWN

ABOVE, FIT ONE REGENT BRACE

13B

TO THE RIDGE BEAM AND FRONT

WALL AS SHOWN. YOU WILL HAVE

TO REMOVE AND REPLACE

EXISTING SCREWS AT FIXING

LOCATIONS. REPEAT THIS

PROCEDURE FOR THE REAR

WALL REGENT BRACE

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 14

Absco Regent Shed - Model: 23141R

FINAL CONSTRUCTION

14A

BEND THE TOP AND BOTTOM

FLANGES AS SHOWN, THEN HOOK

THE BOTTOM FLANGES UNDER

THE ROOF END FLASHINGS (PART

87B) AND SCREW THE TOP

FLANGES AS SHOWN FOR BOTH

GABLE CAPS

ANCHORING OF SHED

LOCATION OF 12

CONCRETE ANCHORS

BOLT & NUT WALL

SHEET

- EACH ANCHOR CONSISTS OF ONE NUT, BOLT,

STEEL

DYNABOLT AND STEEL ANGLE ANGLE

- DRILL A 10mm HOLE INTO

THE WALL SHEET SLAB

- DRILL A 10mm HOLE INTO THE

CONCRETE DYNABOLT

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 23141R 26/11/10 PAGE 15

PRODUCT WARRANTY

Congratulations on your purchase of an ABSCO Product.

ABSCO SHEDS are made using high quality Bluescope™ Australian made Zincalume™ or

Colorbond Steel™.

We are pleased to advise we warrant that this steel will not rust, crack, flake peel or blister for

20 years from date of purchase.

This warranty does not apply to surface deterioration of panels caused by ‘Swarf” (Tiny particles

of steel debris left from cutting, grinding or drilling operations) that has not been removed after

building construction, or as a result of contact with damp soil, chemicals, fertilisers or other

corrosive substances.

This warranty covers any shed used for normal domestic use and installed in accordance with

the installation instructions. The warranty does NOT cover Damage caused by storms, wind, rain

snow or poor foundations.

This warranty does NOT cover ABSCO products installed in severe coastal, industrial or other

highly corrosive environments. The warranty does not cover fasteners (screws, nuts, bolts,

rivets, hasps or bolts).

The warranty is limited to replacement and delivery of components and does not include any

labour or installation costs.

The warranty applies to the exclusion of all other representations, guarantees or warranties

express or implied, our goods come with guarantees that cannot be excluded under the

Australian consumer law and is not transferable

For further information go to http://www.consumerlaw.gov.au.

Please retain a proof of purchase (sales docket or invoice) or register your warranty within 30

days of purchase here: www.absco.com.au/register_warranty.php

In the unlikely event a warranty claim is made it must be supported by photographic evidence

together with proof of purchase documentation (or on-line registration of purchase) and

forwarded to ABSCO INDUSTRIES, PO BOX 119 ACACIA RIDGE QLD AUSTRALIA 4110

Issued January 2011

ABSCO STEEL BUILDINGS- STORAGE GUIDELINES

ABSCO steel buildings include garden sheds, storage units, aviaries, garages and carports.

ABSCO steel buildings are designed to be weatherproof for normal weather conditions. In the

event of extreme weather conditions such as heavy rain, combined with high wind gusts, the

ridge capping, sheeting joins, screw fixings etc., may exhibit minor deformations which may

allow some water entry. These areas should be checked regularly to ensure that maximum

strength and protection is maintained.

Other weather conditions such as extreme heat and extreme cold, moist or dry air can influence

the effects of concrete floor moisture and/or condensation on the underside of the roof sheets.

ABSCO SHEDS and storage units are primarily used for storage of garden equipment such as

lawnmowers, wheelbarrows, garden tools etc. Storage items that might be adversely affected

by any of the above conditions may require additional protection such as being sealed or

covered by plastic sheets and/or stacked above the concrete floor on timber slats.

Waterproof sealants may be used to offer further protection where required around joins and

screw fixings, as can rubber door seals and other products which are available from most

hardware outlets.

Placement of waterproof sealants (silicone) between the base of the shed and concrete slab is

not recommended, as this process can have a reverse effect, preventing excess water from

escaping, resulting with water accumulating and being trapped inside the shed.

Absco accepts no responsibility for water entry, floor moisture, condensation or the condition

of the Contents inside your Absco steel building arising from any of the pre-mentioned weather

conditions.

Вам также может понравиться

- Absco Space Saver Shed MODEL: 30152SECOK: 3.00mW X 1.52mD X 1.80mH, 2.08mHДокумент22 страницыAbsco Space Saver Shed MODEL: 30152SECOK: 3.00mW X 1.52mD X 1.80mH, 2.08mHDown LordОценок пока нет

- Lubricador CiegoДокумент2 страницыLubricador CiegoMARIO100% (1)

- Victaulic Flexible Hose Connecting To Regular Reliable SprinklerДокумент27 страницVictaulic Flexible Hose Connecting To Regular Reliable SprinklerOwais AhmedОценок пока нет

- 1A KZN Quote Mask - No Rates - 1Документ2 страницы1A KZN Quote Mask - No Rates - 1BonginkosiОценок пока нет

- HVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield CableДокумент6 страницHVT Series Terminations 15-35kV Class High Voltage Termination For LC Shield Cable20353124Оценок пока нет

- DiffuseresДокумент24 страницыDiffuseresHakeem AdDarОценок пока нет

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesДокумент21 страницаVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesEliel AbadОценок пока нет

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Документ4 страницы621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1MarvinJarquinОценок пока нет

- Enviro Dual Compact Pack-OffДокумент1 страницаEnviro Dual Compact Pack-Offngueadoum100% (1)

- DIffuser Selection PDFДокумент24 страницыDIffuser Selection PDFpanyamnrОценок пока нет

- Grundfosliterature 5261470Документ3 страницыGrundfosliterature 5261470YashuОценок пока нет

- RTG Range.: Ready To Go StockДокумент56 страницRTG Range.: Ready To Go StockFercomil S.A.SОценок пока нет

- Backhoe - Boom and Swing TowerДокумент3 страницыBackhoe - Boom and Swing TowerNeftali FuentesОценок пока нет

- Hawke ControlEx Connectors Assembly AI500Документ12 страницHawke ControlEx Connectors Assembly AI500Tony Caroline MorganОценок пока нет

- P.R.V CHAMBER Ø400mmДокумент1 страницаP.R.V CHAMBER Ø400mmHesham ElbanaОценок пока нет

- Cadenza Whirlpool 6060.028W Whirlpool Featuring System IIДокумент2 страницыCadenza Whirlpool 6060.028W Whirlpool Featuring System IIbondsupplyОценок пока нет

- Warning: Installation Instructions - 14 Gauge C-Track SystemДокумент4 страницыWarning: Installation Instructions - 14 Gauge C-Track SystemjorafestОценок пока нет

- Janitor SinkДокумент2 страницыJanitor Sinkfarshan296015Оценок пока нет

- A-4S ManualДокумент7 страницA-4S ManualFahriyanda HilmanОценок пока нет

- 2.bien Phap Thi Cong Ong GioДокумент19 страниц2.bien Phap Thi Cong Ong GioQuang Do HoangОценок пока нет

- Moulded Range LeafletДокумент28 страницMoulded Range LeafletAzeemОценок пока нет

- BG Electrical Moulded Range LeafletДокумент28 страницBG Electrical Moulded Range Leafletazeemahmedkhan021Оценок пока нет

- Dnlf13a2 4RДокумент2 страницыDnlf13a2 4RFactory FactoryОценок пока нет

- Nas 1714Документ2 страницыNas 1714YossiОценок пока нет

- MANUAL 2021 ONIX E ONIX DARK - CompressedДокумент16 страницMANUAL 2021 ONIX E ONIX DARK - CompressedRoberto DeiquesОценок пока нет

- Technical Sheet Vacuum Tube Collectors CVTДокумент2 страницыTechnical Sheet Vacuum Tube Collectors CVTgonzalez2678Оценок пока нет

- Technical Specification Sailor N163S Power Supply PDFДокумент1 страницаTechnical Specification Sailor N163S Power Supply PDFseamec2Оценок пока нет

- TV Televes 2.satellite Dishes enДокумент10 страницTV Televes 2.satellite Dishes ensdmitarОценок пока нет

- Datasheet Assembly Cable LugsДокумент6 страницDatasheet Assembly Cable LugsGunjanОценок пока нет

- Encore XHHW 2Документ2 страницыEncore XHHW 2Alexander Huacre TuctoОценок пока нет

- Captador Sonnenkraft SK500Документ2 страницыCaptador Sonnenkraft SK500Abdoullai camaraОценок пока нет

- AM3KA539 Combined Depth/Tension Measurement Device: With Low Voltage Tension AmplifierДокумент27 страницAM3KA539 Combined Depth/Tension Measurement Device: With Low Voltage Tension AmplifierDiego CorderoОценок пока нет

- DX900 Manual Rev 4 Jan 17Документ49 страницDX900 Manual Rev 4 Jan 17Mondiale MondialentrepriseОценок пока нет

- Victaulic Flexible Hose Connecting To Dry Barrel SprinklerДокумент27 страницVictaulic Flexible Hose Connecting To Dry Barrel SprinklerOwais AhmedОценок пока нет

- Standards 001Документ23 страницыStandards 001Civ HerreraОценок пока нет

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Документ3 страницы621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Neftali FuentesОценок пока нет

- DMS Cource ProjectДокумент18 страницDMS Cource ProjectBabu100% (1)

- Plinth LayoutДокумент1 страницаPlinth LayoutShrey DubeyОценок пока нет

- Catalogo Mangueras HidraulicasДокумент61 страницаCatalogo Mangueras HidraulicasCarlosSilvaYruretaОценок пока нет

- PINДокумент4 страницыPINVladimirCarrilloОценок пока нет

- Perspective: Pipe Thru Wall DetailДокумент1 страницаPerspective: Pipe Thru Wall DetailJemil Rose SamosОценок пока нет

- Service SinkДокумент4 страницыService SinkAnita CabassaОценок пока нет

- 9134001EC Decorum Sink ENДокумент2 страницы9134001EC Decorum Sink ENInterplan Puerto RicoОценок пока нет

- Ryobi-512 Crestlain - ESPAÑOLДокумент68 страницRyobi-512 Crestlain - ESPAÑOLvergamás1100% (1)

- PAcking List PDFДокумент2 страницыPAcking List PDFAakash JunejaОценок пока нет

- AC Axial FanДокумент20 страницAC Axial FansunhuynhОценок пока нет

- 2500 DrumДокумент2 страницы2500 DrumPM PandianОценок пока нет

- 5KL GLSR PDFДокумент1 страница5KL GLSR PDFvisali garikapatiОценок пока нет

- Drawing 80AQ15-60 Non CodedДокумент2 страницыDrawing 80AQ15-60 Non Codeddaus nasОценок пока нет

- Cushcraft: Assembly and Installation InstructionsДокумент16 страницCushcraft: Assembly and Installation InstructionsedualoviОценок пока нет

- Admiral S15 OMДокумент12 страницAdmiral S15 OMAtgProyek AvilaОценок пока нет

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesДокумент20 страницVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesbalaasenthilОценок пока нет

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Документ2 страницы621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Nelson ConselhoОценок пока нет

- Structural Details of Column: Table of Reinforcement DetailsДокумент1 страницаStructural Details of Column: Table of Reinforcement DetailsAswin KumarОценок пока нет

- Lab TaubaltionДокумент4 страницыLab TaubaltionLast NameОценок пока нет

- JW Complete Catalogue PDFДокумент86 страницJW Complete Catalogue PDFSRARОценок пока нет

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PОт EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PОценок пока нет

- Comprehensive Engine Part Repair: The Eagle Is EverywhereДокумент4 страницыComprehensive Engine Part Repair: The Eagle Is EverywhereAlejandroОценок пока нет

- Ecoflight Solutions: It'S in Our PowerДокумент4 страницыEcoflight Solutions: It'S in Our PowerAlejandroОценок пока нет

- IceДокумент9 страницIceAlejandroОценок пока нет

- EcoPower Brochure PDFДокумент4 страницыEcoPower Brochure PDFAlejandroОценок пока нет

- LinesДокумент4 страницыLinesAlejandroОценок пока нет

- Abs 0973Документ13 страницAbs 0973AlejandroОценок пока нет

- FT Rolls Insecticide Rolls PDFДокумент1 страницаFT Rolls Insecticide Rolls PDFAlejandro100% (1)

- 46 47rhe ZipДокумент10 страниц46 47rhe ZipAlejandro100% (1)

- Fuel SurveyДокумент3 страницыFuel SurveyAlejandroОценок пока нет

- Parker (T6, T6D) Hydraulic Vane PumpsДокумент12 страницParker (T6, T6D) Hydraulic Vane PumpsMortumDamaОценок пока нет

- Diploma Thesis-P AdamecДокумент82 страницыDiploma Thesis-P AdamecKristine Guia CastilloОценок пока нет

- Heroic Tales Core Rules 1.1.0Документ33 страницыHeroic Tales Core Rules 1.1.0Melobajoya MelobajoyaОценок пока нет

- Variables in The EquationДокумент3 страницыVariables in The EquationfiharjatinОценок пока нет

- Quiz Application in Visual BasicДокумент20 страницQuiz Application in Visual BasicShivangi SahaОценок пока нет

- Manipulation Methods and How To Avoid From ManipulationДокумент5 страницManipulation Methods and How To Avoid From ManipulationEylül ErgünОценок пока нет

- Eps 400 New Notes Dec 15-1Документ47 страницEps 400 New Notes Dec 15-1BRIAN MWANGIОценок пока нет

- Syllabus (2020) : NTA UGC-NET Computer Science and ApplicationsДокумент24 страницыSyllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDiksha NagpalОценок пока нет

- Nursing Care Plan Diabetes Mellitus Type 1Документ2 страницыNursing Care Plan Diabetes Mellitus Type 1deric85% (46)

- JIS-G3455 - Carbon Steel Pipes For High Pressure ServiceДокумент27 страницJIS-G3455 - Carbon Steel Pipes For High Pressure ServiceHoang Tan100% (1)

- Cot 4 Mapeh (Health)Документ15 страницCot 4 Mapeh (Health)RELYN LUCIDOОценок пока нет

- The Mutant Epoch Mature Adult Content Mutations v1Документ4 страницыThe Mutant Epoch Mature Adult Content Mutations v1Joshua GibsonОценок пока нет

- Cosmology Questions and Answers - SanfoundryДокумент9 страницCosmology Questions and Answers - SanfoundryGopinathan MОценок пока нет

- Gulfpub Wo 201805Документ81 страницаGulfpub Wo 201805Patricia.PОценок пока нет

- Dawn of The DhammaДокумент65 страницDawn of The Dhammaarkaprava paulОценок пока нет

- Foreign Affairs May June 2021 IssueДокумент216 страницForeign Affairs May June 2021 IssueSohail BhattiОценок пока нет

- Plato, Timaeus, Section 17aДокумент2 страницыPlato, Timaeus, Section 17aguitar_theoryОценок пока нет

- Certification Programs: Service As An ExpertiseДокумент5 страницCertification Programs: Service As An ExpertiseMaria RobОценок пока нет

- Holy Spirit Mass SongsДокумент57 страницHoly Spirit Mass SongsRo AnnОценок пока нет

- 2400 8560 PR 8010 - A1 HSE Management PlanДокумент34 страницы2400 8560 PR 8010 - A1 HSE Management PlanMohd Musa HashimОценок пока нет

- Chapter 3Документ26 страницChapter 3Francis Anthony CataniagОценок пока нет

- Python Versus Matlab: Examples in Civil EngineeringДокумент32 страницыPython Versus Matlab: Examples in Civil EngineeringNiranjanAryan100% (1)

- The Goldfish and Its Culture. Mulertt PDFДокумент190 страницThe Goldfish and Its Culture. Mulertt PDFjr2010peruОценок пока нет

- Canadian Solar-Datasheet-All-Black CS6K-MS v5.57 ENДокумент2 страницыCanadian Solar-Datasheet-All-Black CS6K-MS v5.57 ENParamesh KumarОценок пока нет

- EDUHUBДокумент6 страницEDUHUBishant sharmaОценок пока нет

- Shaheed Suhrawardy Medical College HospitalДокумент3 страницыShaheed Suhrawardy Medical College HospitalDr. Mohammad Nazrul IslamОценок пока нет

- IBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Документ27 страницIBDP Physics Oxford David - Homer Course Ebook 4th Edition-2014 CH-1Milek Anil KumarОценок пока нет

- Power - of - Suffering 2Документ21 страницаPower - of - Suffering 2jojiОценок пока нет

- Dispersion Relation of Electromagnetic WavesДокумент2 страницыDispersion Relation of Electromagnetic WavesFidel SouzaОценок пока нет

- Berghahn Dana ResumeДокумент2 страницыBerghahn Dana ResumeAnonymous fTYuIuK0pkОценок пока нет