Академический Документы

Профессиональный Документы

Культура Документы

EngineProfessional 2016 Q4 IPDarticle Extract

Загружено:

Falgon IslamАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EngineProfessional 2016 Q4 IPDarticle Extract

Загружено:

Falgon IslamАвторское право:

Доступные форматы

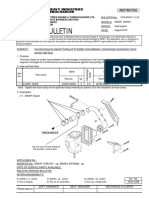

Failed Diesel Pistons

What the damage may tell you…

BY STEVE SCOTT

The initial steps in failure analysis

can be some of the most critical. Most

failure analysis publications lists these

major steps or processes. Not following

a systematic process can jeopardize

identifying and correcting the true root

cause.

Let’s start by looking above at the four higher cylinder pressures (and heat) that

Examining the evidence on a seized

basic designs of pistons used in diesel earlier aluminum alloys simply cannot

piston may indicate whether the seizure

engines. Aluminum pistons (far right) withstand. Below is an example of the

have been around for decades. This design originated at the crown, or at the skirt of

cylinder pressures these pistons may

commonly incorporates a steel insert cast the piston. In the photo above, the crown

encounter.

into the piston to provide added support is beginning to scuff, and the damage

for the piston rings. The bond between shown is primarily around the top of

the steel insert and the aluminum piston the piston and progresses downward.

body is critical in this design. More recent This could be the result of over fueling,

aluminum piston designs have an oil a timing problem, an air restriction, or

gallery cast into the crown. Engine oil is inadequate crown cooling.

sprayed into the gallery to help cool the The burn pattern on the top of the

piston crown. The next piston design piston can also give you an indication

shown is an articulated design, which uses of various problems affecting the

a steel piston crown and an aluminum Differences in material and design can combustion.

skirt with a piston pin holding the two cause these pistons to react differently The next photo shows the injection

together. Next is a one piece steel piston, during a piston seizure condition. spray pattern high in the piston bowl.

which has gained in popularity over the Aluminum pistons are more susceptible to Common causes for this occurrence might

past decade. Finally, a steel “welded” thermal expansion, and require additional be advanced injection timing causing

piston is the most recent design shown, clearance in the cylinder. Steel piston detonation and/or lugging, resulting in

and is produced by friction welding a designs do not expand as much, and fuel wash and scuffed rings.

crown and skirt together. Depending

are designed to have minimal piston to

on the manufacturer and engine model,

cylinder clearances. In any case, either

you may find that one of the later design

with an aluminum or steel piston, seizure

pistons has replaced the original piston

that was in the engine. As a general rule, can result in a catastrophic engine failure.

these design differences cannot be mixed Excessive temperature (heat) is the

within an engine, but there are exceptions. number one reason for piston seizure.

These design changes are a result However, identifying and correcting the

of market demand for increased fuel source of the heat is critical to successfully

efficiency, longer service life, lower repairing the engine. If the cause is not

emissions, and other requirements. And, corrected, there’s a very good probability

with these demands have come much that the engine will fail again.

94 OCT-DEC 2016 engine professional

FAILED DIESEL PISTONS

BY STEVE SCOTT

The photo below shows advanced Most heavy duty pistons at room These are examples of traditional

stages of crown erosion. As the crown temperature are not round, they are aluminum piston crown operating

overheats, it softens, and the injection elliptical (oval), and due to thermal temperatures. Later model applications

pressures actually erode the edge of the expansion they change dimensionally use pistons designed for higher operating

crown. as they reach operating temperatures. temperatures, such as gallery-cooled

Allowing the engine to warm up gives the pistons, two piece articulated pistons, and

piston time to reach the correct operating one piece steel pistons, so the method for

profile. cooling the crowns can differ.

Checking maintenance records and/or

checking critical event codes (on engines

equipped with an ECM/electronic control

module) are good sources of information.

Sometimes, common causes of seizure can

be identified by looking into an engine’s

history. If the engine has been operating

successfully for an extended amount

of time, you may be able to eliminate

As mentioned earlier, the aluminum some of the possible causes. Obviously

piston designs are more susceptible to a failure could be from a defective part;

thermal expansion. This next photo is an however, a fitment problem between the

example of skirt overheating; however, piston and cylinder would most likely be

it can be difficult to determine the root evident shortly after assembly. Likewise,

cause. An aluminum piston is thickest at something as simple as rolling a cylinder

the corners of the pin bosses, and as the Inspecting the bottom of the piston

liner o-ring during installation can distort

piston grows or expands, the clearances crown can provide insight into how the

the cylinder liner, reducing clearances and

to the liner are reduced or eliminated and piston crown was being cooled. In most

resulting in a hot spot that can lead to

the piston begins to scuff at what is called engines, a piston cooling jet sprays engine

piston seizure.

the ¼ points of the pin boss. High coolant oil on the underside of the piston crown.

temperatures, lack of heat transfer, and This absorbs heat from the piston crown

lack of crown cooling can all contribute and cools the piston skirt. The gold color

to this type of failure. shown in the photo below indicates there’s

been a good oil supply and moderate (not

too high) crown temperatures.

Center point scuffing on the skirt (as The photo below indicates high crown

shown below) can indicate that the engine temperatures. Cooked, burnt, or crusty oil

has been operating at high RPM or high on the underside of the piston confirms

load too quickly after start up. Depending there was oil flow while the piston crown

on how severe and often repeated, this was operating at very high temperatures. Not all diesel engines have replaceable

type of skirt damage can continue to Lack of discoloration under the crown cylinder liners. In some engines, the

expand around the entire skirt and seize can indicate that no cooling oil was cylinder bore is repaired using a machine

the piston. reaching the crown. sleeve, or by boring the cylinder oversized.

Cylinder distortion in these types of

engines can be a little more challenging

to identify since properly machining or

measuring the cylinder bores may require

attaching a stress plate to simulate the

same force or stress as would the cylinder

head. Once the stress plate is tightened

in place, the cylinder bores in the block

are brought into the dimensional form or

shape they will be operating in after the

engine is assembled.

96 OCT-DEC 2016 engine professional

FAILED DIESEL PISTONS

BY STEVE SCOTT

If a block that distorts in its free state Attention to details during a failure ring to the cylinder liner, and removed by

is honed round without a stress plate, the investigation can sometimes uncover the engine coolant. The engine’s cooling

cylinders will not stay round when the some “not-so-common” root causes. The system, and the condition of the coolant,

engine is reassembled. photos below are from an engine that is vital to this process. Weak coolant can

The photos below show polishing on seized a piston and continued to operate lead to scale deposits building up on the

the high spots of a cylinder. While the until the piston and connecting rod exited outside of the liners (as shown in the

piston rings can conform to some amount the side of the cylinder block. photo below) and passages of the block,

of distortion in the cylinder wall, they creating a thermal barrier. A 1/16” thick

cannot conform to larger amounts of build up of scale can reduce the engines’

variations as shown here. Cylinder bore cooling systems efficiency by 40% (or

distortion can result in oil consumption, more) according to various studies. If the

compression loss and piston seizure in heat cannot properly dissipate through the

more severe cases. rings, then the piston can overheat.

Another component that has

contributed to more than its share of

piston seizures is the piston cooling jet

(or tube) used in some diesel engines. Sorting through the miscellaneous

There are several different designs of these broken pieces found the piston cooling

tubes, some have a single spray tube, tubes, shown below. Closer examination

others have twin tubes, and some are discovered red sealant packed in one of

made from metal and others are plastic. the tubes. This sealant blocked the oil

These tubes spray engine oil up to the flow and resulted in a catastrophic failure.

bottom of the pistons to cool the piston Gasket sealants may have their uses, but

crowns. Depending on the application, excessive amounts or even pieces that

some are adjustable and others are not. come loose can cause major problems.

One thing they have in common is if they

get damaged, plugged, or misaligned, then

they can cause piston seizure. If the cooler

tube is broken, you may find a small In summary, cylinder components are

polished or impact area on the tube or designed to withstand the demands of

piston skirt where the tube was contacting the operational parameters of the engine.

the piston. If not removed, these tubes Like any other part or component, if

can also be damaged or broken when the those conditions or demands go beyond

piston and connecting rod assemblies are the limits, then there’s a risk of failure.

being installed. Identifying the root cause and correcting

the problem is the key to successfully

repairing the engine.n

Steve Scott joined the service department

at IPD in 1982, working with parts, service

and sales for a variety of equipment, diesel,

and natural gas engines. Since 2004, he has

In addition to the piston being cooled been the director of product development and

by the lube oil, approx. 1/3 of the piston’s technical support for IPD. For more information,

heat is transferred through the piston email sscott@ipdparts.com.

98 OCT-DEC 2016 engine professional

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- PIC For BeginnersДокумент147 страницPIC For Beginnersapi-3695801100% (45)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Operation & Maintenance Manual: (MGS 7310 GCP)Документ47 страницOperation & Maintenance Manual: (MGS 7310 GCP)Falgon IslamОценок пока нет

- Committee History 50yearsДокумент156 страницCommittee History 50yearsd_maassОценок пока нет

- Operation & Maintenance Manual: (MGS 560 Panel)Документ53 страницыOperation & Maintenance Manual: (MGS 560 Panel)Falgon IslamОценок пока нет

- Analyze and Design Sewer and Stormwater Systems with SewerGEMSДокумент18 страницAnalyze and Design Sewer and Stormwater Systems with SewerGEMSBoni ClydeОценок пока нет

- Operation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Документ123 страницыOperation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Falgon IslamОценок пока нет

- Operation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Документ123 страницыOperation & Maintenance Manual: Issued: March 2021 Pub. No. 29A01-00120 Revision: 1Falgon IslamОценок пока нет

- Operation & Maintenance Manual: (S16R2-PTAW2-S)Документ111 страницOperation & Maintenance Manual: (S16R2-PTAW2-S)Falgon IslamОценок пока нет

- Real Estate Broker ReviewerREBLEXДокумент124 страницыReal Estate Broker ReviewerREBLEXMar100% (4)

- Operation & Maintenance Manual: (MGS 7310 GCP)Документ47 страницOperation & Maintenance Manual: (MGS 7310 GCP)Falgon IslamОценок пока нет

- Lewis Corporation Case 6-2 - Group 5Документ8 страницLewis Corporation Case 6-2 - Group 5Om Prakash100% (1)

- ISO 13485-2016 - DR - Pack - Control of Non Conforming ProductsДокумент4 страницыISO 13485-2016 - DR - Pack - Control of Non Conforming ProductskmasanОценок пока нет

- Mitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineДокумент4 страницыMitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineFalgon IslamОценок пока нет

- Mitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineДокумент4 страницыMitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineFalgon IslamОценок пока нет

- Sheet No 12Документ30 страницSheet No 12Falgon IslamОценок пока нет

- Untitled SpreadsheetДокумент23 страницыUntitled SpreadsheetFalgon IslamОценок пока нет

- VFD-M Series AC Motor Drive ManualДокумент173 страницыVFD-M Series AC Motor Drive ManualoarionIIIОценок пока нет

- Mitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineДокумент4 страницыMitsubishi Diesel Engine Technical Information: Specification Sheets of S12H-PTA EngineFalgon IslamОценок пока нет

- Filter Offer PaikaneДокумент1 страницаFilter Offer PaikaneFalgon IslamОценок пока нет

- FLX30d: Spare Parts CatalogueДокумент49 страницFLX30d: Spare Parts CatalogueFalgon IslamОценок пока нет

- FLX30d: Spare Parts CatalogueДокумент49 страницFLX30d: Spare Parts CatalogueFalgon IslamОценок пока нет

- FLX30d: Spare Parts CatalogueДокумент49 страницFLX30d: Spare Parts CatalogueFalgon IslamОценок пока нет

- Spare Parts Catalogue: Handling Systems - Counter Balance Forklift TruckДокумент12 страницSpare Parts Catalogue: Handling Systems - Counter Balance Forklift TruckFalgon IslamОценок пока нет

- Service BulletinДокумент3 страницыService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент2 страницыService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент2 страницыService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент1 страницаService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент4 страницыService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент1 страницаService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент1 страницаService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент3 страницыService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент1 страницаService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент1 страницаService BulletinFalgon IslamОценок пока нет

- Service BulletinДокумент1 страницаService BulletinFalgon IslamОценок пока нет

- SEC QPP Coop TrainingДокумент62 страницыSEC QPP Coop TrainingAbdalelah BagajateОценок пока нет

- Grading System The Inconvenient Use of The Computing Grades in PortalДокумент5 страницGrading System The Inconvenient Use of The Computing Grades in PortalJm WhoooОценок пока нет

- Advantages of Using Mobile ApplicationsДокумент30 страницAdvantages of Using Mobile ApplicationsGian Carlo LajarcaОценок пока нет

- Prlude No BWV in C MinorДокумент3 страницыPrlude No BWV in C MinorFrédéric LemaireОценок пока нет

- White Box Testing Techniques: Ratna SanyalДокумент23 страницыWhite Box Testing Techniques: Ratna SanyalYogesh MundhraОценок пока нет

- Problem Set SolutionsДокумент16 страницProblem Set SolutionsKunal SharmaОценок пока нет

- Propoxur PMRAДокумент2 страницыPropoxur PMRAuncleadolphОценок пока нет

- Strategies For StartupДокумент16 страницStrategies For StartupRoshankumar BalasubramanianОценок пока нет

- MA1201 Calculus and Basic Linear Algebra II Solution of Problem Set 4Документ10 страницMA1201 Calculus and Basic Linear Algebra II Solution of Problem Set 4Sit LucasОценок пока нет

- Lecture NotesДокумент6 страницLecture NotesRawlinsonОценок пока нет

- Essential Rendering BookДокумент314 страницEssential Rendering BookHelton OliveiraОценок пока нет

- Arta Kelmendi's resume highlighting education and work experienceДокумент2 страницыArta Kelmendi's resume highlighting education and work experienceArta KelmendiОценок пока нет

- 7 Aleksandar VladimirovДокумент6 страниц7 Aleksandar VladimirovDante FilhoОценок пока нет

- Master SEOДокумент8 страницMaster SEOOkane MochiОценок пока нет

- Evil Days of Luckless JohnДокумент5 страницEvil Days of Luckless JohnadikressОценок пока нет

- Why Choose Medicine As A CareerДокумент25 страницWhy Choose Medicine As A CareerVinod KumarОценок пока нет

- Week 15 - Rams vs. VikingsДокумент175 страницWeek 15 - Rams vs. VikingsJMOTTUTNОценок пока нет

- Bala Graha AfflictionДокумент2 страницыBala Graha AfflictionNeeraj VermaОценок пока нет

- Chapter 4 DeterminantsДокумент3 страницыChapter 4 Determinantssraj68Оценок пока нет

- Dermatology Study Guide 2023-IvДокумент7 страницDermatology Study Guide 2023-IvUnknown ManОценок пока нет

- Efaverenz p1Документ4 страницыEfaverenz p1Pragat KumarОценок пока нет

- Masteringphys 14Документ20 страницMasteringphys 14CarlosGomez0% (3)

- Annual Plan 1st GradeДокумент3 страницыAnnual Plan 1st GradeNataliaMarinucciОценок пока нет

- Flowmon Ads Enterprise Userguide enДокумент82 страницыFlowmon Ads Enterprise Userguide ennagasatoОценок пока нет

- Philippine Army BDU BidДокумент2 страницыPhilippine Army BDU BidMaria TeresaОценок пока нет