Академический Документы

Профессиональный Документы

Культура Документы

EGD 2012 Training

Загружено:

sengottaiyanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EGD 2012 Training

Загружено:

sengottaiyanАвторское право:

Доступные форматы

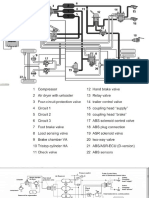

Service Training 2012 - Electrics

April 2012 / Heger /Reiser/KD2012_EN Side 1 of 33

Service Training 2012 - Electrics

Summary

Page Topic

03 – 17 New EGD

18 – 19 Electrical modifications

20 – 22 New Safety Switch RFIT

23 Suction/Return Filter Pressure Sensor

24 - 26 Central Lubrication 2011

27 – 28 New Step Relay

29 - 31 New Sensors for Rotary, Pressure and Angle

32 Chassis Standby Current

33 Autocor Oman

April 2012 / Heger /Reiser/KD2012_EN Side 2 of 33

Service Training 2012 - Electrics

ZMS-EPS, 24 VDC, FFH 20, Gen. 4

Control Box KS 532319

April 2012 / Heger /Reiser/KD2012_EN Side 3 of 33

Service Training 2012 - Electrics

Startup screen ca 5 sec. long

Function key “Home“

Function key “Help“

F4

Service area

Password

Function key F 1 Function key F 2 Function key F 3 Function key F 4

Pump status Pump settings Pump flow meter with Rotate / press to select symbols

engine menu and fault log and set numerical values.

April 2012 / Heger /Reiser/KD2012_EN Side 4 of 33

Service Training 2012 - Electrics

EGD Colour Representation

Symbol colours:

Green: Function active, e.g. central lubrication, fan

switched on.

Red: Error message, important function impaired

with pumping discontinued e.g. E-stop, RSA,

over temperature ..

F4

Yellow: Pump output limited, e.g. oil too cold, too hot,

power limit..

Bar graphs:

Green: Normal range of values

Blue: Value too low, e.g. under temperature,

under speed..

Red: Value too high, e.g. over temperature..

F4

April 2012 / Heger /Reiser/KD2012_EN Side 5 of 33

Service Training 2012 - Electrics

“HOME“ Menu

F4

April 2012 / Heger /Reiser/KD2012_EN Side 6 of 33

Service Training 2012 - Electrics

Pump Status

F4

By rotating function switch F4 you can select the sensors.

F4 rotate to select a function, the symbol will be indicated by a

thick red outline.

F4 press and the symbol flashes.

F4 rotate until the symbol is crossed out.

F4 press and the sensor is deselected.

After turning the ignition off, settings revert to the default values.

April 2012 / Heger /Reiser/KD2012_EN Side 7 of 33

Service Training 2012 - Electrics

Pump Settings

F4

Functions can be switched on or off by rotating function switch F4 .

Rotate F4 to select a function, the symbol is indicated by a thick red outline.

Press F4 and the symbol flashes or for the central lubrication the symbol turns green

and an additional lubrication cycle is triggered.

Rotate F4 until the symbol shows the desired setting.

Press F4 to save the setting.

After turning the ignition off, settings revert to the default values.

April 2012 / Heger /Reiser/KD2012_EN Side 8 of 33

Service Training 2012 - Electrics

Pump Flowmeter

F4

Rotate function switch F4 until the desired value is shown in reverse.

1. Press F4 and the first digit of the set point flashes.

2. Rotate F4 to alter the first digit.

3. Pess F4 to store the first digit. The second digit flashes and can can be set.

Repeat steps 1 – 3 until the set-point has been achieved.

After turning the ignition off, settings revert to the default values.

April 2012 / Heger /Reiser/KD2012_EN Side 9 of 33

Service Training 2012 - Electrics

Pump Flowmeter

In the Pump Flowmeter menu there are sub menus for

engine diagnostics and the error log.

The EBC menu only appears when Service Mode is active.

F4

April 2012 / Heger /Reiser/KD2012_EN Side 10 of 33

Service Training 2012 - Electrics

Engine Diagnostics

F4

Bar charts and error messaging are only active for engines with electronic motor control (EMR).

April 2012 / Heger /Reiser/KD2012_EN Side 11 of 33

Service Training 2012 - Electrics

Fault Log

Fault Code Meaning

1 Agitator safety cut-out

2 Emergency sto

4 „Pumpstop“ switch

8 Engine speed

16 Low level probe

32 Pump central lubrication

F4

64 Over temperature

128 External stop

256 Short circuit

If for example code 108 is shown, this means that 512 Transfer tube sensor

several faults exist. 64 + 32 + 8 + 4 = 108

1024 Pressure sensor

The last 10 faults are always shown. 2048 Gate valve closed

4096 Stroke count reached

April 2012 / Heger /Reiser/KD2012_EN Side 12 of 33

Service Training 2012 - Electrics

Service Menu

In the Service Menu note the following !

You can return to the basic screen by pressing the „HOME“ button, but the control stays

in Service Mode. Return to the service screen by press button F4.

00123

F4 F4

F4

April 2012 / Heger /Reiser/KD2012_EN Side 13 of 33

Service Training 2012 - Electrics

Service Menu

The Service Menu is accessed as follows.

In the base menu press rotary - / push button F4 2 x.

Then you are in a field for entering the password.

Enter the password by turning and pressing F4.

Customer menu 02011. Service menu 00123

Then the PM-Service Menu appears.

In this menu various functions can be turned on and off

F4 for test purposes with the rotary / push button F4.

In addition three more menu items are displayed.

00123

F4

April 2012 / Heger /Reiser/KD2012_EN Side 14 of 33

Service Training 2012 - Electrics

Service Menu

00123

F4

April 2012 / Heger /Reiser/KD2012_EN Side 15 of 33

Service Training 2012 - Electrics

Setup Menu

Programming the Pump and /or S-tube:

Select and activate the symbol in the Learn row / Pump or

S-Valve column by rotating/pressing F4. Whilst programming

the pump note the boundary conditions (pump on, full

throttle, 100% output setting, oil > 45°C).

Saving/ restoring factory settings:

Select the symbol in the Flash row by rotating, and activate

by pressing F4.

F4

View/change parameters:

Enter values in the Parameter row by rotation/pressing,

activate via the “Save“ icon.

The “Land Einheit Zeit“ field

Allows the choice of language for the help pages, the

preselection of units (bar/psi and/or °C/°F) and time format

(12/24h) selection.

Preselection of EQV, EOC....

These settings will remain after the ignition is turned off.

EPM = Ergonic Pump Management. EPM1, long distance

pumping; EPM2, high rise pumping; EPM3, half POH-time.

Parameterization, P340-369.

April 2012 / Heger /Reiser/KD2012_EN Side 16 of 33

Service Training 2012 - Electrics

Setup Menu

F4

1 Display the basic settings from the test field.

2 Display failures and/or monitoring times.

April 2012 / Heger /Reiser/KD2012_EN Side 17 of 33

Service Training 2012 - Electrics

Innovations in the Electrical Field

I/O Modules eliminated by the new EGD

F4

April 2012 / Heger /Reiser/KD2012_EN Side 18 of 33

Service Training 2012 - Electrics

Innovations in the Electrical Field

Possibility of replugging the

receiver in the cab in the future.

April 2012 / Heger /Reiser/KD2012_EN Side 19 of 33

Service Training 2012 - Electrics

Safety switch with RFID technology

New RSA and boom rest switches

No holes in the hopper.

Complies with the Machinery Directive, as the

agitator does not start after closing the grille.

Activated via switch on control box.

April 2012 / Heger /Reiser/KD2012_EN Side 20 of 33

Service Training 2012 - Electrics

Safety switch with RFID technology

Memorising a new actuator

1. Apply the operating voltage to the safety switch.

The green LED flashes rapidly (ca. 10 Hz). During this time (ca. 3 s) a self-test is carried out. Then the LED

flashes three times to indicate it is ready for teaching, this state persists for ca. 3 minutes.

2. Bring the new actuator to the reading head.

The memorising process starts, and the green LED flashes (ca. 1 Hz). During this process the safety switch

checks whether actuator is blocked. If not, the process is completed in ca. 60 seconds, the green LED goes

out, the new code is stored and the old code is blocked.

3. To activate the newly-learned actuator code in the safety switch, the operating voltage supply to the safety

switch must be removed for a minimum of 3 seconds.

If a new actuator has been learned, the safety switch blocks the code of the previous unit. This cannot be

reinstated by a new memorising process. The blocked security code will only be cleared from the switch after

a third code has been learned.

The safety switch can only be operated by the last actuator learned. If the switch recognises a previously

learned actuator during the memorising preparation period, the process stops immediately and the switch

goes into normal operation.

If it does not find the actuator to be learned in the response zone in less than 60 s, it is not activated.

April 2012 / Heger /Reiser/KD2012_EN Side 21 of 33

Service Training 2012 - Electrics

Safety Switches

Conformity with proposed EN 12001

Prepared for monitoring the covers on the emergency operating levers on

the boom and pump controls. Dual operationg mode no longer possible.

April 2012 / Heger /Reiser/KD2012_EN Side 22 of 33

Service Training 2012 - Electrics

New BSF M 42

Pressure sensor on suction/return filter

April 2012 / Heger /Reiser/KD2012_EN Side 23 of 33

Service Training 2012 - Electrics

BSF M 42 New Central Lubrication

New grease pot.

Both pumps are controlled by the CCU/EPS.

1 The boom lubrication is time controlled. A

lubrication cycle is performed every 4 hours. The

1 last grease distribution block has a limit switch.

2 Pump lubrication is initiated after ca. 60 strokes

and continues until a signal is given by the limit

switch on the grease distribution block.

After that the pump has a lubrication cycle ca.

every 60 strokes.

Intermediate lubrication is possible via the EGD.

April 2012 / Heger /Reiser/KD2012_EN Side 24 of 33

Service Training 2012 - Electrics

Central Lubrication 2011

KS 532817

April 2012 / Heger /Reiser/KD2012_EN Side 25 of 33

Service Training 2012 - Electrics

Central Lubrication 2011

New 12 way grease distributor

April 2012 / Heger /Reiser/KD2012_EN Side 26 of 33

Service Training 2012 - Electrics

New Stepping Relay

Kuhnke 24V : Part No. 063516007 Replaced Stepping relay 12 / 24V

Kuhnke 12V : Part No. 063515008 by Size 2 Part No. 543660

The pins correspond one-to-one

April 2012 / Heger /Reiser/KD2012_EN Side 27 of 33

Service Training 2012 - Electrics

New Stepping Relay

Note the following after installation:

If the pistons block in the end position, on machines with a switch fork the pump should

be switched off and then on again.

On machines with inductive switches, pumping can be re-established by means of the

changeover switch.

April 2012 / Heger /Reiser/KD2012_EN Side 28 of 33

Service Training 2012 - Electrics

Transfer Tube Rotary Encoder Part No. 439690

Installing the new encoder.

The connecting cable for the old encoder has 3 cores, the new encoder has 4 cores.

On the new encoder the yellow core has no function and should not be connected.

Note when installing a new encoder that the shaft marking is rotated through 180°.

If this is not observed, the transfer tube cannot be programmed in.

Old shaft marking New shaft marking

Old New

April 2012 / Heger /Reiser/KD2012_EN Side 29 of 33

Service Training 2012 - Electrics

New pressure sensor 420220

Pressure sensor 0 - 600 Bar

previous version new version

compatible

Electronic pressure transducer Electronic pressure transducer

Modification: Putzmeister Standard

April 2012 / Heger /Reiser/KD2012_EN Side 30 of 33

Service Training 2012 - Electrics

New space angle senor for EBC

Requirements for refitting / usage of DIS angle sensors

- EBC software V 23.08 or higher.

- setup of the parameters „Sensor Location Selection“ (116, 156, 196, 236, 276, 316)

Prolec-sensor = 0 or 1

DIS-sensor = 12 or 13

- changing from Prolec to DIS needed adapter plate part-no: 513752.

Prolec basis: DIS basis:

431 348 507 018

ID part no. ID part no.

2 = Arm 1 480 099 2 = Arm 1 533 593

3 = Arm 2 480 101 3 = Arm 2 533 594

4 = Arm 3 480 102 4 = Arm 3 533 595

5 = Arm 4 480 103 5 = Arm 4 533 596

6 = Arm 5 480 104 6 = Arm 5 533 597

7 = Arm 6 480 147 7 = Arm 6 533 598

April 2012 / Heger /Reiser/KD2012_EN Side 31 of 33

Service Training 2012 - Electrics

Standby current on PM truck mounted pumps

Actros M62 with ZMS-EPS

Chassis (without PM) 100 -120 mA

PM total and radio with conservation charging (no Daisy) 310 mA

PM total and radio with normal charging (no Daisy) 580 mA

PM total without radio (no Daisy) 220 mA

Daisy in sleep mode approx. 300 mA

Daisy switched off 0 mA

Total consumption without Daisy approx. 500 mA.

220 Ah batteries will be discharged after a time of 400 hrs.

April 2012 / Heger /Reiser/KD2012_EN Side 32 of 33

Service Training 2012 - Electrics

Information about Autocor projects

MX 28 with BSA 1408E in Oman. Both units are installed in a building The BSA is equipped with a ZMS-

EPS control box and radio contral. The MX has a separate control box. Both machines can be controlled

by radio.

April 2012 / Heger /Reiser/KD2012_EN Side 33 of 33

Вам также может понравиться

- Caterpillar Fault Codes PDFДокумент21 страницаCaterpillar Fault Codes PDFElhadi Enp84% (56)

- C-11, C-13 Dissassembly - Assembly 2006 PDFДокумент80 страницC-11, C-13 Dissassembly - Assembly 2006 PDFAhmer Camdzic100% (2)

- SCHWING TrainingManualДокумент303 страницыSCHWING TrainingManualHarlinton descalzi86% (100)

- 42SXG - Book Operation ManualДокумент235 страниц42SXG - Book Operation Manualahmad80% (10)

- Manual Operating & Maintenance Instructions BSF 36-4.12LДокумент282 страницыManual Operating & Maintenance Instructions BSF 36-4.12LJuan Carlos Centeno100% (10)

- Service Manual PDFДокумент822 страницыService Manual PDFJuan José Matos Ch89% (9)

- Service Manual: SCHWING Ñ Control System " VECTOR "Документ48 страницService Manual: SCHWING Ñ Control System " VECTOR "EVCY92% (24)

- Service ManualДокумент1 страницаService ManualJuan Carlos Desposorio Marmolejo86% (22)

- SanyДокумент380 страницSanyKumlachew Ali100% (7)

- SCHWING Concrete Pump Working Range DrawingsДокумент57 страницSCHWING Concrete Pump Working Range Drawingsiask527583% (6)

- 62M Boom Pump Operation Manual PDFДокумент366 страниц62M Boom Pump Operation Manual PDFSai Yalavarthi100% (13)

- Doosan Daewoo Motor De12, De12t, De12ti & De12tisДокумент165 страницDoosan Daewoo Motor De12, De12t, De12ti & De12tiskevUwUr93% (15)

- Vector Manual PDFДокумент48 страницVector Manual PDFMarco Trejo92% (13)

- Rock ValveДокумент42 страницыRock Valvealdo100% (7)

- Putzmeister Stationary PumpДокумент11 страницPutzmeister Stationary PumpAbdallah Tarek100% (1)

- (KIA) Manual de Taller Kia Rio 2001 PDFДокумент69 страниц(KIA) Manual de Taller Kia Rio 2001 PDFJenny Mora Leon100% (1)

- Volvo Truck Service Schedule Maintenace 1Документ95 страницVolvo Truck Service Schedule Maintenace 1sengottaiyan100% (2)

- Service Manual Service Manual: SCHWING Ñ Control System " VECTOR " SCHWING Ñ Control System " VECTOR "Документ48 страницService Manual Service Manual: SCHWING Ñ Control System " VECTOR " SCHWING Ñ Control System " VECTOR "Fawzi Alzubairy100% (2)

- Vector ManualДокумент48 страницVector Manualcruz daniel100% (1)

- Putzmeister ListДокумент10 страницPutzmeister ListYusco Novi Pazar75% (4)

- Truckmounted Concrete Pump Model BSF32Z.12L EQ 35Документ328 страницTruckmounted Concrete Pump Model BSF32Z.12L EQ 35viemey195293% (15)

- Pump Truck Operator ManualДокумент734 страницыPump Truck Operator ManualGary Page100% (1)

- SCHWING ExpandedPumpParts CatalogДокумент8 страницSCHWING ExpandedPumpParts CatalogRoberto Maggiolo100% (2)

- Catalogo de Peças Zoomlion - Modelo 33X-4ZДокумент341 страницаCatalogo de Peças Zoomlion - Modelo 33X-4ZAlexandre Nicoleti100% (3)

- 600 800 TSG - BookДокумент41 страница600 800 TSG - BookJuan José Matos Ch89% (9)

- Zoomlion Truck Mounted Concrete PumpДокумент14 страницZoomlion Truck Mounted Concrete PumpAsad Aijaz100% (7)

- Manual Mixer LondonДокумент139 страницManual Mixer LondonFredy Roa67% (3)

- (E) Training Placing Boom Rev.02Документ102 страницы(E) Training Placing Boom Rev.02ramy elgammal100% (3)

- RE 00112 - Part 1 Hydraulic Components For Industrial ApplicationsДокумент1 008 страницRE 00112 - Part 1 Hydraulic Components For Industrial Applicationsbee140676100% (2)

- L150H/L180H/L220H/L250H: Operator's ManualДокумент298 страницL150H/L180H/L220H/L250H: Operator's ManualsengottaiyanОценок пока нет

- Chapter 28-BennetДокумент63 страницыChapter 28-BennetsengottaiyanОценок пока нет

- Hengxin RF Leaky Cable PDFДокумент16 страницHengxin RF Leaky Cable PDFculeros1Оценок пока нет

- Putzmeister TK 7 ElectricaДокумент58 страницPutzmeister TK 7 ElectricaSamuel Moreno67% (3)

- Hydralic Circit For SP1200 PumpДокумент2 страницыHydralic Circit For SP1200 PumpAhesanShaikhОценок пока нет

- Hydraulic and Electric DiagramДокумент20 страницHydraulic and Electric DiagramEvert Vargas Torrez100% (2)

- Zoom LionДокумент380 страницZoom LionKumlachew Ali100% (1)

- Check Book (GB) PDFДокумент43 страницыCheck Book (GB) PDFY.EbadiОценок пока нет

- 43Z PumpДокумент454 страницы43Z Pumpthuan85% (13)

- Check Book 2010 (GB)Документ88 страницCheck Book 2010 (GB)Aly Abdelhamed100% (1)

- MANUAL (Español)Документ458 страницMANUAL (Español)jose100% (1)

- C.P Training Module Levl.2 HydraulicДокумент56 страницC.P Training Module Levl.2 HydraulicEslam Mansour100% (1)

- BP 3763 enДокумент9 страницBP 3763 enKhaled Kamel100% (1)

- A008125E - Single Rexroth 12vdc PDFДокумент2 страницыA008125E - Single Rexroth 12vdc PDFaldo100% (2)

- Hydraulic PartsДокумент119 страницHydraulic PartsChaerul Umami80% (5)

- La Calidad Cambia Al Mundo SANY Heavy Industry Co., LTDДокумент34 страницыLa Calidad Cambia Al Mundo SANY Heavy Industry Co., LTDEvert Vargas Torrez100% (1)

- Shwing Zaher PDF PDFДокумент322 страницыShwing Zaher PDF PDFHebron Hydraulic80% (10)

- Boom Pump & ServiceДокумент55 страницBoom Pump & ServiceAhmed AbdallahОценок пока нет

- KCP Parts Catalog 2019Документ9 страницKCP Parts Catalog 2019Jaison McDonaldОценок пока нет

- Service Parts-Brochure PDFДокумент8 страницService Parts-Brochure PDFAnonymous iJshiXGfОценок пока нет

- 34 Meter Data SheetДокумент4 страницы34 Meter Data SheetFawzi AlzubairyОценок пока нет

- HBT80C-1818DIII Trailer-Mo Safety ManualДокумент60 страницHBT80C-1818DIII Trailer-Mo Safety ManualLinzaw Win100% (1)

- User Manual 37R4XXTДокумент160 страницUser Manual 37R4XXTAndrejic Filip100% (4)

- SinoPumpingCatalogue PDFДокумент26 страницSinoPumpingCatalogue PDFChristian Slate100% (1)

- SCHWING TrainingManual (229 261)Документ33 страницыSCHWING TrainingManual (229 261)Petr Kos67% (3)

- Circuit Documents: Vector S38Sx-S47Sx Circiut Diagram S38SX S39SX S42SX S43Sx Iii S47Sx Iii 00 TypeДокумент94 страницыCircuit Documents: Vector S38Sx-S47Sx Circiut Diagram S38SX S39SX S42SX S43Sx Iii S47Sx Iii 00 Typemostafa ali100% (4)

- Electric Cabinet CPL. C46615800 PDFДокумент4 страницыElectric Cabinet CPL. C46615800 PDFSubhash KediaОценок пока нет

- Seccion 1Документ67 страницSeccion 1Christian Fandino94% (16)

- KCP M37RДокумент141 страницаKCP M37RsofianeОценок пока нет

- Manual de Servicio Schwing s28x Valvula RockДокумент66 страницManual de Servicio Schwing s28x Valvula RockEduardo Ariel Bernal100% (2)

- Spare Parts CatalogueДокумент38 страницSpare Parts CatalogueSanhory Abd AlgaderОценок пока нет

- Truck MTD Conc Pump - FinalДокумент50 страницTruck MTD Conc Pump - Finalpgiaut100% (4)

- SCHWING TrainingManual (001 031)Документ31 страницаSCHWING TrainingManual (001 031)Petr KosОценок пока нет

- MH-003 Ecomaster Basic D User ManualДокумент6 страницMH-003 Ecomaster Basic D User ManualДмитро ДзюбаОценок пока нет

- LT9 Manual Mimoinsa KS1 M6 - Rev01 - inДокумент19 страницLT9 Manual Mimoinsa KS1 M6 - Rev01 - inRezhaNugrahaОценок пока нет

- Manual Producto - C3-C10185 Manual (Rev. 2.0)Документ30 страницManual Producto - C3-C10185 Manual (Rev. 2.0)Matias Contreras KöbrichОценок пока нет

- EMCP4 RS485 Remote Annunciator LEHE0142 01Документ2 страницыEMCP4 RS485 Remote Annunciator LEHE0142 01rahuljoagОценок пока нет

- EMCP4 RS485 Remote Annunciator LEHE0142 01Документ2 страницыEMCP4 RS485 Remote Annunciator LEHE0142 01Kaung KharОценок пока нет

- Basic Hydraulics NWTДокумент22 страницыBasic Hydraulics NWTsengottaiyanОценок пока нет

- Thank You For Your Interest in The Renault K 380 P6X4 Heavy.34 E3Документ9 страницThank You For Your Interest in The Renault K 380 P6X4 Heavy.34 E3sengottaiyan0% (1)

- TeSys Control Relays - CAD32BDДокумент3 страницыTeSys Control Relays - CAD32BDsengottaiyanОценок пока нет

- Kobelco SK500LC-10 NaДокумент10 страницKobelco SK500LC-10 NasengottaiyanОценок пока нет

- (Oto-Hui - Com) Caterpillar 966H Wheel Loader HYDRAULIC SYSTEMДокумент33 страницы(Oto-Hui - Com) Caterpillar 966H Wheel Loader HYDRAULIC SYSTEMFernando Sabino100% (2)

- Acs 1000 AbbДокумент389 страницAcs 1000 AbbEvandro Ortega100% (2)

- Chapter 19Документ70 страницChapter 19Hari Hara SuthanОценок пока нет

- 16SP (En) PDFДокумент139 страниц16SP (En) PDFSomda valentinОценок пока нет

- Komatsu Wheel Loader - Final Drive Inspection On Front and Rear Axles 16 Jan 2020Документ10 страницKomatsu Wheel Loader - Final Drive Inspection On Front and Rear Axles 16 Jan 2020sengottaiyanОценок пока нет

- Brake ComponentsДокумент12 страницBrake ComponentssengottaiyanОценок пока нет

- Tyre Basics Training PresentationДокумент30 страницTyre Basics Training PresentationsengottaiyanОценок пока нет

- ms-8-165-2017 (Mixer Drum)Документ14 страницms-8-165-2017 (Mixer Drum)sengottaiyanОценок пока нет

- Antilock Brakes, Traction, and Stability Control: © 2012 Delmar, Cengage LearningДокумент25 страницAntilock Brakes, Traction, and Stability Control: © 2012 Delmar, Cengage Learningsengottaiyan100% (1)

- Concrete Boom Pump Pipelines Checking Procedure 23 Jan 2020Документ19 страницConcrete Boom Pump Pipelines Checking Procedure 23 Jan 2020sengottaiyan100% (1)

- Truck & Primemover Bolts Breaking During Assembly - Torque Value 29 Jan 2020Документ11 страницTruck & Primemover Bolts Breaking During Assembly - Torque Value 29 Jan 2020sengottaiyanОценок пока нет

- Hydraulic Systems: The BasicsДокумент12 страницHydraulic Systems: The BasicssengottaiyanОценок пока нет

- Turbocharger Oil Leaking Training PresentationДокумент18 страницTurbocharger Oil Leaking Training PresentationsengottaiyanОценок пока нет

- Battery - Basic Maintenance PracticesДокумент11 страницBattery - Basic Maintenance Practicessengottaiyan100% (1)

- Truck & Primemovers Roll Over & Topple Acident Vehicles TPДокумент14 страницTruck & Primemovers Roll Over & Topple Acident Vehicles TPsengottaiyanОценок пока нет

- Radiator Caps Maintenance Practices For Trucks and Construction EquipmentsДокумент15 страницRadiator Caps Maintenance Practices For Trucks and Construction EquipmentssengottaiyanОценок пока нет

- Hydraulic Systems: The BasicsДокумент12 страницHydraulic Systems: The BasicssengottaiyanОценок пока нет

- Sohar Training Dec 2018Документ12 страницSohar Training Dec 2018sengottaiyanОценок пока нет

- Engine TroubleshootingДокумент15 страницEngine Troubleshootingsengottaiyan100% (2)

- Magnetic Powder CoresДокумент72 страницыMagnetic Powder Coreszokandza4092Оценок пока нет

- Report Form of Detailed Inspection For Fire ProДокумент35 страницReport Form of Detailed Inspection For Fire Proraul m tuscanoОценок пока нет

- Shielding of Power CablesДокумент6 страницShielding of Power CablesYudo Heru PribadiОценок пока нет

- PG&E 500 KV Series-Compensated Transmission Line Relay Replacement: Design Requirements and RTDS TestingДокумент14 страницPG&E 500 KV Series-Compensated Transmission Line Relay Replacement: Design Requirements and RTDS TestingLuis Enrique Rojas FernándezОценок пока нет

- Future Prospect For Sustainable Urban Transportation in IndiaДокумент54 страницыFuture Prospect For Sustainable Urban Transportation in IndiaKhan Wajahat UllahОценок пока нет

- Hsslive Xi Chem Prvs QN 6. ThermodynamicsДокумент5 страницHsslive Xi Chem Prvs QN 6. ThermodynamicsmazinhussainkОценок пока нет

- LM317Документ4 страницыLM317Ißnu Æ EgēОценок пока нет

- Owner'S Manual: Inverter Plasma CutterДокумент8 страницOwner'S Manual: Inverter Plasma CutterReggie100% (1)

- Tram Rail en Es FR deДокумент6 страницTram Rail en Es FR deJoel100% (1)

- ANSI C37.50 1989 Test Procedures For Low Voltage AC Power Circuit Breakers Used in EnclosuresДокумент29 страницANSI C37.50 1989 Test Procedures For Low Voltage AC Power Circuit Breakers Used in EnclosuresWeiОценок пока нет

- ELE8331 Power System Control Dr. Nuraddeen MagajiДокумент25 страницELE8331 Power System Control Dr. Nuraddeen MagajiumarsaboОценок пока нет

- An Analytical Approach For A High Speed and High Efficiency Induction Motor Considering Magnetic and Mechanical ProblemsДокумент4 страницыAn Analytical Approach For A High Speed and High Efficiency Induction Motor Considering Magnetic and Mechanical ProblemsRodielly IsaiasОценок пока нет

- Science Curriculum Guide Grades 3-10 December 2013Документ64 страницыScience Curriculum Guide Grades 3-10 December 2013api-252270937Оценок пока нет

- Engineering Management Dissertation PDFДокумент4 страницыEngineering Management Dissertation PDFPayPeopleToWritePapersColumbia100% (1)

- Bitsat 2010 PaperДокумент34 страницыBitsat 2010 PaperYumit MorwalОценок пока нет

- 2 - Shell Momentum BalanceДокумент34 страницы2 - Shell Momentum BalanceAdheep DasОценок пока нет

- Energy PracticeДокумент2 страницыEnergy PracticelianamrОценок пока нет

- Pegboard Meeting Minutes Nov14 FinalДокумент2 страницыPegboard Meeting Minutes Nov14 FinalSuparman StОценок пока нет

- Tropospheric Ducting TDMMДокумент16 страницTropospheric Ducting TDMMMuhammad JunaidОценок пока нет

- Human Activity and The Environment: 2. Liquid WasteДокумент3 страницыHuman Activity and The Environment: 2. Liquid WasteDanellОценок пока нет

- Financial Reports March 2012Документ246 страницFinancial Reports March 2012adil1983adilОценок пока нет

- Phrasal Verbs List Vocabulary EnglishClubДокумент16 страницPhrasal Verbs List Vocabulary EnglishClubridhaОценок пока нет

- Exercise 4 Plastic Deformation by Oscillating Force and Observation of Strain Hardening On A CantileverДокумент7 страницExercise 4 Plastic Deformation by Oscillating Force and Observation of Strain Hardening On A CantileverSandip GaikwadОценок пока нет

- Pelton Vs FrancisДокумент2 страницыPelton Vs FrancisSudeep AcharyaОценок пока нет

- Physics Class Xii Sample Paper Test 01 For Board Exam 2023 AnswersДокумент18 страницPhysics Class Xii Sample Paper Test 01 For Board Exam 2023 AnswersGyan BardeОценок пока нет

- Cuna Ge PandaДокумент62 страницыCuna Ge PandaEmilio A Secas100% (1)

- A Pulse TransformerДокумент12 страницA Pulse TransformerPooja Uchagaonkar100% (2)

- Solarizer Elite Hybrid BrochureДокумент2 страницыSolarizer Elite Hybrid BrochureEmmvee SolarОценок пока нет

- MS Notice 3 of 2014 - Bunker Audit PDFДокумент12 страницMS Notice 3 of 2014 - Bunker Audit PDFBala MuruganОценок пока нет