Академический Документы

Профессиональный Документы

Культура Документы

Readme

Загружено:

Joel Perez QuispeАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Readme

Загружено:

Joel Perez QuispeАвторское право:

Доступные форматы

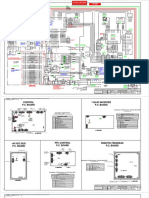

Infoprint 4000 & 4100 IBM

Using the Console Simulator

First Edition November 2002

© Copyright International Business Machines Corporation 2002. All rights reserved.

US Government Users Restricted Rights – Use, duplication or disclosure restricted by GSA ADP Schedule Contract with IBM Corp.

Chapter 1. About the console simulator

This CD-ROM contains the Infoprint 4000 & Infoprint 4100 Enhanced Operator Console Simulator. The simulator

allows you to view the printer console on your workstation. The screens that you see, are the same screens that

will appear on you r printer. You can navigate through the panels and familiarize yourself with the console.

The look of the simulator (the window layouts, buttons, icons etc.) are exactly the same as they appear on the

printer.

The way the console reacts when you push a button or select a field, is the same on the simulator and the printer

console.

Differences between the console simulator and the printer console

Anytime an operation is performed: a window appears for a few seconds with an ″in progress″ message (for

example: Starting....), then the widow goes away, that is an interaction with the printer.

Some interactions that actually require the printer cannot be modelled in the simulator such as:

v What attachments are available

v How much toner and fuser oil are in the printer

Other interactions, such as pressing Start or OK, are simulated and will work about 90% of the time, but are not

100% accurate.

Choosing your access level is done differently on the simulator than on the printer console. Although the

Logon... button and it selections appear on the simulator, choosing a different access level within the Console

Simulator screen will not actually change your access level. To change access levels, you must do from the

AFCCU Simulator window using the Configure function. (See “Changing Access Levels” on page 7.)

© Copyright IBM Corp. 2002 3

About this document and CD-ROM

This document and the CD-ROM are meant to be used as an aid in training Infoprint 4000 and 4100 Operators on

the Enhanced Operator Console.

Chapter 1. About the console simulator 4

Chapter 2. Starting the Console Simulator

Complete the following steps to start the simulator:

Loading the CD

1. Insert the CD into the CD-ROM drive.

Note: If you are running this from your maintenance CD,

a. Wait until the autoload stops.

b. Close the Acrobat reader.

2. Navigate to ″My Computer″ on your desktop and select it by double clicking the left mouse button.

3. Find your CD-ROM drive and left double click on it .

4. The contents of the CD-ROM are displayed. Find the file named runfromcd.bat and left double click on it.

5. An MS DOS Command window will open and the bat file will begin its execution.

Figure 1. MS DOS Command Window

© Copyright IBM Corp. 2002 5

6. After approximately 30-45 seconds IBM AFCCU Simulator window is displayed.

Figure 2. IBM AFCCU Simulator Window

7. Minimize the MS DOS Command window.

8. Go to “Choosing your options and running the Simulator”.

Choosing your options and running the Simulator

Running the Simulator

1. Before starting the simulator you can choose the options that you want to run with.

a. Click on the Configure button to choose your options.

b. Once you’ve chosen your options, click on the OK button to save your choices.

2. To start the simulator, click on the Run button.

3. Once the simulator code is loaded, you can now navigate through the various screens and functions.

4. When are done, to exit the simulator, press the Shutdown button at the bottom of the screen.

From the AFCCU Simulator Screen you can perform the following functions:

Chapter 2. Starting the Console Simulator 6

Configure

Pressing the Configure button allows you to choose the following options:

Model v Duplex *

v Dual Simplex 1

v Dual Simplex 2

v Simplex

Changing Access Levels

The Logon.... button in the console simulator does not actually

change your access level, on the printer console this button will

actually let you change access levels. If you wish to change access

levels within the console simulator you must do it here, before

selecting Run on the console simulator.

Note: The defaults are marked with an asterisk *.

Access v Operator

v Administrator *

v Service

Language v English * v Portuguese

v Spanish v Chinese

v German v Taiwanese

v Japanese v Korean

v French v Romanian

v Italian v Hungarian

Chapter 2. Starting the Console Simulator 7

Run

Selecting the Run button on the AFCCU simulator window will cause the console simulator code to execute. The

following sequence of events will occur:

1. a color bar appears in the simulator window

2. a four digit code scrolls in the window as the simulator code loads

3. in approximately 1:25 to 1:50 minutes the main console screen appears

Figure 3. AFCCU Simulator Window after selecting Run

Notes

Selecting the Notes button allows you to read the developers notes about the simulator.

Quit

Selecting the Quit button allows you to exit from the AFCCU Console simulator window without running anything.

Chapter 2. Starting the Console Simulator 8

Chapter 3. Using the Enhanced Operator’s Console

This part of this document does not replace the Maintenance Information, in fact all of the contents about Using

the Enhanced Console, are directly from the Maintenance Information.

Your customer has received a copy of the simulator on CD-ROM and a ″How to Document″ that shows them the

various operator and adimistrator functions that they can try out on the simulator.

© Copyright IBM Corp. 2002 9

Touchscreen Main Window

The tabs at the top of the touchscreen main window provide access to the following functions: Frequent Tasks,

Forms, Maintenance and Printer Definition. By selecting the tab you can access additional functions.

Table 232. Touchscreen Main Window Tabs

Frequent Printer

Forms Maintenance Logon...

Tasks Definition

Printer 1 Printer 2

Print Count: 123,456 Print Count: 123,456

Custom Count: Reset Custom Count: Reset

Status Operator Messages

Stopped

Warming

Current Settings

AV1U0001

Set print

NPRO

registration

Start Stop Check/Reset Shut Down

Frequent Tasks Forms Maintenance Printer Definition

v Snapshots v Form Settings v Print Samples v Print Quality

v Manage Attachments v Align Form v Touchscreen v Printer

v Cancel Job v Print Registration v Diskette Operations v Attachments

v Clear Buffers v Advance Paper (NPRO) v Traces v Pre/Post Processing

v Pre/Post Processors v Front Face v Diagnostics (CE only) v Remote Access

v Logs (CE only) v Features

Chapter 2. Diagnostics 1442

Table 233. Touchscreen Main Window Buttons

Frequent Printer

The buttons on the touchscreen main window are:

Forms

v Logon... button

Maintenance Logon...

Tasks Definition

Takes you to Change access levels where you can change

Printer 1 Printer 2 your authority level. The authority level displays in the

Operator Messages title bar on the Main panel.

You can also create new user or operator identities. This allows

you to customize the functions that individual users have

Print Count: 123,456 Print Count: 123,456

authority to perform. The capability to Manage Users is

Custom Count: Reset Custom Count: Reset available by default to Administrator and Service authorization

Status Operator Messages

levels.

Stopped Note: Do not change access levels while customer jobs are

Warming printing. Printing performance will be reduced.

Current Settings v ? button

Accesses the online help.

v Start button

Readies the printer for printing from the host.

v Stop button

AV1U0001

Set print

NPRO

registration

Start Stop Check/Reset Shut Down

Makes the printer Not Ready

v Check / Reset button

In dual simplex mode, you can toggle between Printer 1 and Resets the Check condition.

Printer 2 screens by touching one of the printers in the upper left

corner of the screen.

Chapter 2. Diagnostics 1443

Table 233. Touchscreen Main Window Buttons (continued)

Frequent Printer

v Check / Reset button

Forms Maintenance Logon...

Tasks Definition

Resets the Check condition.

v Shutdown button

Printer 1 Printer 2 Prepares the system for shutdown and restart.

If you are in Service mode, you can select Retain Access

Level and the system will restart in Service mode.

v NPRO button

Print Count: 123,456 Print Count: 123,456 Takes you to Forms → Advance paper (NPRO).

Custom Count:

v Set Print Registration button

Custom Count: Reset Reset

Status Operator Messages

Stopped Takes you to Forms → Set Print Registration.

Warming Note: The NPRO and Set Print Registration buttons can be

Current Settings

defined for each user, including Service, using the Manage Users

option under Logon. The default definitions for Service are

Preventative Maintenance and Error Log.

AV1U0001

Set print

NPRO

registration

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1444

Table 234. Touchscreen Main Window Areas

The areas on the touchscreen main window are:

Frequent Printer

v Graphic area

Forms Maintenance Logon...

Tasks Definition

Touching any of the components in the graphic brings up a

window giving information about that component. In addition, if

Printer 1 Printer 2 the printer is in an error state or has a warning message

posted, the graphic for that printer will change color.

– Print Counter: Total print count

– Custom Count: Print count for a specific time

Print Count: 123,456 Print Count: 123,456 To set the counter to zero, select the Reset button.

Custom Count:

v Status area

Custom Count: Reset Reset

Status Operator Messages

Stopped Gives overall status (Receiving, Not Ready, Ready) of both

Warming engines (if in duplex Mode) and pre/post processors when you

Current Settings select them on the touchscreen.

v Current Settings area

Displays the loaded snapshot name, form size, resolution, and

the status of enabled attachments.

AV1U0001

Set print

NPRO

registration

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1445

Table 234. Touchscreen Main Window Areas (continued)

v Operator Messages area

Frequent Forms Maintenance

Printer

Logon...

Displays icons representing errors, warnings, and informational

Tasks Definition

messages along with text. The messages could refer to jams,

toner replacement, forms replacement, and so on.

Printer 1 Printer 2 If preventive maintenance is due, a message will appear in the

Operator Message window alerting you to the fact that there

are PM Tasks due. Select the button next to the message for

further details.

Print Count: 123,456 Print Count: 123,456 Notes:

Custom Count: Reset Custom Count: Reset

Status Operator Messages

1) If your forms are not aligned a message and button will

appear informing you that forms alignment is required. The

Stopped button takes you to Forms → Align Forms.

Warming

Current Settings 2) If you are running traces a message will appear informing

you that traces are running. The button takes you to

Maintenance → Traces.

AV1U0001

Set print

NPRO

registration

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1446

Password

The different levels of authorization are:

v Operator: No password is required for access to Operator procedures.

v Administrator: The Administrator has access to all functions except those related to the service and repair of

the printer.

v Service : The service representative has access to all functions of the printer.

The procedures and information available on the touchscreen depend on the user’s level of authorization. A

procedure is grayed out if it is not authorized for the current user.

The key operator can change the Administrator password, and the customer engineer can change both the

Administrator and the Service passwords.

Initially, the Service password is set as “empty”, meaning that you select the password by selecting only the OK

key on the password keyboard.

If you do not know the password, contact your next level support.

Chapter 2. Diagnostics 1447

Frequent Printer

Changing access levels and passwords

Forms Maintenance Logon

Tasks Definition

This procedure lets you set the authorization level of the person

Toner Fuser Oil Toner Fuser Oil

working on the printer and change the password.

Printer 2 1

Select desired user ID

1) On the touchscreen, select Logon...

User ID 2) On the Change access levels panel, select the Access

Operator

Change

password

Level to which you want to change.

Print Count: 123,4 Administrator 3,456

If you are changing to a higher level of authorization, the

Resettable Counter:

Manage

Reset

Password panel appears. Enter the password and select

Status Service Users

OK.

Stopped 3) To change a password:

Warming

Current Settings

OK Cancel

a) Select Change Password. The Change Password

panel appears.

b) Enter the new password twice and select OK to change

the password.

Advance Print If you decide not to change the password, select

AV1U0010

Paper (NPRO) Registration

Start Stop Check/Reset Shutdown

Cancel.

Chapter 2. Diagnostics 1448

Managing and Defining New Users

Frequent Printer

You can create new user identities and give them a subset of

Forms Maintenance Logon

Tasks Definition access level functionality.

Toner Fuser Oil Toner Fuser Oil

1) On the touchscreen, select Logon....

1

Printer 2

Select desired user ID 2) On the Change access levels panel, select an access level

and then select Manage Users. A window displays that

User ID

contains a list of all the users that are subsets of the current

Change

Operator password and lower access levels. For example, if you chose the

Print Count: 123,4 Administrator 3,456 Administrator access level, all users who are subsets of the

Resettable Counter: Reset

Status Service

Manage

Users

Administrator and Operator access levels will appear in the

list.

Stopped

Warming

Current Settings Cancel

OK

Advance Print

AV1U0010

Paper (NPRO) Registration

Start Stop Check/Reset Shutdown

Chapter 2. Diagnostics 1449

Frequent Forms Maintenance

Printer Logon

3) To add a new user:

Tasks Definition

a) Select Add. The New User panel displays.

Toner Fuser Oil Toner Fuser Oil

b) Give the new user a name and select the base access

Defined Users

you want the user to have. Then select OK.

Operator Base access: Administrator

Administrator

Service Default Login: No If the you decide not to enter a new user, select Cancel.

Victoria

Michael

Language: Default

Print

Button 1: Advance Paper

Resettabl Reset

Status

Button 2: Print Registration

Stopped

Warming User Functions

Current Settings Add Delete

OK Cancel

Advance

AV1U0024

Print

Paper (NPRO) Registration

Start Stop Check/Reset Shutdown

Chapter 2. Diagnostics 1450

Frequent Forms Maintenance

Printer Logon

4) To give the user a subset of functions:

Tasks Definition

a) Select the user in the Defined Users list and then

Toner Fuser Oil Toner Fuser Oil select User Functions.

Functions

Snapshots

Functions Unavailable to 'User' The User Functions panel displays the functions

Load

Save Current Settings

available to the user’s base access level.

Delete

Manage Attachments

TCP/IP Ethernet

b) Select the Functions from the list that you don’t want

TCP/IP Token Ring

TCP/IP ATM the user to have access to. Use the arrows to add those

TCP/IP FDDI

Print C

Resettable

SNA Token Ring

SNA SDLC Reset

functions to the Functions unavailable to ’user’ list.

Escon Channel A

Status Escon Channel B

Ficon Channel A

Stopped Ficon Channel B

Parallel Channel A

Warming Parallel Channel B

Current Settings

Close

Advance Print

AV1U0026

Paper (NPRO) Registration

Start Stop Check/Reset Shutdown

Chapter 2. Diagnostics 1451

Frequent Forms Maintenance

Printer Logon

5) To manage users in other ways:

Tasks Definition

a) Make the user the default login after reboot by selecting

Toner Fuser Oil Toner Fuser Oil the check box next to Default User, which will change

Defined Users to Yes.

Operator

Administrator

Base access: Administrator

Note: Do not make Service the default user.

Service Default Login: No

Victoria

Michael b) Select a default console display language for each user

Language: Default

by selecting a Language from the list.

Resettabl

Button 1: Advance Paper Reset

c) Customize the two hot buttons for each user that will

Status display on the Main panel. Select the panel you want

Button 2: Print Registration

Stopped the hot button to take you to.

Warming User Functions

6) Select OK when you have customized the settings on this

Current Settings Add Delete

panel.

OK Cancel

Advance

AV1U0024

Print

Paper (NPRO) Registration

Start Stop Check/Reset Shutdown

Chapter 2. Diagnostics 1452

Maintenance Functions

Table 235. Maintenance Functions

Frequent Printer

Accessing Maintenance Functions

Forms Maintenance Logon...

Tasks Definition

1) Select the Maintenance tab on the touchscreen main window.

Print Samples

Source Print Samples

Number of copies 0

2) If you have not already Logged In with service access level

Color

Primary then, you will be prompted to enter your password. Use the

Touchscreen

Internal keyboard to enter your password and select OK.

Alternate Print

Diskette

Operations Diskette

Note: If preventive maintenance is due, a message will appear in

All white the Operator Message window alerting you to the fact that there

Traces

CD Rom are PM Tasks due. Select the button next to the message for

Bar code

Diagnostics

further details.

Service

Text 1

Logs

The selections available after selecting the maintenance tab are:

Text 2 v Print Samples

Densitometer

v Touchscreen

Close Help

v Diskette Operations

v Traces

v Diagnostics

AV1M0001

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

v Logs

Chapter 2. Diagnostics 1453

Print Samples

Table 236. Print Samples

Frequent Printer

Note: Disable all attachments before you print samples.

Forms Maintenance Logon...

Tasks Definition

Source Print Samples

From the Print Samples tab you can select the type of samples

Print Samples

Color

Number of copies 0 you wish to print.

Primary

Touchscreen

Internal First you must choose a Source:

Alternate Print

Diskette

Operations Diskette

v Internal - allows you to select and print various types of print

All white samples

Traces

CD Rom

Bar code

v Diskette - you’ll only use this option when you receive a

Diagnostics Service

diskette from support

Text 1

v CD Rom - you’ll only use this option when you receive a CD

Logs

Text 2

Rom from support

Densitometer v Service - allows you to print the printer configuration and logs

Close Help Note: When you are not logged in as Service, this choice is

called Configuration. Configuration only allows you to print

the printer configuration. You cannot print logs.

AV1M0001

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1454

Table 236. Print Samples (continued)

Frequent Printer

Forms Maintenance Logon...

Tasks Definition

Source Print Samples

Printing print samples:

Print Samples

Color

Primary

Number of copies 0

1) Select the Maintenance tab on the touchscreen main

Touchscreen window.

Internal

Diskette

Alternate Print 2) Select Internal in the source field.

Operations Diskette

All white 3) Select the sample you want to print.

Traces

CD Rom v Primary

Bar code

Diagnostics v Alternate

Service

Text 1

v All white

Logs

Text 2 v Gray

Densitometer v Bar code

Close Help

v Postprocessor

v Text 1

v Text 2

AV1M0001

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

v Printhead Power

v MICR

v Color

Eight is the minimum number of copies you need to see 4) Using the keyboard, key in the number of copies you want

repeating spots (2 revolutions) on the photoconductor drum in the Number of copies field.

when you use an 8.5-in. wide form. For other form widths, 5) Select the Print button.

divide twice the circumference of the drum 165.1 cm (65 in.) by 6) Select the Close button.

the form width to determine the minimum number of copies to

print.

Patterns are truncated if the form is smaller than the pattern. If

a failure occurs during a test, the SRC is displayed and can be

used as an entry point to the MAPs.

You made need to press NPRO to get fused prints to exit the

printer.

Chapter 2. Diagnostics 1455

Frequent Printer

Forms Maintenance Logon...

Tasks Definition

Source Print Samples

Printing the configuration:

Print Samples

Color

Primary

Number of copies 0

1) Select the Maintenance tab on the touchscreen main

Touchscreen window.

Internal

Diskette

Alternate Print 2) Select Service in the source field.

Operations Diskette

All white 3) Select Configuration .

Traces 4) Using the keyboard, key in the number of copies you want

CD Rom

Bar code

in the Number of copies field.

Diagnostics Service

Text 1 5) Select Print.

Logs

Text 2

6) Select Close.

Densitometer Note: Only the snapshot that is currently loaded will appear in

Close Help the printout.

AV1M0001

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down Printing the logs:

1) Login as Service.

2) Select the Maintenance tab on the touchscreen main

window.

3) Select Service in the source field.

4) Select Error Log to print the detailed error log.

Select Unfiltered Error Log to print the detailed error log

that includes all events, such as ″The printer was powered

on.″

5) Using the keyboard, key in 1 in the Number of copies field.

6) Select Print.

7) Select Close.

Chapter 2. Diagnostics 1461

Touchscreen

Frequent Printer

Accessing the Touchscreen Functions

Forms Maintenance Logon...

Tasks Definition

1) Select the Maintenance tab on the touchscreen main window.

Print Samples 2) Select the Touchscreen tab.

To clean the screen, select Clean Screen. Clean Screen

3) The choices are:

Touchscreen You will have 30 seconds to clean the screen.

v Clean Screen - after selecting this button a black screen is

Diskette

Operations

To re-calibrate the touchscreen, select Calibrate.

Select the squares as they appear.

Calibrate displayed with a countdown for 30 seconds. All touches will

be ignored for 30 seconds while you clean the screen.

Traces

v Calibrate - select this button to recalibrate the touchscreen.

Diagnostics – Small squares will display near the corners of the

screen.

Logs

– Touch each of the squares to recalibrate the

Densitometer touchscreen.

Close Help

AV1M0002

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1462

Diskette Operations

Frequent Printer

If you select Diskette Operations, you can update the system

Forms Maintenance Logon...

Tasks Definition

microcode, and backup and restore the configuration files.

Print Samples

Accessing Diskette Operations

Touchscreen Recovery diskettes record all unique data that is necessary to recover from a 1) Logon as Service.

hard drive failure.

2) Select the Maintenance tab on the touchscreen main window.

Diskette Create Recovery Diskette Restore from Recovery Diskette

Operations 3) Select the Diskette Operations tab.

Traces

Load specific configuration data from a recovery disk. Load Configuration

Diagnostics

Create Recovery Diskette

Update control unit microcode. Update Microcode

Logs

Select this function to back up the configuration information to

Densitometer

diskette.

Close Help

Select the Create Recovery Diskette button to create the

diskette, or the Close button to close the window without creating

a recovery diskette.

Preventative

AV1M0003

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Restore from Recovery Diskette

Select this function to restore the configuration files from the

recovery diskette to the hard disk files.

Select the Restore from Recovery Diskette button to perform

the restore or the Close button to close the window without

restoring.

Note: After this function is completed, a reboot of the printer is

required. Messages on the screen will provide instructions.

Chapter 2. Diagnostics 1463

Frequent Printer

Tasks

Forms Maintenance

Definition Logon... Update Microcode

Print Samples Attention: Never install a lower version of microcode. If the

Recovery diskettes record all unique data that is necessary to recover from a

new level microcode version does not work correctly, contact your

Touchscreen

hard drive failure. next level support.

Diskette Create Recovery Diskette Restore from Recovery Diskette

Operations

Traces

Load specific configuration data from a recovery disk. Load Configuration Attention: When using a CD to update microcode, use a lower

Diagnostics capacity CD (650MB not 700MB).

Logs

Update control unit microcode. Update Microcode

To update the microcode

1) Logon as Service.

Densitometer

2) Insert the microcode CD-ROM or first microcode diskette into

Close Help

the RS/6000 controller.

3) Select the Maintenance tab.

Preventative 4) Select the Diskette Operations tab.

AV1M0003

Error Log

Maintenance

Start Stop Check/Reset Shut Down

5) Select the Update Microcode button.

Chapter 2. Diagnostics 1464

Frequent Forms Maintenance

Printer

Logon...

6) Select the source Diskette or CD Rom .

Tasks Definition

7) Select OK to perform the update or Cancel to close the

Print Samples window without updating the microcode.

Recovery diskettes record all unique data that is necessary to recover from a

8) A message ″Reading update contents...″ appears and stays

Touchscreen

hard drive failure.

on the screen for several minutes. (The time depends on the

Diskette Create Recovery Diskette Restore from Recovery Diskette size of the code update.)

Operations

9) A screen appears showing the following information: New

Traces

Load specific configuration data from a recovery disk. Load Configuration

Version, New EC level, Current Version, Current EC level.

Diagnostics v Ensure that the code version shown in the New Version

Update control unit microcode. Update Microcode

field is a later code version than that in the Current

Logs Version field.

Densitometer

10) If the New Version is correct, select OK. Otherwise, select

Close Help

Cancel .

11) A message ″Updating code, please wait.″ appears and stays

on the screen for several minutes until the code update is

Preventative complete. (The time depends on the size of the update.)

AV1M0003

Error Log

Maintenance

Start Stop Check/Reset Shut Down

12) A reboot of the RS/6000 will automatically occur.

Chapter 2. Diagnostics 1465

Frequent Printer

Tasks

Forms Maintenance

Definition Logon... Load configuration

Print Samples Select this function to copy specific configuration data from a

recovery diskette. This function allows you to use a diskette that

Recovery diskettes record all unique data that is necessary to recover from a

Touchscreen was created on one printer to copy configuration items, such as

hard drive failure.

Diskette Create Recovery Diskette Restore from Recovery Diskette

Snapshots, to a different printer.

Operations

1) Select Load Configuration to display a list of configuration

Traces items.

Load specific configuration data from a recovery disk. Load Configuration

2) Check the items you want to transfer from the recovery

Diagnostics

dikette to this printer. Items include:

Update control unit microcode. Update Microcode

Logs v Snapshots

Densitometer

v Set Form Attributes

Close Help v Set Print Registration

v Print Quality

v Printer

Preventative

AV1M0003

Error Log

Start Stop Check/Reset Shut Down

Maintenance v Attachments

v Pre/postprocessing

v Remote Access

v Users

v PM Logs

v PQE

v Error Log

If you select every item in the checklist, all configuration data

except RPQ information will be loaded. When some items are

selected, pop-up boxes display, asking you to make more

choices. Make these selections or select Close to close the

window without loading any configuration data.

Note: You will be asked if the configuration data came from

the printer you are loading it to. Make sure you answer this

question correctly.

Chapter 2. Diagnostics 1466

Traces

Table 238. Traces

Frequent Printer

Note: If your trace involves an attachment, disable the

Forms Maintenance Logon...

Tasks Definition

attachment before configuring the trace. Then re-enable the

Print Samples

Enabling additional traces will cause the printer

control unit to save additional information for debugging purposes.

attachment after you exit the Traces window. This provides a

It tracks IPDS data communications with the host and communications with the engine.

You will be directed by IBM support when you need to enable additional tracing. clean boundary to allow better review of the trace.

Touchscreen

To Run and Save a Trace, do the following:

Diskette

Operations Additional tracing enable No 1) Select the Maintenance tab on the touchscreen main

Traces

window.

2) Select the Traces tab.

Record the current trace information to diskette Save traces to diskette

Diagnostics

3) Traces are always running. If you need a normal Control

Logs Format diskette

Unit trace (no IPDS/Additional traces; no changes to the

Control Unit Trace Configuration) for an event that has

Densitometer

Configure control unit trace

already occurred, go to step 9.

OK Cancel Help

4) If you want IPDS Tracing, select the box for Additional

Tracing Enabled. (See “Additional Tracing Enabled (IPDS

Tracing)” on page 1469.)

Preventative

AV1M0004

Error Log

Maintenance

Start Stop Check/Reset Shut Down 5) The default trace options are usually appropriate for

engineering. If you were asked to change them, see

“Configuring the Internal Control Unit Trace” on page 1470.

Traces lets you record channel and microcode events as an aid

Note: Record any values before you change them. You will

in resolving problems.

return them to the default values later.

The Trace function can only be accessed with Administrator or 6) Select the Close button to close the Traces window.

Service access levels. 7) Run the job that causes the problem.

8) After the problem has been recreated, select Traces.

Chapter 2. Diagnostics 1467

Table 238. Traces (continued)

Frequent Forms Maintenance

Printer

Logon...

9) Install a diskette in the RS/6000 diskette drive.

Tasks Definition

Note: All current diskette data will be erased before the

Print Samples

Enabling additional traces will cause the printer

control unit to save additional information for debugging purposes.

new traces are saved. You cannot accumulate traces with

It tracks IPDS data communications with the host and communications with the engine.

You will be directed by IBM support when you need to enable additional tracing. the same diskette. If you need to take multiple traces, use

Touchscreen multiple diskettes.

Diskette 10) If you are using a new diskette, use the Format Diskette

Operations Additional tracing enable No

option.

Traces

11) Select the Save Tracers to Diskette button on the Traces

Diagnostics

Record the current trace information to diskette Save traces to diskette window.

12) When the diskette has been written, remove the diskette

Logs Format diskette

from the RS/6000. (If the traces are long, you will be asked

Densitometer

to insert multiple diskettes.)

Configure control unit trace

OK Cancel Help 13) Select the Close button.

14) If there is a problem that needs to be resolved, send the

diskette to engineering for analysis.

Preventative

AV1M0004

Error Log

Start Stop Check/Reset Shut Down

Maintenance 15) When the problem is resolved, return trace options to their

original default values. This will allow future traces to have

the normal default configuration values.

Chapter 2. Diagnostics 1468

Additional Tracing Enabled (IPDS Tracing)

This trace records the following activity:

v IPDS Line Trace

v IPDS Data Trace

v Machine Interface Trace

To select IPDS Tracing, do the following:

1) Logon with Service access level.

2) Select the Maintenance tab on the touchscreen main window.

3) Select the Traces tab.

4) In the Traces window, select Enable Additional Tracing.

5) Select OK to exit the Traces window and activate the trace.

6) Run the operation that you want to trace.

7) Save the trace to diskette as described in “Run and Save a Trace” on page 1467.

Chapter 2. Diagnostics 1469

Configuring the Internal Control Unit Trace

Table 239. Configuring the Internal Control Unit Trace

Note: You probably will use these traces only when working To configure the Control Unit Trace, do the following:

with your next level support. 1) Logon with Service access level.

Unlike the other traces, you can print this “always on” trace 2) Select the Maintenance tab on the touchscreen main

without stopping it. window.

3) Select the Traces tab.

The Control Unit Traces run in the background and continuously

4) Select the Configure Control Unit Trace button.

record the communications that are generated and sent

between the various subsystems of the control unit. Many of the 5) Select the name of Subsystem (on the right side of the

Control Unit Traces are selected as standard default activities. screen) to be traced.

The standard defaults are: 6) Select the Trace Items of the Subsystem that you want to

v printer ops trace. (See Control Unit Trace Items.)

v console 7) Repeat steps g5 and g6 for each subsystem that you want

to trace.

v mechanism

Note: Multiple subsystems can be traced at the same

v rasterizer time.

v decompressor 8) Select OK to exit the Configure Control Unit Trace

v attachment window.

v internalprint 9) Select OK to exit the Traces window and activate the

v tcp_attachment trace.

v javacon 10) Run the operation that you want to trace.

v op_panel

For a list activities that you can configure for this trace, see

Table 240.

Chapter 2. Diagnostics 1470

Control Unit Trace Items

Table 240. Internal Control Activity Options

You can configure A–AMS 0–User level 0 a–User level 10

this trace to record C–Communications 1–User level 1 b–User level 11

the following

activities: M–Memory creation 2–User level 2 c–User level 12

N–General 3–User level 3 d–User level 13

P–Process creation 4–User level 4 e–User level 14

Q–Queue access 5–User level 5 f–User level 15

R–Resources 6–User level 6 g–User level 16

S–Shared memory access 7–User level 7

T–Timer services 8–User level 8

D–Datenbank 9–User level 9

L–POD Data Base

The activities can global msnread_status2 msn_input1_main

be recorded for printer ops msnwrite_cntl1 msn_input2_main

these subsystems:

touchscreen msnwrite_p1 msn_model_input

mechanism msnwrite_cntl2 tm

rasterizer msnwrite_p2 msnwrite_pd1

decompressor msnshift msnwrite_pd2

attachment internalprint lmo

msnread_status1 tcp_attachment msnwrite_sc1

dm msnwrite_sc2

pmib

Chapter 2. Diagnostics 1471

Diagnostics - General

Frequent Printer

Accessing Diagnostics

Forms Maintenance Logon...

Tasks Definition

1) Select the Maintenance tab on the touchscreen main

Print Samples window.

Parallel channel A basic test

Parallel channel A wrap test 2) Select the Diagnostics tab.

Touchscreen Parallel channel B basic test

Parallel channel B wrap test When you select the Diagnostics tab, the Attachment

Diskette ESCON channel A basic test

diagnostics window appears listing the available tests.

Operations ESCON channel A wrap test

Attachment ESCON channel B basic test Selecting either Mechanism or Pre/Post processors

Traces ESCON channel B wrap test

FICON channel A basic test changes the window to allow you to test printer mechanism

Mechanism

Diagnostics

FICON channel A wrap test

FICON channel B basic test

interfaces and preprocessor and postprocessor interfaces.

Pre/Postprocessors FICON channel B wrap test 3) Read the instructions for the test and make the required

Logs

power status and cabling changes.

Densitometer

Run

4) Select the test you wish to run by touching its name on the

Close Help screen. You can scroll the list up and down by touching the

up and down arrows on the right side of the list.

5) Select the Run button to start the test.

Set print

AV1M0005

NPRO

registration

Start Stop Check/Reset Shut Down

The pop-up window that appears identifies the test running and

provides a Stop button when needed.

If there is a problem with a test, a Printer Error or Intervention

Required window (red title bar) appears with a description of the

problem and how to clear it. If an SRC is displayed, go to the

MAP with that number.

6) To leave the Diagnostics window, select the Close button.

Chapter 2. Diagnostics 1472

Attachment Diagnostics

Frequent Printer

Accessing Attachment Diagnostics

Forms Maintenance Logon...

Tasks Definition

1) Select the Maintenance tab on the touchscreen main window.

Print Samples 2) Select the Diagnostics tab.

Parallel channel A basic test

Parallel channel A wrap test When you select the Diagnostics tab, the Attachment

Touchscreen Parallel channel B basic test

Parallel channel B wrap test

Diagnostics window appears listing the available tests.

Diskette

Operations

ESCON channel A basic test

ESCON channel A wrap test

3) Select the test you wish to run by touching its name on the

Attachment ESCON channel B basic test screen. You can scroll the list up and down by touching the up

Traces ESCON channel B wrap test

FICON channel A basic test

and down arrows on the right side of the list.

Mechanism FICON channel A wrap test

Diagnostics

FICON channel B basic test

Pre/Postprocessors FICON channel B wrap test

Logs

Densitometer

Run

Close Help

Set print

AV1M0005

NPRO

registration

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1473

Mechanism Diagnostics

Frequent Printer

Accessing Mechanism Diagnostics

Forms Maintenance Logon...

Tasks Definition

1) Select the Maintenance tab on the touchscreen main

Print Samples window.

Printer 1

2) Select the Diagnostics tab.

Touchscreen Printer 2

3) Select the Mechanism button.

Diskette

Operations Alarm

Attention light

Select Run to turn on the alarm.

The volume control is on the back of the alarm and light When you select Mechanism button on the Diagnostics screen,

Attachment assembly.

Traces MIC Bacic Select Stop in the pop-up window to turn off the alarm

and end the test.

the window appears listing the available tests.

MIC communication

Mechanism MIC loop

Note: Running these diagnostics prevents further printing until

Diagnostics

Operator panel you do a Restart.

Pre/Postprocessors Printer activation

Logs Printer interface

Densitometer

Run

Close Help

Preventative

AV1M0006

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Alarm Test Attention Light Test

Select this test to check and set the volume on the alarm that Select this test to check the light that flashes when the printer

sounds when the printer requires operator intervention. The requires operator intervention. The electrical contacts for remote

volume control is on the back of the alarm and light assembly. alarm devices are included in this test.

1) Select the Diagnostics tab. 1) Select the Diagnostics tab.

2) Select the Mechanism button. 2) Select the Mechanism button.

3) Select Alarm on the list of diagnostic tests. 3) Select Attention light on the list of diagnostic tests.

4) Select the Run button to start the test. 4) Select the Run button to start the test.

5) Select the Cancel button in the pop-up window to stop the 5) Select the Cancel button in the pop-up window to stop the

test. test.

Chapter 2. Diagnostics 1481

Reading the MIC LED Display Other MIC LED status indicators

v 0 - Normal (Printing)

The LED has 7 segments and displays one digit at a time. The v 2 - Normal (Ready to Print)

numbers that appear are progress indicators. v 3 - Engine cycling up, or out of supplies condition

Three horizontal bars that appear for 5 seconds indicate that an v 6 - Waiting for fuser temperature

error occurred. The digits of the error code are then displayed v 8 - SCSI hang

sequentially. After the last digit, a hyphen (-) appears and the v 9 - Memory test failure

sequence repeats. Trailing zeros are suppressed. v L - Looking for active SSA link

v = - Waiting for RISC memory download

MIC Basic Test MIC Communication Test

Select this test to exercise the functions of the mechanism You can perform this test on any of the printer models. This

interface card. routine searches the communication path and reports which

1) Select the Maintenance tab on the touchscreen main devices are communicating with the control unit. Select this test

window. to determine which device or connection to the device is failing

when a D208 error is detected.

2) Select the Diagnostics tab.

3) Select the Mechanism button. To run the test:

4) Select MIC basic on the list of diagnostic tests. 1) Select the Maintenance tab on the touchscreen main

window.

Select the Run button to start the test.

2) Select the Diagnostics tab.

3) Select the Mechanism button.

4) Select MIC communication on the list of diagnostic tests.

5) Select Run.

The results of the diagnostic test appear in a pop-up window on

the touchscreen.

Note: SSA requires 2 MIC paths. SCSI requires 1 MIC path.

Note: A restart is required after you run this test.

Chapter 2. Diagnostics 1482

MIC Loop Test MIC Isolation Wrap Test

Select this test to further exercise the mechanism interface card Perform this test in standalone mode, not using the

by looping part of the MIC test. touchscreen. The tests are differentiated by the type of

1) Select the Maintenance tab on the touchscreen main printhead installed. See Mechanism Interface Card (MIC)

window. Isolation Wrap Test.

2) Select the Diagnostics tab.

3) Select the Mechanism button.

4) Select MIC loop on the list of diagnostic tests.

5) Select the Run button to start the test.

Results appear on the LED attached to the MIC.

Select the Power Off button in the pop-up window to stop the

test. After the message Shutdown complete appears, power

off the control unit and the printer.

Chapter 2. Diagnostics 1483

Logs

Frequent Printer

The Logs function lets you review the error logs and work with

Forms Maintenance Logon...

Tasks Definition

the preventive maintenance (PM) log.

Print Samples Sort by: Date Display: Printer 1 Printer 2 The error log is a chronological listing of printer errors. The

Touchscreen

Index Date/Time

----- ------------------

SRC

----

Print Count

----------

Discription

---------------------------------------

summary log displays the number of occurrences of each SRC

484

479

2001/06/09

2001/06/09

10:26:35

10:24:41

B003

0133

106,801

106,298

Printer attributes have changed

Skew error

in the error log. The PM log is a cumulative indicator of printer

470 2001/06/09 10:21:02 079A 106,049 Check tension arm

Diskette

Operations

465 2001/06/09 10:15:01 0782 105,899 Splice lever down

usage for PM intervals and specially tracked parts with

projections of when preventive maintenance is due.

Traces Preventative

Maintenance

You can use these logs to:

Diagnostics

Error Log

v Determine the number of failures in a particular area of the

Logs printer

Densitometer

Error log: 338 entries 17 days Bookmark: 84 entries 5 days

v Obtain printer usage information

Show events Go to Summary Bookmark Close Help v Look for parts that fail intermittently

v Verify a customer description of a problem

v Set the PM counters for special situations

AV1M0009

Preventative

Error Log

Start Stop Check/Reset Shut Down

Maintenance

v Record completed preventive maintenance.

To access the logs:

1) Select the Maintenance tab on the touchscreen main

window.

2) Select the Logs tab.

Chapter 2. Diagnostics 1505

PM Log

Table 246. PM Log

Frequent Printer

Using the PM Log

Forms Maintenance Logon...

Tasks Definition

The preventive maintenance (PM) log is a cumulative indicator

Print Samples

Printer 1

of printer usage (rolls, brushes, and so on) with projections of

Touchscreen

when PM is due. You can use the log to do the following:

Printer 2

v Check the usage of various printer areas

Diskette

Operations

v Anticipate when PM will be due

Item Feet used Feet remaining % Days

v Set the PM counters for special situations, such as the

Traces Preventative 1.5 MFT-PM 150,000 0 0% 0

maintance 3 MFT-PM installation of a new part

Diagnostics

v Record completed PM.

Error Log Hot Roll

Backup Roll

Logs Developer Mix

When you select Logs tab, or the Preventive maintenance

button the PM Log window appears. The PM list includes:

Densitometer

Edit Completed Item (maintenance levels and specially tracked parts)

Close Help

Feet used

Feet remaining

Preventative

% (Remaining)

AV1M0008

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Days ( estimate of number of days left ).

Chapter 2. Diagnostics 1506

Table 246. PM Log (continued)

Frequent Printer

Use the information in the PM log to identify printer areas that

Forms Maintenance Logon...

Tasks Definition

need planned maintenance or parts replacement.

Print Samples

Printer 1 Close

Touchscreen

Printer 2

If you select the Close button, the window closes and any PM

Diskette

Operations

changes you have made are accepted.

Item Feet used Feet remaining % Days

Traces Preventative

maintance

1.5 MFT-PM

3 MFT-PM

150,000 0 0% 0

Cancel

Diagnostics

Error Log Hot Roll If you select the Cancel button, the window closes without

Backup Roll

Logs

accepting any changes.

Developer Mix

Densitometer

Edit Completed

Close Help

Preventative

AV1M0008

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1507

Table 246. PM Log (continued)

Frequent Printer

Changing a PM Counter

Forms Maintenance Logon...

Tasks Definition

To change a PM counter:

Print Samples

Printer 1 1) If in Duplex Mode, select the Printer 1 or Printer 2 button.

Touchscreen

Printer 2

2) Select the item in the log window.

PM Change Window

Diskette 3) Select the Edit button. The PM change window appears

Operations Interval: (Valid range) % Days showing the current values for that item. If an item is grayed

Traces Preventative 100% 0 out, it cannot be changed.

maintance Interval Warning: (Valid range)

Diagnostics

4) Select the counter you want to change.

Error Log

PM feet used: 5) Using the keyboard key in the new PM value to appear in

Logs the data field.

Densitometer

Ok Cancel

6) Select the OK button.

Close Help

Note: You must select the Completed button, to clear a PM

warning.

Preventative

AV1M0013

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1508

Table 246. PM Log (continued)

Frequent Printer

Recording the Completed PM

Forms Maintenance Logon...

Tasks Definition

To record that PM has been done:

Print Samples

Printer 1 1) If in Duplex Mode, select the Printer 1 or Printer 2 button.

Touchscreen

Printer 2

2) Select the item in the log window.

Diskette 3) Select the Completed button. This resets the “Feet Used ”

Operations

Item Feet used Feet remaining % Days counter to zero for the item selected.

Traces Preventative 1.5 MFT-PM 150,000 0 0% 0

maintance 3 MFT-PM Note: You must select the Completed button, to clear a PM

Diagnostics warning.

Error Log Hot Roll

Backup Roll

Logs Developer Mix

Densitometer

Edit Completed

Close Help

Preventative

AV1M0008

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1509

Error Logs

Frequent Printer

Tasks

Forms Maintenance

Definition Logon... Accessing the error logs :

1) Select the Maintenance tab on the touchscreen main window.

Print Samples Sort by: Date Display: Printer 1 Printer 2

2) Select the Logs tab.

Index Date/Time SRC Print Count Discription

Touchscreen ----- ------------------ ---- ---------- --------------------------------------- 3) Select the Error Log button.

484 2001/06/09 10:26:35 B003 106,801 Printer attributes have changed

479 2001/06/09 10:24:41 0133 106,298 Skew error

Diskette

470

465

2001/06/09

2001/06/09

10:21:02

10:15:01

079A

0782

106,049

105,899

Check tension arm

Splice lever down

The table error log will be displayed in the window. To choose

Operations

the summary error log, select the Summary button.

Traces Preventative

Maintenance

Diagnostics

Error Log

Logs

Error log: 338 entries 17 days Bookmark: 84 entries 5 days

Densitometer

Show events Go to Summary Bookmark Close Help

AV1M0009

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1510

Frequent Printer

Error log information can be displayed in two formats:

Forms Maintenance Logon...

Tasks Definition

v Detail Error Log

Print Samples Sort by: Date Display: Printer 1 Printer 2 v Summary Error Log

Touchscreen

Index Date/Time

----- ------------------

SRC

----

Print Count

----------

Discription

--------------------------------------- The Detail Error Log is a listing of printer errors (SRCs) for the

484

479

470

2001/06/09

2001/06/09

2001/06/09

10:26:35

10:24:41

10:21:02

B003

0133

079A

106,801

106,298

106,049

Printer attributes have changed

Skew error

Check tension arm

Print Engine, RS/6000 controller, and attachments. It can be

Diskette 465 2001/06/09 10:15:01 0782 105,899 Splice lever down

Operations sorted by date or SRC. The Summary Error Log displays the

number of occurrences of each SRC in the error log. It can be

Traces Preventative

Maintenance sorted by SRC or frequency.

Diagnostics

Error Log You can use the error logs to do the following:

Logs v Determine the number of failures in a particular area of the

Error log: 338 entries 17 days Bookmark: 84 entries 5 days

printer

Densitometer

Show events Go to Summary Bookmark Close Help

v Obtain printer usage information

v Look for parts that fail intermittently

v Verify a customer description of a problem

AV1M0009

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1511

Detail Error Log

Frequent Printer

The Detail Error Log includes:

Forms Maintenance Logon...

Tasks Definition

v Index number - This number provides the sequence number for

Print Samples Sort by: Date Display: Printer 1 Printer 2

messages.

Index Date/Time SRC Print Count Discription

v Date and time

Touchscreen

v SRC number - This number is used as an entry for MAP 0010:

----- ------------------ ---- ---------- ---------------------------------------

484 2001/06/09 10:26:35 B003 106,801 Printer attributes have changed

479 2001/06/09 10:24:41 0133 106,298 Skew error

Diskette

470

465

2001/06/09

2001/06/09

10:21:02

10:15:01

079A

0782

106,049

105,899

Check tension arm

Splice lever down Symptom Start MAP.

Operations

v Print count

Traces Preventative

Maintenance v Printer

Diagnostics

Error Log v Description

Logs Note: A flyover box containing this information plus the name of

Error log: 338 entries 17 days Bookmark: 84 entries 5 days the Snapshot that was loaded when the SRC occurred can be

Densitometer displayed by placing the mouse arrow over an SRC entry. (Do not

Show events Go to Summary Bookmark Close Help

click the mouse.)

AV1M0009

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1512

Frequent Printer

If in Duplex mode, Printer 1 and Printer 2 check boxes will be at

Forms Maintenance Logon...

Tasks Definition

the top of the window.

Print Samples Sort by: Date Display: Printer 1 Printer 2

v When both printers are selected, all print engine and AFCCU

errors are displayed.

Index Date/Time SRC Print Count Discription

Touchscreen -----

484

------------------

2001/06/09 10:26:35

----

B003

----------

106,801

---------------------------------------

Printer attributes have changed

v When only one printer is selected, only the errors for that print

479 106,298 Skew error

Diskette

470

465

2001/06/09

2001/06/09

2001/06/09

10:24:41

10:21:02

10:15:01

0133

079A

0782

106,049

105,899

Check tension arm

Splice lever down

engine are displayed.

Operations

v When neither printer is selected, only the AFCCU errors are

Traces Preventative

Maintenance

displayed.

Diagnostics

v Selecting one or both of the printers also changes which

Error Log

printer’s errors are displayed in the Summary log.

Logs

Error log: 338 entries 17 days Bookmark: 84 entries 5 days

You can sort the Error Log by Date or by SRC.

Densitometer

Show events Go to Summary Bookmark Close Help

You can select whether or not to “Show Events”, such as

powering on or restarting the printer. Events are displayed with

the index number shown in parenthesis. When events are

included, the log is called the Unfiltered Error Log.

AV1M0009

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Checking ″Show Events″ also determines whether or not events

are shown in the Summary log and causes the entry totals to

change.

The text under the bottom left corner of the log displays the

number of errors contained in the log and the number of days

between the first and last entries. The text under the bottom right

shows how many errors have occurred above the bookmark you

set.

Chapter 2. Diagnostics 1513

Frequent Printer

Setting an Error Log Bookmark

Forms Maintenance Logon...

Tasks Definition

You can set or move the error log bookmark:

Print Samples Sort by: Date Display: Printer 1 Printer 2

1) Use the cursor to highlight the line where you want the

Touchscreen

Index Date/Time

----- ------------------

SRC

----

Print Count

----------

Discription

---------------------------------------

bookmark.

484

479

470

2001/06/09

2001/06/09

2001/06/09

10:26:35

10:24:41

10:21:02

B003

0133

079A

106,801

106,298

106,049

Printer attributes have changed

Skew error

Check tension arm

The bookmark will appear above the line you select.

Diskette 465 2001/06/09 10:15:01 0782 105,899 Splice lever down

Operations 2) Select the Bookmark button.

Traces Preventative

Maintenance The Summary view will only show errors newer than the

Diagnostics

bookmark.

Error Log

Logs

Error log: 338 entries 17 days Bookmark: 84 entries 5 days

Densitometer

Printing the Detail Error Log

Show events Go to Summary Bookmark Close Help

You can print the Detail Error Log:

1) Select the Maintenance tab on the touchscreen main window.

2) Select the Print Samples tab.

AV1M0009

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

3) Select Service as the print source type.

4) If you select Error Log, the detailed error log is printed. (See

Printing the Configuration.)

5) If you select Unfiltered Error Log, the detailed error log with

all events, such as ″The printer was powered on″ is printed.

6) If you select Configuration, the error log (without events) is

printed after the configuration information. The printed error

log contains the most recent 120 entries.

Chapter 2. Diagnostics 1514

Summary Error Log

Frequent Printer

If in Duplex mode, Printer 1 and Printer 2 check boxes will be at

Forms Maintenance Logon...

Tasks Definition

the top of the window.

Print Samples Sort by: SRC Display: Printer 1 Printer 2

v When both printers are selected, all print engine and AFCCU

0 10 20 30 40 50

errors are displayed.

Touchscreen

v When only one printer is selected, only the errors for that print

079A

EB44

Diskette B001

engine are displayed.

Operations

07D2

v When neither printer is selected, only the AFCCU errors are

Traces Preventative

Maintenance

0133

displayed.

0784

Diagnostics B003

v Selecting one or both of the printers also changes which

Error Log

022B printer’s errors are displayed in the Summary log.

Logs D70B

Error log: 239 entries 17 days Bookmark: 51 entries 5 Days

You can sort the Summary log by SRC or Frequency.

Densitometer

Show events Go to Detail Close Help You can select whether or not to “Show Events”, such as

powering on or restarting the printer. Events are displayed but the

index number is not shown in parenthesis, like they are in the

Detail Error Log.

AV1M0014

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

The text under the bottom left corner of the log displays the

number of errors contained in the log and the number of days

If you select the Summary button while viewing the Detail error between the first and last entries. The text under the bottom right

log, the Summary error log appears. The Summary error log shows how many errors have occurred above the bookmark you

displays: set.

v SRC number

Printing the Summary Error Log

v Frequency of occurrence of the SRC

The frequency is shown in blue bands. The Summary Error Log cannot be printed.

– Dark blue - most recent errors

– Light blue - older errors

Note: A flyover box containing the SRC, frequency of occurrence,

and SRC description displays when the mouse arrow is placed

over an SRC entry. (Do not click the mouse.)

Chapter 2. Diagnostics 1515

Print Quality Enhancement

Frequent Printer

Accessing PQE Adjustments

Forms Maintenance Logon...

Tasks Definition

1) Logon as Service.

Print Quality Printer2 Printer1 2) Select the Printer Definition tab on the touchscreen main

1 1

1 2 3 4 5 6 7 Contrast 1 2 3 4 5 6 7

window.

Printer

0

Boldness

0

3) Select the PQE Adjustments button.

A 0 20 40 60 80 100 A A 0 20 40 60 80 100 A

Attachments 0 0

Preheat

0 20 40 60 80 100 0 20 40 60 80 100

temperature

0 0

Pre/Post Processing Fuser

0 20 40 60 80 100 temperature 0 20 40 60 80 100

Remote 0 0

Oil rate

Access 0 20 40 60 80 100 0 20 40 60 80 100

0 0

Oil belt

Features 0 20 40 60 80 100 0 20 40 60 80 100

Use backup

Default idler roll Default

Beam Adj. PQE Adj. Examples: Medium (20#) OK Cancel Help

AV1M0010

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1516

Frequent Printer

Accessing PQE Adjustments (cont’d)

Forms Maintenance Logon...

Tasks Definition

Print Quality Enhancement 4) The Print Quality Enhancement window appears.

Print Quality Enhancement

Print Quality

Printer 2 Printer 1

5) Follow the procedures in the following sections to make the

6 7

adjustments:

Beam All Beam All

Printer

v AOM Skew Adjustment Procedure - page 1518

80 100 A

Attachments

Vector 0 Vector 0

v Horizontal High and Low Adjustment - page 1524

80 100

Boldness 0 Boldness 0 v Stroke Width Balancing Adjustment - page 1527

Pre/Post Processing

Stroke width Stroke width

80 100

v Engine Boldness Balancing Adjustment - page 1530

Remote Horizontal high 32 Horizontal high 32

Access 80 100

Horizontal low 18 Horizontal low 18

Features Vertical high 32 Vertical high 32 80 100

Vertical low 18 Vertical low 18

Vector contents Vector contents

Cancel Help

Print test

Copies 1

Print OK Cancel Help

AV1M0012

Alternate master

Error Log

Chapter 2. Diagnostics 1517

AOM Skew Adjustment Procedure

Table 247. AOM Skew Adjustment

1) Perform this procedure for both Printer 1 and Printer 2.

2) Logon as Service.

3) Load 18-inch wide paper into the printer.

4) Load the snapshot named IBM - 2 Up Letter. This snapshot is for 18 inch wide paper and it sets the contrast to 4.

5) Disable host attachments.

6) Run 100 Alternate Print Samples.

Chapter 2. Diagnostics 1518

Table 247. AOM Skew Adjustment (continued)

Note: Beam 1 is the reference beam and all the other beams

are aligned to it.

4

3

2

4

3

2

4

4

C heckerboards C heckerboards

3.5

3.5

7) Observe the unfused prints at the buffer arm area. When the

4 3 4 3

3

3

2 1 2 1

2.5

2.5

1 Pel 2 Pel 3 Pel 4 Pel 6 Pel 1 Pel 2 Pel 3 Pel 4 Pel 6 Pel

2

2

1.5

1.5

6 4 3 2 1-1 1-2 1-3 1-4 1-5 6 4 3 2 1-1 1-2 1-3 1-4 1-5

beams are aligned correctly, the two white spaces (1) in the

1

1

1

1

2

2

.5

.5

5

4

3

2

1

5

4

3

2

1

3

3

4

4

0

0

1 2 3 4 6 1 2 3 4 6

6

6

-.5

-.5

pattern should be of equal width and divide the pattern into

6

6

-1 -1.5 -2 -2.5

-1 -1.5 -2 -2.5

4

4

H

H

3

3

5

4

3

2

1

5

4

3

2

1

2

2

1

1

three equal sections in the 0 position for all four beams (2,

V

V

-3 -3.5 -4 -4.5

-3 -3.5 -4 -4.5

1 1

3, 4 and 5).

Side O ne

Side O ne

85 LPI 106 LPI

Front

8) If the white spaces are not positioned correctly in the 0

4

3

2

4

3

2

4

4

3.5

3.5

3

3

position, locate the position (4 to -4.5 for 600 DPI, 3 to -3 for

2.5

2.5

2

2

1.5

1.5

1

1

480 DPI) where the beams appear to be most closely

.5

.5

0

0

-.5

-.5

-1 -1.5 -2

-1 -1.5 -2

aligned. Record that position for beams 2, 3, 4 and 5.

-2.5 -3

-2.5 -3

-3.5 -4 -4.5

-3.5 -4 -4.5

A ,B ,C ,D A ,B ,C ,D

9) Do not log off as Service.

1.5 1 .5 0 -.5 -1 -1.5

Correct Not Correct

NWTM1055

Chapter 2. Diagnostics 1519

Table 247. AOM Skew Adjustment (continued)

10) Select the Printer Definition tab on the main touchscreen

Frequent Forms Maintenance

Printer

Logon...

window.

Tasks Definition

Beam offsets

11) Select the Beam Adjustments button.

Beam offsets

Print Quality

Printer 2 Printer 1

Printer Beam 1 offset 8.0 Beam 1 offset 8.0

A

Attachments

Beam 2 offset 8.0 Beam 2 offset 8.0

Pre/Post Processing

Beam 3 offset 8.0 Beam 3 offset 8.0

Remote

Access

Beam 4 offset 8.0 Beam 4 offset 8.0

Features

Beam 5 offset 8.0 Beam 5 offset 8.0

Help

OK Cancel Help

AV1M0011

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1520

Table 247. AOM Skew Adjustment (continued)

12) Select the Beam 2 Offset for Printer 1. Note that Beam 1

Frequent Forms Maintenance

Printer

Logon...

is grayed out, because beam 1 is the reference beam and

Tasks Definition

Beam offsets is not adjusted.

Print Quality

Beam offsets

Printer 2 Printer 1

13) A setting of 8.0 is the default setting. Add or subtract the

number corresponding to the pattern that is most closely

Printer Beam 1 offset 8.0 Beam 1 offset 8.0 aligned for each beam, (as recorded in step 8 on

A page 1519), to offset adjustment value for each beam.

Attachments

Beam 2 offset 8.0 Beam 2 offset 8.0 Note: The middle row of lines for columns 1.5, .5, −.5, and −1.5

Pre/Post Processing

have lines that are half a pel shorter than the rest of the lines.

Beam 3 offset 8.0 Beam 3 offset 8.0 This is the way that the test master is designed, so that half a

Remote pel errors in spacing can be noticed.

Access

Beam 4 offset 8.0 Beam 4 offset 8.0

Features

Beam 5 offset 8.0 Beam 5 offset 8.0

Help

OK Cancel Help

AV1M0011

Preventative

Error Log

Maintenance

Start Stop Check/Reset Shut Down

Chapter 2. Diagnostics 1521

Table 247. AOM Skew Adjustment (continued)

4

3

2

Example 1:

4

3

2

If the correctly printed pattern for beam 2 were in the 2.5

4

4

C heckerboards C heckerboards

3.5

3.5

4 3 4 3

3

3

2 1 2 1

2.5

2.5

1 Pel 2 Pel 3 Pel 4 Pel 6 Pel 1 Pel 2 Pel 3 Pel 4 Pel 6 Pel

position, you would add 2.5 to the existing beam offset for beam

2

2

1.5

1.5

6 4 3 2 1-1 1-2 1-3 1-4 1-5 6 4 3 2 1-1 1-2 1-3 1-4 1-5

1

1

1

1

2

2

.5

.5

5

4

3

2

1

5

4

3

2

1

3

3

4

4

0

0

2 offset.

1 2 3 4 6 1 2 3 4 6

6

6

-.5

-.5

6

6

-1 -1.5 -2 -2.5

-1 -1.5 -2 -2.5

4

4

H

H

3

3

5

4

3

2

1

5

4

3

2

1

2

2

Example 2:

1

1

V

V

-3 -3.5 -4 -4.5

-3 -3.5 -4 -4.5

1 1

Side O ne

Side O ne

85 LPI 106 LPI

Front

If the correctly printed pattern for beam 2 were in the −1.5

4

3

2

4

3

2

position, you would subtract 1.5 from the existing beam offset for

4

4

3.5

3.5

3

3

2.5

2.5

beam 2.

2

2

1.5

1.5

1

1

.5

.5

0

0

-.5

-.5

-1 -1.5 -2

-1 -1.5 -2

-2.5 -3

-2.5 -3

-3.5 -4 -4.5

-3.5 -4 -4.5

A ,B ,C ,D A ,B ,C ,D

14) Select the beam(s) to be changed.

1.5 1 .5 0 -.5 -1 -1.5 15) Enter the appropriate number (added or subtracted) to or

from the existing number to bring the corrected position

white spaces into the 0 position.

16) After you have entered the desired number, select OK to

save the changes.

17) Print three Alternate Print Samples and check the

alignment of the groups of marks again. If they are not

exactly in the 0 position, you can change the offset

Correct Not Correct adjustment in 1/10-pel increments to get the alignment

NWTM1055

exact.

1

Chapter 2. Diagnostics 1522

Table 247. AOM Skew Adjustment (continued)

Attention: Failure to have all beams correctly aligned will

4

3

2

4

3

2

result in banding, which is the appearance of scan direction light

4

4

C heckerboards C heckerboards

3.5

3.5

4 3 4 3

3

3

2 1 2 1

2.5

2.5

1 Pel 2 Pel 3 Pel 4 Pel 6 Pel 1 Pel 2 Pel 3 Pel 4 Pel 6 Pel

and dark bands or streaks.

2

2

1.5

1.5

6 4 3 2 1-1 1-2 1-3 1-4 1-5 6 4 3 2 1-1 1-2 1-3 1-4 1-5

1

1

1

1

2

2

.5

.5

5

4

3

2

1

5

4

3

2

1

3

3

4

4

0

0

1 2 3 4 6 1 2 3 4 6

6

6

-.5

-.5

18) Repeat steps 10 through 17 for the second printer if this is

6

6

-1 -1.5 -2 -2.5

-1 -1.5 -2 -2.5

4

4

H

H

3

3

5

4

3

2

1

5

4

3

2

1

2

2

a duplex system.

1

1

V

V

-3 -3.5 -4 -4.5

-3 -3.5 -4 -4.5

1 1

19) Go to PQE Stroke Width.

Side O ne

Side O ne

85 LPI 106 LPI

4 Front

3

2

4

3

2

4

4

3.5

3.5

3

3

2.5

2.5

2

2

1.5

1.5

1

1

.5

.5

0

0

-.5

-.5

-1 -1.5 -2

-1 -1.5 -2

-2.5 -3

-2.5 -3

-3.5 -4 -4.5

-3.5 -4 -4.5

A ,B ,C ,D A ,B ,C ,D

1.5 1 .5 0 -.5 -1 -1.5

Correct Not Correct

NWTM1055

Chapter 2. Diagnostics 1523

Horizontal High and Low Adjustment

100% Boldness extremes Sample 0% Boldness extremes Sample

ALTERNATE PRINT SAMPLE V2.2 ALTERNATE PRINT SAMPLE V2.2

A A

B B

-3 -2 -1 0 1 2 3 -3 -2 -1 0 1 2 3

NWTS2001

NWTS2002

A

A

Horizontal Vertical Horizontal

Vertical

High High Low Low

B B

Chapter 2. Diagnostics 1524

Frequent Printer

This procedure assumes that the printhead is correctly aligned.

Forms Maintenance Logon...

Tasks Definition See Printhead Checks and Adjustments.

Print Quality Printer2 Printer1 1) Power-on the printer.

1 1

1 2 3 4 5 6 7 Contrast 1 2 3 4 5 6 7

2) Load 18-inch wide paper into the printer. This makes it easier

Printer

0 0 to observe the boldness extremes test prints in the printer.

Boldness

A 0 20 40 60 80 100 A A 0 20 40 60 80 100 A

Attachments 0 0

3) Logon as Service.

Preheat

0 20 40 60 80 100

temperature 0 20 40 60 80 100

4) Load the Snapshot IBM - 2 Up Letter.

0 0

Pre/Post Processing Fuser

0 20 40 60 80 100 temperature 0 20 40 60 80 100

5) Select the Printer number.

Remote 0 0

Access 0 20 40 60 80 100 Oil rate 0 20 40 60 80 100 6) Select the Printer Definition tab on the main touchscreen

0 0 window.

Oil belt

Features 0 20 40 60 80 100 0 20 40 60 80 100

Use backup

7) Set the Contrast to 7.

Default idler roll Default

8) Select the PQE Adjustments button.

Beam Adj. PQE Adj. Examples: Medium (20#) OK Cancel Help

AV1M0010

Preventative

Error Log

Maintenance