Академический Документы

Профессиональный Документы

Культура Документы

HKD Push-In Anchor: Mean Ultimate Resistance

Загружено:

Frankie ChanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HKD Push-In Anchor: Mean Ultimate Resistance

Загружено:

Frankie ChanАвторское право:

Доступные форматы

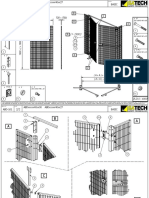

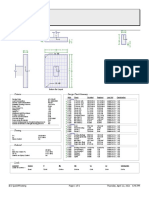

HKD | Push-in anchor HKD | Push-in anchor

HKD Push-in anchor Mean Ultimate Resistance

(5/16”x30)

Anchor size

M10x40

M12x50

M16x65

M20x80

(1/4”x25)

(3/8”x40)

(1/2”x50)

(5/8”x65)

M6x25

M8x30

Anchor version Benefits

HKD - simple and well proven

Carbon steel - approved, tested and confirmed Tensile NRu,m

with lip by everyday jobsite experience HKD [kN] 8,4 11,0 17,0 23,8 32,9 48,1

- reliable setting thanks to simple HKD-SR, HKD-ER [kN] 8,2 10,8 16,6 23,3 34,5 47,1

visual check

HKD-SR Shear VRu,m

- versatile

stainless steel

- for medium-duty fastening with HKD [kN] 5,5 9,4 12,2 20,1 37,1 53,9

with lip

bolts or threaded rods HKD-SR, HKD-ER [kN] 8,3 10,9 13,7 24,3 41,7 66,3

- available in various materials and

HKD-ER

sizes for maximized coverage of

stainless steel

possible applications

without lip

Characteristic Resistance

(5/16”x30)

Anchor size

M10x40

M12x50

M16x65

M20x80

(1/4”x25)

(3/8”x40)

(1/2”x50)

(5/8”x65)

M6x25

M8x30

Tensile NRk

HKD [kN] 6,3 8,3 12,8 17,8 26,4 36,1

Page 6

HKD-SR, HKD-ER [kN] 6,3 8,3 12,8 17,8 26,4 36,1

Shear VRk

European Hilti anchor HKD [kN] 5,0 8,6 11,0 18,3 33,8 49,0

Corrosion CE Fire

Concrete Technical design

resistance conformity resistance HKD-SR, HKD-ER [kN] 6,2 8,4 10,5 18,7 32,1 51,0

Approval software

Approvals / certificates Design Resistance

(5/16”x30)

Anchor size

M10x40

M12x50

M16x65

M20x80

(1/4”x25)

(3/8”x40)

(1/2”x50)

(5/8”x65)

Description Authority / Laboratory No. / date of issue

M6x25

M8x30

ETA-02/0032 / 2010-04-22

a)

European technical approval DIBt, Berlin ETA-06/0047 / 2010-04-22

Refer HKD (Redundant)

Tensile NRd

HKD [kN] 4,2 5,5 8,5 11,9 17,6 24,0

HKD-SR, HKD-ER [kN] 3,0 4,6 7,1 9,9 17,6 24,0

Shear VRd

Basic loading data (for a single anchor) HKD [kN] 4,0 6,9 8,8 14,6 27,0 39,4

All data in this section applies to For details see Simplified design method HKD-SR, HKD-ER [kN] 4,1 5,5 6,9 12,3 21,1 33,6

- Correct setting (See setting instruction)

- No edge distance and spacing influence

- Concrete as specified in the table

- Steel failure

- Minimum base material thickness

- Concrete C 20/25, fck,cube = 25 N/mm²

- screw or rod with steel grade 5.8 (carbon steel) and/or A4-70 (stainless steel)

May 2013

174 2 / 2011 2 / 2011 175

HKD | Push-in anchor HKD | Push-in anchor

Recommended load Material quality

Part Material

(5/16”x30)

Anchor size

M10x40

M12x50

M16x65

M20x80

(1/4”x25)

(3/8”x40)

(1/2”x50)

(5/8”x65)

M6x25

M8x30

HKD Steel Fe/Zn5 galvanised to min. 5 μm

Anchor Body

HKD-SR

Tensile Nrec

a) Stainless steel, 1.4401, 1.4404, 1.4571

HKD-ER

HKD [kN] 2,1 2,8 4,3 5,9 8,8 12,0

HKD Steel material

HKD-SR, HKD-ER [kN] 2,1 2,8 4,3 5,9 8,8 12,0 Tapered expansion

a) plug HKD-SR

Shear Vrec Stainless steel, 1.4401, 1.4404, 1.4571

HKD-ER

HKD [kN] 1,7 2,9 3,7 6,1 11,3 16,3

HKD-SR, HKD-ER [kN] 2,1 2,8 3,5 6,2 10,7 17,0 Anchor size

a) With overall global safety factor J = 3. The recommended loads vary according to the safety factor requirement Anchor version

(5/16“ x 30)

(3/8“ x 40)

(1/2“ x 50)

(5/8“ x 65)

(1/4“ x 25)

M10x40

M12x50

M16x65

M20x80

HKD

M6x25

M8x30

from national regulations.

HKD-SR

HKD-ER

Materials Effective

hef [mm] 25 30 40 50 60 80

Mechanical properties of HKD, HKD-SR and HKD-ER anchorage depth

Anchor size M6 M8 M10 M12 M16 M20 Anchor diameter d1 [mm] 7,9 9,95 11,95 14,9 19,75 24,75

Nominal HKD [N/mm²] 570 570 570 570 640 590 Plug diameter d2 [mm] 5,1 6,5 8,2 10,3 13,8 16,4

tensile

Page 7

strength fuk HKD-SR

[N/mm²] 540 540 540 540 - 540 Plug length l1 [mm] 10 12 16 20 29 30

HKD-ER

HKD [N/mm²] 460 460 460 480 510 470

Yield Anchor body

strength fyk HKD-SR

[N/mm²] 355 355 355 355 - 355

HKD-ER

Stressed HKD [mm²] 20,7 26,7 32,7 60,1 105 167

cross-

section As HKD-S (R)

[mm²] 20,9 26,1 28,8 58,7 - 163

HKD-E (R)

Moment of HKD [mm³] 32,3 54,6 82,9 184 431 850

resistance

W HKD-S (R)

[mm³] 50 79 110 264 602 1191

HKD-E (R)

Char. With 5.8 Gr.

[Nm] 7,6 18,7 37,4 65,5 167 325

bending Steel

resistance HKD-SR

for rod or HKD-ER with [Nm] 11 26 52 92 187 454

0

bolt M Rk,s A4-70

Expansions plugs

ød2

ød2

l1

May 2013

l1

176 2 / 2011 2 / 2011 177

HKD | Push-in anchor HKD | Push-in anchor

Setting Setting details: depth of drill hole h1 and effective anchorage depth hef

Installation equipment

Anchor size

(5/16”x30)

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

M6x25

M8x30

Rotary hammer TE 2 – TE 16 TE 40 – 80

Machine setting

HSD-M

tool 6x25/30 8x25/30 10x40 12x25 16x65 20x80

Hand Setting tool HSD-G

Other tools hammer, torque wrench, blow out pump

Setting instruction

Anchor size

(5/16”x30)

M10x40

M16x65

M20x80

M12x50

(1/4”x25)

(3/8”x40)

(1/2”x50)

(5/8”x65)

M6x25

M8x30

Nominal diameter of

do [mm] 8 10 12 15/16* 20 25

drill bit

Cutting diameter of

dcut ≤ [mm] 8,45 10,5 12,5 15,5/16,5* 20,5 25,5

Page 8

drill bit

Depth of drill hole h1 ≥ [mm] 27 33 43 54 70 85

ls,min [mm] 6 8 10 12 16 20

Screwing depth

ls,max [mm] 12 14,5 18 22 30,5 42

Diameter of clearance

df ≤ [mm] 7 9 12 14 18 22

hole in the fixture

Effective anchorage

hef [mm] 25 30 40 50 65 80

depth

Max. torque moment Tinst [Nm] 4 8 15 35 60 120

* Drill bit diameter for HKD ½” x 50 is 16 mm, for HKD M12x 50 is 15mm

For detailed information on installation see instruction for use given with the package of the product.

For technical data for anchors in diamond drilled holes please contact the Hilti Technical advisory service.

May 2013

178 2 / 2011 2 / 2011 179

HKD | Push-in anchor HKD | Push-in anchor

Base material thickness, anchor spacing and edge distances Simplified design method

Anchor size M6x25 M10x30 M10x40 M12x50 M16x65 M20x80

(1/4”x25) (5/16”x30) (3/8”x40) (1/2”x50) (5/8”x30) Simplified version of the design method according ETAG 001, Annex C. Design resistance

Minimum base

according data given in ETA-02/0032, issue 2010-04-22.

material thickness

hmin [mm] 100 100 100 100 130 160 Influence of concrete strength

Influence of edge distance

Minimum spacing smin [mm] Influence of spacing

and minimum edge 60 60 80 125 130 160

distance Valid for a group of two anchors. (The method may also be applied for anchor groups

cmin [mm] with more than two anchors or more than one edge. The influencing factors must then be

HKD-SR 88 105 140 175 230 280

HKD-ER considered for each edge distance and spacing. The calculated design loads are then on

the save side: They will be lower than the exact values according ETAG 001, Annex C.

smin [mm] 80 60 80 125 130 160

Minimum spacing To avoid this, it is recommended to use the anchor design software PROFIS anchor)

HKD

for c≥ [mm] 140 105 140 175 230 280 The design method is based on the following simplification:

No different loads are acting on individual anchors (no eccentricity)

Minimum edge cmin [mm] 100 80 140 175 230 280 The values are valid for one anchor.

distance

HKD for s≥ [mm] 150 120 80 125 130 160 For more complex fastening applications please use the anchor design software PROFIS Anchor.

Critical spacing and

edge distance for scr,N [mm] 80 90 120 150 200 240

concrete cone failure

Tension loading

HKD

Page 9

ccr,N [mm] 40 45 60 75 100 120

HKD-SR The design tensile resistance is the lower value of

HKD-ER

- Steel resistance: NRd,s

scr,sp [mm] 200 210 280 350 455 560

fB

0

Critical - Concrete pull-out resistance: NRd,p = N Rd,p

spacing HKD

Rd,c fB f1,N f2,N f3,N fre,N

0

and edge ccr,sp [mm] 100 105 140 175 227 280 - Concrete cone resistance: NRd,c = N

distance - Concrete splitting resistance (only non-cracked concrete):

NRd,sp = N Rd,c fB f1,sp f2,sp f3,sp f h,sp fre,N

for splitting 0

scr,sp [mm] 176 210 280 350 455 560

failure HKD-SR

HKD-ER

ccr,sp [mm] 88 105 140 175 227 280

Basic design tensile resistance

Design steel resistance NRd,s for HKD Steel Grade 5.8 and for HKD-ER/SR A4-70

Anchor size

(5/16”x30)

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

M6x25

M8x30

HKD [kN] 6,7 11,4 14,7 24,4 45,0 65,3

NRd,s

For spacing (edge distance) smaller than critical spacing (critical edge distance) the design loads have to be HKD-SR,

reduced. [kN] 6,9 9,2 11,5 20,4 35,1 55,7

HKD-ER

May 2013

180 2 / 2011 2 / 2011 181

HKD | Push-in anchor HKD | Push-in anchor

Design pull-out resistance NRd,p = N0Rd,p · fB Influence of anchor spacing a)

s/scr,N

(5/16”x30)

Anchor size

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

M6x25

M8x30

s/scr,sp

f3,N = 0,5(1 + s/scr,N) ≤ 1

0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1

HKD [kN] - - - - - - f3,sp = 0,5(1 + s/scr,sp) ≤ 1

N

0

Rd,p

a) The anchor spacing shall not be smaller than the minimum anchor spacing s min given in the table with the

HKD-SR, setting details. This influencing factor must be considered for every anchor spacing.

[kN] - - - - - -

HKD-ER

Influence of base material thickness

Design concrete cone resistance NRd,c = N0Rd,c fB f1,N f2,N f3,N fre,N h/hef 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 3,6 ≥ 3,68

Design splitting resistancea) NRd,sp = N0Rd,c fB f1,sp f2,sp f3,sp fh,sp fre, f h,sp = [h/(2hef)]2/3 1 1,07 1,13 1,19 1,25 1,31 1,37 1,42 1,48 1,5

Anchor size

(5/16”x30)

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

Influence of reinforcement

M6x25

M8x30

(5/16”x30)

Anchor size

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

M6x25

M8x30

0

N Rd,c HKD [kN] 4,2 5,5 8,5 11,9 17,6 24,0

a) a) a) a) a) a)

HKD-SR, fre,N = 0,5 + hef/200mm ≤ 1 0,63 0,65 0,7 0,75 0,83 0,9

[kN] 3,0 4,6 7,1 9,9 17,6 24,0 a) This factor applies only for dense reinforcement. If in the area of anchorage there is reinforcement with a

HKD-ER

spacing ≥ 150 mm (any diameter) or with a diameter ≤ 10 mm and a spacing ≥ 100 mm, then a factor fre,N = 1

a) Splitting resistance must only be considered for non-cracked concrete

may be applied.

Page 10

Influencing factors Shear loading

Influence of concrete strength

Concrete strength designation

The design shear resistance is the lower value of

C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 C 50/60

(ENV 206) - Steel resistance: VRd,s

1/2 a) b)

fB = (fck,cube/25N/mm²) 1 1,1 1,22 1,34 1,41 1,48 1,55 fB f1,N f2,N f3,N fre,N

0

- Concrete pryout resistance: VRd,cp = V Rd,cp

a) fck,cube = concrete compressive strength, measured on cubes with 150 mm side length

fB fß f h f4

0

b) For design data of fck,cube = 15 and 20, please contact Hilti Technical Advisory Service - Concrete edge resistance: VRd,c = V Rd,c

Influence of edge distance a)

c/ccr,N

0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1

c/ccr,sp Basic design shear resistance

f1,N = 0,7 + 0,3c/ccr,N ≤ 1

0,73 0,76 0,79 0,82 0,85 0,88 0,91 0,94 0,97 1 Design steel resistance VRd,s for HKD Steel Grade 5.8 and for HKD-ER/SR A4-70

f1,sp = 0,7 + 0,3c/ccr,sp ≤ 1

Anchor size

(5/16”x30)

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

0,5(1 + c/ccr,N) ≤ 1

M6x25

M8x30

f2,N =

0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1

f2,sp = 0,5(1 + c/ccr,sp) ≤ 1

a) The edge distance shall not be smaller than the minimum edge distance c min given in the table with the setting

details. These influencing factors must be considered for every edge distance. HKD [kN] 4,0 6,9 8,8 14,6 27,0 39,6

VRd,s HKD-SR,

[kN] 4,1 5,5 6,9 12,3 21,1 33,6

HKD-ER

May 2013

Design concrete pryout resistance VRd,cp = V0Rd,cp fB f1,N f2,N f3,N fre,N

182 2 / 2011 2 / 2011 183

HKD | Push-in anchor HKD | Push-in anchor

Anchor size Influence of reinforcement

(5/16”x30)

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

M6x25

M8x30

Anchor size

(5/16”x30)

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

M6x25

M8x30

HKD [kN] 4,2 11,0 17,0 23,8 35,2 48,1

a) a) a) a) a) a)

V

0 fre,N = 0,5 + hef/200mm ≤ 1 0,63 0,65 0,7 0,75 0,83 0,9

Rd,cp

HKD-SR, a) This factor applies only for dense reinforcement. If in the area of anchorage there is reinforcement with a

[kN] 4,2 11,0 17,0 23,8 35,2 48,1

HKD-ER spacing ≥ 150 mm (any diameter) or with a diameter ≤ 10 mm and a spacing ≥ 100 mm, then a factor fre,N = 1

may be applied.

Design concrete edge resistancea) VRd,c = V0Rd,c fB fß fh f4

Anchor size Influence of angle between load applied and the direction perpendicular to the free edge

(5/16”x30)

M10x40

M12x50

M16x65

M20x80

(3/8”x40)

(1/2”x50)

(5/8”x65)

(1/4”x25)

M6x25

M8x30

Angle ß 0° - 55° 60° 65° 70° 75° 80° 85° 90° - 180°

HKD [kN] 0,9 1,4 2,3 3,7 6,2 8,9 fß 1,00 1,07 1,14 1,23 1,35 1,50 1,71 2,00

0

V Rd,c

HKD-SR,

[kN] 0,9 1,4 2,3 3,7 6,2 9,5

HKD-ER

a) For anchor groups only the anchors close to the edge must be considered

Influence of base material thickness

h/c 0,15 0,3 0,45 0,6 0,75 0,9 1,05 1,2 1,35 ≥ 1,5

Influencing factors fh = {h/(1,5 c)}

2/3

≤1 0,22 0,34 0,45 0,54 0,63 0,71 0,79 0,86 0,93 1,00

Influence of concrete strength Influence of anchor spacing and edge distance a) for concrete edge resistance: f4

Page 11

Concrete strength designation

C 20/25 C 25/30 C 30/37 C 35/45 C 40/50 C 45/55 C 50/60 f4 = (c/hef)1,5 (1 + s / [3 c]) 0,5

(ENV 206)

1/2 a) b) Single Group of two anchors s/hef

fB = (fck,cube/25N/mm²) 1 1,1 1,22 1,34 1,41 1,48 1,55 c/hef

anchor 0.75 1.50 2.25 3.00 3.75 4.50 5.25 6.00 6.75 7.50 8.25 9.00 9.75 10.50 11.25

a) fck,cube = concrete compressive strength, measured on cubes with 150 mm side length 0,50 0,35 0,27 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35 0,35

b) For design data of fck,cube = 15 and 20, please contact Hilti Technical Advisory Service

0,75 0,65 0,43 0,54 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65 0,65

1,00 1,00 0,63 0,75 0,88 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00 1,00

Influence of edge distance a) 1,25 1,40 0,84 0,98 1,12 1,26 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40 1,40

c/ccr,N 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1 1,50 1,84 1,07 1,22 1,38 1,53 1,68 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84 1,84

f1,N = 0,7 + 0,3c/ccr,N ≤ 1 0,73 0,76 0,79 0,82 0,85 0,88 0,91 0,94 0,97 1 1,75 2,32 1,32 1,49 1,65 1,82 1,98 2,15 2,32 2,32 2,32 2,32 2,32 2,32 2,32 2,32 2,32

2,00 2,83 1,59 1,77 1,94 2,12 2,30 2,47 2,65 2,83 2,83 2,83 2,83 2,83 2,83 2,83 2,83

f2,N = 0,5(1 + c/ccr,N) ≤ 1 0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1 2,25 3,38 1,88 2,06 2,25 2,44 2,63 2,81 3,00 3,19 3,38 3,38 3,38 3,38 3,38 3,38 3,38

a) The edge distance shall not be smaller than the minimum edge distance c min given in the table with the setting 2,50 3,95 2,17 2,37 2,57 2,77 2,96 3,16 3,36 3,56 3,76 3,95 3,95 3,95 3,95 3,95 3,95

details. These influencing factors must be considered for every edge distance. 2,75 4,56 2,49 2,69 2,90 3,11 3,32 3,52 3,73 3,94 4,15 4,35 4,56 4,56 4,56 4,56 4,56

3,00 5,20 2,81 3,03 3,25 3,46 3,68 3,90 4,11 4,33 4,55 4,76 4,98 5,20 5,20 5,20 5,20

Influence of anchor spacing a) 3,25 5,86 3,15 3,38 3,61 3,83 4,06 4,28 4,51 4,73 4,96 5,18 5,41 5,63 5,86 5,86 5,86

s/scr,N 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1 3,50 6,55 3,51 3,74 3,98 4,21 4,44 4,68 4,91 5,14 5,38 5,61 5,85 6,08 6,31 6,55 6,55

3,75 7,26 3,87 4,12 4,36 4,60 4,84 5,08 5,33 5,57 5,81 6,05 6,29 6,54 6,78 7,02 7,26

f3,N = 0,5(1 + s/scr,N) ≤ 1 0,55 0,60 0,65 0,70 0,75 0,80 0,85 0,90 0,95 1

4,00 8,00 4,25 4,50 4,75 5,00 5,25 5,50 5,75 6,00 6,25 6,50 6,75 7,00 7,25 7,50 7,75

a) The anchor spacing shall not be smaller than the minimum anchor spacing s min given in the table with the 4,25 8,76 4,64 4,90 5,15 5,41 5,67 5,93 6,18 6,44 6,70 6,96 7,22 7,47 7,73 7,99 8,25

setting details. This influencing factor must be considered for every anchor spacing. 4,50 9,55 5,04 5,30 5,57 5,83 6,10 6,36 6,63 6,89 7,16 7,42 7,69 7,95 8,22 8,49 8,75

4,75 10,35 5,45 5,72 5,99 6,27 6,54 6,81 7,08 7,36 7,63 7,90 8,17 8,45 8,72 8,99 9,26

5,00 11,18 5,87 6,15 6,43 6,71 6,99 7,27 7,55 7,83 8,11 8,39 8,66 8,94 9,22 9,50 9,78

5,25 12,03 6,30 6,59 6,87 7,16 7,45 7,73 8,02 8,31 8,59 8,88 9,17 9,45 9,74 10,02 10,31

5,50 12,90 6,74 7,04 7,33 7,62 7,92 8,21 8,50 8,79 9,09 9,38 9,67 9,97 10,26 10,55 10,85

a) The anchor spacing and the edge distance shall not be smaller than the minimum anchor spacing s min and the

minimum edge distance cmin.

May 2013

Combined tension and shear loading

For combined tension and shear loading see section “Anchor Design”.

184 2 / 2011 2 / 2011 185

Вам также может понравиться

- How to optimize a document title for SEOДокумент1 страницаHow to optimize a document title for SEOJuan PeñaОценок пока нет

- Technical Data Sheet For The HKD Push in Anchor Single Application Technical Information ASSET DOC 2331048Документ7 страницTechnical Data Sheet For The HKD Push in Anchor Single Application Technical Information ASSET DOC 2331048Alex DeschevogОценок пока нет

- Technical Data Sheet For The HKD Push in Anchor Single Application Technical Information ASSET DOC 2331048Документ7 страницTechnical Data Sheet For The HKD Push in Anchor Single Application Technical Information ASSET DOC 2331048Hoa Ly TrắngОценок пока нет

- Whirlpool ADG 689-2 IX Installation InstructionsДокумент20 страницWhirlpool ADG 689-2 IX Installation InstructionsKyriakos AnagnostouОценок пока нет

- CNC Macine DimesionsДокумент1 страницаCNC Macine Dimesionstarek jedidiОценок пока нет

- CNC Macine Dimesions PDFДокумент1 страницаCNC Macine Dimesions PDFnikОценок пока нет

- Elevación Pórtico Eje 1-1: HSS 8"X6"X5/8" HSS 8"X6"X5/8"Документ1 страницаElevación Pórtico Eje 1-1: HSS 8"X6"X5/8" HSS 8"X6"X5/8"bito_12Оценок пока нет

- Vigas 4X2Документ1 страницаVigas 4X2Alfonso LopezОценок пока нет

- PDP02 actualizadoДокумент1 страницаPDP02 actualizadoale348hotmail.comОценок пока нет

- K251 EngДокумент2 страницыK251 EngGeorge CamarisoОценок пока нет

- Second FloorДокумент1 страницаSecond FloorMohamed AboElmagdОценок пока нет

- Ee 01 General Notes Ee 01Документ1 страницаEe 01 General Notes Ee 01Mikko MagtibayОценок пока нет

- Detail of Blackboard: Standard Dpwh-Deped One (1) Storey Unique Workshop BuildingДокумент1 страницаDetail of Blackboard: Standard Dpwh-Deped One (1) Storey Unique Workshop BuildingJun Rey MoralesОценок пока нет

- Outline of Canopy/Balcony Above Steel Grating WalkwayДокумент10 страницOutline of Canopy/Balcony Above Steel Grating WalkwayRaphael212219Оценок пока нет

- Props PDFДокумент13 страницProps PDFxyzhynОценок пока нет

- Ground FloorДокумент1 страницаGround FloorMohamed AboElmagdОценок пока нет

- Sample FormatДокумент7 страницSample FormataksОценок пока нет

- 04 - Cima - Aulas Definitivo-02Документ1 страница04 - Cima - Aulas Definitivo-02Andres CabelloОценок пока нет

- Ground Floor Level and Foundation StructureДокумент1 страницаGround Floor Level and Foundation StructureRicky KhannaОценок пока нет

- Vigas 6X2Документ1 страницаVigas 6X2Alfonso LopezОценок пока нет

- Shop project exploded viewДокумент1 страницаShop project exploded viewadanОценок пока нет

- Es WD Mea BD 1110Документ1 страницаEs WD Mea BD 1110sharoopОценок пока нет

- BP SP106Документ1 страницаBP SP106shashank sharmaОценок пока нет

- SIAT OneWrap-1Документ2 страницыSIAT OneWrap-1Novan Aprlio KomponistОценок пока нет

- Podium Top PlanДокумент1 страницаPodium Top PlansamueljrОценок пока нет

- Roata de Transmisie OLC 45: FOCTI3754-68Документ1 страницаRoata de Transmisie OLC 45: FOCTI3754-68GigelОценок пока нет

- Drawing1 ModelДокумент1 страницаDrawing1 Modelshirishkatkarmidc21Оценок пока нет

- Mould 8-EbookДокумент38 страницMould 8-EbookDarren GanОценок пока нет

- Coffrage RDCДокумент1 страницаCoffrage RDCPatrick AdjeОценок пока нет

- Steel beam connection detailsДокумент1 страницаSteel beam connection detailspaúl quicañoОценок пока нет

- Steel beam connection detailsДокумент1 страницаSteel beam connection detailspaúl quicañoОценок пока нет

- Coffrage Plancher CourantДокумент1 страницаCoffrage Plancher CourantPatrick AdjeОценок пока нет

- Ergotron 33 296 195 Display Lift Stand InstallationДокумент8 страницErgotron 33 296 195 Display Lift Stand InstallationFederico Estrella RosarioОценок пока нет

- Inswing door electromagnetic lock installation guideДокумент1 страницаInswing door electromagnetic lock installation guideBan Darl PonshiОценок пока нет

- BP SP107Документ1 страницаBP SP107shashank sharmaОценок пока нет

- Proyecto Acero - Marco MurilloДокумент1 страницаProyecto Acero - Marco MurilloCriss GomezОценок пока нет

- 2022 03 No51 Install GuideДокумент5 страниц2022 03 No51 Install GuideJuasadf IesafОценок пока нет

- Mep Request Inner Wall Box 1200Mm X 400Mm: Qbic Engineers & Architects Co.,LtdДокумент1 страницаMep Request Inner Wall Box 1200Mm X 400Mm: Qbic Engineers & Architects Co.,LtdChilo InОценок пока нет

- 1F-01 - COMBINE MEP LAYOUT - 1ST FLOOR PLAN-LayoutДокумент2 страницы1F-01 - COMBINE MEP LAYOUT - 1ST FLOOR PLAN-LayoutHuy NguyễnОценок пока нет

- System Cabinet Unpacking InstructionsДокумент2 страницыSystem Cabinet Unpacking InstructionsSaurabhОценок пока нет

- 65' X 65' (EF) + (G+1) - ModelДокумент1 страница65' X 65' (EF) + (G+1) - ModelDinesh KumarОценок пока нет

- Hilti HLV Sleeve AnchorДокумент4 страницыHilti HLV Sleeve AnchorHafizul ZaidanОценок пока нет

- Eave To Slab Detail Valley Gutter Detail Ridge Detail: Scale 1:10Документ1 страницаEave To Slab Detail Valley Gutter Detail Ridge Detail: Scale 1:10Jordan BrownОценок пока нет

- Side Scan: LargeДокумент2 страницыSide Scan: LargeYudo HaryadiОценок пока нет

- Bridge Attachment Hanger Material ListДокумент5 страницBridge Attachment Hanger Material Listthaw kaung mawОценок пока нет

- Optical Splitter LossДокумент2 страницыOptical Splitter Lossave_heartsОценок пока нет

- Alternatif Fasad - Emerald SumbawaДокумент3 страницыAlternatif Fasad - Emerald SumbawaIrvan MaulanaОценок пока нет

- Plancher RDC 1Документ1 страницаPlancher RDC 1OSSINGA ANDY FREDERICОценок пока нет

- SCALE 1: 50: 4) - Flange and Nozzle AssemblyДокумент1 страницаSCALE 1: 50: 4) - Flange and Nozzle AssemblyHarshil TejaniОценок пока нет

- Contact Sheet Reference-Contact SheetДокумент1 страницаContact Sheet Reference-Contact SheetMaitryi ManglaОценок пока нет

- SLD - 5526662Документ1 страницаSLD - 5526662sales.elemechОценок пока нет

- SLDДокумент1 страницаSLDsales.elemechОценок пока нет

- Chosen - Maneskin - Drums Sheet MusicДокумент1 страницаChosen - Maneskin - Drums Sheet MusicGiosueОценок пока нет

- FBM 1024 BLK - ManДокумент4 страницыFBM 1024 BLK - Manibnu adha rezaОценок пока нет

- Safety Technology Sheet and Series DetailsДокумент3 страницыSafety Technology Sheet and Series DetailsAnderson Jesus SilvaОценок пока нет

- Design Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Документ6 страницDesign Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Christian PintoОценок пока нет

- Wall Footing Plan View Rebar CuttingДокумент1 страницаWall Footing Plan View Rebar CuttingJacylou CepedozaОценок пока нет

- EC-1600ZT Machine Layout Drawing: Haas Technical PublicationsДокумент3 страницыEC-1600ZT Machine Layout Drawing: Haas Technical PublicationsCraig WaxОценок пока нет

- AS BUILT PNG PIPING LAYOUT-Layout1Документ1 страницаAS BUILT PNG PIPING LAYOUT-Layout1Aditya MalhotraОценок пока нет

- ASTM Standard For GlassДокумент12 страницASTM Standard For GlassFrankie ChanОценок пока нет

- AIRECweek 2018 The Argentina ReportДокумент38 страницAIRECweek 2018 The Argentina ReportFrankie ChanОценок пока нет

- Details Ytong Blocks EN PDFДокумент71 страницаDetails Ytong Blocks EN PDFsebkahnОценок пока нет

- Beam Deflection FormulaeДокумент2 страницыBeam Deflection Formulae7575757575100% (6)

- Flexible and Rigid Diaphragms PDFДокумент1 страницаFlexible and Rigid Diaphragms PDFFrankie ChanОценок пока нет

- 29-2001 Macao Steelwork Design Code PDFДокумент94 страницы29-2001 Macao Steelwork Design Code PDFFrankie ChanОценок пока нет

- Design Guide On Vibration of FloorДокумент50 страницDesign Guide On Vibration of FloorFrankie ChanОценок пока нет

- AD 391: Guidance on Lateral Torsional Buckling of Rectangular PlatesДокумент1 страницаAD 391: Guidance on Lateral Torsional Buckling of Rectangular PlatesFrankie ChanОценок пока нет

- Signbond® Aluminium Composite Product and Fabrication GuideДокумент9 страницSignbond® Aluminium Composite Product and Fabrication GuideFrankie ChanОценок пока нет

- Details Ytong Blocks EN PDFДокумент71 страницаDetails Ytong Blocks EN PDFsebkahnОценок пока нет

- 29-2001 Macao Steelwork Design CodeДокумент94 страницы29-2001 Macao Steelwork Design CodeFrankie ChanОценок пока нет

- CF249 - Firecut FM-900 PDFДокумент7 страницCF249 - Firecut FM-900 PDFStar HOОценок пока нет

- Design of Pre Stressed ConcreteДокумент76 страницDesign of Pre Stressed ConcreteFrankie ChanОценок пока нет

- 6303A HP Flare Drain DrumДокумент16 страниц6303A HP Flare Drain DrumMohammad MohseniОценок пока нет

- Allcargo Corporate BrochureДокумент12 страницAllcargo Corporate BrochureallinonecargologisticsОценок пока нет

- Conveyor Chain GuideДокумент59 страницConveyor Chain GuideajaykrishnaaОценок пока нет

- QUICK GUIDE ON WRITING PATENT SPECIFICATION v1Документ37 страницQUICK GUIDE ON WRITING PATENT SPECIFICATION v1Muhammad Azuan TukiarОценок пока нет

- 38.11 Cum Total Qty of 4 Nos. Culvests 38.11x4 152.43 CumДокумент14 страниц38.11 Cum Total Qty of 4 Nos. Culvests 38.11x4 152.43 CumMandeep SinghОценок пока нет

- Safety Training Evaluation Form: Instructor RatingДокумент1 страницаSafety Training Evaluation Form: Instructor RatingNate JamesОценок пока нет

- Volume 1 Drafting Design and Presentation StandardsДокумент328 страницVolume 1 Drafting Design and Presentation StandardsAntonio Herrera PérezОценок пока нет

- Friday Night FightsДокумент8 страницFriday Night Fightsapi-629904068Оценок пока нет

- BSC Prospectus 2019-20Документ37 страницBSC Prospectus 2019-20Gaurav VamjaОценок пока нет

- The hyperwall: A multiple display wall for visualizing high-dimensional dataДокумент4 страницыThe hyperwall: A multiple display wall for visualizing high-dimensional dataMahendra PututОценок пока нет

- Project Vision DocumentДокумент5 страницProject Vision DocumentorjuanОценок пока нет

- YEZ-Conical Brake MotorДокумент3 страницыYEZ-Conical Brake MotorMech MallОценок пока нет

- Data Visualization Q&A With Dona Wong, Author of The Wall Street Journal Guide To Information Graphics - Content Science ReviewДокумент14 страницData Visualization Q&A With Dona Wong, Author of The Wall Street Journal Guide To Information Graphics - Content Science ReviewSara GuimarãesОценок пока нет

- Direct Burial Optic Fiber Cable Specification - KSD2019 PDFДокумент5 страницDirect Burial Optic Fiber Cable Specification - KSD2019 PDFjerjyОценок пока нет

- Template Icme 13 PosterДокумент1 страницаTemplate Icme 13 PosterZulma Xiomara Rueda GarciaОценок пока нет

- STS - (3000K 6000K) - H1 Smart Transformer Station Installation GuideДокумент105 страницSTS - (3000K 6000K) - H1 Smart Transformer Station Installation GuideSav SashaОценок пока нет

- GestioIP 3.0 Installation GuideДокумент17 страницGestioIP 3.0 Installation GuidepiterasОценок пока нет

- The Five Generations of Computers: AssignmentДокумент10 страницThe Five Generations of Computers: Assignmentjismon_kjОценок пока нет

- Learning One-to-One - Book ReviewДокумент3 страницыLearning One-to-One - Book Reviewwhistleblower100% (1)

- Rc16-17 Etc Sem-IV, May 19Документ5 страницRc16-17 Etc Sem-IV, May 19Prasad KavthakarОценок пока нет

- Design of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockДокумент10 страницDesign of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockStalynMEcОценок пока нет

- Varco Manual ElevatorДокумент54 страницыVarco Manual ElevatorJohn Jairo Simanca Castillo100% (1)

- Oracle Baseline Security ChecklistДокумент15 страницOracle Baseline Security ChecklistChidi OkerekeОценок пока нет

- Brake Pedals and ValveДокумент4 страницыBrake Pedals and Valveala17Оценок пока нет

- DC Motor Direction Control ReportДокумент6 страницDC Motor Direction Control ReportEngr Farhanullah SarkiОценок пока нет

- Surface Vortices and Pressures in Suction Intakes of Vertical Axial-Flow PumpsДокумент22 страницыSurface Vortices and Pressures in Suction Intakes of Vertical Axial-Flow PumpssauroОценок пока нет

- Raft Foundations - Design & Analysis With A Practical Approach PDFДокумент140 страницRaft Foundations - Design & Analysis With A Practical Approach PDFemmanuel83% (6)

- Daily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFДокумент6 страницDaily DAWN News Vocabulary With Urdu Meaning (05 April 2020) PDFAEO Begowala100% (2)

- Strategic Information Systems Planning: Course OverviewДокумент18 страницStrategic Information Systems Planning: Course OverviewEmmy W. RosyidiОценок пока нет

- Shipping Label GuideДокумент41 страницаShipping Label GuidebriggantiiОценок пока нет