Академический Документы

Профессиональный Документы

Культура Документы

PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production Systems

Загружено:

vassaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production Systems

Загружено:

vassaАвторское право:

Доступные форматы

PC (polycarbonate)

PRODUCTION-GRADE THERMOPLASTIC FOR

FORTUS 3D PRODUCTION SYSTEMS

A true industrial thermoplastic, PC (polycarbonate) is widely used in automotive, aerospace, medical and many other applications.

PC offers accuracy, durability and stability, creating strong parts that withstand functional testing. A PC part manufactured on a

Fortus® 3D Production System is 5 to 60 percent stronger than a part made on previous FDM® systems. It also has superior mechanical

properties to ABS and a number of other thermoplastics. When combined with a Fortus 3D Production System, PC gives you strong parts

for conceptual modeling, functional prototyping, manufacturing tools, and end-use parts. PC runs the Xtend 500 Fortus Plus option, which

enables more than 400 hours of unattended build time.

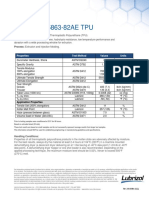

ENGLISH METRIC

MECHANICAL PROPERTIES1 TEST METHOD

XZ A XIS ZX A XIS XZ A XIS ZX A XIS

Tensile Strength, Yield (Type 1, 0.125”, 0.2”/min) ASTM D638 5,800 psi 4,300 psi 40 MPa 30 MPa

Tensile Strength, Ultimate (Type 1, 0.125”, 0.2”/min) ASTM D638 8,300 psi 6,100 psi 57 MPa 42 MPa

Tensile Modulus (Type 1, 0.125”, 0.2”/min) ASTM D638 282,000 psi 284,000 psi 1,944 MPa 1,958 MPa

Tensile Elongation at Break (Type 1, 0.125”, 0.2”/min) ASTM D638 4.8% 2.5% 4.8% 2.5%

Tensile Elongation at Yield (Type 1, 0.125”, 0.2”/min) ASTM D638 2.2% 2% 2.2% 2%

Flexural Strength (Method 1, 0.05”/min) ASTM D790 13,000 psi 9,900 psi 89 MPa 68 MPa

Flexural Modulus (Method 1, 0.05”/min) ASTM D790 291,000 psi 261,000 psi 2,006 MPa 1,800 MPa

Flexural Strain at Break (Method 1, 0.05”/min) ASTM D790 No break 4% No break 4%

IZOD Impact, notched (Method A, 23°C) ASTM D256 1.4 ft-lb/in 0.5 ft-lb/in 73 J/m 28 J/m

IZOD Impact, un-notched (Method A, 23°C) ASTM D256 16.4 ft-lb/in 3.5 ft-lb/in 877 J/m 187 J/m

Compressive Strength, Yield (Method 1, 0.05”/min) ASTM D695 10,000 psi 9,200 psi 69 MPa 64 MPa

Compressive Strength, Ultimate (Method 1, 0.05”/min) ASTM D695 28,000 psi 9,400 psi 193 MPa 65 MPa

Compressive Modulus (Method 1, 0.05”/min) ASTM D695 1,100,000 psi 227,000 psi 7,564 MPa 1,565 MPa

THERMAL PROPERTIES 2 TEST METHOD ENGLISH METRIC

Heat Deflection (HDT) @ 66 psi ASTM D648 280°F 138°C

Heat Deflection (HDT) @ 264 psi ASTM D648 261°F 127°C

Vicat Softening ASTM D1525 282°F 139°C

Glass Transition (Tg) DMA (SSYS) 322°F 161°C

Melting Point --------- Not Applicable 3 Not Applicable 3

S T R ATA S Y S . C O M

THE 3D PRINTING SOLUTIONS COMPANY

PC (polycarbonate)

PRODUCTION-GRADE THERMOPLASTIC FOR

FORTUS 3D PRODUCTION SYSTEMS

At the core: ELECTRICAL PROPERTIES 4 TEST METHOD VALUE RANGE

Advanced FDM Technology

Volume Resistivity ASTM D257 6.0x1013 - 2.0x1014 ohm-cm

Fortus systems are based on

FDM (fused deposition modeling) Dielectric Constant ASTM D150-98 2.8 - 3.0

technology. FDM is the industry’s Dissipation Factor ASTM D150-98 .0005 - .0006

leading additive manufacturing

Dielectric Strength ASTM D149-09, Method A 80 - 360 V/mil

technology, and the only one that uses

production-grade thermoplastics,

OTHER 2 TEST METHOD VALUE

enabling the most durable parts.

Specific Gravity ASTM D792 1.2

Fortus systems use a wide range Flame Classification UL94 HB

of thermoplastics with advanced Coefficient of Thermal Expansion ASTM E831 3.8x10 -05 in/in/°F

mechanical properties so your Rockwell Hardness ASTM D785 R115

parts can endure high heat, caustic UL File Number --------- E345258

chemicals, sterilization and high-

SYSTEM AVAILABILITY LAYER THICKNESS SUPPORT AVAIL ABLE

impact applications.

CAPABILITY STRUCTURE COLORS

Fortus 360mc™ 0.013 inch (0.330 mm) Breakaway, White

No special facilities needed

Fortus 380mc™ Fortus 0.010 inch (0.254 mm) Soluble

You can install a Fortus 3D Production

400mc™ 0.007 inch (0.178 mm)

System just about anywhere. No special

Fortus 450mc™

venting is required because Fortus 0.005 inch (0.127 mm)5

Fortus 900mc™

systems don’t produce noxious fumes,

The information presented are typical values intended for reference and comparison purposes only. They should not be used for design

chemicals or waste. specifications or quality control purposes. End-use material performance can be impacted (+/-) by, but not limited to, part design, end-use

conditions, test conditions, etc. Actual values will vary with build conditions. Tested parts were built on Fortus 400mc @ 0.010” (0.254 mm)

slice. Product specifications are subject to change without notice.

No special skills needed

Fortus 3D Production Systems The performance characteristics of these materials may vary according to application, operating conditions, or end use. Each user is

responsible for determining that the Stratasys material is safe, lawful, and technically suitable for the intended application, as well as for

are easy to operate and maintain identifying the proper disposal (or recycling) method consistent with applicable environmental laws and regulations. Stratasys makes no

compared to other additive fabrication warranties of any kind, express or implied, including, but not limited to, the warranties of merchantability, fitness for a particular use, or

warranty against patent infringement.

systems because there are no messy

1

Build orientation is on side long edge.

powders to handle and contain.

They’re so simple, an operator can be 2

Literature value unless otherwise noted.

trained to operate a Fortus system in 3

Due to amorphous nature, material does not display a melting point.

less than 30 minutes. 4

All Electrical Property values were generated from the average of test plaques built with default part density (solid). Test plaques were

4.0 x 4.0 x 0.1 inches (102 x 102 x 2.5 mm) and were built both in the flat and vertical orientation. The range of values is mostly the result of

Get your benchmark on the the difference in properties of test plaques built in the flat vs. vertical orientation.

future of manufacturing 5

PC can attain 0.005 inch (0.127mm) layer thickness when used with SR-100 soluble support. 0.005 inch layer thickness is not available on

the Fortus 900mc.

Fine details. Smooth surface finishes.

Accuracy. Strength. The best way to Orientation: See Stratasys Testing white paper for more detailed description of build orien tations.

see the advantages of a Fortus 3D

XZ = X or “on edge” Upright (ZX)

Production System is to have your own On-Edge (XZ)

XY = Y or “flat”

part built on a Fortus system. Get your Y

Z Flat (XY)

X

free part at: stratasys.com. ZX = or “upright”

HEADQUARTERS

7665 Commerce Way, Eden Prairie, MN 55344 2 Holtzman St., Science Park, PO Box 2496

+1 888 480-3548 (US Toll Free) Rehovot 76124, Israel

+1 952 937-3000 (Intl) +972 74 745-4000

E info@stratasys.com / STRATASYS.COM +1 952 937-0070 (Fax) +972 74 745-5000 (Fax)

ISO 9001:2008 Certified

©2015 Stratasys Inc. All rights reserved. Stratasys, FDM, Fortus and Finishing Touch are registered trademarks of Stratasys Inc. FDM Technology, Fused Deposition Modeling, Fortus 250mc, Fortus 360mc, Fortus 400mc, Fortus

450mc, Fortus 900mc, Insight, Control Center, FDM Team, Smart Supports, SR-30, SR-100, ABSplus, ABS-ESD7, ABSi and TouchWorks are trademarks of Stratasys, Inc. *ULTEM is a trademark of SABIC Innovative Plastics IP

BV. All other trademarks are the property of their respective owners, and Stratasys assumes no responsibility with regard to the selection, performance, or use of these non-Stratasys products. Product specifications subject to

change without notice. Printed in the USA. MSS_FDM_PC_EN_0815

Вам также может понравиться

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionОт EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersДокумент2 страницыPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppОценок пока нет

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsОт EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsОценок пока нет

- Spec Sheet - ABS-M30 ENДокумент2 страницыSpec Sheet - ABS-M30 ENTUSHAR BANGERAОценок пока нет

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersДокумент2 страницыABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSIОценок пока нет

- ULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersДокумент3 страницыULTEM 9085: Production-Grade Thermoplastic For Fortus 3D PrintersRui MatiasОценок пока нет

- Microstructure Evolution in Metal Forming Processes (2012)Документ2 страницыMicrostructure Evolution in Metal Forming Processes (2012)MedSparkОценок пока нет

- PC Abs Spec SheetДокумент2 страницыPC Abs Spec SheetAli YudiОценок пока нет

- ABS-M30: Real Production-Grade ThermoplasticДокумент2 страницыABS-M30: Real Production-Grade ThermoplasticqualityfreekОценок пока нет

- ABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrintersДокумент2 страницыABS-M30i: Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppОценок пока нет

- Absplus-P430: Production-Grade Thermoplastic For 3D PrintersДокумент2 страницыAbsplus-P430: Production-Grade Thermoplastic For 3D PrinterscontrolorОценок пока нет

- Stratasys - MSS FDM ABSplusP430Документ2 страницыStratasys - MSS FDM ABSplusP430feltofsnakeОценок пока нет

- Pc-Iso: Mechanical Properties Test Method ValueДокумент2 страницыPc-Iso: Mechanical Properties Test Method ValuekaledioskoppОценок пока нет

- Polycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricДокумент1 страницаPolycarbonate-ABS Blend (PC-ABS) : Mechanical Properties Test Method Imperial MetricIsabel Narloch CardosoОценок пока нет

- Manufacturing Processes and Materials ExercisesДокумент2 страницыManufacturing Processes and Materials ExercisesMedSparkОценок пока нет

- Sé Etec: ApplicationsДокумент1 страницаSé Etec: ApplicationsMohit MohataОценок пока нет

- Lexan™ 8010 Uncoated Polished Film DatasheetДокумент3 страницыLexan™ 8010 Uncoated Polished Film DatasheetTeng Yan ChanОценок пока нет

- Tds Ecozen t110gДокумент1 страницаTds Ecozen t110galfred quinОценок пока нет

- Um180821 TDS Tpu 95a RB V11Документ3 страницыUm180821 TDS Tpu 95a RB V11Steven DonosoОценок пока нет

- 3 Property R3450 EngДокумент1 страница3 Property R3450 EngMohit MohataОценок пока нет

- LNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetДокумент2 страницыLNP™ THERMOCOMP™ Compound - DX11355 - Global - Technical - Data - SheetYJ WangОценок пока нет

- Propriedades Das Matrizes PolimericasДокумент7 страницPropriedades Das Matrizes PolimericasllepsterlОценок пока нет

- Delrin100 NC10Документ2 страницыDelrin100 NC10avinashchauhan2695Оценок пока нет

- TECASINT 2011 Natural 14Документ1 страницаTECASINT 2011 Natural 14e.montgomeryОценок пока нет

- Pellethane 5863-82AE TPU: Technical Data SheetДокумент2 страницыPellethane 5863-82AE TPU: Technical Data SheetaОценок пока нет

- ABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)Документ1 страницаABS (Acrylonitrile Butadiene Styrene) : Technical Data Sheet (ASTM)hugo santiago chavez godoyОценок пока нет

- TDS Infinam ST 6100 LДокумент5 страницTDS Infinam ST 6100 LKacperОценок пока нет

- Mitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedДокумент2 страницыMitsubishi Chemical Advanced Materials Acetron ® LSG POM-C Copolymer Acetal, Porosity-Free, Unfilled, ExtrudedJuan Orlando Loaiza MurilloОценок пока нет

- Lexan™ Copolymer 943X: Region AmericasДокумент3 страницыLexan™ Copolymer 943X: Region AmericasAdirSchoierОценок пока нет

- CYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetДокумент2 страницыCYCOLOY™ Resin - MC1300 - Americas - Technical - Data - SheetJoseОценок пока нет

- Séetec: ApplicationsДокумент1 страницаSéetec: ApplicationsAdonis BasilioОценок пока нет

- Ensinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Документ2 страницыEnsinger Tecapeek® CF30 Polyetheretherketone, 30% Carbon Reinforced (PEEK)Arthur EmidioОценок пока нет

- UHMW-PE Tivar 1000Документ2 страницыUHMW-PE Tivar 1000centurion2988Оценок пока нет

- 3 Property H1501 EngДокумент1 страница3 Property H1501 EngMohit MohataОценок пока нет

- Powder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialДокумент1 страницаPowder Properties Test Method Alm Pa 650: Nylon 12 Laser Sintering MaterialLuiskar MedinaОценок пока нет

- TDS CPE V3.010-EnДокумент3 страницыTDS CPE V3.010-EnspicefooОценок пока нет

- Product Data SheetДокумент2 страницыProduct Data SheetshahneillОценок пока нет

- Hdi0653u1 Enus AstmДокумент1 страницаHdi0653u1 Enus AstmJonathan GuadarramaОценок пока нет

- LEXAN™ Resin - 123R - Americas - Technical - Data - SheetДокумент2 страницыLEXAN™ Resin - 123R - Americas - Technical - Data - SheetRodrigoMachadoОценок пока нет

- Wanhua PC Injection Moulding 20 Mfi Clarnate A1227Документ2 страницыWanhua PC Injection Moulding 20 Mfi Clarnate A1227lucasОценок пока нет

- DRISCOPLEX 6500 Tubería y AccesoriosДокумент7 страницDRISCOPLEX 6500 Tubería y AccesoriosBrayan CJОценок пока нет

- PBT GF17% DR48-7001Документ2 страницыPBT GF17% DR48-7001pava16230.meОценок пока нет

- NORYL™ Resin - FM3020V - Asia - Technical - Data - SheetДокумент2 страницыNORYL™ Resin - FM3020V - Asia - Technical - Data - SheetRishiОценок пока нет

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetДокумент2 страницыLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroОценок пока нет

- TDS Nylon101Документ2 страницыTDS Nylon101wilderness_666Оценок пока нет

- Braskem Braskem PE GP100ORXP Pead GAS PE100Документ2 страницыBraskem Braskem PE GP100ORXP Pead GAS PE100weimar solizОценок пока нет

- LLDPE-218BJ EditДокумент3 страницыLLDPE-218BJ EditChu ChuОценок пока нет

- Sabic Chile Ptfe Hoja TecnicaДокумент1 страницаSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroОценок пока нет

- 3M Heavy Wall Heat Shrink Tubing ITCSNДокумент4 страницы3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibОценок пока нет

- Filament Specifications Unit ValueДокумент4 страницыFilament Specifications Unit ValueRoberto Gonzalo PelazОценок пока нет

- Tds A1105 en 2017pdfpdfДокумент2 страницыTds A1105 en 2017pdfpdfagungОценок пока нет

- Tecasint 1011 Natural 0Документ1 страницаTecasint 1011 Natural 0Suraj_73Оценок пока нет

- PBT Data SheetДокумент2 страницыPBT Data Sheetabhishek chaudharyОценок пока нет

- TIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsДокумент2 страницыTIVAR® 1000 Natural Virgin UHMW-PE: Physical Properties Metric English CommentsVictor AguirreОценок пока нет

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetДокумент2 страницыCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloОценок пока нет

- Polygomma EPDM Roofing Membrane CatalogueДокумент4 страницыPolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdОценок пока нет

- PE-TIVAR® 88 UHMW-PE - en - USДокумент3 страницыPE-TIVAR® 88 UHMW-PE - en - USAnthony AngОценок пока нет

- SABIC Cycolac MG47FДокумент3 страницыSABIC Cycolac MG47FChu ChuОценок пока нет

- PC-ABS Cycoloy™ C6600Документ2 страницыPC-ABS Cycoloy™ C6600countzeroaslОценок пока нет

- Fluteck P7500 CA v01.19Документ2 страницыFluteck P7500 CA v01.19fprovitaliОценок пока нет

- Appg PDFДокумент2 страницыAppg PDFvassaОценок пока нет

- Flutter Is A Self-Starting, Potentially Destructive VibrationДокумент3 страницыFlutter Is A Self-Starting, Potentially Destructive VibrationvassaОценок пока нет

- Ultimate GD&T Pocket Guide - Bas - Alex KrulikowskiДокумент135 страницUltimate GD&T Pocket Guide - Bas - Alex KrulikowskiKristof MC90% (20)

- Wipro Chennai MarathonДокумент1 страницаWipro Chennai MarathonvassaОценок пока нет

- Deep Opacity Maps - Yuksel, Keyser - SlidesДокумент33 страницыDeep Opacity Maps - Yuksel, Keyser - SlidesvassaОценок пока нет

- Current GF ScheduleДокумент2 страницыCurrent GF SchedulevassaОценок пока нет

- Flow Visualisation TechniquesДокумент33 страницыFlow Visualisation TechniquesvassaОценок пока нет

- ME 5442 Advanced Fluid Dynamics Differential Equations of MotionДокумент5 страницME 5442 Advanced Fluid Dynamics Differential Equations of MotionvassaОценок пока нет

- Journals: - 263, 23rd To 24th Aug 2013. (RECEIVED BEST PAPER Award)Документ1 страницаJournals: - 263, 23rd To 24th Aug 2013. (RECEIVED BEST PAPER Award)vassaОценок пока нет

- Derives 2 DДокумент1 страницаDerives 2 DvassaОценок пока нет

- Laminar Boundary Layers: A. IntroductionДокумент6 страницLaminar Boundary Layers: A. IntroductionvassaОценок пока нет

- Similarity Solutions: A. IntroductionДокумент5 страницSimilarity Solutions: A. IntroductionvassaОценок пока нет

- Diff Eq Motion LTДокумент6 страницDiff Eq Motion LTvassaОценок пока нет

- DiffEqMotion Ann 2Документ1 страницаDiffEqMotion Ann 2vassaОценок пока нет

- CompFlow Ann 2Документ7 страницCompFlow Ann 2vassaОценок пока нет

- CompFlow Ann 1Документ1 страницаCompFlow Ann 1vassaОценок пока нет

- Syllabus For Advanced Fluid Mechanics - ME-5442-01Документ3 страницыSyllabus For Advanced Fluid Mechanics - ME-5442-01vassaОценок пока нет

- Petsc Developers Manual: Argonne National LaboratoryДокумент32 страницыPetsc Developers Manual: Argonne National LaboratoryvassaОценок пока нет

- Homework 5Документ3 страницыHomework 5vassaОценок пока нет

- ManualДокумент241 страницаManualvassaОценок пока нет

- SM 5Документ1 страницаSM 5vassaОценок пока нет

- ABS - P430: Production-Grade Thermoplastic For Design Series 3D PrintersДокумент2 страницыABS - P430: Production-Grade Thermoplastic For Design Series 3D PrintersqualityfreekОценок пока нет

- WaterJet Spec Sheet - English WebДокумент2 страницыWaterJet Spec Sheet - English WebRamnish SharmaОценок пока нет

- Additive ManufacturingДокумент20 страницAdditive Manufacturingjoeborderline100% (1)

- Unit 3Документ36 страницUnit 3akshaymm1616Оценок пока нет

- FDM Systems and Materials Overview - en BrochureДокумент13 страницFDM Systems and Materials Overview - en BrochureShabi HadashОценок пока нет

- Dental Investment Casting White Paper PDFДокумент6 страницDental Investment Casting White Paper PDFJinoop A NОценок пока нет

- Snaker SpoonДокумент3 страницыSnaker SpoonMiguel D HaroОценок пока нет

- History 2014Документ34 страницыHistory 2014Grace De León NopeОценок пока нет

- Vero Material Data SheetДокумент3 страницыVero Material Data SheetsleonОценок пока нет

- 5 Biggest 3D Printing Companies: #1 Stratasys, Ltd. (SSYS)Документ3 страницы5 Biggest 3D Printing Companies: #1 Stratasys, Ltd. (SSYS)Angelica floresОценок пока нет

- Now and Get: Best VTU Student Companion App You Can GetДокумент50 страницNow and Get: Best VTU Student Companion App You Can Getswaroop kenganalОценок пока нет

- FDM MaterialesДокумент3 страницыFDM Materialesmarbett10Оценок пока нет

- StratasysДокумент8 страницStratasysPeitaçaОценок пока нет

- F170 - F270 - F370 User Guide - EnglishДокумент228 страницF170 - F270 - F370 User Guide - EnglishMark PinphongОценок пока нет

- 3 D Printing Inort WriteupДокумент29 страниц3 D Printing Inort WriteupPZОценок пока нет

- Upload 1 Document To Download Upload Your Original Presentations, Research Papers, Class Notes, or Other Documents To Download Embassy Perimeter Improvement Concepts & Design GuidelinesДокумент5 страницUpload 1 Document To Download Upload Your Original Presentations, Research Papers, Class Notes, or Other Documents To Download Embassy Perimeter Improvement Concepts & Design GuidelinesvictorОценок пока нет

- The Invention of FDM TechnologyДокумент2 страницыThe Invention of FDM TechnologyMinciunescu RobertОценок пока нет

- Eb PJ CMF Design 0722aДокумент5 страницEb PJ CMF Design 0722aMihai BuzzОценок пока нет

- ULTEM 1010 Resin: Mechanical Properties Test Method ValueДокумент3 страницыULTEM 1010 Resin: Mechanical Properties Test Method ValueRui MatiasОценок пока нет

- 3D Printing AdvantagesДокумент7 страниц3D Printing AdvantagesionutmbОценок пока нет

- Plagiarism Checker - Free Online Software by EduBirdieДокумент4 страницыPlagiarism Checker - Free Online Software by EduBirdiePulokesh Ghosh0% (2)

- Desktop Engineering 2010-03Документ82 страницыDesktop Engineering 2010-03PerryShopsОценок пока нет

- WP PJD Exocad 0915 WebДокумент7 страницWP PJD Exocad 0915 WebDonghan ChoОценок пока нет

- Fused Deposition Modeling - A Rapid Prototyping Technique For Product Cycle Time Reduction Cost Effectively in Aerospace ApplicationsДокумент7 страницFused Deposition Modeling - A Rapid Prototyping Technique For Product Cycle Time Reduction Cost Effectively in Aerospace ApplicationssaurabhpetheОценок пока нет

- U01-01 Historical ReviewДокумент32 страницыU01-01 Historical ReviewLearn19Оценок пока нет

- 3D Printing of MoldsДокумент43 страницы3D Printing of MoldsPramendra7Оценок пока нет

- Cad2stl SettingsДокумент6 страницCad2stl SettingsvassaОценок пока нет

- Dental Investment Casting White PaperДокумент6 страницDental Investment Casting White PaperJinoop A NОценок пока нет

- Stratasys v. Microboards TechnologyДокумент20 страницStratasys v. Microboards TechnologyPriorSmartОценок пока нет