Академический Документы

Профессиональный Документы

Культура Документы

Site Dumper Prestart Safety Checklist

Загружено:

Musharaf Shah0 оценок0% нашли этот документ полезным (0 голосов)

468 просмотров2 страницыnil

Оригинальное название

Site Dumper 360 Excavator Pre-start Checks

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документnil

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

468 просмотров2 страницыSite Dumper Prestart Safety Checklist

Загружено:

Musharaf Shahnil

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

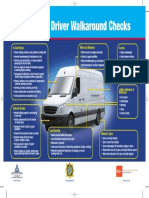

Site Dumper Prestart Checks

External Walkaround Checks Load Security If intended to be used on Public Roads

• Check that the vehicle is level & check for any • Ensure the vehicle is loaded within load limits • Check that all lights & indicators are in place,

visible damage to the machine • Ensure the skip is fully lowered & the load is undamaged, clean & in good working order

distributed evenly & doesn’t block the driver’s i.e. headlights, rear lamps, stop lights &

• Check that tyres are correctly inflated & are number plate lights

not damaged (e.g. no bulges, tears etc.) view of the road ahead

• Ensure registration plate is secure, clean &

• Ensure wheel nuts are in place, correctly fitted clearly visible

& secured • Ensure rear view mirrors are undamaged &

• Remove any obstructions & loose material clean (on dumpers with cabs)

from the accelerator, footbrake & footwell • If the dumper capacity is less than 3m3

( floor ) area ensure you do not travel loaded more than

• Check skip for damage & ensure front skip 1km on a public road to & from the site you

are working on

pins are in place & undamaged

• If the dumper capacity is greater than 3m3

• Check decals in place & legible with a travelling speed capability less than

• Check underneath the vehicle for fluid leaks 55kph ensure you have a Local Authority

• Check hydraulic rams & pipe/hose are in good special permit with you when you travel any

distance with a load on a public road

condition, secured in place & not leaking

• Check the fuel cap & hydraulic cap are in place

& in good condition

• Check when cold: engine oil, coolant, water, Driving Position Checks • Check steering, handbrake & footbrake Roll Over Protection

are working correctly

brake fluid, transmission oil & hydraulic oil for • Ensure seat is properly secured to • Ensure adequate Roll Over

levels & leaks etc machine • Check reversing alarm & flashing Protection (ROPs) is securely in

beacons are in place & in good working place (retrofitted ROPs must be CE

• Check steps & hand holds are in good • Check safety belt(s)are accessible, in order

correct position & working correctly marked to EN:474-6 & BS EN 13510)

condition • Ensure the windows are clean & wipers

• Turn on engine & check all instrument • ROPs with a folding capability (the

• For dumpers with cab ensure suitable mirror(s) working properly (on dumpers with cab) folded position used for limited

gauges & warning lights working

(including convex mirror) are secure & aligned • Operator should wear a high visibility headroom access only in

correctly • Check handles for all hand controls are vest/jacket & safety helmet (on controlled conditions e.g. on a

secure & that controls are working dumpers with no cab) solid level surface) must have the

Note: Always consult with the manufacturers manual and follow all checks required. pins & split keys securely in place

www.hsa.ie www.garda.ie www.rsa.ie

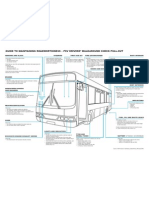

360 Excavator (Tracked) Prestart Checks

External Walkaround Checks In Cab Checks (Running In Cab Checks

• Check for any visible damage • Check ‘Falling Object • Ensure quick hitch Checks) (prior to full ignition)

to the machine Protection’ (FOPs) system is mechanism is free from • Check driving controls are in good • Check safety belt(s) accessible,

• Check track assembly for obstruction & loose working orderCheck all instrument in correct position & working

in good order (where

damage, tightness etc. materials. Ensure quick hitch gauges & warning lights are working correctly

required) springs (manual quick hitch)

Visually check rollers, idlers, • Check/Sound movement alarm & • Check seat is secure and in good

sprockets etc. are in order • Remove any obstructions & are in place & not damaged working condition

ensure it is audible and working

loose materials from • Check all lights are in good correctly • Ensure heater is in good working

• Check underneath machine

accelerator and foot brake order condition

for fluid leaks • Check control lever lock arm (“dead

• Check when cold, engine oil, • Check steps and hand holds • Check reversing camera, man lever”) is operational • Ensure windows are clean, not

are in good condition where fitted, is in place and cracked & wipers are working

coolant, water, brake fluid,

transmission oil and • Ensure check valves are in undamaged • Check/Sound horn & ensure it is

hydraulic oil for levels and place on hydraulic system audible and working correctly

leaks etc. where required • Turn on and check that all lights,

• Check hydraulic rams and including flashing beacons, are

• Check pipes and cables are working

pipe/hose are in good not frayed or broken

condition, secured in place • Check handles for all hand

and not leaking controls are secure and that

controls are working

• Check decals in place and

• Check all mirrors (including

legible

convex mirror) are secured,

• Check the fuel cap and unbroken & aligned correctly

hydraulic cap are in place • Check reversing camera and

and in good condition camera screen, where fitted, are

• Check work attachment working

(bucket, rock breaker etc.) is • Check control lever lock arm

properly secured and correct (“dead man lever”) is in place

pins and clips are securely in and not damaged

place

When used as crane • Ensure the load is not

• Check condition of ground obstructing drivers view

engaging tools i.e. – tips, • Ensure Safe Working Load

information is readily accessible • Ensure a competent

adapters not broken or slinger/signaller used

excessively worn etc. • Ensure the vehicle/ machine is

loaded within limits • Check the overload warning

devices are working correctly

Note: Always consult with the manufacturers manual and follow all checks required. www.hsa.ie

Вам также может понравиться

- HGV Driver Walk-Around Checks PosterДокумент1 страницаHGV Driver Walk-Around Checks PosterPawan SinghОценок пока нет

- Van Driver Walk-Around Checks PosterДокумент1 страницаVan Driver Walk-Around Checks PosterMac MОценок пока нет

- Van and LCV Driver PosterДокумент1 страницаVan and LCV Driver PosterCUNNANE EOINОценок пока нет

- Excavatio Risk AssessmentДокумент6 страницExcavatio Risk AssessmentMohammedSajidОценок пока нет

- Job Description: Area Owner: JSA Control Number: Prepared By: Department/Location: Reviewed By: Date/Time: Approved By: Supervised byДокумент1 страницаJob Description: Area Owner: JSA Control Number: Prepared By: Department/Location: Reviewed By: Date/Time: Approved By: Supervised bybadrul hisyamОценок пока нет

- Driving Commercial Vehicles Manual Class 4 Unrestricted Pre-Trip InspectionДокумент7 страницDriving Commercial Vehicles Manual Class 4 Unrestricted Pre-Trip InspectionjwОценок пока нет

- Grand I10 MaintainanceДокумент10 страницGrand I10 Maintainancerick slyОценок пока нет

- Belt Conveyor RT45-BДокумент2 страницыBelt Conveyor RT45-BMahmoud HanafyОценок пока нет

- Safety Golden Rules PDFДокумент7 страницSafety Golden Rules PDFAnuj RawatОценок пока нет

- Class4 Pre Trip InspectionДокумент3 страницыClass4 Pre Trip Inspection法璋Оценок пока нет

- SWP xWheelLoaderДокумент3 страницыSWP xWheelLoaderReygen SaryowanОценок пока нет

- Hydro Jetting and Sludge RemovalДокумент18 страницHydro Jetting and Sludge Removalmarvin100% (1)

- JHA HDDДокумент2 страницыJHA HDDShubham ShuklaОценок пока нет

- Busduct & Plug inДокумент2 страницыBusduct & Plug in97faithoОценок пока нет

- Excavator Safety Training Slides FINALДокумент40 страницExcavator Safety Training Slides FINALJu Li Tan100% (4)

- 10 - Risk Assessment - PlumpingДокумент7 страниц10 - Risk Assessment - Plumpingmahmoud nada0% (1)

- Civil Construction Safety GuidesДокумент72 страницыCivil Construction Safety GuidesMALAYIL UNNIОценок пока нет

- Excavator SlidesДокумент15 страницExcavator SlidesDaeng KulleОценок пока нет

- JSA for Drain Line ReplacementДокумент5 страницJSA for Drain Line ReplacementMadhan KannanОценок пока нет

- Jsa For Hvac Equipment InstallДокумент4 страницыJsa For Hvac Equipment Installpowergroup engineersОценок пока нет

- Tractor Backhoe Pre-Operation ChecklistДокумент3 страницыTractor Backhoe Pre-Operation Checklistmanny daleonОценок пока нет

- Ehv SWP Form SpaceringДокумент3 страницыEhv SWP Form SpaceringSn AhsanОценок пока нет

- Overhead Crane: Maintenance ProgramДокумент3 страницыOverhead Crane: Maintenance ProgramMuhammad RafiОценок пока нет

- Excavator Instructors NotesДокумент31 страницаExcavator Instructors NotesWALTER EMMANUEL FLORES COSCOОценок пока нет

- Belt Conveyor RFBE-B1800 X 9.7Документ2 страницыBelt Conveyor RFBE-B1800 X 9.7Mahmoud HanafyОценок пока нет

- ChecklistTyres-invulbaar LEAF EN 09-2020Документ2 страницыChecklistTyres-invulbaar LEAF EN 09-2020Melwyn FernandesОценок пока нет

- JSA Any OprationДокумент12 страницJSA Any Oprationn.aboshhewaОценок пока нет

- Risk Assessment - ExcavationДокумент7 страницRisk Assessment - Excavationmahmoud nadaОценок пока нет

- Note Chap 8Документ2 страницыNote Chap 8Nur FarhanahОценок пока нет

- Trailer SopДокумент1 страницаTrailer SopDeepak SahooОценок пока нет

- Excavator Sop PDFДокумент1 страницаExcavator Sop PDFhengky achmadОценок пока нет

- Prepare For Pre-DeliveryДокумент2 страницыPrepare For Pre-DeliveryHazel CompendioОценок пока нет

- Site Safety Standard FOR ALLДокумент2 страницыSite Safety Standard FOR ALLSahin NuriyevОценок пока нет

- Hot Work and Modification PDFДокумент19 страницHot Work and Modification PDFmyo lwinОценок пока нет

- Coating Work PDFДокумент7 страницCoating Work PDFAliОценок пока нет

- JSA For Scaffolding.Документ16 страницJSA For Scaffolding.jeswinimanualОценок пока нет

- 1 Scaffolding Work PDFДокумент16 страниц1 Scaffolding Work PDFfadliОценок пока нет

- Transformer Oil FilterationДокумент3 страницыTransformer Oil FilterationVishnu PradeepОценок пока нет

- Loader/Backhoe Safety ChecklistДокумент14 страницLoader/Backhoe Safety ChecklistNeel VaderaОценок пока нет

- 1M210 11 - MaintenanceДокумент43 страницы1M210 11 - Maintenanceasri novhandiОценок пока нет

- MV, HV LV Transformer Installation SafetyДокумент6 страницMV, HV LV Transformer Installation SafetyKiran Bhatt75% (4)

- Document No. Revision No. Date Compiled: Date of Next Review: SHE/PRO/4.4.6.30 1 September 2016 September 2017Документ3 страницыDocument No. Revision No. Date Compiled: Date of Next Review: SHE/PRO/4.4.6.30 1 September 2016 September 2017victorОценок пока нет

- Dump Truck PPT 1Документ18 страницDump Truck PPT 1Omosigho Osaro100% (1)

- Material Handling Equipment Test Method Rev. 2 (Dood)Документ8 страницMaterial Handling Equipment Test Method Rev. 2 (Dood)ThomasОценок пока нет

- DOCS AND FILES-19128068-v1-DIT Min Const Safety Expectations Second Edition Aug 2022Документ1 страницаDOCS AND FILES-19128068-v1-DIT Min Const Safety Expectations Second Edition Aug 2022Nuragus HariyadiОценок пока нет

- Tata Power Central Odisha Distribution Limited Doc NoДокумент7 страницTata Power Central Odisha Distribution Limited Doc No9853318441Оценок пока нет

- OVERHEAD CRANES - PptsДокумент54 страницыOVERHEAD CRANES - PptsMohammed BaderОценок пока нет

- 22 Rig Audit PDF AlyДокумент10 страниц22 Rig Audit PDF AlyKhaled YazidОценок пока нет

- ESC LSR OverviewДокумент2 страницыESC LSR OverviewAdan CalleОценок пока нет

- JSA For Preparation of Roads and Asphalt WorkДокумент6 страницJSA For Preparation of Roads and Asphalt Workbaseet gazaliОценок пока нет

- Visualized Flight Maneuvers Handbook - Low Wing PDFДокумент10 страницVisualized Flight Maneuvers Handbook - Low Wing PDFpablo0% (1)

- Overhead CranesДокумент50 страницOverhead CraneshamzanusratОценок пока нет

- Safe Work Method StatementДокумент5 страницSafe Work Method StatementShujaRehmanОценок пока нет

- Asphalt Plant Inspection ItemДокумент2 страницыAsphalt Plant Inspection ItemsacsewОценок пока нет

- Encl (4) A-Driver TrainingДокумент93 страницыEncl (4) A-Driver TrainingIhrul FaumuiОценок пока нет

- Presentation On RIG and CRANESДокумент58 страницPresentation On RIG and CRANESSathya NarayanaОценок пока нет

- PSV PulloutДокумент1 страницаPSV PulloutKeenanCoachesОценок пока нет

- Lifting Operation Rev2Документ29 страницLifting Operation Rev2Chong Yun QingОценок пока нет

- BP Life Saving Rules Pocket CardДокумент2 страницыBP Life Saving Rules Pocket CardRoman BabaevОценок пока нет

- Compressed Gases Self-Assessment Checklist 1/8/2019: All Purpose Checklist Page 1 of 4 PagesДокумент4 страницыCompressed Gases Self-Assessment Checklist 1/8/2019: All Purpose Checklist Page 1 of 4 PagesMusharaf ShahОценок пока нет

- Monthly Oxygen/Nitrous Oxide Cylinder Inspection ChecklistДокумент1 страницаMonthly Oxygen/Nitrous Oxide Cylinder Inspection ChecklistMusharaf ShahОценок пока нет

- Anchorage Connector Inspection Form Rev CДокумент1 страницаAnchorage Connector Inspection Form Rev CMusharaf ShahОценок пока нет

- Cis52 PDFДокумент4 страницыCis52 PDFShofwan HilalОценок пока нет

- Ohdq$Jhqw) Luh ( (Wlqjxlvklqj6/Vwhpv: ) 0$Ssurydov$Oouljkwvuhvhuyhg RIДокумент2 страницыOhdq$Jhqw) Luh ( (Wlqjxlvklqj6/Vwhpv: ) 0$Ssurydov$Oouljkwvuhvhuyhg RIMusharaf ShahОценок пока нет

- Ohdq$Jhqw) Luh ( (Wlqjxlvklqj6/Vwhpv: ) 0$Ssurydov$Oouljkwvuhvhuyhg RIДокумент2 страницыOhdq$Jhqw) Luh ( (Wlqjxlvklqj6/Vwhpv: ) 0$Ssurydov$Oouljkwvuhvhuyhg RIMusharaf ShahОценок пока нет

- Compressed Gases Self-Assessment Checklist 1/8/2019: All Purpose Checklist Page 1 of 4 PagesДокумент4 страницыCompressed Gases Self-Assessment Checklist 1/8/2019: All Purpose Checklist Page 1 of 4 PagesMusharaf ShahОценок пока нет

- Retard Chamber PDFДокумент1 страницаRetard Chamber PDFMusharaf ShahОценок пока нет

- Chapter03pp 111115153958 Phpapp01Документ36 страницChapter03pp 111115153958 Phpapp01Musharaf ShahОценок пока нет

- Chapter05pp 111115154010 Phpapp01 PDFДокумент134 страницыChapter05pp 111115154010 Phpapp01 PDFMusharaf ShahОценок пока нет

- Nazar Hussain: ObjectiveДокумент2 страницыNazar Hussain: ObjectiveMusharaf ShahОценок пока нет

- Company OperationsДокумент45 страницCompany OperationsMusharaf ShahОценок пока нет

- Chapter02pp 111117142131 Phpapp02Документ117 страницChapter02pp 111117142131 Phpapp02Musharaf ShahОценок пока нет

- BrochureДокумент4 страницыBrochureJose Antonio Medina GarciaОценок пока нет

- Fire Protection SystemsДокумент107 страницFire Protection SystemsMusharaf ShahОценок пока нет

- Chapter01pp 111115153501 Phpapp02Документ85 страницChapter01pp 111115153501 Phpapp02Musharaf ShahОценок пока нет

- APN0004 Gas Turbines PDFДокумент5 страницAPN0004 Gas Turbines PDFMusharaf ShahОценок пока нет

- CD Training School LahoreДокумент1 страницаCD Training School LahoreMusharaf ShahОценок пока нет

- Power GuillotinesДокумент74 страницыPower GuillotinesMusharaf ShahОценок пока нет

- National Institute of Fire Technology IslamabadДокумент1 страницаNational Institute of Fire Technology IslamabadMusharaf ShahОценок пока нет

- PSLG Principles of Process Safety LeadershipДокумент3 страницыPSLG Principles of Process Safety LeadershipMusharaf ShahОценок пока нет

- Dump Truck SafetyДокумент1 страницаDump Truck SafetyMusharaf ShahОценок пока нет

- Safe Use of Site Dumpers On Construction SitesДокумент4 страницыSafe Use of Site Dumpers On Construction SitesMusharaf ShahОценок пока нет

- Veterinary Medicines: Safe Use by Farmers and Other Animal HandlersДокумент8 страницVeterinary Medicines: Safe Use by Farmers and Other Animal HandlersRamesh BeniwalОценок пока нет

- Cis52 PDFДокумент4 страницыCis52 PDFShofwan HilalОценок пока нет

- Description & Design of Sprinkler SystemsДокумент20 страницDescription & Design of Sprinkler SystemsIrfanshah2013100% (4)

- Board of Certified Safety Professionals ASP9 Blueprint ReferencesДокумент2 страницыBoard of Certified Safety Professionals ASP9 Blueprint ReferencesMusharaf ShahОценок пока нет

- CD Training School Faisalabad PDFДокумент1 страницаCD Training School Faisalabad PDFMusharaf ShahОценок пока нет

- PSM DatasheetДокумент2 страницыPSM DatasheetMusharaf ShahОценок пока нет

- Road Sor Volume - IДокумент59 страницRoad Sor Volume - ISaurabh PednekarОценок пока нет

- CBSE Class X Social Science Sample Paper SolvedДокумент17 страницCBSE Class X Social Science Sample Paper SolvedAnanay ChaudhryОценок пока нет

- Construction Manual - Oct 2014Документ56 страницConstruction Manual - Oct 2014Sakaria JonasОценок пока нет

- MOTOR TRAFFIC (AMENDMENT) Act Sri LankaДокумент111 страницMOTOR TRAFFIC (AMENDMENT) Act Sri LankaramaaramaaОценок пока нет

- Newsletter - October-March2014Документ16 страницNewsletter - October-March2014Devela AvinashОценок пока нет

- Case Studies With Jute Geotextiles JGT in Rural Road ConstructionДокумент17 страницCase Studies With Jute Geotextiles JGT in Rural Road ConstructionasifОценок пока нет

- Hargeisa-Berbera Road Project 1975Документ56 страницHargeisa-Berbera Road Project 1975Garyaqaan Muuse YuusufОценок пока нет

- Safety of Raised Pavement Markers in Freeway Tunnels Based On Driving Behavior - Xialhua Zhao, Yunjie Ju, Haijian Li, Changfen Zhang, Jianming Ma.Документ15 страницSafety of Raised Pavement Markers in Freeway Tunnels Based On Driving Behavior - Xialhua Zhao, Yunjie Ju, Haijian Li, Changfen Zhang, Jianming Ma.TEOH ENG TAT / UPMОценок пока нет

- Risk-Vulnerability Checklist Procedures:: Oplan Ligtas Na PamayananДокумент4 страницыRisk-Vulnerability Checklist Procedures:: Oplan Ligtas Na PamayananAdmin Bataraza Fire Station PalawanОценок пока нет

- Chapter One: What Is Traffic Engineering?Документ8 страницChapter One: What Is Traffic Engineering?Mustafa KhalilОценок пока нет

- 2 - The Indian Roads Congress (IRC)Документ4 страницы2 - The Indian Roads Congress (IRC)Sasikumar ViswanathanОценок пока нет

- Infrastructure: Roads and BridgesДокумент55 страницInfrastructure: Roads and Bridgestitu_1552Оценок пока нет

- Energy Consumption of Asphalt and Reinforced Concrete Pavement Materials and ConstructionДокумент12 страницEnergy Consumption of Asphalt and Reinforced Concrete Pavement Materials and ConstructionValentina Rojas PercyОценок пока нет

- IRC 035-2015-Road Marking PDFДокумент78 страницIRC 035-2015-Road Marking PDFYagnesh DaveОценок пока нет

- Issue 37 Alloa Sites and ProposalsДокумент17 страницIssue 37 Alloa Sites and ProposalsClackmannanshire CouncilОценок пока нет

- Mohd Thiyahuddin, Mohd Thambiratnam, David Gu, Yuantong Gover, RoryДокумент12 страницMohd Thiyahuddin, Mohd Thambiratnam, David Gu, Yuantong Gover, RoryKory SantiagoОценок пока нет

- (WMC-035) MCA Facility Road Improvements - Plan Set 4.6.21Документ23 страницы(WMC-035) MCA Facility Road Improvements - Plan Set 4.6.21Brandon Buffalo EverhartОценок пока нет

- The Important of Traffic SignsДокумент3 страницыThe Important of Traffic Signsshady publicoОценок пока нет

- Managing Traffic Congestion With GIS PDFДокумент10 страницManaging Traffic Congestion With GIS PDFReynaldo AldamarОценок пока нет

- Concrete Pavement Sub-BaseДокумент56 страницConcrete Pavement Sub-BaseAniket Salvi100% (5)

- Production of Pavement Blocks from Plastic WasteДокумент9 страницProduction of Pavement Blocks from Plastic WasteJyoti GaurОценок пока нет

- Design of Flexible PavementsДокумент165 страницDesign of Flexible Pavementskyugu67% (3)

- Canals 25072022Документ44 страницыCanals 25072022Reiger RoyalОценок пока нет

- Session - 1 - Afghan Highway and Street Codes (AHSC) IntroductionДокумент23 страницыSession - 1 - Afghan Highway and Street Codes (AHSC) Introductionahmad jawed siddiqiОценок пока нет

- Sor Ruidp - 2023Документ779 страницSor Ruidp - 2023akhil111Оценок пока нет

- Road Safety Audit A Case Study On NH-65Документ7 страницRoad Safety Audit A Case Study On NH-65aditya gargОценок пока нет

- Civil BoQ Document for 50MW Solar Power PlantДокумент35 страницCivil BoQ Document for 50MW Solar Power PlantRaviraj ThoratОценок пока нет

- Geometric Design Chapter SummaryДокумент90 страницGeometric Design Chapter SummaryANup GhiMire100% (1)

- Road Design: Maitland City Council - Manual of Engineering Standards - Road Design p21Документ19 страницRoad Design: Maitland City Council - Manual of Engineering Standards - Road Design p21inno musiimeОценок пока нет

- Ipc2022 - 87102 A Risk-Based Design Approach For Uncased Pipe Under Roads and RailwaysДокумент10 страницIpc2022 - 87102 A Risk-Based Design Approach For Uncased Pipe Under Roads and RailwaysOswaldo MontenegroОценок пока нет