Академический Документы

Профессиональный Документы

Культура Документы

Cement Grout AAA

Загружено:

abualamalАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cement Grout AAA

Загружено:

abualamalАвторское право:

Доступные форматы

Departmental Materials Specification DMS-4675

DMS-4675

Cementitious Grouts and Mortars for Miscellaneous

Applications

Effective Date: December 2014

1. DESCRIPTION

This Specification governs the pre-qualification procedure, packaging, and material properties of

cementitious grouts and mortars used for miscellaneous applications. These applications include but are not

limited to:

grouting precast member connections,

grouting anchor bolts and dowels,

grouting lateral connectors for prestressed beams,

bearing seat build ups, and

jointing of concrete pipe and box culverts with mortar.

The grouts and mortars governed by this Specification are not suitable for encapsulating post-tensioning

strands. Refer to DMS-4670, “Grouts for Post-Tensioning,” for the material requirements for post-tensioning

grout material.

2. UNITS OF MEASUREMENTS

The values given in parentheses (if provided) are not standard and may not be exact mathematical

conversions. Use each system of units separately. Combining values from the two systems may result in

nonconformance with the standard.

3. MATERIAL PRODUCER LIST

The Materials and Pavements Section of the Construction Division (CST/M&P) maintains the Material

Producer List (MPL) of all materials conforming to the requirements of this Specification. Materials appearing

on the MPL, entitled “Cementitious Grouts and Mortars for Miscellaneous Applications,” require no further

sampling and testing unless deemed necessary by the Project Engineer or CST/M&P.

4. BIDDERS’ AND SUPPLIERS’ REQUIREMENTS

The Department will only purchase or allow on projects those products listed by producer and product code

or designation shown on the MPL.

Use of pre-qualified product does not relieve the Contractor of the responsibility to provide product that

meets this Specification. The Department may inspect or test material at any time and reject any material

that does not meet the specifications.

5. PRE-QUALIFICATION PROCEDURE

5.1. Pre-Qualification Request. Submit a request for evaluation under DMS-4675 to DMS_Prequal@txdot.gov.

Construction Division 1–4 Effective Date: December 2014

Departmental Materials Specification DMS-4675

Include the following information in the request:

company name;

physical and mailing addresses;

contact person, phone number, and email address; and

material type (grout or mortar).

5.2. Pre-Qualification Sample. Submit a minimum 100-lb. sample of grout material or 50-lb. sample of mortar

material to the Texas Department of Transportation, CST/M&P (CP51), 9500 North Lake Creek Parkway,

Austin, TX 78717.

Include the following with the sample:

test report from an independent laboratory audited and inspected by the Cement Concrete Research

Laboratory (CCRL) containing test results and certifying compliance of the material with this

Specification;

manufacturer’s certification and lot number for submitted sample;

manufacturer’s certification that the material contains no added chlorides;

technical data sheets typically accompanying the product with printed instructions for mixing,

application, and shelf life;

current safety data sheet (SDS) that complies with OSHA Hazard Communication Standard

29 CFR 1910.1200; and

list of all possible package quantities and types of packaging.

Submit all materials for pre-qualification at no cost to the Department.

5.3. Evaluation. The Department reserves the right to perform any or all of the tests specified as a check on the

tests reported by the manufacturer. In the case of any variance, the Department's tests will govern.

CST/M&P will notify prospective bidders and suppliers after completion of material evaluation.

5.3.1. Qualification. If approved for Department use, CST/M&P will add the material to the MPL.

To maintain pre-approved status, submit annual notarized certifications stating that the product has not been

altered since it was originally submitted for approval.

Report changes in the composition or in the manufacturing process of any material to CST/M&P. Significant

changes reported by the producer, as determined by the Director of CST/M&P, may require a re-evaluation

of performance. The Department reserves the right to conduct whatever tests it deems necessary to identify

a pre-qualified material and determine if there is a change in the composition, manufacturing process, or

quality that may affect its durability or performance. In case of variance, the Department’s tests will govern.

5.3.2. Failure. Producers not qualified under this Specification may not furnish materials for use on Department

projects.

Producers failing to qualify may submit a request for re-evaluation after 6 months have elapsed from the date

of the original request. CST/M&P may modify this time limit at its discretion. In the request for re-evaluation,

document the cause of the issue and corrective action taken.

The Department normally bears the costs of sampling and testing; however, the producer will bear the costs

associated with materials failing to conform to the requirements of this Specification. The Director of

CST/M&P will assess this cost at the time of testing, and amounts due will be billed to the producer.

5.4. Periodic Evaluation. The Department reserves the right to randomly sample and evaluate pre-qualified

materials for conformance with this Specification and to perform random audits of documentation.

Construction Division 2–4 Effective Date: December 2014

Departmental Materials Specification DMS-4675

Department representatives may sample material from the manufacturing plant, the project site, and the

warehouse.

Failure of materials to comply with the requirements of this Specification as a result of periodic evaluation

may be cause for removal of those materials from the MPL. In case of variance, the Department’s tests will

govern.

5.5. Disqualification. Causes for disqualification and removal from the MPL may include, but are not limited to:

falsification of documentation,

producer fails to report any change in material composition or manufacturing process to CST/M&P,

material fails to meet the requirements of this Specification as a result of periodic evaluation, or

producer has unpaid charges for failing samples.

CST/M&P will remove disqualified producers from the MPL and will not allow submission of material for re-

qualification for 6 months, at the discretion of the Department.

5.6. Re-Qualification. Once the disqualification period established by CST/M&P has elapsed, producers

disqualified and removed from the MPL may begin the re-qualification process by submitting a request in

accordance with Section 5.1, including additional documentation identifying the cause of the problem and

corrective action taken. The re-qualification process will then follow all subsequent Sections of Article 5.

The Department normally bears the costs of sampling and testing; however, the disqualified producer will

bear the costs associated with re-qualification. The Director of CST/M&P will assess this cost at the time of

re-evaluation, and amounts due will be billed to the producer.

6. MATERIAL REQUIREMENTS

Products must not contain metallic formulations or chlorides. Additives to pre-packaged materials are not

allowed.

The material requirements and test methods listed in Tables 1 and 2 are for laboratory testing only. Field

testing may require different tests and/or specimen sizes or geometries.

6.1. Grouts. Pre-packaged grouts must conform to ASTM C 1107 and meet the additional material requirements

stated in Table 1. Where there is conflict between ASTM C 1107 and the requirements listed in Table 1, the

requirements of this Specification govern. Additionally, the Department will only allow extension of a grout

mixture with pea gravel if recommended by the manufacturer.

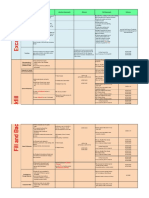

Table 1

Material Requirements of Cementitious Grout

Property Requirement Test Method

Fluidity – efflux time from flow cone 20–30 sec. Tex-437-A, Method 1

Setting time

Initial set 2.5–5.0 hr. ASTM C 191

Final set 4.0–8.0 hr.

Volume change 0.0–0.3% expansion at 24 hr. and 28 days ASTM C 10901

Coefficient of thermal expansion 3.0–10.0 micro strain/°F Tex-428-A

Modulus of elasticity 2,800 ksi–5,000 ksi at 28 days ASTM C 469

3,000 psi at 16 hr. Tex-442-A

3,500 psi at 1 day

Compressive strength (average of 3 cubes), Min

4,000 psi at 3 days

5,800 psi at 28 days

Freeze/thaw resistance 90% at 300 cycles ASTM C 666

1. Modified to include verification at only 24 hr. and 28 days.

Construction Division 3–4 Effective Date: December 2014

Departmental Materials Specification DMS-4675

6.2. Mortars. Pre-packaged mortars used for reinforced concrete pipe joints and bearing seat build-ups must

meet the material requirements stated in Table 2.

Table 2

Material Requirements of Cementitious Mortars

Property Requirement Test Method

Mortars for RC Pipe Joints

Compressive strength (average of 3 cubes), Min 1,800 psi at 28 days ASTM C 109

Mortars for Bearing Seat Build-Ups

3,000 psi at 16 hr.

Compressive strength (average of 3 cubes), Min 3,500 psi at 1 day ASTM C 109

4,500 psi at 28 days

7. PACKAGING AND LABELING

Prepackage grout or mortar in plastic lined or coated bags. Grout or mortar bags must indicate the brand

name, date of manufacture, lot number, and mixing instructions. The grout or mortar supplier must provide

the Contractor and Engineer with a copy of the quality control data sheet for each lot number and shipment

sent to the jobsite.

Construction Division 4–4 Effective Date: December 2014

Вам также может понравиться

- MasterSeal 550Документ38 страницMasterSeal 550Ahmad ElghazolyОценок пока нет

- Effect of Different Sand Grading On Strength Properties of Cement Grout PDFДокумент8 страницEffect of Different Sand Grading On Strength Properties of Cement Grout PDFyoussefОценок пока нет

- Refining Major Projects General ManagementДокумент9 страницRefining Major Projects General ManagementJacarreroОценок пока нет

- IP MS 09 GroutingДокумент4 страницыIP MS 09 GroutingZubair Ahmed KhaskheliОценок пока нет

- Approval of - Concurewb309-As Concrete Curing CompoundДокумент4 страницыApproval of - Concurewb309-As Concrete Curing Compoundsalman tariqОценок пока нет

- Grouting Systems - 620Документ6 страницGrouting Systems - 620arunkumarОценок пока нет

- Conbextra HF - Grout For Tank Gaps PDFДокумент4 страницыConbextra HF - Grout For Tank Gaps PDFEngr.Mohammed KhaledОценок пока нет

- Concure WB309: Water Based Concrete Curing CompoundДокумент2 страницыConcure WB309: Water Based Concrete Curing CompoundtalatzahoorОценок пока нет

- Study On The Durability of Surface Coating Materials For Concrete StructuresДокумент12 страницStudy On The Durability of Surface Coating Materials For Concrete StructuresagustinussetОценок пока нет

- Technical Note TN 01 Cementitious Mortars and Grouts PDFДокумент4 страницыTechnical Note TN 01 Cementitious Mortars and Grouts PDFebetaniaОценок пока нет

- Grout CatalogДокумент36 страницGrout CatalogJohneey DeepОценок пока нет

- Nitomortar FCДокумент3 страницыNitomortar FCBalasubramanian AnanthОценок пока нет

- Structured Method Statement For Concrete Repair - 2Документ10 страницStructured Method Statement For Concrete Repair - 2m.umarОценок пока нет

- PS-32 - Concrete Discharge Time Requirements PDFДокумент1 страницаPS-32 - Concrete Discharge Time Requirements PDFgrahambrasicОценок пока нет

- TDS Fosroc Polyurea WH 200 IndiaДокумент4 страницыTDS Fosroc Polyurea WH 200 Indiaprem prakash mishraОценок пока нет

- Method Statement Floor and Speciality JointsДокумент10 страницMethod Statement Floor and Speciality JointsJamsheed Ap KadangodОценок пока нет

- Polyurea Hot Spray Steel Surfaces Method StatementДокумент9 страницPolyurea Hot Spray Steel Surfaces Method StatementGvsr SunnyОценок пока нет

- Nugrout Hi SpecДокумент2 страницыNugrout Hi SpecPaul RuckОценок пока нет

- 16 - Specification of Work - Part 22Документ161 страница16 - Specification of Work - Part 22Yadunath RavikumarОценок пока нет

- Field CBR Test: Penetration (MM)Документ1 страницаField CBR Test: Penetration (MM)nugraha desainОценок пока нет

- (UJS-CON-E-30029 V0) MS For Concreting WorksДокумент7 страниц(UJS-CON-E-30029 V0) MS For Concreting WorksSiegfred RaccaОценок пока нет

- Certificate of Compliance: Att: Dorat Al TameerДокумент1 страницаCertificate of Compliance: Att: Dorat Al TameerMohammad ArslanОценок пока нет

- GEOTECHNICAL REPORT - Plot 748 - Ghala - Rev 01 PDFДокумент50 страницGEOTECHNICAL REPORT - Plot 748 - Ghala - Rev 01 PDFHazem Badawy100% (1)

- Saes A 114Документ2 страницыSaes A 114Nino Celso AstilleroОценок пока нет

- Model Specification For Protective Coatings For ConcreteДокумент106 страницModel Specification For Protective Coatings For Concretejohn1668Оценок пока нет

- Specifications of Painting WorksДокумент7 страницSpecifications of Painting WorksSiddharth Gamare100% (1)

- Gopinath MuniandyДокумент97 страницGopinath MuniandyatieyaeОценок пока нет

- Concrete Repair Quality ControlДокумент3 страницыConcrete Repair Quality ControlRisath AzeezОценок пока нет

- Fosroc Polyurea FLMДокумент4 страницыFosroc Polyurea FLMtalatzahoorОценок пока нет

- CC030 Assessment and Rehabilitation of Concrete Structure PDFДокумент5 страницCC030 Assessment and Rehabilitation of Concrete Structure PDFGhie CruzОценок пока нет

- Nitomortar TC2000Документ3 страницыNitomortar TC2000talatzahoorОценок пока нет

- Epoxy LiteratureДокумент11 страницEpoxy Literaturepratap naiduОценок пока нет

- Injection SystemДокумент8 страницInjection SystemMohammed Alkhateeb100% (1)

- Shrinkage Compensated Cementitious GroutДокумент3 страницыShrinkage Compensated Cementitious GroutPramod SinghОценок пока нет

- Recron 3S GuideДокумент11 страницRecron 3S GuideJay BhayaniОценок пока нет

- Cold Weather Concrete PDFДокумент4 страницыCold Weather Concrete PDFyanickdouce1206Оценок пока нет

- Epoxy Painting MethodДокумент3 страницыEpoxy Painting MethodKaram MoatasemОценок пока нет

- Lanko Grout 280 Eco BrochureДокумент2 страницыLanko Grout 280 Eco BrochureMrgsrzОценок пока нет

- Honey Comb - Treatment MethodologyДокумент4 страницыHoney Comb - Treatment MethodologyR.ThangarajОценок пока нет

- Superswell 47BДокумент4 страницыSuperswell 47BMuhd Abd MalikОценок пока нет

- CV-0013-005 - Method Statement For Concrete Work (Revised)Документ13 страницCV-0013-005 - Method Statement For Concrete Work (Revised)한상호Оценок пока нет

- Civil Engineering ExaminationДокумент4 страницыCivil Engineering Examinationshardultagalpallewar100% (2)

- Al-Jazeera Firedamp 263Документ2 страницыAl-Jazeera Firedamp 263EngTamer100% (1)

- Method of Statement Template For Marble InstallationДокумент6 страницMethod of Statement Template For Marble InstallationumitОценок пока нет

- 1 MS - Pouring of ConcreteДокумент8 страниц1 MS - Pouring of ConcreteFauzi MastamОценок пока нет

- 1 SATIP-B-006-02 Intumiscent Fireproofing-Rev 1Документ2 страницы1 SATIP-B-006-02 Intumiscent Fireproofing-Rev 1JithuJohnОценок пока нет

- Engineering Properties: Compression Consolidation Shear Strength PermeabilityДокумент19 страницEngineering Properties: Compression Consolidation Shear Strength PermeabilityKiranmayi NethalaОценок пока нет

- Quality Control and Quality AssuranceДокумент7 страницQuality Control and Quality AssuranceMoeen Khan Risaldar100% (1)

- Testing Services (MSML)Документ4 страницыTesting Services (MSML)Nassif Abi AbdallahОценок пока нет

- Post Cast Strip PDFДокумент2 страницыPost Cast Strip PDFKwoshaba PidsonОценок пока нет

- Anti Termite TreatmentДокумент8 страницAnti Termite TreatmentMYTHRI INFRA VIZAGОценок пока нет

- Super Stone Seamless-Epoxy-TDДокумент3 страницыSuper Stone Seamless-Epoxy-TDJoan FosterОценок пока нет

- 33 05 13 Manholes and Structures 10Документ4 страницы33 05 13 Manholes and Structures 10salamОценок пока нет

- Concrete Crack and Partial-Depth Spall RepairДокумент78 страницConcrete Crack and Partial-Depth Spall RepairRafeeq WazirОценок пока нет

- Concrete TestsДокумент2 страницыConcrete TestsdaraweereОценок пока нет

- DMS-4510 Mechanical Couplers For Reinforcing Steel: 1. DescriptionДокумент4 страницыDMS-4510 Mechanical Couplers For Reinforcing Steel: 1. DescriptionKenneth CabacunganОценок пока нет

- TXDOT 6260 Reinforced Fabric Joint Underseal PDFДокумент4 страницыTXDOT 6260 Reinforced Fabric Joint Underseal PDFthadikkaranОценок пока нет

- Supplier Quality Manual-PWSIL - Rev. 01 Dt.20-12-2017Документ21 страницаSupplier Quality Manual-PWSIL - Rev. 01 Dt.20-12-2017ilayaraja MKОценок пока нет

- Txdot DMS-4640 Chemical Admixtures For ConcreteДокумент3 страницыTxdot DMS-4640 Chemical Admixtures For ConcretefiercecatОценок пока нет

- Sop 03Документ29 страницSop 03kamatgauravОценок пока нет

- Simplified Approach For Soil-Spring Stiffness Prediction of Pile GroupДокумент12 страницSimplified Approach For Soil-Spring Stiffness Prediction of Pile Groupabualamal100% (1)

- Shear Area Correction-Direct ShearДокумент1 страницаShear Area Correction-Direct ShearabualamalОценок пока нет

- Thin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesДокумент10 страницThin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesabualamalОценок пока нет

- BS en 13888-2009Документ18 страницBS en 13888-2009abualamal100% (2)

- Megger-DET 5 - 4RДокумент2 страницыMegger-DET 5 - 4RarsenaldoОценок пока нет

- The New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsДокумент10 страницThe New Empirical Formula Based On Dynamic Probing Test Results in Fine Cohesive SoilsabualamalОценок пока нет

- Load Carrying Capacity of PilesДокумент75 страницLoad Carrying Capacity of PilesabualamalОценок пока нет

- قهوة باليورانيومДокумент193 страницыقهوة باليورانيومHazem MohamedОценок пока нет

- Astm C900 06Документ10 страницAstm C900 06abualamalОценок пока нет

- Test Results of Bitumen Content Gradation Determination of Dense Graded Bituminous MacadamДокумент25 страницTest Results of Bitumen Content Gradation Determination of Dense Graded Bituminous MacadamabualamalОценок пока нет

- E1 16Документ30 страницE1 16mitualves100% (1)

- Astm e 100Документ32 страницыAstm e 100abualamalОценок пока нет

- Aggregates FMДокумент5 страницAggregates FMabualamalОценок пока нет

- Nbsbulletinv12n4p469 A2b PDFДокумент10 страницNbsbulletinv12n4p469 A2b PDFAnonymous FmtXlUVyMGОценок пока нет

- BS en 419251-1-2013Документ54 страницыBS en 419251-1-2013abualamalОценок пока нет

- BS en 00477-1999Документ8 страницBS en 00477-1999abualamalОценок пока нет

- BS en 03745-301-2012Документ10 страницBS en 03745-301-2012abualamalОценок пока нет

- BS en Iso 17892-12Документ36 страницBS en Iso 17892-12abualamal80% (5)

- BS en 00003-5-1996Документ18 страницBS en 00003-5-1996abualamalОценок пока нет

- BS en 14602-2012Документ16 страницBS en 14602-2012abualamal100% (1)

- Bearing Capacity and Settlement Response of Raft Foundation PDFДокумент6 страницBearing Capacity and Settlement Response of Raft Foundation PDFabualamalОценок пока нет

- Cement Grout Type FДокумент4 страницыCement Grout Type FabualamalОценок пока нет

- EDR ADR CtalougeДокумент33 страницыEDR ADR CtalougeabualamalОценок пока нет

- Engineering Properties of SoilДокумент6 страницEngineering Properties of Soilpapilolo2008Оценок пока нет

- MarshalДокумент3 страницыMarshalabualamalОценок пока нет

- Asphalt Test Specific GravityДокумент2 страницыAsphalt Test Specific GravityabualamalОценок пока нет

- Wrana 2015 4 PDFДокумент11 страницWrana 2015 4 PDFarslanpasaОценок пока нет

- Estimation of The Coefficient of Permeability in Deep Sedimentary GroundДокумент5 страницEstimation of The Coefficient of Permeability in Deep Sedimentary GroundabualamalОценок пока нет

- Chapter 4 Mix Design MethodДокумент10 страницChapter 4 Mix Design Methodprobook450_ehsanОценок пока нет

- Principles of Heating, Ventilating, and Air Conditioning, 6th EditionДокумент7 страницPrinciples of Heating, Ventilating, and Air Conditioning, 6th EditionerajasОценок пока нет

- On BondsДокумент18 страницOn BondsMahesh Ramteke100% (1)

- Clarkson KGFДокумент8 страницClarkson KGFJorge Castro CucurellaОценок пока нет

- Install A Concealed Conduit Wiring System - A Step by Step GuideДокумент12 страницInstall A Concealed Conduit Wiring System - A Step by Step Guidedirsubdfliq.comОценок пока нет

- Plain and Steel-Laminated Elastomeric Bearings For BridgesДокумент1 страницаPlain and Steel-Laminated Elastomeric Bearings For BridgesMirza SakibОценок пока нет

- Polyurethane Coating Specification Steel PipeДокумент11 страницPolyurethane Coating Specification Steel PipeDaniel Barni HulbertОценок пока нет

- Preventive CareДокумент2 страницыPreventive Careapi-622649284Оценок пока нет

- ASTM For ConcreteДокумент2 страницыASTM For ConcreteJo-anne RiveraОценок пока нет

- Manual de Viviendas de AdobeДокумент36 страницManual de Viviendas de AdobeAnonymous ZOBQd62pОценок пока нет

- 08 - Underpinning Piles of Segmental Precast ConcreteДокумент2 страницы08 - Underpinning Piles of Segmental Precast ConcreteaggibudimanОценок пока нет

- False Ceiling TheoryДокумент54 страницыFalse Ceiling Theorymuktha mukuОценок пока нет

- LintelДокумент5 страницLintelCésar Cortés GutiérrezОценок пока нет

- M157Документ6 страницM157FRANZ RICHARD SARDINAS MALLCOОценок пока нет

- Steel Heat Treatment Handboook Metalluurgy and TechnologiesДокумент850 страницSteel Heat Treatment Handboook Metalluurgy and Technologiestien100% (1)

- AWS SWPS MatrixДокумент12 страницAWS SWPS MatrixMalcolm DiamondОценок пока нет

- Fabrication Comparison TablesДокумент5 страницFabrication Comparison TablesFouzia MangaОценок пока нет

- ASTM Volume 03.05, October 2018 Analytical Chemistry For Metals, Ores, and Related MaterialsДокумент3 страницыASTM Volume 03.05, October 2018 Analytical Chemistry For Metals, Ores, and Related Materialssanthosh dsОценок пока нет

- Advanced Concrete Technology Assignment-1 High Performance ConcreteДокумент12 страницAdvanced Concrete Technology Assignment-1 High Performance Concreteyedida v r aviswanadhОценок пока нет

- Abstract of 05Th Final Bill SR - No. Particulars Amount (RS.) Previous Present TotalДокумент11 страницAbstract of 05Th Final Bill SR - No. Particulars Amount (RS.) Previous Present TotalJay Rupchandani100% (1)

- SS 332-2007+amd 1&2 - Preview PDFДокумент10 страницSS 332-2007+amd 1&2 - Preview PDFEe JoОценок пока нет

- Analisa Cipta Karya 2020 RevisiДокумент122 страницыAnalisa Cipta Karya 2020 RevisiAlfiyaОценок пока нет

- OPS Complete Manual - Vol 2 - Rev 62 - Nov 2022Документ96 страницOPS Complete Manual - Vol 2 - Rev 62 - Nov 2022reza zalmayОценок пока нет

- Commercial Catalog - Kymik Zincalume TanksДокумент6 страницCommercial Catalog - Kymik Zincalume TanksSaptarshi RoyОценок пока нет

- Tapco Pro 3 ManualДокумент16 страницTapco Pro 3 Manualacsscruf33% (3)

- Mechanical Engineering Drawing: SR KaleДокумент22 страницыMechanical Engineering Drawing: SR KaleAdnan RanaОценок пока нет

- DSR 2012 Excel FormatДокумент141 страницаDSR 2012 Excel FormatAkash Goyal50% (2)

- Catalogue Pressure GaugesДокумент50 страницCatalogue Pressure GaugesIra MartianiОценок пока нет

- Effect of Aggregate Size and Gradation o PDFДокумент5 страницEffect of Aggregate Size and Gradation o PDFZain Ali AwanОценок пока нет

- SIGA CLT Cross Laminated Timber GuideДокумент20 страницSIGA CLT Cross Laminated Timber GuideAlberto CumerlatoОценок пока нет

- BDA Free Standing WallsДокумент7 страницBDA Free Standing WallsEnginerdouglasОценок пока нет

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookОт EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookОценок пока нет

- Sodium Bicarbonate: Nature's Unique First Aid RemedyОт EverandSodium Bicarbonate: Nature's Unique First Aid RemedyРейтинг: 5 из 5 звезд5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisОт EverandGuidelines for Chemical Process Quantitative Risk AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookОт EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookОценок пока нет

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesОт EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesОценок пока нет

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Bow Ties in Risk Management: A Concept Book for Process SafetyОт EverandBow Ties in Risk Management: A Concept Book for Process SafetyОценок пока нет

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksОт EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksОценок пока нет

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОт EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОценок пока нет

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlОт EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlРейтинг: 4 из 5 звезд4/5 (4)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Distillation Design and Control Using Aspen SimulationОт EverandDistillation Design and Control Using Aspen SimulationРейтинг: 5 из 5 звезд5/5 (2)

- Understanding Process Equipment for Operators and EngineersОт EverandUnderstanding Process Equipment for Operators and EngineersРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringОт EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillРейтинг: 3.5 из 5 звезд3.5/5 (3)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86От EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Оценок пока нет

- Fundamentals of Risk Management for Process Industry EngineersОт EverandFundamentals of Risk Management for Process Industry EngineersОценок пока нет

- Physical and Chemical Equilibrium for Chemical EngineersОт EverandPhysical and Chemical Equilibrium for Chemical EngineersРейтинг: 5 из 5 звезд5/5 (1)

- Transport Phenomena in Heat and Mass TransferОт EverandTransport Phenomena in Heat and Mass TransferJ.A. ReizesРейтинг: 5 из 5 звезд5/5 (1)