Академический Документы

Профессиональный Документы

Культура Документы

2005 Lim Eurocode3andtheinplanestabilityofportalframes PDF

Загружено:

Olesea NesterencoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2005 Lim Eurocode3andtheinplanestabilityofportalframes PDF

Загружено:

Olesea NesterencoАвторское право:

Доступные форматы

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/242649942

Eurocode 3 and the in-plane stability of portal frames

Article in Structural Engineer · November 2005

CITATIONS READS

6 408

6 authors, including:

James B.P. Lim Vikki Edmondson

University of Auckland Northumbria University

116 PUBLICATIONS 636 CITATIONS 8 PUBLICATIONS 21 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Diaphragms View project

CFST Column Design View project

All content following this page was uploaded by James B.P. Lim on 26 November 2016.

The user has requested enhancement of the downloaded file.

paper: lim et al

Eurocode 3 and the in-plane stability

of portal frames

Synopsis rules, portal frames could continue to be designed plastically, J. B. P. Lim

Simple design rules are proposed that will enable engineers without the need to resort to second-order elastic-plastic analy-

BEng, PhD, CEng,

to take into account in-plane stability when designing single- sis.These rules, however, were later shown to be over-optimistic

MICE

storey steel portal frames plastically to Eurocode 3, without and unreliable for certain types and shapes of frame4, 5. The

The Steel Construction

the need to resort to second-order elastic-plastic analysis rules were subsequently revised in BS 5950-1: 20006 in order

Institute

software. The proposed design rules, developed from the to avoid unsafe designs but this resulted in a reduction in

results of a parametric study of different types of frame, are economy for certain frames.

based on the Merchant-Rankine reduction method and take The forthcoming Eurocode 3 (EC 3)7, will supersede the C. M. King

into account a modest amount of benefit from strain- current national codes of practice. However, unlike BS 5950: BSc, MSc, DIC,

hardening. A simple hand method for estimating the elastic 2000, there are no simple methods given for plastic design of CEng, MIStructE

critical load, required for calculating the Merchant-Rankine portal frames to avoid the need for second-order elastic-plastic The Steel Construction

reduction, is also presented. From the results of the analysis. Institute

parametric study, the proposed design rules place frames into Furthermore, the load combinations prescribed in BS EN

one of two categories: 19908 differ from those in BS 5950-1: 2000. In addition to differ- A. J. Rathbone

• Category A: Regular, symmetric and mono-pitched frames ent partial load factors, the critical load combination for portal

BEng, CEng, FICE

• Category B: Frames that fall outside of Category A but frames designed in accordance to EC3 normally includes a

CSC (UK) Ltd.

excluding tied portals lateral wind load component; under BS 5950-1: 2000, the criti-

For each category of frame, a reduction factor based on the cal load combination for portal frames is usually only vertical

Merchant-Rankine reduction method is proposed. load. For this reason, the BS 5950-1: 2000 design rules concern- J. M. Davies

ing global stability and second-order effects cannot be applied BSc, PhD, DSc,

Notation directly to design in accordance with EC 3. FREng, FIStructE,

E Young’s modulus This paper presents non-contradictory and complementary FICE

G permanent load (dead load in UK practice) information for the plastic design of portal frames in accor- The University of

H horizontal reaction at column base dance with EC 3. The BS EN 1990 load combinations are Manchester

h height of column presented, and the beneficial effect of strain-hardening

HEHF equivalent horizontal force at column top (see Fig 8(c)) explained. A parametric study of different types of frame is V. Edmondson

IR second moment of area of rafters then described. From the results of the parametric study, design

BSc, MEng, CEng,

k strain hardening factor (determined from tests) rules are presented, based on the Merchant-Rankine reduction

MICE

L span of frame method, that will allow the majority of portal frames to be

The University of

NR,ULS axial load in rafter at ULS calculated from first- order designed plastically without the need to resort to second-order

Manchester

plastic analysis (see Fig 8 (b)) elastic-plastic analysis software.

Q variable load (live load in UK practice)

V vertical reaction at column base Reduction in strength due to second-order effects Received: 02/05

VULS factored vertical reaction at ULS calculated from first- Fig. 1(a) shows a simply supported beam under a uniformly Modified: 06/05

order plastic analysis (see Fig 8(b)) distributed load (w). From first-order elastic theory, the central Accepted: 07/05

Keywords: Eurocode 3,

αp1 load factor at plastic collapse in first-order plastic deflection of the beam can be estimated accurately (ignoring

Design, Stability, Portal

analysis shear deflection) from 5wL4/384EI. Fig 1(b) shows the same Frames, Steel, Strength,

αp2 load factor at plastic collapse in second-order elastic- elastic beam under a small additional axial load (P); intuitively, Loads

plastic analysis the effect of such an axial load will be a small increase in the

© J. B. P. Lim, C. M.

αcr elastic critical buckling factor (calculated exactly) central deflection of the beam. However, as the axial load is

King, A. J. Rathbone, J.

αcr,est αcr estimated for the first sway mode increased further, the central deflection of the elastic beam will M. Davies and V.

αcr,H αcr estimated by Horne increase exponentially until failure occurs through instability Edmondson

δEHF horizontal deflection of column top (see Fig 8(c)) due to buckling. The value of the axial load that will cause

γG partial factor for permanent loads failure will depend on the magnitude of the uniformly distrib-

γP partial factor for pre-stressing forces uted load; an upper bound to the value of the axial load will be

γQ partial factor for variable loads the Euler strut buckling load π2EI/L2 (Fig 1(c)).

ξ reduction factor on permanent loads

ψi ‘combination factor’ reducing the ith variable load

Introduction

Single-storey pitched roof steel portal frames are a very econom-

ical and popular form of structure, widely used for industrial

and retail purposes. In the UK, such structures account for

90% of single-storey buildings and about 50% of all the steel

used in construction.

Engineers generally achieve maximum economy in the

design of single-storey steel portal frames through the use of

plastic design. While in BS 4491 the use of plastic design was

permitted by a single clause, the trend towards lighter struc-

tures and more slender members has meant that the more

modern codes of practice have been required to be more rigor-

ous and take into account, amongst other things, in-plane frame Fig 1.

instability. Diagram illustrating

BS 5950: Part 1: 1985 and BS 5950: Part 1: 19902, 3 included sensitivity of axially

rules giving limits of sway stiffness such that global stability loaded beams to

and second-order effects could be ignored. As a result of these second-order effects

1 November 2005 – The Structural Engineer|43

paper: lim et al

Fig 2. small enough to be ignored, they need to be taken into account

Diagram illustrating in design9. The formal method of taking into account the influ-

sensitivity of portal ence of second-order effects on the plastic collapse of steel

frames to second- frames is by means of a second-order elastic-plastic analysis

order effects which traces the successive formation of plastic hinges as the

load is increased. This requires sophisticated software which

may not be necessary in many cases. This paper presents a

greatly simplified method for taking into account second-order

effects in design in accordance with EC 3.

Beneficial effect of strain-hardening

There are two distinct benefits which may arise from the pres-

ence of strain hardening in the formation of a plastic hinge. The

first benefit is that in a region of approximately constant

bending moment, the moment of resistance may rise to up to

8% above the calculated value of the fully plastic moment (Mp)

and then stays approximately constant as the plastic hinge

rotates10.Though beneficial, this effect is conservatively ignored

in the following sections of this paper.

The second benefit is that when a plastic hinge forms in a

region of significant bending moment gradient, it initially forms

at the calculated nominal value of the fully plastic moment

(Mp) and then rises steadily as this hinge rotates during the

elastic-plastic stage of loading to collapse. When conducting a

frame analysis, taking into account the effect of strain-harden-

ing in this way will result in an increased plastic collapse load

of the frame and this helps to offset the reduction in strength

due to second-order effects. It is implicit that this may result in

The above example illustrates that the effect of axial load on a modest increase in the bending moments at some of the

a beam will be to increase deflections (and therefore bending connections, notably at the eaves, and this should be borne in

moments, stresses and strains) beyond those calculated from mind when carrying out the detailed design of these connec-

first-order elastic theory. In order to predict accurately deflec- tions.

tions of axially loaded beams, such as that shown in Fig 1(b), a The relationship between plastic hinge rotation (φ) and

second-order theory, which takes into account the destabilising increased bending moment due to strain hardening (dM) has

effect of axial compressive loads together with finite deflec- been expressed by Davies11, 12 in terms of a numerical strain-

tions, will need to be applied. Axially loaded beams can there- hardening factor (k)

fore be seen to be sensitive to second-order effects, the degree J z N

of sensitivity in the elastic range being dependent on the ratio k = KK O d EI n

dM O h *

of the axial load to the Euler strut buckling load. L P

Fig 2(a) shows the case of a portal frame with members of where

uniform section loaded by a uniformly distributed load (w). φ rotation of the hinge

This load induces both vertical reactions (V) and horizontal dM increase in bending moment above Mp

reactions (H) at the column bases (Fig 2(b)). The ratio H/V is h* length related to the ratio of plastic moment to shear force

dependent on the span-to-height ratio L/h of the frame, and is at the hinge (see Ref 11 and Ref 12 for a more detailed

given by explanation).

H = _ L/h i

2

From the above equation it can be seen that the higher the

V 4 + 6 _ L/h i

value of k, the smaller the increase in moment resistance of the

It can be seen that for a frame having an L/h ratio of one, hinge (dM) due to strain-hardening. The assumed strain-hard-

the horizontal reaction is only one tenth of the vertical reaction. ening factor embodied in design rules is around 10 to 12, as

On the other hand, if the L/h ratio is as large as seven, the hori- exemplified in the BCSA ‘Black Book’ No 2913. This is justified

zontal reaction, and consequently the axial compressive force by a recent study14 utilising numerical integration of stress-

in the rafter, is approximately equal to the vertical reaction. strain data from mill tests which showed that, neglecting any

As a result of the axial forces in the rafters and columns, local or lateral-torsional buckling, for both S275 and S355 steel,

portal frames can be susceptible to in-plane buckling; the first and for a wide range of section sizes, k is close to 10.

and second buckling modes of a portal frame under vertical However, a recent review of test results15 indicates that a

loading are shown in Fig 2(c). Thus, as in the case of axially more realistic value of k in typical I-sections may be about 20.

loaded beams, portal frames are sensitive to second-order Current work by Davies at Manchester12, also indicates that the

effects, the degree of sensitivity in the elastic range being value of k may indeed be greater than 10, the reduced benefit

dependent on the ratio of the applied load to the load which of strain-hardening being attributed to interaction between

causes elastic critical buckling of the frame. local instability of the compression flange at the plastic hinge

It was explained in the introduction that economy in the and lateral torsional buckling of the adjacent member. In the

design of steel portal frames is obtained by using plastic theory. parametric study described in later on in this paper, a value of

However, portal frames designed using first-order plastic theory k of 20 has been adopted.

will not, by definition, take into account second-order effects.

Consequently, first-order plastic theory will tend to overesti- Frame loading

mate the load at which sufficient plastic hinges form in the Load combinations to BS EN1990

frame to give rise to a collapse mechanism. A designer there- In accordance to EC 3, the load combinations for steel structures

fore has to determine whether or not the reduction in load are defined in BS EN 19908 as either

capacity due to second-order effects is small enough to be

ignored. Here, the sensitivity is related to the ratio of elastic crit- !c G, j Gk, j " + " c p P " + " c Q, 1 Qk, 1 " + " !c Q, i }0, i Qk, i

ical buckling load to the plastic collapse load of the frame. If the j $ 1 i > 1

effects are small enough to be ignored, first-order plastic theory ...(eq 6.10)

can be used for design. On the other hand, if the effects are not or the less favourable of the two following expressions

44|The Structural Engineer – 1 November 2005

paper: lim et al

!c G, j Gk, j " + " c p P " + " c Q, 1 }0, 1 Qk, 1 " + " !c Q, i }0, i Qk, i rafters of uniform slope and columns of equal length. Regular

j $ 1 i > 1 multi-span frames have a series of identical spans. The column

(eq 6.10a) bases of all of the frames were taken as pinned. The length and

depth of the eaves haunch were assumed to be span/10 and

!p j c G, j Gk, j " + " c p P " + " c Q, 1 Qk, 1 " + " !c Q, i }0, i Qk, i span/50, respectively; similarly, the length and depth of the

j $ 1 i > 1 apex haunch were assumed to be span/20 and span/75, respec-

(eq 6.10b) tively. A bay spacing of 6m was adopted.

As equations 6.10a and 6.10b will result in lighter loads than

equation 6.10, equations 6.10a and 6.10b were applied in the Member sizing

parametric study. Using the prototype analysis engine each frame was designed,

Using the recommended values of ξ, γG, γQ, ψ0 (slightly differ- and its members sized, taking into account both second-order

ent values may be recommended by the UK National Annex) effects and strain-hardening.As discussed in a previous section,

the following four load combinations (LC) were considered: only load combinations 1 and 2 were considered. When design-

1.15 Dead + 1.50 Live + 0.75 Wind + NHL (LC1) ing each frame, the members were sized so that the critical

1.15 Dead + 0.75 Live + 1.50 Wind + NHL (LC2) second-order elastic-plastic collapse load factor of the frame, αp2,

1.35 Dead + 0.75 Live + 0.75 Wind + NHL (LC3) would be as close to unity as possible without the frame failing.

1.15 Dead + 1.50 Live + NHL (LC4) It should be noted that only in-plane stability was considered,

and not out-of-plane stability of the lengths of frame member

The notional horizontal load (NHL), applied horizontally to the between adjacent purlins and side rails. As universal beam

top of each column, is taken as 0.5% of the factored reaction at section sizes are discrete, obtaining a value of αp2 close to unity

the base of the column, the basic value given in EN 1993-1-1. was not always easy to achieve.

LC1, LC2 and LC3 all include a lateral wind load component.

However, from inspection, it can be seen that LC3 (in which only Analysis results

the dead load component is higher than those of LC1 and LC2) For each of the frames designed, and for each of the two load

will result in the lightest loads. Only LC1 and LC2 were applied

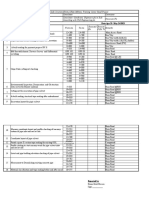

in the parametric study. Table 1: Frames considered as part of parametric study

Load combination 4, comprising only vertical load, has the Frame Number Frame L/h(2) Pitch Description

same partial load factors as LC1. On a long span single-storey of spans category(1)

building, LC4 could be critical as the wind load may result in a 1 1 A 8 -– – 6° Single span

significant uplift, reducing the total vertical load. However, for 2 1 A 5 – – 6° Single span

the purposes of the parametric study, LC4 was ignored because 3 2 A 2 – - 6° Twin span

uplift reduces the compression forces thus reducing second- 4 2 A 5 - - 6° Twin span

order effects. 5 3 A 8 – – 6° Three span

It should be noted that under BS 5950-1: 2000, the critical 6 3 A 5 – - 6° Three span

load combination is usually the vertical load combination: 7 3 A 2 – – 6° Three span

1.4 Dead + 1.6 Live + NHL 8 6 A 5 – – 6° Six span

As explained in the introduction, the presence of the wind 9 1 A 5 – – 30° Steep single span

load (giving lateral loads) in the EC3 load combinations 10 1 B 5 – – 65° Mansard

means that the rules for taking into account second-order 11 1 B 5 – – 60° Pseudo curved

effects in BS 5950: 2000 should not be applied to design in 12 2 B 8 5 – 6° Varied span

accordance to EC 3. 13 3 B 8 5 5 6° Varied span

14 1 B 5 – -– 6° Mezzanine

Dead and live loads 15 2 B 5 – – 6° Mezzanine

In the parametric study, the following dead and live loads were 16 2 B 5 – – 6° Varied height twin span

applied to the frames: 17 3 B 5 5 2 6° Varied height three span

Dead load: 0.15 kN/m2 + self-weight of frame 18 2 B 5 – – 30° Flat-topped

Live load: 0.6 kN/m2 19 1 excluded 5 – – 6° Tied portal

20 2 excluded 5 – – 6° Tied portal

1

Wind load Frame Category defined in ‘Proposed design rules’ section

2

L/h for other spans only given if different from first span

The wind load adopted for the parametric study assumes that

the portal frame will be subject to the average wind speed in the

U.K. of 23.5m/s, but that the portal frame will be situated 0m Table 2: Reduction factor of frames for load combination 1

from the sea. The effect of such a combination is a wind load

Frame αcr,norm αp2/αp1 (αp2/αp1)MR (αp2/αp1)

intensity 40% higher than that of a portal frame designed for

/(αp2/αp1)MR

a wind speed of 23.5m/s and situated 100km from the sea, or

1 5.66 0.96 0.82 1.17

5% higher than that of a portal frame designed for a wind speed 2 7.03 0.95 0.86 1.11

of 24m/s and situated 5km from the sea. 3 6.92 0.88 0.86 1.03

As the portal frames considered in the parametric study will 4 4.18 0.89 0.76 1.17

be subjected to a high wind load intensity, the design rules 5 2.63 0.88 0.62 1.42

proposed can be considered as being conservative. 6 3.49 0.90 0.71 1.26

7 2.76 0.77 0.64 1.21

Parametric study 8 2.11 0.86 0.53 1.63

Parametric studies were conducted using a prototype 9 7.39 0.90 0.86 1.04

analysis engine that can take into account both second- 10 4.84 0.75 0.79 0.95

order effects and strain-hardening, similar to that 11 6.67 0.78 0.85 0.92

described in Reference 16. The geometry and loading were 12 7.67 0.85 0.87 0.98

set up for the analysis using the portal frame design 13 5.48 0.82 0.82 1.00

program CSC Fastrak. In total, 20 frames were analysed as 14 3.75 0.82 0.73 1.12

part of the parametric study, covering a large range of 15 3.54 0.78 0.72 1.09

geometry and types of frame. 16 5.54 0.93 0.82 1.13

17 5.03 0.93 0.80 1.16

Frame geometry 18 5.17 0.88 0.81 1.09

The frames considered as part of the parametric study are 19 1.93 0.57 0.48 1.18

shown in Table 1. Regular frames have symmetrical bays with 20 2.02 0.63 0.50 1.25

1 November 2005 – The Structural Engineer|45

paper: lim et al

Table 3: Reduction factor of frames for load combination 2 Rankine reduction factor to the actual reduction factor

Frame αcr,norm αp2/αp1 (αp2/αp1)MR (αp2/αp1)

(αp2/αp1)MR has also been calculated.

/(αp2/αp1)MR The middle of the three curves shown in Fig 3 is the

1 6.46 0.90 0.85 1.06 Merchant-Rankine reduction factor. The lower of the three

2 8.03 0.93 0.8 1.06 curves corresponds to that of a reduced Merchant-Rankine

3 10.94 0.90 0.91 0.99 defined as

4 5.61 0.84 0.82 1.02 a p2

e a p1 o

a cr - 1

5 3.54 0.73 0.72 1.02 =

1.1a cr

6 4.36 0.80 0.77 1.04 MR, red

7 4.45 0.75 0.78 0.97 The upper of the three curves corresponds to that of an

8 2.64 0.74 0.62 1.19 enhanced Merchant-Rankine defined as

9 9.87 0.94 0.90 1.05

a p2

e a p1 o

10 7.15 0.84 0.86 0.98

a cr - 1

=

0.9a cr

11 9.78 0.89 0.90 0.99 MR, enh

12 7.02 0.94 0.86 1.10 Frames having a reduction factor lower than that predicted

13 5.38 0.87 0.81 1.07 by Merchant-Rankine have been identified in Fig 3.

14 5.28 0.85 0.81 1.05 The design rules proposed later in this paper require use of

15 4.38 0.80 0.77 1.04 both the Merchant-Rankine and the reduced Merchant-

16 8.61 0.90 0.88 1.02 Rankine curves, but not of the enhanced Merchant-Rankine

17 7.69 0.82 0.87 0.94 curve. Nevertheless, the enhanced Merchant-Rankine curve is

18 7.39 0.76 0.86 0.88 shown in all the plots presented in this paper. The enhanced

19 1.11 0.56 0.10 5.65 Merchant-Rankine curve is similar to a curve proposed by

20 2.83 0.60 0.65 0.93

Wood19.Wood intended this curve to be used for frames in multi-

storey buildings, but not for portal frames, when no direct

Fig 3. account is taken of the stiffening effects of the cladding, parti-

Plot showing tions etc. Subsequently, it has appeared in BS 5950 and has

reduction factor for been regarded as some justification for EC 3 allowing first-

all frames order analysis if αcr is at least 10. The results presented in this

paper confirm Wood’s view, based on engineering judgement,

that the enhanced Merchant-Rankine curve is too optimistic for

portal frames.

Discussion of results

Regular single-span and multi-span frames

The results for regular single-span and multi-span frames are

shown in Fig 4.As can be seen, only Frame 7, a three span frame

having an L/h of 2, has a reduction factor 3% lower than that

predicted by Merchant-Rankine.

Previously in this paper it was explained that frames having

combinations, two collapse load factors were determined: a low value of L/h are less susceptible to second-order effects

than frames having a high value of L/h. It may therefore seem

• Second-order elastic-plastic with strain-hardening (αp2) surprising that Frame 7, having an L/h of 2, has a reduction

• First-order plastic (without strain-hardening) (αp1) factor lower than that predicted by Merchant-Rankine while

Frame 6, having an L/h of 8, has a reduction factor higher than

The reduction factor αp2/αp1 was then calculated for each load Fig 4.

combination. Plot showing

In addition, for each frame and load combination, Fastrak reduction factor for

was used to determine the elastic-critical load factor, αcr. A single and multi span

normalised value of the elastic-critical load factor, αcr, norm was frames (Frames 1-9)

calculated from

a

a cr, norm = a pcr2

This normalised value for the elastic-critical load factor corre-

sponds to that of a frame having a value of αp2 of unity. Table 2

and Table 3 show these results for load combinations 1 and 2,

respectively.

Merchant-Rankine

Fig 3 shows the reduction factor αp2/αp1 plotted for each frame

against the normalised elastic critical load factor αcr, norm. The Fig 5.

load combination to which each result corresponds can be iden- Plot showing

tified, as well as whether or not the load combination is criti- reduction factor for

cal. arched frames

Merchant17, 18 proposed that the reduction factor from first- (Frames 10, 11 and

order plastic to second-order elastic-plastic may be related to 18)

a p2

e a p1 o

a cr - 1

= a cr

MR

This expression is analogous to the ‘Rankine’ equation for

predicting the failure load of a pin-ended strut. For this reason,

it is generally known as the ‘Merchant-Rankine’ formula. In

Table 2 and Table 3, the Merchant-Rankine reduction factor

(αp2/αp1)MR has been calculated. The ratio of the Merchant-

46|The Structural Engineer – 1 November 2005

paper: lim et al

Fig 6. tically significant in the design procedure which follows.

Arched frames Frame 18 is a 2-span flat topped frame having a value of L/h

of 5 and a pitch of 30°. A further parametric study was

conducted in which the pitch of the 2-span flat topped frame

was varied between 15° and 45°. The results of this parametric

study are plotted in Fig 7. As can be seen, frames having a pitch

of 30° have the lowest reduction factor αp2/αp1.

From interpolation of the results, if the pitch was approxi-

mately 18° then the value of αp2/αp1 would be equal to that

predicted by Merchant-Rankine. Similarly, if the pitch of the

frame was 25° then the value of αp2/αp1 would be equal to that

predicted by the reduced Merchant-Rankine.

Estimate of αcr

In the previous section, the Merchant-Rankine formula was used

to predict the reduction factor αp2/αp1 from the elastic critical

buckling load acr; the value of αcr was calculated exactly using the

Fastrak software.As the design rules proposed later in the paper

will be based on the Merchant-Rankine formula, a method for

estimating αcr, based on frame deflections, will be required.

Horne20, 21, 22, 23 demonstrated that αcr could be calculated

sufficiently accurately for a for a multi-storey frame from

a cr, H = d h n d H EHF n

Vuls d EHF

The parameters used to calculate αcr,H for a portal frame are

shown in Fig 8. As can be seen, δHEF is the lateral deflection at

the top of each column when subjected to an arbitrary lateral

load HEHF.

It should be noted that although the magnitude of the lateral

load is arbitrary (as it is simply used to calculate the sway stiff-

ness HEHF/δEHF), the horizontal load applied at the top of each

Fig 7. (left) column should satisfy the following relationship

Plot showing

reduction factor for

two span flat topped

frames having

different pitches

Fig 8. (right)

Diagram showing

parameters required

to estimate αcr

that predicted by Merchant-Rankine.

The results of Frames 6 and 7 may be explained by the fact

that the hinge rotation of a frame having a low value of L/h is

less than that of a frame having a high value of L/h. Previously,

it was explained that beneficial effect of strain-hardening can

offset the reduction in strength due to second-order effects. The

results of Frames 6 and 7 therefore show that frames having a

low value of L/h benefit less from strain-hardening than frames

having a high value of L/h.

The fact that a single frame, Frame 7, has a reduction factor

3% lower than that predicted by Merchant-Rankine is consid-

ered to be statistically acceptable and will be ignored for the

purposes of proposing design rules.

Fig 9.

Arched frames Plot showing

The results for the flat topped, Mansard and pseudo-curved reduction factor

frames are shown in Fig 5. Owing to their shape, these three using αcr,est for all

frames will be referred to as arched frames (Fig 6). The arch frames except tied

shape of these frames means that the bending moment diagram portals

closely follows the shape of the frame; as a result, such frames

therefore have more slender rafter members than duo-pitch

frames of similar geometry.

From Fig 5 it can be seen that the reduction factor αp2/αp1 for

all three frames is below that predicted by Merchant-Rankine.

In the case of Frame 18 the value of αp2/αp1 is 3% less than that

predicted by the reduced Merchant-Rankine, defined in the

previous section.This single result is not considered to be statis-

1 November 2005 – The Structural Engineer|47

paper: lim et al

Fig 10. Rankine reduction factor than use of the exact value of αcr

Examples of (calculated from software).

Category A frames

(a) Mono-pitch Exclusion of certain types of frame from proposed

(b) Single-span design rules

(c) Multi-span It was explained previously that frames having high values of

L/h will be more susceptible to second-order effects. Frames

having a value of L/h greater than 8 are therefore excluded

from the proposed design rules given below; such frames should

be designed using second-order elastic-plastic analysis.

Tied portals are designed with low roof slopes and for least

weight sections. Owing to the high axial force in the rafters, the

non-linear behaviour of these frames is complex. As the

Merchant-Rankine formula will not be able to take accurately

into account the instability in tied-portals, such frames are there-

fore also excluded from the proposed design rules given in the

Fig 11. following section. Tied portals should be designed using second-

Plot showing order elastic-plastic analysis; it should be noted that BS 5950:

reduction factor for 2000 also requires second-order elastic-plastic analysis for tied

Category A frames portals.

Proposed design rules

The proposed design rules are based on the Merchant-Rankine

reduction method and exclude the following

• Frames in which L > 8 for any span

h

• Frames in which αcr ≤ 3

• Tied portals

Frames excluded from the proposed design rules should be

designed plastically using second-order elastic-plastic analysis

software.

Fig 12. Category A: Regular, symmetric and asymmetric pitched

Plot showing and mono-pitched frames

reduction factor for Regular, symmetric and mono-pitched frames (Fig 10) are

Category B frames either single-span frames or multi-span frames in which there

is only a small variation in height (h) and span (L) between the

different spans; variations in height and span of the order of

10% may be considered as being sufficiently small. For such

frames, the second-order elastic-plastic collapse factor, αp2, may

be calculated using the Merchant-Rankine formula

a p2 = a p1 d a n

a cr - 1

cr

Table 1 identifies Category A frames. As an example, Frame

9, the 30° single span frame, is classified as a Category A frame.

The results for all Category A frames described in this paper are

H EHF = H EHF, A = H EHF, B shown in Fig 11.

VULS VULS, A VULS, B

Horne’s method for estimating αcr is unconservative when Category B: Frames that fall outside of Category A and

applied to portal frames i.e. overestimating the value of αcr.This excluding tied portals

is because Horne’s method does not take into account the axial For frames that fall outside of Category A and are not tied

force in the rafters and also may underestimate the second- portals, the second-order elastic-plastic collapse factor, αp2, may

order effects in the columns. King24 proposed the following be calculated from the reduced Merchant-Rankine expression,

modification to Horne’s method, to take into account the axial defined previously

force in the rafters and to increase the influence of second-

a p2 = a p1 d n

a cr - 1

order effects in the columns

1.1a cr

a cr, est = 0.8 *1 - e 4 a cr, H

N R, cr o

N R, ULS

The results for all Category B frames described in this paper

max are shown in Fig 12; the reduced Merchant-Rankine curve is

where the dashed curve shown below the Merchant-Rankine curve. It

2 should be noted that the Mezzanine frames and the varied

N R, cr = r EI R

height frames fall within Category B frames.

L2

Fig 9 shows the reduction factor αp2/αp1 plotted for each Conclusions

frame against αcr, est, norm , the normalised elastic critical load • The parametric study has shown that for many portal frames

factor; the two tied portal frames have been excluded. The the second-order elastic-plastic collapse factor can safely be

frames identified in Fig 3 as having a reduction factor lower predicted using either Merchant-Rankine or a reduced

than that predicted by Merchant-Rankine have also been iden- Merchant-Rankine, applied to first-order plastic analysis.

tified in Fig 9. • The application of Merchant-Rankine requires a reasonable

As can be seen from Fig 9, if αcr is calculated using King’s estimate of the elastic critical buckling load factor. A conser-

estimate, only Frames 17 and 18 have a reduction factor lower vative method is proposed in this paper that avoids the neces-

than that proposed by Merchant-Rankine. In general, it can be sity to use software to determine this load factor.

seen that use of αest results in a more conservative Merchant- • Categories of frame are defined to which the Merchant-

48|The Structural Engineer – 1 November 2005

paper: lim et al

Rankine or reduced Merchant-Rankine approach can be Acknowledgments

applied – designated ‘Category A’ and ‘Category B’. The authors would like to acknowledge the technical support

• Certain frames fall outside of these categories e.g. tied portals provided by David Brown and Dr Martin Heywood of SCI and

and for these frames second-order elastic-plastic analysis is David Sanderson of CSC.The work was undertaken with finan-

required. cial support from the DTI and Corus C&I.

REFERENCES

1. BS 449: Part 2: 1969 Specification for the use of Normalisation, 2002 analysis of plane frames’, J. Construct. Steel

structural steel in building, London, British 9. King, C. M.: In-plane stability of portal frames Res., 58, 2002, p1315-1330

Standards Institution,1969 to BS 5950-1:2000, The Steel Construction 17. Merchant, W.: ‘Failure of rigid jointed frame-

2. BS 5950: Part 1: 1985 Structural use of steel- Institute, 2001 works as influenced by stability’, The Structural

work in building. Code of practice for design in 10. Byfield, M. P. and Nethercot, D. A.: ‘An analy- Engineer, 32, 1954, p185

simple and continuous construction: Hot rolled sis of the true bending strength of steel 18. Merchant, W., Rashid, C. A., Bolton, A. and

sections, London, British Standards Institution, beams’, Proc. I. C. E, Structs. And Bldgs, 128, Salem, A.: ‘The behaviour of unclad frames’,

1985 May 1998, p 188-197. Proc Fiftieth Anniversary Conference, IStructE,

3. BS 5950: Part 1: 1990 Structural use of steelwork 11. Davies, J. M.: ‘Frame instability and strain 1958

in building. Code of practice for design in simple hardening in plastic theory’, Proc. ASCE, 2/3, 19. Wood, R. H.: ‘Effective lengths of columns in

and continuous construction: Hot rolled sections, 1966, p1-15 multi-storey buildings: Part 3’, The Structural

London, British Standards Institution, 1990 12. Davies, J. M.: ‘Strain hardening, local buckling Engineer, 52/9, 1974

4. Davies, J. M.: ‘In plane stability in portal and lateral torsional buckling in plastic hinges’, 20. Horne, M. R.: ‘Elastic-plastic failure loads of

frames’, The Structural Engineer, 68/8, 1990, Proc. SEMC 2004, 2nd Int. Conf. on Structural plane frames’, Proc. Roy. Soc., A(274), 1963

p141-147 Engineering, Mechanics and Computation, 5-7 21. Horne, M. R.: ‘An approximate method for

5. Davies, J. M.: ‘The stability of multi bay portal July 2004, Cape Town calculating the elastic critical loads of multi-

frames‘, The Structural Engineer, 69/12, 1991, 13. BCSA: ‘Plastic design of portal frames in steel storey plane frames’, The Structural Engineer,

p223-229 to BS 968’, BCSA ‘Black Book No 29’, 1966 53/6, 1975, p242-248

6. BS 5950-1: 2000 Structural use of steelwork in 14. Byfield, M. P., Davies, J. M. and Dhanalakshmi, 22. Horne, M. R.: ‘Safeguards against frame insta-

building. Part 1: Code of practice for design - M.: ‘Calculation of the strain hardening bility in the plastic design of pitched roof

Rolled and welded sections, London, British behaviour of steel structures based on mill frames’, Conf. Behaviour of Slender Structures,

Standards Institution, 2001 tests’, J. Construct. Steel Res., 61, 2005, p 133- City University, London, 1977

7. BS EN 1993-1-1 Eurocode 3: Design of steel 150 23. Horne, M. R. and Morris, L. S.: Plastic design of

structures. General requirements, British 15. Chew, A. A.: ‘Strain hardening – ranges of low rise frames, Granada Publishing, 1981

Standards Institution, 2005 effects on plastic hinges’, Document RT828, 24. King, C. M.: Improved Economy of Eurocode 3

8. BS EN 1990: Eurocode. Basis of structural Ascot, The Steel Construction Institute, 2000 for portal frames - Draft for consultation, Ascot,

design, Brussels, Committee European de 16. Davies, J. M.: ‘Second-order elastic-plastic The Steel Construction Institute, 2003

1 November 2005 – The Structural Engineer|49

View publication stats

Вам также может понравиться

- Performance of RC Frame Structure With Various Beam To Column Flexural Capacity Ratio - A Case Study Sudip KaranjitДокумент7 страницPerformance of RC Frame Structure With Various Beam To Column Flexural Capacity Ratio - A Case Study Sudip KaranjitBinod ManandharОценок пока нет

- Evaluate The Lateral Displacement That Occurs in Each Storey of High Rise Buildings by Using Staad Pro SoftwareДокумент5 страницEvaluate The Lateral Displacement That Occurs in Each Storey of High Rise Buildings by Using Staad Pro SoftwareEditor IJTSRDОценок пока нет

- Beam Design in PR Braced Steel FramesДокумент13 страницBeam Design in PR Braced Steel FramesgullipalliОценок пока нет

- Merchant-Rankine Approach For The Design of SteelДокумент24 страницыMerchant-Rankine Approach For The Design of Steelel000011Оценок пока нет

- Damage PlasticityДокумент12 страницDamage PlasticityVibhanshu Mishra100% (1)

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceДокумент14 страницAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoОценок пока нет

- Load and Resistance Factors For Concrete Design: Aci Journal Technical PaperДокумент9 страницLoad and Resistance Factors For Concrete Design: Aci Journal Technical PaperHasanain AlmusawiОценок пока нет

- Parametric Study of Cold Formed Steel Zee Sections For Optimum Design StrengthДокумент8 страницParametric Study of Cold Formed Steel Zee Sections For Optimum Design StrengthKAVITHA GARIDIОценок пока нет

- Analytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceДокумент14 страницAnalytical Model For Predicting Shear Strengths of Exterior Reinforced Concrete Beam-Column Joints For Seismic ResistanceAndres NaranjoОценок пока нет

- Cyclic Load Testing of Precast Hybrid Frame Connections: 13 World Conference On Earthquake EngineeringДокумент15 страницCyclic Load Testing of Precast Hybrid Frame Connections: 13 World Conference On Earthquake EngineeringrajarajathanОценок пока нет

- A Critical Review On Buckling and Post-Buckling AnalysisДокумент13 страницA Critical Review On Buckling and Post-Buckling AnalysisAtsis PapadopoulosОценок пока нет

- Seismic Design Procedures For Concentrically Braced Frames: A. Y. ElghazouliДокумент14 страницSeismic Design Procedures For Concentrically Braced Frames: A. Y. ElghazouliOmar Eduardo Alvarado ValleОценок пока нет

- Previous Research and Design FormulationДокумент28 страницPrevious Research and Design FormulationJennifer RodriquezОценок пока нет

- What Do We Know About Confinement in Reinforced Concrete Columns-Sakai-SheikhДокумент16 страницWhat Do We Know About Confinement in Reinforced Concrete Columns-Sakai-SheikhAlberto Ezequiel León TamayoОценок пока нет

- Jeas 0721 8622Документ19 страницJeas 0721 8622Gatha S.GiridharОценок пока нет

- Sliding Hinge Joint PDFДокумент11 страницSliding Hinge Joint PDFjcvalenciaОценок пока нет

- Probabilistic Joint Shear Strength Models For Design of RC Beam-Column ConnectionsДокумент11 страницProbabilistic Joint Shear Strength Models For Design of RC Beam-Column ConnectionsangthiankongОценок пока нет

- Design Procedure For Steel Frame Structures According To Bs 5950Документ46 страницDesign Procedure For Steel Frame Structures According To Bs 5950Chong Chee Yen100% (2)

- A Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack StructuresДокумент8 страницA Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack Structuresvirat_daveОценок пока нет

- FibersДокумент26 страницFibersQurrain MirОценок пока нет

- A Monotonic Smeared Truss Model To Predict The Envelope Shear Stress-Shear Strain Curve For Reinforced Concrete Panel Elements Under Cyclic ShearДокумент21 страницаA Monotonic Smeared Truss Model To Predict The Envelope Shear Stress-Shear Strain Curve For Reinforced Concrete Panel Elements Under Cyclic ShearGonzalo TorrisiОценок пока нет

- Concrete JointsДокумент10 страницConcrete JointsTamaduianu IoanОценок пока нет

- Long and Lee - Modelling of Two Dimensional Reinforced Concrete Beam-Column Joints Subjected To Monotonic LoadingДокумент15 страницLong and Lee - Modelling of Two Dimensional Reinforced Concrete Beam-Column Joints Subjected To Monotonic LoadingVladekОценок пока нет

- Buckling Mode Classification of Members With Open Thin-Walled Cross-SectionsДокумент11 страницBuckling Mode Classification of Members With Open Thin-Walled Cross-SectionsLeonardo Pereira SilvaОценок пока нет

- Buckling Restrained Braces (BRB) - A ReviewДокумент5 страницBuckling Restrained Braces (BRB) - A ReviewAnonymous kw8Yrp0R5r100% (1)

- Strong Column-Weak Beam Concept and Stiffness Factor Study For Moment Ressisting FramesДокумент9 страницStrong Column-Weak Beam Concept and Stiffness Factor Study For Moment Ressisting FramesInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Concrete Encased Composite Column ACI - AISCДокумент14 страницConcrete Encased Composite Column ACI - AISCAli KhalafОценок пока нет

- ShearTorsionObel BH LB 2022Документ34 страницыShearTorsionObel BH LB 2022BERNARDO HOROWITZОценок пока нет

- Shear Strength Evaluation of Concrete Bridge Girders: Aci Structural Journal Technical PaperДокумент11 страницShear Strength Evaluation of Concrete Bridge Girders: Aci Structural Journal Technical PaperangthiankongОценок пока нет

- Buckling of Rectangular Isolated R.C. Columns Closed-Form ApproximaДокумент9 страницBuckling of Rectangular Isolated R.C. Columns Closed-Form ApproximaAhmed MohammedОценок пока нет

- Simplified Seismic Analysis of Woodframe StructureДокумент16 страницSimplified Seismic Analysis of Woodframe StructuresoftlikerockОценок пока нет

- Appendix 8Документ19 страницAppendix 8Vijay KumarОценок пока нет

- Pushover AnalysisДокумент12 страницPushover AnalysisJonathan FelixОценок пока нет

- Zhou SCBRB PTДокумент18 страницZhou SCBRB PTgopa dasОценок пока нет

- Parastesh 2021Документ16 страницParastesh 2021Luiz AlmeidaОценок пока нет

- Creep Model For Reinforced Concrete Columns: Aci Structural Journal Technical PaperДокумент5 страницCreep Model For Reinforced Concrete Columns: Aci Structural Journal Technical PaperpicottОценок пока нет

- Chapter - 2 O G S S: Verview of RID Tiffened TructureДокумент12 страницChapter - 2 O G S S: Verview of RID Tiffened TructureJohnson AnthonyОценок пока нет

- 2023-The Continuous Strength Method - Review and OutlookДокумент16 страниц2023-The Continuous Strength Method - Review and OutlookNora MostafaОценок пока нет

- In-Plane Stability of Portal Frames: Rainham SteelДокумент3 страницыIn-Plane Stability of Portal Frames: Rainham SteelMonsieur PatateОценок пока нет

- 1 s2.0 S2214509522007987 MainДокумент18 страниц1 s2.0 S2214509522007987 Maingopa dasОценок пока нет

- Design of Conical Steel Wind Turbine Towers Manufactured With Automated Spiral WeldingДокумент9 страницDesign of Conical Steel Wind Turbine Towers Manufactured With Automated Spiral WeldingLaferostica CorreaОценок пока нет

- Chapter 1 IntroductionДокумент7 страницChapter 1 Introductionct571999Оценок пока нет

- 5 - Paulay Equilibrium Criteria For Reinforced ConcreteДокумент9 страниц5 - Paulay Equilibrium Criteria For Reinforced ConcreteMarimuthu KaliyamoorthyОценок пока нет

- Star Seismic Europe Cost AnalysisДокумент19 страницStar Seismic Europe Cost Analysist3487810interzetruОценок пока нет

- 2023 STRUCT The Effect of The Gravity Column in The Seismic Design of Steel CBFsДокумент12 страниц2023 STRUCT The Effect of The Gravity Column in The Seismic Design of Steel CBFsVincenzo PilusoОценок пока нет

- Vigas CelularesДокумент13 страницVigas Celularesjose ronaldoОценок пока нет

- 1 s2.0 S0143974X10002208 Main PDFДокумент13 страниц1 s2.0 S0143974X10002208 Main PDFjose ronaldoОценок пока нет

- 23 PDFДокумент13 страниц23 PDFviverefeliceОценок пока нет

- BRBF Vs MRFДокумент13 страницBRBF Vs MRFrondana1Оценок пока нет

- 15578-Article Text-47464-1-10-20180109Документ19 страниц15578-Article Text-47464-1-10-20180109Syed YaminОценок пока нет

- Mechanical Shear Strength Model For Reinforced Concrete Beams Strengthened With FRP MaterialДокумент11 страницMechanical Shear Strength Model For Reinforced Concrete Beams Strengthened With FRP MaterialOmarОценок пока нет

- Engineering Fracture Mechanics: W. Bleck, W. Dahl, A. Nonn, L. Amlung, M. Feldmann, D. Schäfer, B. EichlerДокумент17 страницEngineering Fracture Mechanics: W. Bleck, W. Dahl, A. Nonn, L. Amlung, M. Feldmann, D. Schäfer, B. EichlerShubhom PaulОценок пока нет

- Design and Analysis of Structural Steel Tower Assembly Subject To High Axial and Transverse Stresses Using BS EN1993-1-1 and BS EN1993-1-5Документ6 страницDesign and Analysis of Structural Steel Tower Assembly Subject To High Axial and Transverse Stresses Using BS EN1993-1-1 and BS EN1993-1-5John AndersonОценок пока нет

- Narita Binti Noh 10 - 24 PDFДокумент24 страницыNarita Binti Noh 10 - 24 PDFajgarcesv7301Оценок пока нет

- Engineering Structures: Hyo-Gyoung Kwak, Ji-Hyun KwakДокумент12 страницEngineering Structures: Hyo-Gyoung Kwak, Ji-Hyun KwakVishalSelvanОценок пока нет

- A Design Method For Concrete-Filled, Hollow Section, Composite ColumnsДокумент7 страницA Design Method For Concrete-Filled, Hollow Section, Composite ColumnsZim DausОценок пока нет

- Seismic Design Basis For Internally-Braced RC Frames: M.R. Maheri and H. GhaffarzadehДокумент8 страницSeismic Design Basis For Internally-Braced RC Frames: M.R. Maheri and H. Ghaffarzadehhlong123123Оценок пока нет

- REWERS I - Numerical Analysis of RC Beam With High Strength Steel REinforcement Using CDP ModelДокумент11 страницREWERS I - Numerical Analysis of RC Beam With High Strength Steel REinforcement Using CDP Modelno_milk_todayОценок пока нет

- Abdul-Razzaq 2019 IOP Conf. Ser. Mater. Sci. Eng. 518 022057Документ11 страницAbdul-Razzaq 2019 IOP Conf. Ser. Mater. Sci. Eng. 518 022057alpegambarliОценок пока нет

- Reinforced Concrete Buildings: Behavior and DesignОт EverandReinforced Concrete Buildings: Behavior and DesignРейтинг: 5 из 5 звезд5/5 (1)

- Chapter Two: Reinforced Concrete Structures 2Документ29 страницChapter Two: Reinforced Concrete Structures 2Olesea NesterencoОценок пока нет

- Lecture 3 Design of 2 Way SlabsДокумент6 страницLecture 3 Design of 2 Way SlabsOlesea NesterencoОценок пока нет

- Lecture 3 Design of 2 Way Slabs PDFДокумент52 страницыLecture 3 Design of 2 Way Slabs PDFOlesea Nesterenco100% (1)

- Example1.1.: I. Uncracked Section PropertiesДокумент13 страницExample1.1.: I. Uncracked Section PropertiesOlesea NesterencoОценок пока нет

- Fundatii Pe PilotiДокумент41 страницаFundatii Pe PilotiOlesea NesterencoОценок пока нет

- UNO P.J. Plastic Shrinkage Cracking +evaporation Formulas ACI-1998 Vol95-M34Документ12 страницUNO P.J. Plastic Shrinkage Cracking +evaporation Formulas ACI-1998 Vol95-M34Olesea NesterencoОценок пока нет

- Fiche 774-3 R Track-Bridge Interaction PDFДокумент76 страницFiche 774-3 R Track-Bridge Interaction PDFOlesea NesterencoОценок пока нет

- StressHead CL-Restrap Factsheet ENДокумент4 страницыStressHead CL-Restrap Factsheet ENJuan ManuelОценок пока нет

- Design AnchorДокумент10 страницDesign AnchorzilemanoОценок пока нет

- Project ReportДокумент37 страницProject ReportXiaoman TuОценок пока нет

- Surveying Monthly Report MAY 2023.Документ3 страницыSurveying Monthly Report MAY 2023.AshebirОценок пока нет

- Post Tension Slab Design ExampleДокумент6 страницPost Tension Slab Design ExampleKiran D AnvekarОценок пока нет

- Concrete Slab Track - 2011 - : Section/Article DescriptionДокумент30 страницConcrete Slab Track - 2011 - : Section/Article DescriptionMike2322Оценок пока нет

- Presentasi Monopole Odc 12u PDFДокумент18 страницPresentasi Monopole Odc 12u PDFrudi albertОценок пока нет

- WH# 06 - Petrokemya NorthДокумент4 страницыWH# 06 - Petrokemya NorthEAC Alim KhanОценок пока нет

- Design of RCC BuildingДокумент94 страницыDesign of RCC BuildingRashed0% (2)

- Design of Composite Bridge PDFДокумент25 страницDesign of Composite Bridge PDFSudip AdhikariОценок пока нет

- S-AAA-CIV-CONCRETE (Rev.0-2015) PDFДокумент16 страницS-AAA-CIV-CONCRETE (Rev.0-2015) PDFSwathish SivaprasadОценок пока нет

- E-Tabs GuideДокумент9 страницE-Tabs GuideabdizamadОценок пока нет

- Abutment JembatanДокумент7 страницAbutment JembatanDewa PosthardОценок пока нет

- Qatar Piling ContractorsДокумент1 страницаQatar Piling Contractorssilvereyes18100% (1)

- Sist en 13377 2002Документ11 страницSist en 13377 2002koliodimitrovОценок пока нет

- Reinforced Concrete Design II - ACI 318: Design of Two Way SlabsДокумент60 страницReinforced Concrete Design II - ACI 318: Design of Two Way Slabsmedo eidОценок пока нет

- Gambrel Shed Building Guide: by John Shank, Owner of Shedking, LLC 2014Документ39 страницGambrel Shed Building Guide: by John Shank, Owner of Shedking, LLC 2014Brînzoi CiprianОценок пока нет

- Example Flat Slab Design - CarДокумент31 страницаExample Flat Slab Design - CarRayGaintОценок пока нет

- National Building Code 2016Документ22 страницыNational Building Code 2016LantОценок пока нет

- Plate GirderДокумент74 страницыPlate Girderarif_rubin100% (1)

- NS18steeldesign 3 PDFДокумент51 страницаNS18steeldesign 3 PDFLemark R.Оценок пока нет

- Errata For ACI 318-14 2nd PrintingДокумент4 страницыErrata For ACI 318-14 2nd PrintingKikoCanОценок пока нет

- Fatigue Behavior of Ring Stiffened Tubular JointДокумент8 страницFatigue Behavior of Ring Stiffened Tubular JointManishОценок пока нет

- Load Path and Tributary Area ExamplesДокумент7 страницLoad Path and Tributary Area Examplesvariablespice100% (1)

- Agreement 1Документ6 страницAgreement 1kart_rlОценок пока нет

- Seismic Force Resisting Systems and Response of Concrete BuildingДокумент30 страницSeismic Force Resisting Systems and Response of Concrete BuildingtaosyeОценок пока нет

- Reinforced Concrete Tilt Up Wall With Opening Panel Analysis Design ACI551Документ42 страницыReinforced Concrete Tilt Up Wall With Opening Panel Analysis Design ACI551mikollimОценок пока нет

- Equipment Schedule HVACДокумент7 страницEquipment Schedule HVACHussainShabbirОценок пока нет

- Numerical Insights Into The Effect of ITZ and Aggregate Strength On Concrete PropertiesДокумент11 страницNumerical Insights Into The Effect of ITZ and Aggregate Strength On Concrete PropertiesAndres ForeroОценок пока нет

- BXUV7.GuideInfo - Fire-Resistance Ratings - CAN - ULC-S101 Certified For Canada - UL Product IqДокумент2 страницыBXUV7.GuideInfo - Fire-Resistance Ratings - CAN - ULC-S101 Certified For Canada - UL Product IqEmanuel Ciprian CiucurОценок пока нет