Академический Документы

Профессиональный Документы

Культура Документы

Eni Turbine Oil Brochure PDF

Загружено:

ranjanguptОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Eni Turbine Oil Brochure PDF

Загружено:

ranjanguptАвторское право:

Доступные форматы

from eni research

choose the best

for industry

Via Laurentina, 449 - 00142 Rome

Tel.: + 39 06 5988.1

eni.com

agip lubricants

Edition December 2009

turbine technology comes alive

oils Via Laurentina

Tel.: + 39 06 5

eni.com

I_8246_380x190_Turbine_Oil.indd 1 03/12/09 14:12

turbine oils

Turbines are the fundamental and critical machinery in the electrical energy production cycle. They consist of a fixed element and

a mobile element that converts the energy of a fluid, generally steam, water or combusted gas, into mechanical energy.

To ensure their maximum effectiveness a very high quality lubricant is indispensable to provide:

• the lubrication of the shaft bearings

• the removal of the heat transmitted to the bearings

• the function of hydraulic oil

eni, through its Agip brand, is the leading company in the industrial lubricant market in Italy.

• the function of gear oil.

Technical and commercial leadership is maintained and reinforced by eni’s commitment to

technology, quality, environmental protection and technical customer support.

technology

properties

The internationally recognised advanced level of expertise and equipment at the San Donato excellent viscosity and high viscosity index

Milanese laboratories generate the development of products and processes for the most

modern production requirements. The viscosity grades required for turbine oils range from ISO VG 32 to ISO VG 100.

The lower grades are mainly used in the electricity generation sector, due to the high rotating speed of the shaft. In contrast, units

quality containing reducers require higher viscosities, able to support the load transmitted to the teeth. The highest viscosities are

for industrial turbines, naval steam turbines and water turbines. The high viscosity index limits viscosity variations with changes in

All plants in the lubricant production cycle operate in accordance to a certified quality temperature.

management system in conformity with standard ISO 9002.

resistance to oxidation

environment

Attention to the environment is one of the main guiding principles in product development and The oil is subjected to a strong oxidising action in use, due to heat, infiltrated water (in the case of steam turbines) and air absorbed

in the production cycle. All plants implement a certified environmental management system and trapped in the circuit. It must therefore have an extremely long life and maintain its characteristics.

in conformity with standard ISO 14001.

antirust and anticorrosion properties

technical support

Rust and oxidised metal particles increase corrosion and oxidation and cause wear and malfunction of components.

The highly qualified technical manpower are the highly dispersed global operations, ensured

outstanding technical back up support services to customers, security in total customers demulsibility

satisfaction.

The lubricant must be able to separate rapidly and completely from water which is inevitably present in a steam turbine.

The industrial product line includes lubricants and special products to satisfy all the lubrication The presence of water generates emulsions with oil which compromise correct lubrication because

requirements of any type of industrial plant at a qualitative level at the top of the market. they increase viscosity and cause sludge formation.

low foaming and air holding

More information about application, characteristics and TDS is available on https://nalis.eni.it/Alis

and by e-mail alis@eni.it

The inevitable presence of air in the lubrication circuit causes the dispersion of air in oil that can result

both internally and externally in the form of foam. The oil must have properties, which limit foam formation

and air retention. The presence of air can break the lubricant film and accelerate the oxidation of the oil.

I_8246_380x190_Turbine_Oil.indd 2 03/12/09 14:13

the agip product range

The Agip products for steam and gas turbines are formulated with special bases oils. The technological advances in Agip turbine oils AGIP OTE conform to the following classifications and specifications and/or are approved by the following international organizations

include updating the additives used. or manufacturers:

> iso 6743/5 > abb htdg 90117 e mod. m

> iso – l-tsa /-tga > alstom htdg 90117 v0001 v

agip ote > iso – l-tha > ansaldo energia 3.2-0092-8430

> iso 8068 > general electric gek 28143a - type i, ii and iii

AGIP OTE oils are available in ISO VG viscosity grades from 32 to 100 for the lubrication of all parts of steam, gas and hydraulic > astm d 4304 type 1 > mitsubishi spec. no. e00-001 rev.1

turbines. Gradation 46 exceeds 5,000 hours in the Turbine Oil Stability Test (TOST) of oxidation. > bs 489:1999 > nuovo pignone n. sos 02111/4 (ote 46)

> cei 10-8 (1994) > nuovo pignone som 17366 (ote 32)

> din 51515-1 l-td > siemens tlv 9013 04/01

> jis k 2213 – (1983)

agip ote 32 46 68 80* 100

viscosity at 40°C mm2/s 29.3 45.4 64.1 74.0 99.6 AGIP OTE 80 is aimed essentially for use in military naval steam turbines and conforms to the following classifications and specifications:

viscosity at 100°C mm2/s 5.37 7.18 8.94 9.69 11.62

viscosity index - 118 118 114 110 105 > nato o-240

flash point v.a. °C 230 235 245 280 260 > defence standard 91-25 (2002)

pour point °C -18 -15 -15 -12 -12 > m.m. o-2001

mass density at 15°C kg/l 0.850 0.856 0.861 0.869 0.872

agip ote gt

(*) non iso vg gradation

AGIP OTE GT, available in ISO VG viscosity gradations from 32 to 68, are principally intended for the lubrication of high performance

gas turbines. The special additives include a “mild EP” antiwear function which allows ISO gradation 46 to exceed the 9th

stage in the FZG test. These characteristics make these products particularly versatile and able to lubricate both gas and steam

turbines, thus they are the ideal products for plants where one lubricant in a combined cycle is required. ISO grade 46 exceeds

10,000 hours in the Turbine Oil Stability Test (TOST) of oxidation.

agip gt 32 46 68

viscosity at 40°C mm2/s 29.2 45.3 64.0

viscosity at 100°C mm2/s 5.35 7.17 8.93

viscosity index - 118 118 114

flash point v.a. °C 230 235 245

pour point °C -18 -15 -15

mass density at 15°C kg/l 0.850 0.856 0.861

I_8246_380x190_Turbine_Oil.indd 3 03/12/09 14:13

AGIP OTE GT conform to the following classifications and specifications and/or are approved by the following bodies or agip ote tc 46

manufacturers:

Special ISO VG 46 grade lubricant, with very low pour point, is recommended specifically for the lubrication of turbo compressors

> iso 6743/5 > general electric gek 28143a, type iv, v and vi in process and/or synthesis plants, e.g. for ethylene, ammonia, etc.

> iso –l-tsa /-tse/ -tga/ -tgb/ -tge/ -tgsb/ -tgse > general electric gek 32568f (ote 32gt)

> iso 8068 > general electric gek 101941 (ote 32gt) agip turbo 23699

> din 51515-1 l-td > general electric gek 107935a (ote 32gt) Synthetic lubricant for industrial gas turbines used in aeronautic applications that require a product conforming to MIL-L 23699D

> din 51515-2 l-tg > ge thermodyn ispsh 902sdi (ote 46gt) and PWA 521B specifications.

> astm d 4304 type 2 > nuovo pignone som 23543 (ote 32gt)

> alstom htdg 90117 v0001v (tipo ep) > nuovo pignone som 23687 (ote 32gt)

> alstom power sweden mat812109 > man ghh borsig sp 079984 e 0000 e 98

> caterpillar / solar es 9-224u > siemens tvl 9013 04 (tipo ep)

> gm no. lj-03-1-97, lj-04-1-97, lj-06-1-97 > siemens westinghouse m-spec 55125z3

special products range

agip alisma 32 pv

AGIP ALISMA 32 PV is a special product for steam and gas turbines and turbo compressors which acts as a lubricant during test

runs and as protection during storage, shipment and long shutdowns.

agip ote 80 ep

AGIP OTE 80 EP (non ISO VG grade) is recommended for the lubrication of naval steam turbines and gears.

Conforms to MIL-PRF-17331 – NATO O-250 specifications.

I_8246_380x190_Turbine_Oil.indd 4 03/12/09 14:13

Вам также может понравиться

- Eni's heat transfer oils for industryДокумент4 страницыEni's heat transfer oils for industryChintan GondaliaОценок пока нет

- Components Systems Processes For Chemical IndustryДокумент32 страницыComponents Systems Processes For Chemical IndustryAmlan BanerjeeОценок пока нет

- Products Catalog - ACORE Filtration Co - LTDДокумент22 страницыProducts Catalog - ACORE Filtration Co - LTDMauricio RaúlОценок пока нет

- Eni Lubricants: Solutions for all round performanceДокумент3 страницыEni Lubricants: Solutions for all round performanceLokesh GowdaОценок пока нет

- Vacuum Oil Purifiers: E865A SeriesДокумент4 страницыVacuum Oil Purifiers: E865A SeriesdanielcelОценок пока нет

- Electric Motor Bearing Grease SelectionДокумент1 страницаElectric Motor Bearing Grease SelectionProject Sales CorpОценок пока нет

- Revolution in turbine lubricationДокумент6 страницRevolution in turbine lubricationman_iphОценок пока нет

- Trends in Industrial Gear OilДокумент8 страницTrends in Industrial Gear OilM.TayyabОценок пока нет

- Glass-CatalДокумент12 страницGlass-Catalm.cavalcanti59Оценок пока нет

- Thermax spentwash co-generation solutions for distilleriesДокумент6 страницThermax spentwash co-generation solutions for distilleriesPrashanth VaranasiОценок пока нет

- Selmatic Brosur 1.compressedДокумент34 страницыSelmatic Brosur 1.compressedjekiОценок пока нет

- .Au ProductsAndServices Pages LubricantProДокумент3 страницы.Au ProductsAndServices Pages LubricantProabid azizОценок пока нет

- Technical InfoДокумент17 страницTechnical InfoJosue GonzalezОценок пока нет

- Sealmatic Design Manual2.1Документ113 страницSealmatic Design Manual2.1varunzhao86Оценок пока нет

- Lithium Grease Manufacturers in IndiaДокумент16 страницLithium Grease Manufacturers in IndiaUnit GreaseОценок пока нет

- Lubricants For Cement ProductionДокумент21 страницаLubricants For Cement Productiongrameshkreddy2013100% (1)

- Tranformer Oils & Fluids: Development of Transformer Fluids Over The Last CenturyДокумент7 страницTranformer Oils & Fluids: Development of Transformer Fluids Over The Last CenturyJosé Luis Rivera EscuderoОценок пока нет

- 108 PyroshieldДокумент2 страницы108 PyroshieldPatrick FoОценок пока нет

- 1bdacb_146ac3fbe27e4b17b88d9123846421d1Документ4 страницы1bdacb_146ac3fbe27e4b17b88d9123846421d1ROBERT PONCEОценок пока нет

- GPCDOC GTDS Shell Rimula D Extra 40 1 PDFДокумент2 страницыGPCDOC GTDS Shell Rimula D Extra 40 1 PDFphucdc095041Оценок пока нет

- Shell Rimula D Extra 40: High Quality, Heavy Duty Monograde Diesel Engine OilДокумент2 страницыShell Rimula D Extra 40: High Quality, Heavy Duty Monograde Diesel Engine Oilphucdc095041Оценок пока нет

- MilitaryAeroTherm 6003595Документ8 страницMilitaryAeroTherm 6003595shahinОценок пока нет

- Mobil Cylinder OilsДокумент2 страницыMobil Cylinder Oilsalexander900616Оценок пока нет

- (Paperhub Ir) 10 1109@eeic 1999 826196Документ6 страниц(Paperhub Ir) 10 1109@eeic 1999 826196Kolvin SenevirathnaОценок пока нет

- Sinopec Tulux Series - GELДокумент17 страницSinopec Tulux Series - GELSumaya AkterОценок пока нет

- IMI Critical Engineering Brochure DownloadДокумент24 страницыIMI Critical Engineering Brochure DownloadArun Babu0% (1)

- Hydrodyne ProfileДокумент9 страницHydrodyne Profiletrinath161980Оценок пока нет

- Contents Centrifugal Oil CleanersДокумент12 страницContents Centrifugal Oil Cleanersg33sp0tОценок пока нет

- Wind Turbine Brochure CastrolДокумент8 страницWind Turbine Brochure CastrolAnibal RiosОценок пока нет

- Series TY Vacuum Turbine Oil Purifier for Power PlantsДокумент15 страницSeries TY Vacuum Turbine Oil Purifier for Power PlantsKevin Chiang100% (1)

- Oli Caltex Meropa 220Документ4 страницыOli Caltex Meropa 220a3.msaputraОценок пока нет

- B162001002 Wind EN 0420Документ28 страницB162001002 Wind EN 0420Ludovic LeroyОценок пока нет

- Electric MachinesДокумент19 страницElectric MachinesSridhar TholasingamОценок пока нет

- Brochure Wind Industry Solutions For More Wind Force PDFДокумент28 страницBrochure Wind Industry Solutions For More Wind Force PDFphucdc095041Оценок пока нет

- Oil Refinery LubricantsДокумент7 страницOil Refinery LubricantsDipankar KhawasОценок пока нет

- 2 Mann Hummel CentrifugesДокумент4 страницы2 Mann Hummel CentrifugesMintomo IrawanОценок пока нет

- 143 484 Crushing Malaxing EngДокумент12 страниц143 484 Crushing Malaxing EngWAFAОценок пока нет

- New Generation Lubricating Oils For Indian NavyДокумент59 страницNew Generation Lubricating Oils For Indian NavyAkari SoeОценок пока нет

- Molykote Lubrication Petro IndustriesДокумент6 страницMolykote Lubrication Petro IndustriesDicky PratamaОценок пока нет

- Mobil Rust Preventives BrochureДокумент4 страницыMobil Rust Preventives BrochureJake 1Оценок пока нет

- 6.4 BenchmarksДокумент6 страниц6.4 BenchmarksYhaneОценок пока нет

- Overhaul of Raw Material Mill Gearbox Saves More Than 300,000 EurosДокумент5 страницOverhaul of Raw Material Mill Gearbox Saves More Than 300,000 Eurosjesus rodriguezОценок пока нет

- Accumulators and Coolers For Wind PowerДокумент8 страницAccumulators and Coolers For Wind PowerMiguel Angel LopezОценок пока нет

- TIMKEN Wind Energy BrochureДокумент7 страницTIMKEN Wind Energy BrochuresamagoustОценок пока нет

- FUCHS Turbine and Compressor Oils Ghanim Trading LLC UAEДокумент16 страницFUCHS Turbine and Compressor Oils Ghanim Trading LLC UAEHuu Tri HuynhОценок пока нет

- GPCDOC Local TDS Switzerland Shell Spirax S6 GXME 75W-80 (en-CH) TDSДокумент2 страницыGPCDOC Local TDS Switzerland Shell Spirax S6 GXME 75W-80 (en-CH) TDSgrs030391Оценок пока нет

- 25 - Sector Module - Mining Quarrying Cement - FilterДокумент24 страницы25 - Sector Module - Mining Quarrying Cement - FilterJack PranОценок пока нет

- If Your Engine Could Choose: Scania Oil Technical Paper November 2019Документ14 страницIf Your Engine Could Choose: Scania Oil Technical Paper November 2019Vaida Man KanОценок пока нет

- Turbo For The Aftermarket Mo 4 811Документ8 страницTurbo For The Aftermarket Mo 4 811xmen norОценок пока нет

- At 03383 WP Refinery ProfitsДокумент18 страницAt 03383 WP Refinery Profitszubair1951100% (1)

- Oil Purification Plants REOIL Regeneration SystemsДокумент35 страницOil Purification Plants REOIL Regeneration SystemsFer PolОценок пока нет

- Oil Purification Plants REOIL Regeneration SystemsДокумент35 страницOil Purification Plants REOIL Regeneration SystemsFer PolОценок пока нет

- Cooling & Heating: Revomax SeriesДокумент4 страницыCooling & Heating: Revomax SeriesBoonaa KiyyaОценок пока нет

- Complex GreaseДокумент1 страницаComplex Greasecarlos samilaОценок пока нет

- Delo Gold Isosyn Multi CH4Документ1 страницаDelo Gold Isosyn Multi CH4sanathcgrОценок пока нет

- Delo Gold: Multifunctional Diesel Engine OilДокумент2 страницыDelo Gold: Multifunctional Diesel Engine OilsanathcgrОценок пока нет

- Cetus Hipersyn Oils: Product Data SheetДокумент2 страницыCetus Hipersyn Oils: Product Data SheetAymanSayedElantableeОценок пока нет

- Microturbines: Applications for Distributed Energy SystemsОт EverandMicroturbines: Applications for Distributed Energy SystemsРейтинг: 5 из 5 звезд5/5 (1)

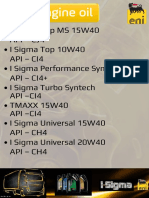

- ENI Engine Oil Range LubricantsДокумент1 страницаENI Engine Oil Range LubricantsranjanguptОценок пока нет

- AGIP Blasia SXДокумент1 страницаAGIP Blasia SXranjanguptОценок пока нет

- Eni BlasiaДокумент2 страницыEni BlasiaranjanguptОценок пока нет

- Eni BLASIA FSXДокумент2 страницыEni BLASIA FSXranjanguptОценок пока нет

- PDS Ho46Документ1 страницаPDS Ho46ranjanguptОценок пока нет

- Eni Product Range 2021Документ1 страницаEni Product Range 2021ranjanguptОценок пока нет

- Eni Product Range 2021Документ1 страницаEni Product Range 2021ranjanguptОценок пока нет

- Engine Oil Hydraulic Oil: Lubricants One Brand Many SolutionsДокумент1 страницаEngine Oil Hydraulic Oil: Lubricants One Brand Many SolutionsranjanguptОценок пока нет

- Eni Punica 570 - Cylinder OilДокумент3 страницыEni Punica 570 - Cylinder OilranjanguptОценок пока нет

- Eni Grease HTX - SIL Is A Translucent Silicone GreaseДокумент2 страницыEni Grease HTX - SIL Is A Translucent Silicone GreaseranjanguptОценок пока нет

- Characteristics (Typical Figures) Eni OTE 32 46 68 80 100Документ2 страницыCharacteristics (Typical Figures) Eni OTE 32 46 68 80 100ranjanguptОценок пока нет

- Eni Punica 525Документ2 страницыEni Punica 525ranjanguptОценок пока нет

- Eni PUNICA 540 SAE 50: ApplicationsДокумент2 страницыEni PUNICA 540 SAE 50: ApplicationsranjanguptОценок пока нет

- Eni Acer EST 100Документ2 страницыEni Acer EST 100ranjanguptОценок пока нет

- AGIP GREASE SM 2 Molybdenum GreaseДокумент1 страницаAGIP GREASE SM 2 Molybdenum GreaseranjanguptОценок пока нет

- SERVOkool PlusДокумент1 страницаSERVOkool PlusJoker DanОценок пока нет

- Grease PHT PDFДокумент1 страницаGrease PHT PDFranjanguptОценок пока нет

- Characteristics (Typical Figures) Eni CLADIUM 50 SAE Grade 30Документ1 страницаCharacteristics (Typical Figures) Eni CLADIUM 50 SAE Grade 30ranjanguptОценок пока нет

- Autol Top 2000 Getriebefliessfett 000 PDFДокумент1 страницаAutol Top 2000 Getriebefliessfett 000 PDFranjanguptОценок пока нет

- Agip GR SLL 00Документ1 страницаAgip GR SLL 00ranjanguptОценок пока нет

- Characteristics (Typical Figures) Autol Top 2000 NLGI Grade 2Документ1 страницаCharacteristics (Typical Figures) Autol Top 2000 NLGI Grade 2ranjanguptОценок пока нет

- Characteristics (Typical Figures) Autol Fliessfett Zsa NLGI Grade 000Документ2 страницыCharacteristics (Typical Figures) Autol Fliessfett Zsa NLGI Grade 000Ranjan GuptaОценок пока нет

- Eni PUNICA 540 SAE 50: ApplicationsДокумент2 страницыEni PUNICA 540 SAE 50: ApplicationsranjanguptОценок пока нет

- Eni Punica 525Документ2 страницыEni Punica 525ranjanguptОценок пока нет

- Eni Cladium 140 S SAE 40Документ2 страницыEni Cladium 140 S SAE 40ranjanguptОценок пока нет

- Eni I Sigma TOP MS 15W40Документ2 страницыEni I Sigma TOP MS 15W40ranjanguptОценок пока нет

- AGIP CLADIUM S Provides Premium Protection for Marine EnginesДокумент1 страницаAGIP CLADIUM S Provides Premium Protection for Marine EnginesranjanguptОценок пока нет

- Eni BLASIA FSXДокумент2 страницыEni BLASIA FSXranjanguptОценок пока нет

- Eni Engine Oil FlyerДокумент1 страницаEni Engine Oil FlyerranjanguptОценок пока нет

- Eni Turbine Oil BrochureДокумент25 страницEni Turbine Oil BrochureranjanguptОценок пока нет

- SQL 1: Basic Statements: Yufei TaoДокумент24 страницыSQL 1: Basic Statements: Yufei TaoHui Ka HoОценок пока нет

- Motivations for Leaving Public Accounting FirmsДокумент33 страницыMotivations for Leaving Public Accounting Firmsran0786Оценок пока нет

- Where On Earth Can Go Next?: AppleДокумент100 страницWhere On Earth Can Go Next?: Applepetrushevski_designeОценок пока нет

- LAC-Documentation-Tool Session 2Документ4 страницыLAC-Documentation-Tool Session 2DenMark Tuazon-RañolaОценок пока нет

- Hastrof Si Cantril. 1954. The Saw A Game. A Case StudyДокумент6 страницHastrof Si Cantril. 1954. The Saw A Game. A Case Studylandreea21Оценок пока нет

- Week 6Документ7 страницWeek 6Nguyễn HoàngОценок пока нет

- Ilham Bahasa InggrisДокумент12 страницIlham Bahasa Inggrisilhamwicaksono835Оценок пока нет

- EMMS SpecificationsДокумент18 страницEMMS SpecificationsAnonymous dJtVwACc100% (2)

- Using Snapchat For OSINT - Save Videos Without OverlaysДокумент12 страницUsing Snapchat For OSINT - Save Videos Without OverlaysVo TinhОценок пока нет

- Exam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023Документ285 страницExam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023maniОценок пока нет

- Executive Education Portfolio Soft Copy-INSEADДокумент58 страницExecutive Education Portfolio Soft Copy-INSEADОля КусраеваОценок пока нет

- Palgrave Handbook of Research in Historical Culture and EducationДокумент847 страницPalgrave Handbook of Research in Historical Culture and EducationGonzalo Garcia100% (1)

- E Learning: A Student Guide To MoodleДокумент16 страницE Learning: A Student Guide To MoodleHaytham Abdulla SalmanОценок пока нет

- The Polynesians: Task1: ReadingДокумент10 страницThe Polynesians: Task1: ReadingHəşim MəmmədovОценок пока нет

- OROLO & W. D. GannДокумент56 страницOROLO & W. D. GannGaurav Garg100% (1)

- VNC Function Operation InstructionДокумент11 страницVNC Function Operation InstructionArnaldo OliveiraОценок пока нет

- Ne 01 20 09 2018Документ436 страницNe 01 20 09 2018VaradrajОценок пока нет

- Eudragit ReviewДокумент16 страницEudragit ReviewlichenresearchОценок пока нет

- Published Filer List 06072019 Sorted by CodeДокумент198 страницPublished Filer List 06072019 Sorted by Codeherveduprince1Оценок пока нет

- Riedijk - Architecture As A CraftДокумент223 страницыRiedijk - Architecture As A CraftHannah WesselsОценок пока нет

- The Graduation Commencement Speech You Will Never HearДокумент4 страницыThe Graduation Commencement Speech You Will Never HearBernie Lutchman Jr.Оценок пока нет

- Android Attendance Management SystemДокумент54 страницыAndroid Attendance Management Systemskpetks75% (12)

- 99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudДокумент6 страниц99 181471 - Sailor System 6000b 150w Gmdss MFHF - Ec Type Examination Module B - Uk TuvsudPavankumar PuvvalaОценок пока нет

- Mba Project GuidelinesДокумент8 страницMba Project GuidelinesKrishnamohan VaddadiОценок пока нет

- AP Euro Unit 2 Study GuideДокумент11 страницAP Euro Unit 2 Study GuideexmordisОценок пока нет

- Rakpoxy 150 HB PrimerДокумент1 страницаRakpoxy 150 HB Primernate anantathatОценок пока нет

- EPF Passbook Details for Member ID RJRAJ19545850000014181Документ3 страницыEPF Passbook Details for Member ID RJRAJ19545850000014181Parveen SainiОценок пока нет

- Wsi PSDДокумент18 страницWsi PSDДрагиша Небитни ТрифуновићОценок пока нет

- Center of Gravity and Shear Center of Thin-Walled Open-Section Composite BeamsДокумент6 страницCenter of Gravity and Shear Center of Thin-Walled Open-Section Composite Beamsredz00100% (1)

- ThesisДокумент250 страницThesislax mediaОценок пока нет