Академический Документы

Профессиональный Документы

Культура Документы

Cut Groove English

Загружено:

makmak9Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cut Groove English

Загружено:

makmak9Авторское право:

Доступные форматы

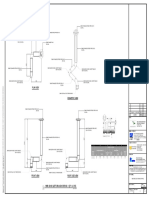

Piedmont Pacific cut groove pipe standards

Table 1.1 (Cut groove specifications in English units).

Column Notes:

Gasket seat ‘A’: must be smooth and free of indentations,

roll marks, scratches, imperfections and projections from the

end of the pipe to the groove in order to provide a proper

sealing surface. Dimension ‘A’ to be measured from square-

cut end of pipe. Beveled end pipe not recommended.

Table 1.2 (Cut groove specifications in International units). Groove Width "B": The bottom of the groove to be free of

dirt, chips etc. that may interfere with coupling assembly. See

radius notes on drawing above.

Groove Depth "D": must be of uniform depth for the entire

pipe circumference and must be maintained within the 'C'

dimension tolerance listed.

Min . Wall Thickness "T": For information only. Actual

dimensions must be per groove diameter ‘C’.

Notes:

1. Pipe ends to be square cut and shall be neat and free from

imperfections that may affect durability, operability and safety.

2. Metal shall be free from fins, burrs and sharp/rough edges,

flame cutting is not permitted.

3. Break all corners 0.01 - 0.03 in. chamfer unless otherwise

specified.

4. In the event of a conflict between these notes and

references cited in the drawings, except for detail

specifications, these notes shall take precedence.

Piedmont Pacific Corporation 7 Rev. B

Вам также может понравиться

- 5 MBR Branch Piping-5 MBR Left Branch PipingДокумент1 страница5 MBR Branch Piping-5 MBR Left Branch Pipingmakmak9Оценок пока нет

- Filmtec™ Reverse Osmosis / Nanofiltration Element (S) Three-Year Limited Prorated Element WarrantyДокумент10 страницFilmtec™ Reverse Osmosis / Nanofiltration Element (S) Three-Year Limited Prorated Element Warrantymakmak9Оценок пока нет

- Sprinkler System Specification PrimaryДокумент1 страницаSprinkler System Specification Primarymakmak9Оценок пока нет

- Employee TrainingДокумент10 страницEmployee Trainingmakmak9Оценок пока нет

- Quick Study For Computer Keyboard Short CutsДокумент2 страницыQuick Study For Computer Keyboard Short Cutsmahazari100% (3)

- Full Sprinkler SpecificationДокумент22 страницыFull Sprinkler Specificationmakmak9100% (1)

- fddfdf23 E34 RFДокумент3 страницыfddfdf23 E34 RFmakmak9Оценок пока нет

- Column Setting Plan PDFДокумент1 страницаColumn Setting Plan PDFmakmak9Оценок пока нет

- Wade, Floor DrainДокумент12 страницWade, Floor DrainzfrlОценок пока нет

- Rectangular Duct & FittingsДокумент26 страницRectangular Duct & Fittingsmakmak90% (1)

- Hvac Accessory CatalogДокумент19 страницHvac Accessory Catalogmakmak9Оценок пока нет

- Engineering and Purchasing Controls for Workplace SafetyДокумент13 страницEngineering and Purchasing Controls for Workplace Safetymakmak9Оценок пока нет

- Spec - Sheet Clarke Engine - Ju4h-24 3000rpmДокумент2 страницыSpec - Sheet Clarke Engine - Ju4h-24 3000rpmmakmak9100% (1)

- Construction Safety ManualДокумент51 страницаConstruction Safety Manualmakmak9Оценок пока нет

- Acident/Incident Analysis: By: Eng'r. Edwin D. VillanuevaДокумент8 страницAcident/Incident Analysis: By: Eng'r. Edwin D. Villanuevamakmak9Оценок пока нет

- Virtual Area HsДокумент1 страницаVirtual Area Hsoverdrive0Оценок пока нет

- Procedural Guideline Do 13-ConstructionДокумент41 страницаProcedural Guideline Do 13-ConstructionKim Limuel Tabago Gomez86% (14)

- Safety Manual ConstructionДокумент56 страницSafety Manual Constructionrafaelcardena73Оценок пока нет

- 3”-6” vertical recirculator chopper pump specificationsДокумент2 страницы3”-6” vertical recirculator chopper pump specificationsmakmak9Оценок пока нет

- Cabinet Selection GuideДокумент4 страницыCabinet Selection Guidemakmak9Оценок пока нет

- Vasco 2 PDFДокумент8 страницVasco 2 PDFalexmuchmure2158Оценок пока нет

- 1000 Series Hose Cabinets Accommodate 11/2” Fire Hose RacksДокумент1 страница1000 Series Hose Cabinets Accommodate 11/2” Fire Hose Racksmakmak9Оценок пока нет

- Wade, Floor DrainДокумент12 страницWade, Floor DrainzfrlОценок пока нет

- 3"-6" Vertical Wet Well Screw Centrifugal Pumps: Materials of ConstructionДокумент2 страницы3"-6" Vertical Wet Well Screw Centrifugal Pumps: Materials of Constructionmakmak9Оценок пока нет

- Orbital welding equipment for pulled-tee jointsДокумент2 страницыOrbital welding equipment for pulled-tee jointsmakmak9Оценок пока нет

- OSHPD Approved Sway Brace AttachmentДокумент1 страницаOSHPD Approved Sway Brace Attachmentmakmak9Оценок пока нет

- End Suction Centrifugal: TH SeriesДокумент2 страницыEnd Suction Centrifugal: TH Seriesmakmak9Оценок пока нет

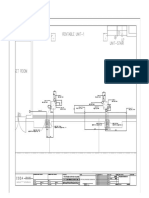

- Ground Floor Sewer & Vent/Drainage Layout: Scale: P-4 1:100 MTSДокумент1 страницаGround Floor Sewer & Vent/Drainage Layout: Scale: P-4 1:100 MTSmakmak9Оценок пока нет

- fddfdf23 E34 RFДокумент3 страницыfddfdf23 E34 RFmakmak9Оценок пока нет

- Stub-Out Plan Ground Floor - AДокумент1 страницаStub-Out Plan Ground Floor - Amakmak9Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Alimak AustraliancontractminingДокумент5 страницAlimak AustraliancontractminingmanudemОценок пока нет

- Curriculum Vitae of Masilo ModibaДокумент11 страницCurriculum Vitae of Masilo Modibalevy2011Оценок пока нет

- PLOTINUS: On Beauty (Essay On The Beautiful)Документ12 страницPLOTINUS: On Beauty (Essay On The Beautiful)Frederic LecutОценок пока нет

- English Idea BookДокумент2 страницыEnglish Idea Bookapi-551731988Оценок пока нет

- Creative NonfictionДокумент11 страницCreative NonfictionRubelyn CagapeОценок пока нет

- DLP Science Week 6 Day 5Документ3 страницыDLP Science Week 6 Day 5John Carlo DinglasanОценок пока нет

- Network 18Документ44 страницыNetwork 18Ashok ThakurОценок пока нет

- Actividad 3.1B-Xport-Model-Exercises-SCMДокумент5 страницActividad 3.1B-Xport-Model-Exercises-SCMDante Rivera SalinasОценок пока нет

- Epson LQ-2090Документ248 страницEpson LQ-2090Dejan StamenovОценок пока нет

- Microsoft PowerPoint - ECHOCARDIOGRAPHY IN ADULT CONGENITAL HEART DISEASE PDFДокумент51 страницаMicrosoft PowerPoint - ECHOCARDIOGRAPHY IN ADULT CONGENITAL HEART DISEASE PDFHanafieHeluthОценок пока нет

- Interpretation of Static Load Tests On The Burj Khalifa's FoundationДокумент9 страницInterpretation of Static Load Tests On The Burj Khalifa's FoundationMALIKОценок пока нет

- 01 UM Nutrition Training PlanДокумент11 страниц01 UM Nutrition Training PlanJohn Leclair100% (2)

- Me 6401 Kom - Uti Ans KeyДокумент11 страницMe 6401 Kom - Uti Ans Keylogeshboy007100% (1)

- Engagement & Akad PDFДокумент3 страницыEngagement & Akad PDFedputriОценок пока нет

- MỘT SỐ CÂU HỎI TRẮC NGHIỆM ÁP DỤNG CHUYÊN ĐỀ GIỚI TỪ TRONG ĐỀ THI ĐHДокумент6 страницMỘT SỐ CÂU HỎI TRẮC NGHIỆM ÁP DỤNG CHUYÊN ĐỀ GIỚI TỪ TRONG ĐỀ THI ĐHPhương ThảoОценок пока нет

- #4 Types of Food, Ingredients and Procedures.Документ7 страниц#4 Types of Food, Ingredients and Procedures.Peter GonzálezОценок пока нет

- PV Elite ResultДокумент18 страницPV Elite ResultVeny MartianiОценок пока нет

- ABRACON's Tuning Fork Crystals and Oscillators for 32.768kHz RTC ApplicationsДокумент13 страницABRACON's Tuning Fork Crystals and Oscillators for 32.768kHz RTC Applicationsdit277Оценок пока нет

- The Evolution of Order DiprotodontiaДокумент35 страницThe Evolution of Order DiprotodontiaMarianne Michelle Quiambao de la RosaОценок пока нет

- CP I-O Modules PDFДокумент91 страницаCP I-O Modules PDFVlad ChioreanОценок пока нет

- John 16 33 Sweet Peace For Tried Believers - Charles SpurgeonДокумент15 страницJohn 16 33 Sweet Peace For Tried Believers - Charles Spurgeonstevel75Оценок пока нет

- Astm F477-08Документ4 страницыAstm F477-08ALARCONISTAОценок пока нет

- Rec2009 025 PDFДокумент172 страницыRec2009 025 PDFEkaStaVTVОценок пока нет

- SmogДокумент5 страницSmogAlain MoratallaОценок пока нет

- Manual CastingДокумент64 страницыManual CastingDjRacksОценок пока нет

- Sap MRP ConfigДокумент23 страницыSap MRP Configsharadapurv100% (1)

- Captain Marvel (DC Comics) : Shazam! Navigation SearchДокумент34 страницыCaptain Marvel (DC Comics) : Shazam! Navigation SearchAce Orense Cupid Uranus Ace Sphinx Galzu Acetr444 son of Multiverses Chaos Gaeia Eros ACETR444Оценок пока нет

- Assignment 1 Systems Analysis - EME5601Документ7 страницAssignment 1 Systems Analysis - EME5601Travis GrantОценок пока нет

- The Indonesian Food Processing Industry (Final)Документ48 страницThe Indonesian Food Processing Industry (Final)patalnoОценок пока нет

- CQ B TECHNIQUESДокумент37 страницCQ B TECHNIQUESeddie6355100% (3)