Академический Документы

Профессиональный Документы

Культура Документы

Design of Crane Runway Beam With Channel PDF

Загружено:

Oscar ChappilliquénОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design of Crane Runway Beam With Channel PDF

Загружено:

Oscar ChappilliquénАвторское право:

Доступные форматы

Design of Crane Runway Beam

with Channel Cap

DUANE S. ELLIFRITT and DUNG-MYAU LUE

INTRODUCTION nC,

Mn = ^ { V ^ a 7 ^ 1 + Vi+52 + ^ ) } (l)

A common practice in industrial buildings is to weld a

channel, open side down, to the top flange of a standard rolled

where

beam for use as a crane runway. In many cases, it is not

possible to brace a crane runway laterally between columns,

so the channel provides additional lateral stiffness. (2)

1

There are several interesting structural questions associ- 2KL VG7

ated with the practice, like, what should be the welding

pattern? How are the residual stresses affected? What if the T?ECW

B,= (3)

channel has a yield strength different from the beam? How- (KLfGJ

ever, the primary question addressed in this paper is, how does

one check such a beam for lateral-torsional buckling? $x = \jytf+ y2)dA-2y0 (4)

The AISC Specification provides formulas for lateral-tor-

sional buckling of monosymmetric sections, but these are

derived for three-plate sections, as shown in Figure 1(a). Cw = )W2ntds, Wn = I f Wjds - W0, W„ = fPods (5)

Some of these equations require the calculation of section o o o

properties that are not readily available from handbooks, like

J = jr2dA (6)

the warping constant, nor do they apply to the real section as A

shown in Figure 1(b).

The purpose of this research was to develop an analytical K= effective length factors (AssumeKx = Ky = Kz= 1.0)

solution to the problem of lateral-torsional buckling of a

To evaluate the elastic nominal moment (Mn) according to

rolled beam with channel cap in terms that are readily avail-

Equations 1, 2, and 3, one has to determine the coefficient of

able from standard section property tables. A program of

full-scale testing was carried out to verify the analytical

r

solution. It should be noted here that the solution proposed in

this paper applies only to light- to medium-duty cranes, those

classified as A, B, or C by the Crane Manufacturers Associa-

tion of America (CM AA).

n

ANALYTICAL SOLUTION FOR

ELASTIC BUCKLING

According to Clark and Hill (1960), Galambos (1968 &

1988), and Johnston (1976), the elastic nominal moment

(Mn) of a monosymmetric beam, including the section of a

rolled beam with a channel cap, can be expressed by the

following equations:

Duane S. Ellifritt is professor of structural design, University of

(a) (b)

Florida, Gainesville, FL.

Dung-Myau Lue is associate professor, National Chung-Hsing

University, Taiwan. Fig. 1. Common monosymmetric sections: (a) 3-plate

section, (b) rolled beam with channel cap.

ENGINEERING JOURNAL / SECOND QUARTER / 1998 41

monosymmetry (fy, the warping constant (CJ, and the tor- 2L, D,

sional constant (J). P, = 0.9 1 D+- (10)

For a monosymmetric section made of three dissimilar

plates, Equations 2 and 3 can be simplified into Using the forty-five sections shown in the AISC Manual

(AISC, 1989) as a data base, it was found that Equation 11

gave a very close approximation of Equation 9

^ = 2.25

(L

-1

Vf (7)

(3, = 0.87(7?-1) D + (ii)

Y

B, = 25 (8) where

In this way, the need to calculate the warping constant is R 2J

avoided. Equations 7 and 8 are identical to the equations in

= r

the footnote on page 6-114 of the AISC-LRFD Specification The solution (Kitipornchai and Trahair) and the proposed

(1993). model are plotted in Figure 2. It can be seen that the approxi-

However, these equations are correct only for the three- mate model (Equation 11) is accurate within ± 4 percent.

plate section; they are conservative for the section which is

the subject of this paper. For the beam-and-channel section, The Cwc Model

one should calculate Px, Cwc, and J according to Equations 4, The authors used a computer program originally written in

5 and 6, but this can be a daunting task for routine design BASIC language by Dr. T. V. Galambos, to calculate the exact

office use. It would be better to have models for these three values of warping constants (Cwc) of a beam with a channel

items which make use of known properties, or easy-to-find cap. The results for the forty-five sections shown in the AISC

properties, that are still reasonably accurate. manuals (AISC 1989 and AISC 1993) are plotted in Figure 3.

PROPOSED MODELS By applying a multiple linear regression technique to the data,

the following curve was found to be a good fit.

The (3, Model

According to Kitipornchai and Trahair (1980), Px for a section

C =C 0.79+1.79 (12)

with a lipped top flange is given by ^w/~ ^ w

w J

2 x

2^ where

$x = 0.9h -1 1- 1+ (9)

2D

0.2 < -f- < 0.95

Recognizing that (Iy/Ixf is a very small number, and letting

h = D, this equation can be reduced to The resulting curve is superimposed on the data of Figure 3.

The model as given by Equation 12 requires no calculation of

1.1 2.6-

.08 -"fc

.06 C n2 A4 ~

• ^ ^

(Q '

.04 ^ ^

.02 ^ 2.3"

1 J) , ,. ^

.98

* * y , # • - -g•m =t-

•H

Z, 2.1"

12*

.96 -**-

.94 ft

u 9H

z ~ *

.92

0)

-•2?

• >*" " "

0.9 T> 1.8"

0.88

r*

0.86

0.84 5

8 i1 6fi-

-

ym

m

0.82

0.8

0. 2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 AC/AW

Ac/Aw

Fig. 3. The warping constant model as a

Fig. 2. The accuracy of the Px model. function of beam and channel area.

42 ENGINEERING JOURNAL / SECOND QUARTER / 1998

section properties and uses only Cw and the ratio Ac /Aw as the t2 = flange thickness of the wide flange

independent variables. These variables A c , A w , and Cw are

given in the AISC Manual of Steel Construction. In Figure 4, All the variables shown are listed in the AISC manual.

it can be observed that the model gives results with errors of Again, the model is applied to the forty-five sections in the

- 3 percent to +5 percent in most sections. [It should be noted AISC Manual and the results are plotted in Figure 5. It can be

that Equation 12 is slightly different from the formula pub- seen that the model overestimates the value of / by +2.1

lished by Lue and Ellifritt (Lue, 1993) previously. This equa- percent to +8.2 percent.

tion is more accurate, while retaining the simplicity of the one

published in 1993.] APPROXIMATE DESIGN USING

THE PROPOSED MODELS

The/Model The proposed models based on the previous discussions can

The torsional constant (J) can be expressed by be summarized by the following equations.

•/=J^=il^ (13) Mn = -^-^Mpj{Bl+^\+B2 + B\^ (16)

where

where

bt and tt = width and thickness, respectively of each n2ECwc

element of the cross-section Bx. *P*-*/^ B, (17)

2KL y GJ (KLfGJ

n = number of plate elements

A further modification of Equation 13 has been done for the 1^ = 0 . 8 7 ( 2 / ? - 1 ) D + A R-2I>< (18)

need of the practical designer. The modified formula of J is

J

calculated based on the section properties and dimensions of

wide flanges and channel caps as listed in AISC manual. The I =1 +1 I = — + I (19)

proposed J is given by the following equations. *y yw ' xxc> -*yc ^ ' *xc

J = iibit^ = Jw+jc + hf(tl + t2)3^hf^1 + ti)(14) C -C 0.79+1.79 , 0.2 < - ^ < 0.95 (20)

V W

= Jw + Jc + bftlt2(tl + t2) (15) / = / w + / c + flf1f2(f1 + f2) (21)

where The forty-five AISC sections are used to examine the differ-

Jw and Jc = torsional constants for the wide flange and the ences between the exact nominal moments (Mn) and the ones

channel, respectively based on the proposed models.

bf = flange width of the wide flange The curves of nominal moment (Mn) versus unbraced

fi = web thickness of the channel length (Lb) were examined by using the proposed models. A

l.i 1.1

.08 .08

.06 .06

1.04 .04 -*%r&—•"*—

1.02 .02-

1 i _ i 1-

0.98 4*H .98

0.96 .96-

0.94 .94-

0.92 .92-

0.9 0.9-

0.88 0.88

0.86 0.86-

0.84 0.84-

0.82- 0.82-

0.8- 0.8-

0 0.3 0.4 0.5 0.6 0.7 0.8 0.9 0 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Ac/Aw Ac/AW

Fig. 4. The accuracy of the warping constant model. Fig. 5. The accuracy of the torsion constant model.

ENGINEERING JOURNAL / SECOND QUARTER / 1998 43

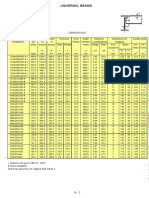

straight line, which is adopted by the current LRFD method, Table 1.

is used for the inelastic nominal moment between the plastic Percent Error in Proposed Elastic Buckling

moment (Mp) and the limiting moment (Mr). The results of the Moment Model for Combination Beam

and Channel Sections Shown in

twenty-eight sections in the AISC-LRFD Manual are re- the AISC-LRFD Manual (1993)

corded in Table 1. It can be seen that the model gives errors

of-2.5 percent to +1.8 percent. Beam Channel AQ / Ayy % Error

The proposed formulation, shown in Equations 16 through 920x223 (36x150) 380x50 (15x33.9) 0.225 -0.8 to-0.1

21, makes use of only dimensions and properties readily 840x210 (33x141) 380x50 (15x33.9) 0.239 -0.9 to -0.2

available from the AISC Manual and produces results only 610x125 (24x84) 310x31 (12x20.7) 0.247 -1.8 to -0.7

±2.5 percent from the exact solution. 920x223 (36x150) 460x64 (18x42.7) 0.285 -1.4 to-0.4

Bear in mind that the foregoing is only an elastic solution 840x176 (33x118) 380x50 (15x33.9) 0.287 -1.1 to-0.3

and the increased lateral strength of adding a channel cap may 760x173 (30x116) 380x50 (15x33.9) 0.291 -1.3 to-0.4

mean that lateral-torsional buckling will be inelastic. How-

840x210 (33x131) 460x64 (18x42.7) 0.303 -1.3 to-0.7

ever, the inelastic transition curve will still be affected by the

610x101 (24x68) 310x31 (12x20.7) 0.303 -2.1 to-1.0

elastic curve. In this research, the AISC-LRFD approach of

530x101 (21x68) 310x31 (12x20.7) 0.305 -1.9 to -0.5

using a straight line inelastic transition curve between Mp and

530x92 (21x62) 310x31 (12x20.7) 0.333 -2.0 to-0.5

Mr was followed.

760x147 (30x99) 380x50 (15x33.9) 0.342 -1.4 to-0.4

690x140 (27x94) 380x50 (15x33.9) 0.360 -1.2 to-0.5

Experimental Study 840x176 (33x118) 460x64 (18x42.7) 0.363 -1.3 to-0.5

Full-scale tests were performed on the beams shown in Ta- 760x173 (30x116) 460x64 (18x42.7) 0.368 -1.2 to-0.5

ble 3. The testing apparatus is shown in Figure 6. The beams 690x125 (27x84) 380x50 (15x33.9) 0.402 -1.2 to-0.3

were tested with a single concentrated load applied to the top 610x125 (24x84) 380x50 (15x33.9) 0.403 -1.2 to-0.5

flange through a ball joint either at mid-span or at the one 460x74 (18x50) 310x31 (12x20.7) 0.414 -2.0 to-0.8

third-point. A gravity load simulator, as shown in Figure 6, 760x147 (30x99) 460x64 (18x42.7) 0.433 -1.0 to-0.2

was used to ensure that the load would remain vertical during 610x101 (24x68) 380x50 (15x33.9) 0.496 -1.1 to-0.2

lateral buckling of the beam. An independent stand held two 530x101 (21x68) 380x50 (15x33.9) 0.498 -0.6 to+0.1

LVDT's for measuring both vertical and horizontal displace- 360x44 (14x30) 250x23 (10x15.3) 0.507 -1.2 to+0.2

ments. The ends of the beams rested on rollers and could 530x92 (21x62) 380x50 (15x33.9) 0.544 -0.5 to+0.1

rotate about both horizontal and vertical axes, but were re- 410x53 (16x36) 310x31 (12x20.7) 0.575 -0.4 to+1.4

strained from torsional rotation about a longitudinal axis. 310x39 (12x26) 250x23 (10x15.3) 0.587 -2.5 to-0.8

460x74 (18x50) 380x50 (15x33.9) 0.678 +0.1 to+0.6

Load Point 360x44 (14x30) 310x31 (12x20.7) 0.688 -0.4 to+0.6

l e s t Specimen 310x39 (12x26) 310x31 (12x20.7) 0.796 -1.6 to-1.3

410x53 (16x36) 380x50 (15x33.9) 0.940 +0.4 to+1.8

r— Loading Yoke

Notes: Ac = Area of Channel Aw = Area of Beam

Fy= 350 MPa (50 ksi)

Unbraced Length = 19 to 23 m (60 to 70 ft.)

Mni = Theoretical Nominal Moment

Mri2 = Nominal Moment by Proposed Model

% Error = (Mn2 - Mn\)/Mn\ * 100

In selecting the beam and channel sizes to be tested, an

attempt was made to devise combined specimens that repre-

sented low, intermediate and high values of the area ratios

(See Table 1 for representative values of Ac/Aw).

In order to get the most out of the material, each beam was

tested twice: once without the channel cap and once with it.

In the first test, the beam was made long enough to ensure

buckling in the elastic range. Then it was unloaded, taken

down and a channel was welded to the top flange. The

composite beam was then put back in the fixture and tested

again. In the second stage, failure was either by inelastic

Fig. 6. Experimental loading apparatus.

44 ENGINEERING JOURNAL / SECOND QUARTER / 1998

Table 2.

Beam Test Results (without Channels)

Span Pu Pe

Test N o . Beam m(ft) Load @ kN(k) kN(k) Pu/Pe

W-1 310x28 (W12x19) 7.3 (24) V2-pt. 15.6(3.50) 10.8(2.44) 1.43

W-2 310x33 (W12x22) 5.5(18) V 3 -pt. 46.7(10.5) 32.4 (7.29) 1.44

W-3 250x22 (W10x15) 5.5(18) V3-pt. 18.6(4.20) 15.1 (3.40) 1.24

W-4 310x28 (W12x19) 5.5(18) V3-pt. 44.8(10.0) 23.5 (5.28) 1.89

W-5 310x28 (W12x19) 3.7(12) V2-pt. 70.3(15.8) 56.9(12.8) 1.23

W-6 250x22 (W10x15) 3.7(12) V2-pt. 40.0 (9.00) 36.3(8.15) 1.10

W-7 200x9.7 (M8x6.5) 3.7(12) V 2 -pt. 8.0(1.80) 4.8(1.08) 1.67

W-8 200x9.7 (M8x6.5) 3.7(12) V2-pt. 6.7(1.50) 4.8(1.08) 1.39

Notes:

Pu is the elastic buckling load from test

Pe is the theoretical elastic buckling load, based on Cb = 1

buckling or yielding and plastic hinge formation at the load elastically, while most of those with a channel cap either

point. Because of the limitations in our laboratory, it was buckled inelastically or formed a plastic hinge.

difficult to get lengths of combined specimens long enough Note the test load/predicted load in Table 2. The predicted

to produce elastic behavior. The results of all tests are shown load was calculated using a moment diagram modifier, (called

in Tables 2 and 3 and graphically in Figures 7 and 8. Tensile Cb in AISC) of 1.0. The Pu/Pe values then should be somewhat

coupons were taken from each member and those results are representative of the proper Cb values. The loading was done

shown in Table 4. with a single concentrated load at either the mid-span or V3

Figure 9 shows a beam being loaded. Note the end fixtures point. Calculated Cb values vary from 1.32 to 1.41. With a

that prevent rotation about the longitudinal axis but allows couple of exceptions, most tests fall into this range. The

rotation about the x and y axes. Figure 10 shows a beam with average for all tests is 1.42.

channel cap after buckling. Note that the load at mid-span is The Pu/Pe values for the tests with channel, however, are

applied uniformly across the flange, rather than at a ball-joint much lower, ranging from 0.93 to 1.23 with an average of

as in Figure 9. This was to see if the loading device had any 1.10. This indicates that the current formula for Cb in the 1993

restraining effect on lateral-torsional buckling. AISC-LRFD Specification is accurate enough for bisymmet-

ric sections, but overestimates the value of the moment coef-

Evaluation of Test Results ficient for monosymmetric sections.

In Figures 7 and 8, the test results are plotted against the Nethercot and Rockey (1971) proposed a moment modifier

theoretical solution described in the early pages of this paper. that was dependent on where on a cross section the load was

Note that all rolled beams without a channel cap buckled

1.2 1.2

1.1 - ----- - ... — 1.1 -- ----- - ' -

'•• !

1 .1.

• • •

_. - |

0.9

0.9 %

0.8 - - 0.8

a . 0.7 Q-0.7 ------ --•- • ----- •- -

f 0.6 ~".

- A vT -- '- - - - -'

I E 0.5 2 0.5

•S

• - - "

0.4 0.4

0.3 :_. >! > • .._ — 0.3

0.2 «* 0.2 ..... ._..

0.1

- — --• --' "j- • !

0.1 __..:

0 0

C 0. 4 0. 8 2 1. 2 2. 4 2. 8 0.4 0.8 1.2 1.6 2 2.4 2.8

6

1Lanibd a = Sq rt(i\Ap/\Vie) Lambda = Sqrt(Mp/Me)

Fig. 7. Tests of rolled beams without channels. Fig. 8. Tests of beams with channel caps.

ENGINEERING JOURNAL / SECOND QUARTER / 1998 45

Table 3.

Test Results, Beam with Channel Cap

Span Pu Pe

Test No. Beam Channel m(ft) Load @ kN(k) kN(k) Pu/Pe

WC-1 310x28 (W12x19) 150x12 (C6x8.2) 7.3 (24) v2 53.8(12.0) 57.8(12.9) 0.93

WC-1 A 310x28 (W12x19) 150x12 (C6x8.2) 5.5(18) v2 84.5(19.0) N/A

WC-2 310x33 (W12x22) 150x12 (C6x8.2) 5.5(18) v3 136(30.5) 148(33.3) 0.93

WC-2A 310x33 (W12x22) 150x12 (C6x8.2) 5.5(18) v3 173(39.0) N/A

WC-3 250x22 (W10x15) 150x12 (C6x8.2) 5.5(18) V3 102(22.9) 81.8(18.4) 1.23

WC-4 310x28 (W12x19) 150x12 (C6x8.2) 5.5(18) v3 158(35.5) 128(28.8) 1.23

WC-5 310x28 (W12x19) 150x12 (C6x8.2) 3.7(12) v2 220 (49.5) 222 (49.9) 0.99

WC-6 250x22 (W10x15) 150x12 (C6x8.2) 3.7(12) v2 145(32.5) 125(28.2) 1.15

WC-7 200x9.7 (M8x6.5) 100x8 (C4x5.4) 3.7(12) v2 44.5(10.0) 36.3(8.16) 1.23

WC-8 200x9.7 (M8x6.5) 100x8 (C4x5.4) 3.7(12) v2 40.0 (9.0) 36.3(8.16) 1.10

Notes:

iding load or the inelastic buckling load, based on the LRFD straight line transition,

Pe in this table is either the plastic ber

The "A" subscript refers to those tests in which the load was applied through a flat surface in contact with the entire compression flange, as

opposed to a ball joint.

applied. It consisted of two terms A and B, and Cb was A SUGGESTED DESIGN PROCEDURE

computed as: The standard unbraced length vs. moment capacity curve for

Cb = A /B if load is applied to top flange doubly symmetric sections as published in AISC is shown in

Cb = A if load is applied at centroid Figure 11. It is completely defined by Mp, Mr, Lp, Lr and the

Cb = A • B if load is applied to bottom flange elastic buckling curve, all of which are easily calculated for

rolled shapes whose properties are found in tables.

They derived values for A and B for the case of a concentrated For monosymmetric sections, everything about the curve

load at the mid-span of a doubly symmetric section. While becomes more complicated. Mr is the smaller of FLSXC and

this does not exactly fit the beams described in this paper, it Fy Sxt; some vital section properties have to be calculated, with

seems to offer a plausible explanation for the values of

R/PP from Table 3.

Fig. 9. Channel-capped beam under load.

Note the end restraints against rotation

and the top-flange, ball-joint load. Fig. 10. Test beam after loading, showing buckled shape.

46 ENGINEERING JOURNAL / SECOND QUARTER / 1998

Table 4.

Mechanical Properties of Test Specimens

Beams Fy Channels Fy

310x28 (W12x19) 432 MPa (62.1 ksi) 150x12(06x8.2) 435 MPa (62.6 ksi)

310x33 (W12x22) 431 (64.0) 150x12(06x8.2) 334 (48.0)

250x22 (W10x15) 370 (53.3) 150x12(06x8.2) 350 (50.3)

200x9.7 (M8x6.5) 278 (40.0) 100x8(04x5.4) 316(45.4)

no small effort; Lr cannot be determined directly, but is the with a Cl5x33.9 cap on a 30-foot simple span. It is assumed

result of an iterative process. that the entire span length is unbraced laterally.

One can help things a bit by initializing the curve, dividing The first example makes use of the curve-fit properties of

Mn by Mp and changing the horizontal axis from Lb to X = P-,, CWC, and J (Equations 11, 12, and 13) of this report. This

^Mp/Me, where Me is the elastic lateral-torsional buckling provides, of course, only an elastic buckling solution. For the

moment. Using the forms of $x, Cwc, and J presented in this inelastic case, it is assumed that the AISC straight-line tran-

paper (Equations 11, 12, and 13), and developing curves for sition between Lp and Lr is appropriate.

all 48 combination sections from AISC LRFD (pp. 1-106, In calculating M„ there is a fundamental question that must

107) and AISC ASD (pp. 1-83, 85), it was found that, with be addressed: What residual stress is appropriate? The Speci-

small error, "one curve fits all." There is a narrow band fication requires 10 ksi for rolled sections and 16.5 for welded

between Lp and Lr, but the elastic curves were practically shapes, but does not say what to use if you weld two rolled

identical. This led to the approximate curve shown in Fig- shapes together. The welding of a channel to the top flange of

ure 12. a crane beam is usually intermittent—it only being required

This eliminates the iteration to find Lr, but also obscures to transmit horizontal shear, which is low. A 2- or 3-in. weld

the unbraced length a bit. With this curve, you will have to every 4 feet is usually adequate. In the author's opinion, this

calculate Me for a given unbraced length, determine A,, then is not a great amount of heat input to the beam and it seems

Mn is either Mp, Me, or reasonable to use 10 ksi for the residual stresses in the Mr

calculation.

( The determination of Lr in Example 1 is still troublesome.

A-0.49 ^

Mn = M-(M-Mr) (22) There is no way to calculate it directly: It must be iterated,

1.15-0.49

until the unbraced length used in the elastic buckling formu-

lation produces anM e = Mr. That length is then Lr.

Example 2 uses the generalized approach discussed which

DESIGN EXAMPLE

plots Mn/Mp against VMp /Me. This has the advantage of

There are two design examples attached to this report. The eliminating the annoying iterations for Lr, but the disadvan-

beam, channel cap, and span are the same as the example in tage of somewhat camouflaging the unbraced length.

the AISC Steel Design Guide Series #7—Industrial Build- The procedure is: calculate Me as described herein for

ings: Roofs to Column Anchorage, (p. 52). It is a W27X94

0.75

M.

UnMp

0.49 1.15

A =^vyM e

Unbraced Length, 1^

Fig. 11. Nominal moment capacity curve according Fig. 12. Generalized M-X curve for rolled beams

to AISC-LRFD Specification. with channel cap (A36 steel).

ENGINEERING JOURNAL / SECOND QUARTER / 1998 47

whatever unbraced length you have, then calculate X. If X is Journal of the Structural Division, ASCE, Vol. 86, No. ST7,

between 1.15 and 0.49, use the straight line transition shown 1960, pp. 175-196.

in Equation 22; if it is less than 0.49, Mn = Mp; if it is greater Galambos, T. V., Structural Members and Frames, Prentice-

than 1.15, Mn = Me. Note that the results of the two examples Hall, Englewood Cliffs, NJ, 1968, pp. 80-158.

differ by only 1 percent.

Galambos, T. V., Guide to Stability Design Criteria for Metal

Structures, Wiley, NY, 1988, pp. 155-188.

SUMMARY AND CONCLUSIONS

Johnston, B. G., Guide to Stability Design Criteria for Metal

A mathematical model was developed to predict the elastic Structures (SSRC), Wiley, NY, 1976, pp. 95-115.

buckling capacity of a hot-rolled wide flange beam with a

Kitipornchai, S., and Trahair, N. S., "Buckling Properties of

channel cap, using only those section properties that can be

Monosymmetric I-beams," Journal of the Structural Divi-

found in steel manuals. The cumbersome calculation of a

sion, ASCE, Vol. 106, No. ST5,1980, pp. 941-957.

warping constant has been reduced to a simple function of

handbook properties. Lue, D. M., and Ellifritt, D. S., "The Warping Constant for

Full scale tests were made on beams without channels. the W-Section with a Channel Cap," Engineering Journal,

These specimens were chosen with unbraced lengths and AISC, 1st Qtr., 1993, pp. 31-33.

cross-sections designed to ensure elastic buckling. The aver- Nethercot, D. A., and Rockey, K. C , "A Unified Approach to

age of test load/calculated load was 1.42. After testing, chan- the Elastic Lateral Buckling of Beams," The Structural Engi-

nels were welded to the top flanges of all these beams and neer, Vol. 49, No. 7, London, UK, 1971, pp. 321-330.

tested again. This time the average test/calculated load

was 1.10. NOMENCLATURE

The calculated buckling loads assumed Cb = 1, so the E = Young's Modulus—200 MPa (29,000 ksi)

test/calculated values roughly correspond to the correct Cb G = Shear Modulus—80 MPa (11,300 ksi)

values. Because the shear center and centroid do not coincide Lb = Unbraced Length mm (in.)

in the monosymmetric shapes, the Cb indicated is somewhat Moments of inertia about x and y, axis, respectively,

lower than would be calculated by the current AISC Specifi- mm 4 (in.4)

cation. This suggests that, in the absence of more testing, it Moment of inertia of compression flange about

might be appropriate to take Cb as 1.0 for monosymmetric y-axis

sections. D = Depth of Rolled Beam, mm (in.)

DL = Depth of Lip on Channel Cap, mm (in.)

6 6

ADDITIONAL COMMENTS Cw = Warping Constant of Rolled Beam, mm (in. )

Another aspect of this problem, (not a part of the research C = Warping Constant of Rolled Beam with Channel

reported herein) is the restraining effect of the crane runway Cap

on the other side of the aisle. The maximum wheel load occurs Ac = Area of Channel, mm 2 (in.2)

when the trolley and lifted load is all the way to one side. Aw = Area of Rolled Beam, mm 2 (in.2)

Because most cranes have double-flanged wheels, the runway J = Torsional Constant, mm 4 (in.4)

beam on the other side, being very lightly loaded, will add its Moment of inertia of rolled beam about y-axis, mm 4

*yw """ (in. 4 )

buckling resistance in the same way a stable column supports

a "leaning" column. This was not a part of the University of Moment of inertia of channel about its local x-axis,

he = mm 4 , (in.4)

Florida research. In fact, this author knows of no physical tests

of this phenomenon, but it makes one wonder if lateral-tor- Monosymmetry Parameter

sional buckling of a crane runway beam can really occur in a

fc = Effective Length Factors

normally-proportioned girder, given the lateral support from K = Plastic Moment

the other side. Mp = Elastic Buckling Moment

Me = Nominal Moment Capacity

Mn = (Fy-Fr)S„

REFERENCES

Mr =

American Institute of Steel Construction, Manual of Steel

X =

Construction, Allowable Stress Design, 9th Ed., Chicago, EL, M,

1989. APPENDIX

American Institute of Steel Construction, Manual of Steel

Construction, Load and Resistance Factor Design, 2nd Ed., Example 1

Chicago, IL, 1993. W27X94: Aw = 27.7 in. 2 , 7 ^ = 1 2 4 in. 4 Cw = 21,300 in. 6

Clark J. W., and Hill, H. N., "Lateral Buckling of Beams," Cl5x33.9:A c = 9.96in. 2 , Ixc= 315in. 4 bf=DL = 3.4in.

48 ENGINEERING JOURNAL / SECOND QUARTER /1998

(This is the example used by Fisher in the AISC Steel Design

Me = ^ [<Elpj(Bx + Vl+B2 + B2)}

Guide Series #7, Industrial Buildings, p. 53)

L* = 30ft

= ^ V v ( B 1 + VTT^f)

Warping Constant, Cwc (from Equation 12)

=^ p V439 x 8.46 (o.904 + Vl +0.925+ (0.904)2)

CWC =C

^ W 0.79+1.79

= 24,530 in-k or 2044 ft-k (2773 kN-m)

Mr = FlSxcoxFySxt

= 21,300 0.79 +1.79-y H I

T = (36-10)f>

= 39,690 in.6 (1.066 x 1013 mm6)

= 945 ft-k (1282 kN-m) or

Monosymmetry Parameter, px (from Equation 11)

| | x 268 = 804 ft-k (1091 kN-m)

4 8 4

Iyc = % + IM = ^ + 315 = 377 in. (1.57 x 10 mm )

2

Lr = 51.6 ft (15.8 m) (from iteration)

Ac 377

= 0.859

/, 439 Mp = | | x 357 = 1071 ft-k (1453 kN-m)

R = 2x0.859 =1.718

% = 0.%l(R-\)(D + DL/2)

^ W 9 . 9 6 + ?0 7 x0.745" = 4 - 6 5 i n ( 1 1 8 m m )

f

34^

= 0.87(1.718 - 1) = 17.88 in. (454 mm)

26.92 + ^ 3O0^=3O^5 = 194

l

v J " -4F7 \2<36

Torsion Constant, J (from Equation 15)

J=Jw + Jc + bftxt2(ti + t2)

Mn = Mp-(Mp-Mr) %-c

bf= flange width = 9.99 in. (255 mm) KLr~hj

(

tx = flange thk = 0.745 in. (19 mm) 30 -19.4 A

= 1071-(1071-804)

51.6-19.4

t2 = channel web thk = 0.40 in. (10 mm)

= 983 ft-kips (1334 kN-m)

£=1.0

J = 4.03 + 1.02 + 9.99 x 0.745 x 0.40 (0.745 + 0.40) Example 2

Using Me from Example 1, calculate X

= 8.46 in.4 (3.52 x 1 0 s mm)

Bl

n$

~ 2KLy

[El;

GJ~

2.5270[T

L \ J

X= -4 1071

2044

= .724

0.49 < A, < 1.15, .-. use Equation 22

2.527 f

X-0.49 A

x 17.88 = 0.9042

360 Mn = Mp-(Mp-Mr)

1.15-0.49

n2£C„, 25.56C„

fi,= ^0.724-0.49^

L2GJ L2J = 1071-(1071-804)

1.15-0.49

25.56x39,690

= 0.925 = 976 ft-k (1324 kN-m)

(360) 2 x 8.459

ENGINEERING JOURNAL / SECOND QUARTER / 1998 49

Вам также может понравиться

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesОт EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesОценок пока нет

- Buckling Properties of Monosymmetric I-BeamsДокумент37 страницBuckling Properties of Monosymmetric I-Beamsscribd6062100% (1)

- Changes in Punching Shear Design in Canadian Standard CSA A23.3-04-A Critical Review PDFДокумент13 страницChanges in Punching Shear Design in Canadian Standard CSA A23.3-04-A Critical Review PDFsuitamОценок пока нет

- Cantilevered Hung FramesДокумент43 страницыCantilevered Hung FramesG-off Robson100% (1)

- Working Design of Single AnglesДокумент2 страницыWorking Design of Single AnglesAnonymous 1BdR0EQgbu100% (1)

- 4 Splice Connections ETOOLKITДокумент27 страниц4 Splice Connections ETOOLKITLesego Matojane100% (1)

- SFD Csa S16 01 PDFДокумент116 страницSFD Csa S16 01 PDFGerardo MacedoОценок пока нет

- Design of Crane Runway Beams With Channel Cap PDFДокумент9 страницDesign of Crane Runway Beams With Channel Cap PDFNguyen Duc CuongОценок пока нет

- Beams Calculation - AISC SummaryДокумент40 страницBeams Calculation - AISC SummarycooL_whO_saint100% (2)

- SFD Csa S16 14Документ118 страницSFD Csa S16 14Emily Stafford0% (1)

- Behavior and Design of Single AngleДокумент18 страницBehavior and Design of Single AngleandyhrОценок пока нет

- S-Frame Day 1 - Standard - April 2012 (Electronic)Документ180 страницS-Frame Day 1 - Standard - April 2012 (Electronic)AUNGPS100% (1)

- Bracing Connections Green BookДокумент29 страницBracing Connections Green BookLesego MatojaneОценок пока нет

- Sherman - Extended Shear TabsДокумент148 страницSherman - Extended Shear TabsRohan KarandeОценок пока нет

- Moment Connection HSS Top Plate 9-27-2014Документ36 страницMoment Connection HSS Top Plate 9-27-2014Jesus Rafael Curiel PensoОценок пока нет

- Steel ManualДокумент114 страницSteel ManualkysucoОценок пока нет

- Awc Wood Connection Design Des330 1 Slide Per PageДокумент112 страницAwc Wood Connection Design Des330 1 Slide Per Pagecerratosys100% (1)

- Cisc Vs AiscДокумент11 страницCisc Vs Aiscanon_326950184100% (1)

- 429 Wind Actions Design GuideДокумент12 страниц429 Wind Actions Design GuidedavidpchackoОценок пока нет

- Seismic Design To S16-09 PDFДокумент13 страницSeismic Design To S16-09 PDFDarryn McCormickОценок пока нет

- A Design Guide For Bracing Cold-Formed Steel StructuresДокумент10 страницA Design Guide For Bracing Cold-Formed Steel StructuresSaravanan SilambanОценок пока нет

- AISI DSM Design Guide Schafer VersionДокумент180 страницAISI DSM Design Guide Schafer VersionOmar Eduardo Alvarado Valle100% (1)

- Wind Loading of Industrial, Mining and Petrochemical StructuresДокумент16 страницWind Loading of Industrial, Mining and Petrochemical StructuresapirakqОценок пока нет

- Practical Design of Cold-Formed Steel Z Sections With Lapped ConnectionsДокумент8 страницPractical Design of Cold-Formed Steel Z Sections With Lapped ConnectionsJoseAngelFernandezOrtegaОценок пока нет

- SD Column Design 2Документ8 страницSD Column Design 2egozenovieОценок пока нет

- Vicwest DiaphragmsДокумент62 страницыVicwest Diaphragmsrmsa17Оценок пока нет

- Comparison of Geometric Axis and Principal Axis Bending in Single AnglesДокумент4 страницыComparison of Geometric Axis and Principal Axis Bending in Single Anglesapirakq100% (1)

- MonorailДокумент14 страницMonorailZain AndabloОценок пока нет

- Steel Beams With Web Openings-V2Документ369 страницSteel Beams With Web Openings-V2Brian Krug100% (1)

- F WeldДокумент4 страницыF Weldshantanu chowdhuryОценок пока нет

- CSA Beam Column DesignДокумент21 страницаCSA Beam Column DesignOvidiu PetruescuОценок пока нет

- Design Aid For Triangular Bracket Plates Using AISC SpecificationsДокумент10 страницDesign Aid For Triangular Bracket Plates Using AISC Specificationsmaroco1098100% (7)

- HSS Connection Design After 2005Документ17 страницHSS Connection Design After 2005mrangusОценок пока нет

- Design of Shelf AngleДокумент3 страницыDesign of Shelf AngleMohanОценок пока нет

- Joints in Steel Construction - Simple Connections - Part 22 PDFДокумент1 страницаJoints in Steel Construction - Simple Connections - Part 22 PDFkakem61Оценок пока нет

- Wood Shear Wall Design Examples For WindДокумент4 страницыWood Shear Wall Design Examples For WindAbdurrahman ÇINARОценок пока нет

- Shear Key or Shear Lug Design - US AISC SectionДокумент3 страницыShear Key or Shear Lug Design - US AISC SectionYash PaulОценок пока нет

- Behavior of Corbels With External Prestressing Bars Experimental Study - Nagrodzka Godycka PDFДокумент21 страницаBehavior of Corbels With External Prestressing Bars Experimental Study - Nagrodzka Godycka PDFRômulo Menck RomanichenОценок пока нет

- Design of Bearing Stiffeners in Cold Formed Steel C-SectionsДокумент151 страницаDesign of Bearing Stiffeners in Cold Formed Steel C-SectionsFabio Saraiva BoxОценок пока нет

- Etabs-Automatic Seismic LoadsДокумент54 страницыEtabs-Automatic Seismic LoadsAn Tran Quoc83% (6)

- Section Modulus Equations and Calculators Common Shapes: Got It!Документ4 страницыSection Modulus Equations and Calculators Common Shapes: Got It!Fatih AdamОценок пока нет

- Steel Deck Design Manual Third EditionДокумент294 страницыSteel Deck Design Manual Third EditionFernando Rivera100% (2)

- Metal Deck DesignДокумент38 страницMetal Deck DesignKenneth DavisОценок пока нет

- AISC SCM2013 - Appendix6 Stability Bracing For Columns and BeamsДокумент27 страницAISC SCM2013 - Appendix6 Stability Bracing For Columns and BeamsMeylana Arum KandilasariОценок пока нет

- IDEA Statica Theoretical BackroundДокумент104 страницыIDEA Statica Theoretical Backroundskorabn100% (1)

- Timber Bridge Manual 3 2Документ89 страницTimber Bridge Manual 3 2Anugerah JoshuaОценок пока нет

- Discussion - Design of W-Shapes For Combined Bending and TorsionДокумент2 страницыDiscussion - Design of W-Shapes For Combined Bending and TorsionnaimОценок пока нет

- The Effect of Eccentricity On Brace-To-Gusset AnglesДокумент6 страницThe Effect of Eccentricity On Brace-To-Gusset AnglesAnonymous 7MdZQn10% (1)

- CFD Csa A23.3 14Документ89 страницCFD Csa A23.3 14lee100% (2)

- Structural Steel Desig - Recommended PDFДокумент63 страницыStructural Steel Desig - Recommended PDFNatalia Oviedo100% (1)

- Simpson Strong-Tie CFS Designer ManualДокумент44 страницыSimpson Strong-Tie CFS Designer ManualCarsonBakerОценок пока нет

- 8th DH Errata PDFДокумент10 страниц8th DH Errata PDFClaudioОценок пока нет

- SFD Csa S16 01 PDFДокумент116 страницSFD Csa S16 01 PDFEmily StaffordОценок пока нет

- S6 LoadingsДокумент21 страницаS6 Loadings700spymaster007Оценок пока нет

- Bracing Design To Eurocode 3Документ13 страницBracing Design To Eurocode 3Greg Rabulan100% (1)

- Defining Design Strips: 23.1 Definition of A Design StripДокумент55 страницDefining Design Strips: 23.1 Definition of A Design Stripphong00x3100% (1)

- Design of Crane Runway Beam With Channel Cap: M C KL Eigjb B BДокумент9 страницDesign of Crane Runway Beam With Channel Cap: M C KL Eigjb B BalbertoxinaОценок пока нет

- New Analytical Calculation Models For Compressive Arch Action in Reinforced Concrete StructuresДокумент2 страницыNew Analytical Calculation Models For Compressive Arch Action in Reinforced Concrete Structureskashif2298Оценок пока нет

- Fidic 1999 Red Book PDFДокумент129 страницFidic 1999 Red Book PDFamitjustamit100% (2)

- Performance of Weak-Beam, Strong-Column RC Frames Strengthened at The Joints by FRPДокумент19 страницPerformance of Weak-Beam, Strong-Column RC Frames Strengthened at The Joints by FRPOscar ChappilliquénОценок пока нет

- Hollow Sections 2nd EdtДокумент240 страницHollow Sections 2nd Edtksuscribdacct100% (2)

- IBC1997-UBC2000 Structural Comparison and Cross ReferenceДокумент240 страницIBC1997-UBC2000 Structural Comparison and Cross Referencerobersasmita100% (1)

- FEBeam NotesДокумент32 страницыFEBeam NotesAymanengОценок пока нет

- Hollow Sections 2nd EdtДокумент240 страницHollow Sections 2nd Edtksuscribdacct100% (2)

- Durability of FRP Reinforcements For ConcreteДокумент7 страницDurability of FRP Reinforcements For ConcreteOscar ChappilliquénОценок пока нет

- Okonkwo, V.O., Aginam, C.H., and Chidolue, C. AДокумент9 страницOkonkwo, V.O., Aginam, C.H., and Chidolue, C. AOscar ChappilliquénОценок пока нет

- Pile Design and Installation: Purpose: Key FactorsДокумент4 страницыPile Design and Installation: Purpose: Key FactorsOscar ChappilliquénОценок пока нет

- E-Nakamura 080616 PDFДокумент10 страницE-Nakamura 080616 PDFOscar ChappilliquénОценок пока нет

- FB 40 PDFДокумент4 страницыFB 40 PDFOscar ChappilliquénОценок пока нет

- D7 - Piping SystemsДокумент44 страницыD7 - Piping SystemsOscar ChappilliquénОценок пока нет

- Numerical Modelling of Seismic Behaviour of Earth-Retaining Walls PDFДокумент159 страницNumerical Modelling of Seismic Behaviour of Earth-Retaining Walls PDFMuhanad SalemОценок пока нет

- Strength of Shear Studs in Steel Deck On Composite Beams and JoistsДокумент12 страницStrength of Shear Studs in Steel Deck On Composite Beams and JoistsOscar ChappilliquénОценок пока нет

- Design Code Development For FRP StructuresДокумент12 страницDesign Code Development For FRP StructuresOscar ChappilliquénОценок пока нет

- Design of Single Plate Shear ConnectionsДокумент12 страницDesign of Single Plate Shear Connectionssecanet10Оценок пока нет

- Cable StayedДокумент289 страницCable StayedAnurag KumarОценок пока нет

- Design Steel - Efficient Analysis For Steel Design Using The 2005 AISC Specification PDFДокумент352 страницыDesign Steel - Efficient Analysis For Steel Design Using The 2005 AISC Specification PDFOscar ChappilliquénОценок пока нет

- Design and Control of Concrete Mixtures, 14th EdДокумент360 страницDesign and Control of Concrete Mixtures, 14th Edelnazeer100% (12)

- Design of Prestressed Concrete Flat SlabsДокумент37 страницDesign of Prestressed Concrete Flat SlabsMaad Ahmed Al-MaroofОценок пока нет

- BCSA Code of Practice For Metal Decking and Stud WeldingДокумент0 страницBCSA Code of Practice For Metal Decking and Stud WeldingDifa LiuОценок пока нет

- Typical Limit of DEFLECTIONДокумент4 страницыTypical Limit of DEFLECTIONfreddielistoОценок пока нет

- Beam Design Formulas With Shear and MomentДокумент20 страницBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- 2 Design of Reinforce Concrete BeamsДокумент60 страниц2 Design of Reinforce Concrete BeamsTshepiso NthiteОценок пока нет

- Design of Concrete TanksДокумент198 страницDesign of Concrete Tankssuman33100% (1)

- Uk Truss BrochureДокумент104 страницыUk Truss BrochureJFAFPОценок пока нет

- Response Spectrum Method GuptaДокумент181 страницаResponse Spectrum Method Guptagyan_th9229100% (2)

- Design of Ribbed and Waffle SlabДокумент3 страницыDesign of Ribbed and Waffle Slab2BA19CV059 Rakshita SarangmathОценок пока нет

- Tee-Beam Bridge - Morrice-Little Method (For Longitudinal and Transverse Moments)Документ56 страницTee-Beam Bridge - Morrice-Little Method (For Longitudinal and Transverse Moments)ADITHYA SKОценок пока нет

- CHP 6. Structural InstabilityДокумент37 страницCHP 6. Structural InstabilityisafeeneyОценок пока нет

- Voyager-Project SetsДокумент153 страницыVoyager-Project SetsMyriadisОценок пока нет

- Structural Behaviour of Welded I-Beam To Box-Column Connections Under Dynamic LoadingДокумент12 страницStructural Behaviour of Welded I-Beam To Box-Column Connections Under Dynamic LoadingIJRASETPublicationsОценок пока нет

- Technical Manual Metsec Mezzanine FloorsДокумент23 страницыTechnical Manual Metsec Mezzanine FloorsMusheer BashaОценок пока нет

- RCD Chaptetr 5Документ9 страницRCD Chaptetr 5jereck loquisoОценок пока нет

- Shear in Bending PDFДокумент18 страницShear in Bending PDFChakraphan WuttimuagkwanОценок пока нет

- Guidelines of Suspension Bridges FinalДокумент11 страницGuidelines of Suspension Bridges FinalAjaz HussainОценок пока нет

- BS Section PDFДокумент96 страницBS Section PDFUpendra WalinjkarОценок пока нет

- UC UB 356x368x177 S275: SectionДокумент10 страницUC UB 356x368x177 S275: SectionAtul SinghОценок пока нет

- 5 Cross Section Classification HandoutДокумент2 страницы5 Cross Section Classification HandoutMohan BhalmeОценок пока нет

- Uplift Load Test Procedure TT - 1Документ2 страницыUplift Load Test Procedure TT - 1Mohanadoss UrathuОценок пока нет

- Seismic Behavior and Retrofit of Steel Moment Connections Considering Slab EffectsДокумент13 страницSeismic Behavior and Retrofit of Steel Moment Connections Considering Slab EffectsAmylee SunnОценок пока нет

- Steel BridgesДокумент556 страницSteel BridgesShaun D Gaf100% (4)

- British Steel Sections DatasheetsДокумент18 страницBritish Steel Sections DatasheetsSyamil DzulfidaОценок пока нет

- Design Procedure For Steel Column Bases With Stiff PDFДокумент8 страницDesign Procedure For Steel Column Bases With Stiff PDFAchilles TroyОценок пока нет

- Advanced Structural Mechanics (CSE 20204) Lecture 3: OutlineДокумент8 страницAdvanced Structural Mechanics (CSE 20204) Lecture 3: OutlineYUK LAM WONGОценок пока нет

- Design of Steel I-Section (BS5950)Документ3 страницыDesign of Steel I-Section (BS5950)gertjaniОценок пока нет

- CEE 411 Steel Structures W10-L01: Flexural Member Introduction, Analysis/Design StepsДокумент39 страницCEE 411 Steel Structures W10-L01: Flexural Member Introduction, Analysis/Design StepshummayunkhanОценок пока нет

- Example Beam Column Design IS800 PDFДокумент3 страницыExample Beam Column Design IS800 PDFvrajan1988Оценок пока нет

- Comparison Between Three Different CompositeДокумент11 страницComparison Between Three Different CompositemulualemОценок пока нет

- Tata Steel Advance Sections To BS5950 Nov12Документ60 страницTata Steel Advance Sections To BS5950 Nov12bryan.hesp5491Оценок пока нет

- EN1994 4 HanswilleДокумент73 страницыEN1994 4 Hanswillearamosgavilan100% (1)

- Conceptual Study of A Fast Landing Craft Unit: Part 2 - AnalysisДокумент100 страницConceptual Study of A Fast Landing Craft Unit: Part 2 - AnalysisAshik RahmanОценок пока нет

- Week 11 Lecture Material - WatermarkДокумент57 страницWeek 11 Lecture Material - WatermarkVaibhav SharmaОценок пока нет

- Chapter-1: 1.1 Introduction To Industrial WorkshopДокумент66 страницChapter-1: 1.1 Introduction To Industrial WorkshopsureshОценок пока нет

- PreviewpdfДокумент76 страницPreviewpdfrichardОценок пока нет

- Plate GirderДокумент6 страницPlate Girdermaniram7Оценок пока нет