Академический Документы

Профессиональный Документы

Культура Документы

Safety Data Sheet: Nitrogen, Compressed Gas

Загружено:

abe_seinИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Safety Data Sheet: Nitrogen, Compressed Gas

Загружено:

abe_seinАвторское право:

Доступные форматы

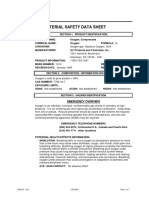

SAFETY DATA SHEET

Nitrogen, Compressed Gas

SECTION 1: PRODUCT AND COMPANY IDENTIFICATION

1.1 Product Details

Product Name : Nitrogen, Compressed gas

Trade name : Industrial Nitrogen, Oxygen Free Nitrogen, Pure Nitrogen, high purity

Nitrogen, Ultra High Purity Nitrogen

Identified uses : General industrial.

1.2 Company Identification

Company’s Name : Leeden Gases Sdn. Bhd

Company’s Address : Lot PT 5074,5075, Jalan Jangur 28/43,

Seksyen 28, 40400 Shah Alam, Selangor.

Emergency telephone Number : 03-55228222 (Hunting Line) / 03-55228288 (Hotline)

SECTION 2: HAZARD IDENTIFICATION

Classification according to Regulation (EC) No 1272/2008 as amended:

Gases under pressure - Compressed gas - H280: Contains gas under pressure; may explode if

heated.

Hazard pictograms :

Signal word : Warning

Hazard statements : Contains gas under pressure; may explode if heated.

Precautionary statements:

Storage : Store in a well-ventilated place.

Environmental Effects : Not harmful.

Other hazards which do not result in classification:

High pressure gas.

Can cause rapid suffocation.

Self-contained breathing apparatus (SCBA) may be required.

SDS No.: 009 Date of revision: 01 August 2016

SECTION 3: COMPOSITION/INFORMATION ON INGREDIENTS

Chemical name : Nitrogen

CAS number : 7727-37-9

Proportion : >99.995%

SECTION 4: FIRST AID MEASURES

Inhalation : Remove to fresh air. If breathing has stopped or is labored, give assisted

respirations. Supplemental oxygen may be indicated. If the heart has stopped,

trained personnel should begin cardiopulmonary resuscitation immediately. In

case of shortness of breath, give oxygen.

Ingestion : Ingestion is not considered a potential route of exposure.

Symptoms : Exposure to oxygen deficient atmosphere may cause the following symptoms:

Dizziness. Salivation. Nausea. Vomiting. Loss of mobility/consciousness.

SECTION 5: FIRE FIGHTING MEASURES

Suitable Extinguishing Media : All known extinguishing media can be used.

Special hazards : Upon exposure to intense heat or flame, cylinder will vent

rapidly and or rupture violently. Product is non-flammable

and does not support combustion. Move away from

container and cool with water from a protected position.

Keep containers and surroundings cool with water spray.

Special protective equipment : Wear self-contained breathing apparatus for fire fighting if

for fire-fighters necessary.

SECTION 6: ACCIDENTAL RELEASE MEASURE

Personal precautions, protective equipment and emergency procedures:

Evacuate personnel to safe areas. Wear self-contained breathing apparatus when entering area

unless atmosphere is proved to be safe. Monitor oxygen level. Ventilate the area.

Environmental Precautions : Do not discharge into any place where its accumulation

could be dangerous. Prevent further leakage or spillage if

safe to do so.

Methods and material for : Ventilate the area.

containment and cleaning up

Additional advice : If possible, stop flow of product. Increase ventilation to the

release area and monitor oxygen level. If leak is from

cylinder or cylinder valve, call the Air Products emergency

SDS No.: 009 Date of revision: 01 August 2016

telephone number. If the leak is in the user's system, close

the cylinder valve and safely vent the pressure before

attempting repairs.

SECTION 7: HANDLING AND STORAGE

Handling : Protect cylinders from physical damage; do not drag, roll, slide or drop. Do not

allow storage area temperature to exceed 50°C (122°F). Only experienced and

properly instructed persons should handle compressed gases/cryogenic liquids.

Before using the product, determine its identity by reading the label. Know and

understand the properties and hazards of the product before use. When doubt

exists as to the correct handling procedure for a particular gas, contact the

supplier. Do not remove or deface labels provided by the supplier for the

identification of the cylinder contents. When moving cylinders, even for short

distances, use a cart (trolley, hand truck, etc.) designed to transport cylinders.

Leave valve protection caps in place until the container has been secured against

either a wall or bench or placed in a container stand and is ready for use. Use an

adjustable strap wrench to remove over-tight or rusted caps. Before connecting

the container, check the complete gas system for suitability, particularly for

pressure rating and materials. Before connecting the container for use, ensure that

back feed from the system into the container is prevented. Ensure the complete

gas system is compatible for pressure rating and materials of construction. Ensure

the complete gas system has been checked for leaks before use. Employ suitable

pressure regulating devices on all containers when the gas is being emitted to

systems with lower pressure rating than that of the container. Never insert an

object (e.g. wrench, screwdriver, pry bar, etc.) into valve cap openings. Doing so

may damage valve, causing a leak to occur. Open valve slowly. If user

experiences any difficulty operating cylinder valve discontinue use and contact

supplier. Close container valve after each use and when empty, even if still

connected to equipment. Never attempt to repair or modify container valves or

safety relief devices. Damaged valves should be reported immediately to the

supplier. Close valve after each use and when empty. Replace outlet caps or plugs

and container caps as soon as container is disconnected from equipment. Do not

subject containers to abnormal mechanical shock. Never attempt to lift a cylinder

by its valve protection cap or guard. Do not use containers as rollers or supports

or for any other purpose than to contain the gas as supplied. Never strike an arc on

a compressed gas cylinder or make a cylinder a part of an electrical circuit. Do

not smoke while handling product or cylinders. Never re-compress a gas or a gas

mixture without first consulting the supplier. Never attempt to transfer gases from

one cylinder/container to another. Always use backflow protective device in

piping. When returning cylinder install valve outlet cap or plug leak tight. Never

use direct flame or electrical heating devices to raise the pressure of a container.

Containers should not be subjected to temperatures above 50°C (122°F).

SDS No.: 009 Date of revision: 01 August 2016

Storage : Full containers should be stored so that oldest s tock is used first. Containers

should be stored in a purpose build compound which should be well ventilated,

preferably in the open air. Stored containers should be periodically checked for

general condition and leakage. Observe all regulations and local requirements

regarding storage of containers. Protect containers stored in the open against

rusting and extremes of weather. Containers should not be stored in conditions

likely to encourage corrosion. Containers should be stored in the vertical position

and properly secured to prevent toppling. The container valves should be tightly

closed and where appropriate valve outlets should be capped or plugged.

Container valve guards or caps should be in place. Keep containers tightly closed

in a cool, well-ventilated place. Store containers in location free from fire risk and

away from sources of heat and ignition. Full and empty cylinders should be

segregated. Do not allow storage temperature to exceed 50°C (122°F). Return

empty containers in a timely manner.

SECTION 8: EXPOSURE CONTROL AND PERSONAL PROTECTION

Appropriate : Provide natural or mechanical ventilation to prevent oxygen deficient

engineering atmospheres below 19.5% oxygen.

controls

Individual protection measures, such as personal protective equipment:

Respiratory : Self-contained breathing apparatus (SCBA) or positive pressure airline

protection with mask are to be used in oxygen-deficient atmosphere. Air

purifying respirators will not provide protection. Users of breathing

apparatus must be trained.

Hand protection : Wear working gloves when handling gas containers. Chemical-

resistant, impervious gloves complying with an approved standard

should be worn at all times when handling chemical products if a risk

assessment indicates this is necessary.

Eye protection : Safety glasses recommended when handling cylinders.

Skin and body : Safety shoes are recommended when handling cylinders.

protection

Special instructions : Ensure adequate ventilation, especially in confined areas.

for protection and

hygiene

SDS No.: 009 Date of revision: 01 August 2016

SECTION 9: PHYSICAL AND CHEMICAL PROPERTIES

Appearance : Compressed gas

Colour : Colourless.

Odour : Odourless

Melting point : -346 °F (-210 °C)

Boiling point : -321 °F (-196 °C)

Flammability (solid, gas) : Refer to product classification in Section 2

Solubility in Water : 0.02 g/l

Relative vapour density : 0.97 (air = 1) Lighter or similar to air.

Molecular weight : 28 g/mole

Density : 0.075 lb/ft3 (0.0012 g/cm3) at 70 °F (21 °C) Note: (as vapour)

Specific Volume : 13.80 ft3/lb (0.8615 m3/kg) at 70 °F (21 °C)

SECTION 10: STABILITY AND REACTIVITY

Chemical stability : Stable under normal conditions.

SECTION 11: TOXICOLOGICAL INFORMATION

Inhalation Effects : In high concentrations may cause asphyxiation. Asphyxiation may bring

about unconsciousness without warning and so rapidly that victim may

be unable to protect themselves.

Ingestion Effects : Ingestion is not considered a potential route of exposure.

Symptoms : Exposure to oxygen deficient atmosphere may cause the following

symptoms: Dizziness. Salivation. Nausea. Vomiting. Loss of

mobility/consciousness.

SECTION 12: ECOLOGICAL INFORMATION

No known ecological damage caused by this product.

SECTION 13: DISPOSAL INFORMATION

Waste from residues / : Contact supplier if guidance is required. Return unused product in

unused products original cylinder to supplier.

Contaminated packaging : Return cylinder to supplier.

SDS No.: 009 Date of revision: 01 August 2016

SECTION 14: TRANSPORT INFORMATION

UN Number : UN 1066

UN Proper Shipping Name : NITROGEN, COMPRESSED

Hazard class / Division : 2.2 (Non-flammable gas)

SECTION 15: REGULATORY INFORMATION

Occupational Safety and Health Act 1994 and Regulations.

Use and Standards of Exposure of Chemical Hazardous to Health Regulation 2000.

Occupational Safety and Health (Classification, Labeling and Safety Data Sheet of

Hazardous Chemicals) Regulations 2013.

Country Regulatory list Notification

USA TSCA Included on Inventory.

EU EINECS Included on Inventory.

Canada DSL Included on Inventory.

Australia AICS Included on Inventory.

South Korea ECL Included on Inventory.

China SEPA Included on Inventory.

Philippines PICCS Included on Inventory.

Japan ENCS Included on Inventory.

SECTION 16: OTHER INFORMATION

Training information : Users of breathing apparatus must be trained. The hazard of

asphyxiation is often overlooked and must be stressed during

operator training. Ensure operators understand the hazards.

Other information : Before using this product in any new process or experiment, a

thorough material compatibility and safety study should be carried

out. Ensure adequate air ventilation. Ensure all national/local

regulations are observed. Whilst proper care has been taken in the

preparation of this document, no liability for injury or damage

resulting from its use can be accepted.

SDS No.: 009 Date of revision: 01 August 2016

Вам также может понравиться

- Interview With Hohepa Mapiria Joseph - Joe - Murphy Royal Regent 7 July 2003Документ61 страницаInterview With Hohepa Mapiria Joseph - Joe - Murphy Royal Regent 7 July 2003kiwiit100% (8)

- Marketing Scales HandbookДокумент27 страницMarketing Scales Handbookhasib_ahsanОценок пока нет

- L-M349 (L1b1a) Kenézy Ancestral JourneyДокумент20 страницL-M349 (L1b1a) Kenézy Ancestral JourneyGábor Balogh100% (2)

- R Don Steele - How To Date Young Women For Men Over 35Документ232 страницыR Don Steele - How To Date Young Women For Men Over 35gonzalo_barandiarán83% (6)

- Chemours Freon R 22 MSDSДокумент12 страницChemours Freon R 22 MSDSKhairul Muzamil100% (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryОт EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryОценок пока нет

- Mobile Crane ChecklistДокумент2 страницыMobile Crane Checklistabe_sein100% (1)

- Shyla Jennings Ebook FinalДокумент17 страницShyla Jennings Ebook FinalChye Yong HockОценок пока нет

- MSDS GHe AirProductsДокумент7 страницMSDS GHe AirProductsAirGroupGasОценок пока нет

- MSDS - NitrogenДокумент7 страницMSDS - NitrogenSatish Kumar MauryaОценок пока нет

- SF6 MSDSДокумент7 страницSF6 MSDSjaycarpioОценок пока нет

- Safety Data Sheet: 1. Product and Company IdentificationДокумент9 страницSafety Data Sheet: 1. Product and Company Identificationather1985Оценок пока нет

- Oxygen MSDSДокумент7 страницOxygen MSDSchidanandОценок пока нет

- MSDS 109430 ArgДокумент8 страницMSDS 109430 ArgJackОценок пока нет

- Argon MSDS ApДокумент8 страницArgon MSDS ApMaterial Coordinator - WLОценок пока нет

- Material Safety Data Sheet: Emergency OverviewДокумент7 страницMaterial Safety Data Sheet: Emergency OverviewsahilchemОценок пока нет

- Propylene: Material Safety Data SheetДокумент9 страницPropylene: Material Safety Data Sheetismaeel247Оценок пока нет

- N2-MSDS (Energas)Документ3 страницыN2-MSDS (Energas)haranus2000Оценок пока нет

- Carbon DioxideДокумент9 страницCarbon Dioxideazreen96.worksОценок пока нет

- Isobutylene C4H8 Safety Data Sheet SDS P4614Документ8 страницIsobutylene C4H8 Safety Data Sheet SDS P4614Wayan PartaОценок пока нет

- Msds of OxygenДокумент7 страницMsds of OxygensahilchemОценок пока нет

- Dimethyl Ether SDS E4589Документ7 страницDimethyl Ether SDS E4589Daniil GhilescuОценок пока нет

- SOP Compressed GasДокумент4 страницыSOP Compressed GasSandeep ShettyОценок пока нет

- Compressed GasДокумент3 страницыCompressed GassherinОценок пока нет

- Welding Gas-ArgonДокумент6 страницWelding Gas-ArgonArpit MaheshwariОценок пока нет

- Dry HCL Gas HandlingДокумент5 страницDry HCL Gas HandlingtpchoОценок пока нет

- Material Safety Data SheetДокумент7 страницMaterial Safety Data SheetLaarnie ManalastasОценок пока нет

- Material Safety Data Sheet: Emergency OverviewДокумент6 страницMaterial Safety Data Sheet: Emergency OverviewPuntanata SiagianОценок пока нет

- SOP Operating A Pressure Cooker and AutoclaveДокумент5 страницSOP Operating A Pressure Cooker and AutoclavejuliaОценок пока нет

- Compressed Gas Cylinder SafetyДокумент7 страницCompressed Gas Cylinder SafetyJer HomeОценок пока нет

- Material Safety Data Sheet: Chemical Name Class: AIRДокумент8 страницMaterial Safety Data Sheet: Chemical Name Class: AIRprasad5034Оценок пока нет

- Material Safety Data Sheet: R170 EthaneДокумент7 страницMaterial Safety Data Sheet: R170 Ethanebleve68Оценок пока нет

- MSDS Isobutane UKДокумент6 страницMSDS Isobutane UKmrnickmrnickОценок пока нет

- 07 SDS Cl2Документ8 страниц07 SDS Cl2Fadlul Akbar HerfiantoОценок пока нет

- Compressed Gas Cylinder SafetyДокумент3 страницыCompressed Gas Cylinder SafetyMohamed AhmedОценок пока нет

- Compressed Gas Cryogenic Liquid Cylinder SafetyДокумент5 страницCompressed Gas Cryogenic Liquid Cylinder SafetyHebron DawitОценок пока нет

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationДокумент7 страницMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationPraful E. PawarОценок пока нет

- Argon Compressed GasДокумент6 страницArgon Compressed GasAnto MaryadiОценок пока нет

- ArgonДокумент8 страницArgonariane8910Оценок пока нет

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationДокумент6 страницMaterial Safety Data Sheet: Section 1. Chemical Product and Company Identificationandy hamonanganОценок пока нет

- AcetyleneДокумент6 страницAcetylenemalimsaidi_160040895Оценок пока нет

- Product Name: Oxygen, Refrigerated LiquidДокумент7 страницProduct Name: Oxygen, Refrigerated LiquidHugo AlvarezОценок пока нет

- Osha Outreach Training General Industry Safety Standards Compressed Gases & Gas Cylinders OSHA 29 CFR 1910.101Документ10 страницOsha Outreach Training General Industry Safety Standards Compressed Gases & Gas Cylinders OSHA 29 CFR 1910.101jhoniОценок пока нет

- SDS-Graferex - Lubricant-AdditiveДокумент6 страницSDS-Graferex - Lubricant-AdditiveCanchindoОценок пока нет

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationДокумент6 страницMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationJHbakerОценок пока нет

- Material Safety Data SheetДокумент7 страницMaterial Safety Data SheetmoceОценок пока нет

- Material Safety Data Sheet: 1. Product and Company IdentificationДокумент7 страницMaterial Safety Data Sheet: 1. Product and Company IdentificationSiti NasiroОценок пока нет

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationДокумент6 страницMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationHeo DatОценок пока нет

- Nitrogen MsdsДокумент6 страницNitrogen MsdssalcabesОценок пока нет

- Safety GramДокумент4 страницыSafety GramsjmpakОценок пока нет

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationДокумент6 страницMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationpetercrispОценок пока нет

- Msds AcetyleneДокумент7 страницMsds AcetyleneSyaifuddin Ma'rufОценок пока нет

- The American University in Cairo Environmental Health & Safety DepartmentДокумент10 страницThe American University in Cairo Environmental Health & Safety DepartmentAhmed TarekОценок пока нет

- Handling of RefrigerantДокумент5 страницHandling of RefrigerantAllelie UgotОценок пока нет

- 氢气Hydrogen - MSDSДокумент6 страниц氢气Hydrogen - MSDSRafa JalОценок пока нет

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationДокумент6 страницMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationHenry OdulioОценок пока нет

- Safety Data Sheet Methane, CompressedДокумент5 страницSafety Data Sheet Methane, Compressedamcleod3522Оценок пока нет

- Material Safety Data Sheet: Emergency OverviewДокумент6 страницMaterial Safety Data Sheet: Emergency OverviewMakhdum Muhardiana PutraОценок пока нет

- NES 713 Manual (v3)Документ32 страницыNES 713 Manual (v3)NguyenChiThanhОценок пока нет

- Hydrogen Gas SafetyДокумент1 страницаHydrogen Gas SafetyPrakash KumarОценок пока нет

- 530 - Dryers ManualДокумент10 страниц530 - Dryers Manualck19654840Оценок пока нет

- SDS Ipa (Bi)Документ7 страницSDS Ipa (Bi)syahrizal5479Оценок пока нет

- Msds EthaneДокумент7 страницMsds Ethanenirmal_subudhiОценок пока нет

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsОт EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsОценок пока нет

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryОт EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryОценок пока нет

- Emergency Evacuation RouteДокумент1 страницаEmergency Evacuation Routeabe_seinОценок пока нет

- UMW Workover Sdn. Bhd. Chemical Log Form List of Chemicals Hazardous Chemicals To HealthДокумент4 страницыUMW Workover Sdn. Bhd. Chemical Log Form List of Chemicals Hazardous Chemicals To Healthabe_seinОценок пока нет

- Environmental Mainstreaming Directive and EMT Compliance Report PDFДокумент7 страницEnvironmental Mainstreaming Directive and EMT Compliance Report PDFabe_seinОценок пока нет

- Qualitative Research Chapter 1-5Документ16 страницQualitative Research Chapter 1-5Mikhaela Centeno100% (1)

- The Spokesman Weekly Vol. 32 No. 39 May 30, 1983Документ12 страницThe Spokesman Weekly Vol. 32 No. 39 May 30, 1983SikhDigitalLibraryОценок пока нет

- TaxationДокумент26 страницTaxationReynamae Garcia AbalesОценок пока нет

- Activity 9 Let's Check and Let's AnalyzeДокумент3 страницыActivity 9 Let's Check and Let's AnalyzeJean Tronco100% (5)

- Material Safety Data Sheet: Manufacturer Pt. Bital AsiaДокумент3 страницыMaterial Safety Data Sheet: Manufacturer Pt. Bital AsiaediОценок пока нет

- Once Upon A Timein AmericaДокумент335 страницOnce Upon A Timein Americaqwerty-keysОценок пока нет

- Reflection PseudoscienceДокумент3 страницыReflection PseudoscienceSuganthi RamasamyОценок пока нет

- My Personal Brand and Career GoalsДокумент3 страницыMy Personal Brand and Career GoalsPhúc ĐàoОценок пока нет

- Rawson Homes Duplex DesignsДокумент16 страницRawson Homes Duplex DesignsJhondy TibubosОценок пока нет

- End-Of-Chapter Questions: CambridgeДокумент17 страницEnd-Of-Chapter Questions: CambridgeMido MidoОценок пока нет

- STD 12 Accountancy1Документ264 страницыSTD 12 Accountancy1Chetan KhonaОценок пока нет

- Mico - Hydraulic Power Brake Systems For ForkliftsДокумент4 страницыMico - Hydraulic Power Brake Systems For ForkliftsJenner Volnney Quispe Chata100% (1)

- EXERCISE 1-Passive FormДокумент5 страницEXERCISE 1-Passive FormMichele LangОценок пока нет

- Tutorial 2 - Financial EnvironmentДокумент5 страницTutorial 2 - Financial EnvironmentShi ManОценок пока нет

- (EN) Google Developer Policy - September 1, 2021Документ56 страниц(EN) Google Developer Policy - September 1, 2021JimmyОценок пока нет

- Alcatel 9400 PDFДокумент4 страницыAlcatel 9400 PDFNdambuki DicksonОценок пока нет

- AtharvasheershamДокумент5 страницAtharvasheershamforthegroupsОценок пока нет

- Reflective Journal 4Документ3 страницыReflective Journal 4api-550030025Оценок пока нет

- Chapter 3 ContДокумент12 страницChapter 3 ContVenus Frias-AntonioОценок пока нет

- Denglish TestДокумент139 страницDenglish TestNabil HasanОценок пока нет

- ReportДокумент6 страницReportLâmViênОценок пока нет

- Glide Reflection Folding InstructionsДокумент1 страницаGlide Reflection Folding Instructionsapi-355107616Оценок пока нет

- SPE 166182 Radio Frequency Identification (RFID) Leads The Way in The Quest For Intervention Free Upper Completion InstallationДокумент9 страницSPE 166182 Radio Frequency Identification (RFID) Leads The Way in The Quest For Intervention Free Upper Completion InstallationjangolovaОценок пока нет

- PRP RationaleДокумент12 страницPRP Rationalemarquezjayson548Оценок пока нет

- Types of Media and Media ConvergenceДокумент70 страницTypes of Media and Media ConvergenceYsmile De LaraОценок пока нет