Академический Документы

Профессиональный Документы

Культура Документы

Basementwall 1

Загружено:

John SmithОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Basementwall 1

Загружено:

John SmithАвторское право:

Доступные форматы

Proposed Project Page:

Address of Project Project No.: 15-0001

Architect Designed: b

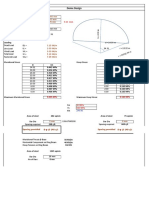

Basement Wall SBW03

STRUTTED BASEMENT WALL V5.00 Demo User

Piers: (Basement Wall SBW03) 500mm dia. piers at 2300mm cts, 32MPa, 8000mm excavation depth

25kPa surcharge, Ks =0.6, Ka = 6

Refer analysis for pier design

Wall: 50% pressure allowance on wall for arching

RL818 (main wires in horizontal direction), N16-400 to wall interface

M* = 16.7kNm > øMuo = 14.8kNm No Good (1.13)

V* = 37.1kN < øVu = 52.7kN OK (0.70)

Pier Geometry

Excavation depth (H) = 8000 mm

Pier centres (cts) = 2300 mm

Pier diameter (dia) = 500 mm

Concrete strength (f'c) = 32 MPa

Cover to steel = 60 mm

Effective cover (Cover - 20mm) = 40 mm

Exposure classification = B1 Table 4.10.3.2 (Standard formwork)

Geotechnical

Geotechnical report =

Lateral surchage coeff (Ks) = 0.6

Surcharge (W) = 25 kPa

Lateral earth pressure (Ka) = 6 x H uniform

Anchor friction = 100 kPa

Socket bearing = 1000 kPa

Socket side friction = 300 kPa

Top proportion = 0.2 (Proportion to full lateral pressure - refer diagram)

% pressure for infill walls = 50 % (50% - 100%)

Soldier pier pressure distribution (free draining)

Working

1 0.20H

At 1 = Ks*W = 15.0 kPa

At 2 = Ks*W + Ka*H = 63.0 kPa 2

At 1 = 34.5 kN/m

At 2 = 144.9 kN/m 0.80H

Ultimate

Earth factor = 1.25 AS 4678 - Cl 4.1

Live load factor = 1.5 AS 4678 - Cl 4.1

At 1 = 51.8 kN/m 0.6W 6.0H

At 2 = 189.8 kN/m

Load factor (LF = Ult*/Working) = 1.31

Analysis for moment and deflection using other methods.

Spray wall

Reinforcement = RL818 (main wires in horizontal direction)

Wall thickness (t) = 150 mm

Concrete strength (f'c) = 32 MPa

Bar size = 7.6 mm

Bar cts/No/mm² = 100 mm

Yield strength (fsy) = 500 MPa

Cover from inside face = 40 mm

Steel area (Ast) = 454 mm²/m

Depth to tensile steel (dsw) = 106 mm

No. bars = 10.0

Bar centres = 100 mm

Exposure classification = A1 Cl 4.10.3.5 (Standard formwork)

Loadings

Horizontal wall span (L) = 1800 mm M* = w*.*L²/8 = 16.7 kNm

w.max = % pressure * lateral surcharge = 31.5 kPa Reaction (R*) = 37.1 kN/m

w* = w.max * LF = 41.3 kPa

Bending Capacity - Cl 8.1

Reinf't ductility class = L (N)ormal,(L)ow

Minimum steel (Ast.min) = 288 mm²/m - Eq 8.1.6.1(2)

alpha (α2 = 1.00-0.003*f'c) = 0.850 (0.67 ≤ α2 ≤ 0.85) Eq 8.1.3(1)

gamma (γ = 1.05-0.007*f'c) = 0.826 (0.67 ≤ γ ≤ 0.85) Eq 8.1.3(2)

kuo = fsy*Ast/(α2*f'c*γ*ds*bw) = 0.095

ø = 1.19-13*kuo/12 = 0.640 (0.60 ≤ ø ≤ 0.64) Table 2.2.2 for L Class

Design capacity (øMuo) = 14.8 kNm/m - Cl 9.1.1 & Cl 8.1.6.1 No Good (1.13)

Dowels = N16-400

Diameter = 16 mm

Centres = 400 mm

Steel area (Ast) = 503 mm²/m

do = t/2 = 75 mm

β1 = Max(0.8 & 1.1*(1.6-do/1000)) = 1.68 Cl 8.2.7.1

fcv = f'c¹′³ ≤ 4MPa = 3.17 MPa

Strength reduction factor ø = 0.70 Table 2.2.2

øVuc = ø*β1*β2*β3*bv*do*fcv*(Ast/(bv*do))¹′³ = 52.7 kN/m - Cl 8.2.7.1 OK (0.70)

Socket resistance

Working reaction (R) = 250 kN horizontal reaction at toe

Socket depth (sd) = 1000 mm

Wedge calculation method = W (W)edge,(A)ngle,(C)ustom

Wedge area (A = 4.5*sd²+2.25*sd*dia) = 5.40 m² (Approx. 27° failure wedge angle) Trimmed

Failure angle = 26.6 ° from horizontal

Angled area (A = 4.47*sd²+2.24*sd*dia) = 5.19 m²

Alternative failure plane area (A) = 5.19 m² Adopt A = 5.40 m²

Case 1 (Shear across coated plane) = R/A = 46.3 kPa ≤ 50 kPa OK (0.93)

Case 2 (Shear across 50% jointed rock plane) = 2*R/A = 92.6 kPa ≤ 150 kPa OK (0.62)

Case 3 (Lateral Bearing) = R/(dia*sd) = 500.0 kPa ≤ 1000 kPa OK (0.50)

Vertical load resistance = 667.6 kN (End bearing and side friction)

Anchors

Anchor friction = 100 kPa

Anchor reaction (T) = 500 kN (horizontal - working)

Anchor declination to horz. (horz) = 15 ° (0° ≤ angle ≤ 45°)

Anchor diameter (adia) = 100 mm

Anchor capacity = 31 kN/m

Required pullout = 518 kN

Estimated anchor length = 16.5 m

Notes:

Exposure classification:

Exposure calculated is based on 20mm reduced

cover - Cl 4.10.3.5(b).

Socket bearing and friction:

Both the socket bearing and side friction

values are not used (reference only).

% pressure for infill walls

A reduced value of the lateral pressure

may be permitted for the design of the

infill walls to take into account soil arching.

Refer to the Geotechnical recommendations.

Ast.min - Cl 9.1.1 & Cl 8.1.6.1

Ast.min = 0.20*(D/ds)²*f'ct.f/fsy*b*ds

f'ct.f = 0.6*√f'c (Cl 3.1.1.3)

Concrete Bending Capacity:

øMuo = ø*fsy*Ast*ds*[1-fsy*Ast/(2*α2*f'c*bw*ds)]

bw = 1000mm

Shear capacity- Cl 8.2.7.1

β2 = 1.00

β3 = 1.00

Socket stability:

Refer to the Geotechnical Consultant for advice

on appropriate design methodology and stability

calculations and values.

< Assume joints are bedding planes in at least a favourable orientation and are clay coated.

< Assume joints clean but 50% are open therefore effective area = 0.5A

< Direct bearing on projected area of pier

Soil anchors - AS 4678 - Appendix B:

Appendix B provides informative guidance

on ground anchors. Refer to the Geotechnical Consultant

for appropriate anchor design advice.

Вам также может понравиться

- Longitudinal Frame Seismic LoadДокумент19 страницLongitudinal Frame Seismic LoadAlex de GuzmanОценок пока нет

- Hydraulic Calculation For Bridge No.:-39 Mahesana-Taranga Gauge Conversion ProjectДокумент3 страницыHydraulic Calculation For Bridge No.:-39 Mahesana-Taranga Gauge Conversion ProjectAnkitaОценок пока нет

- Bar Bending Schedule (BBS) Project Name:-For A2 Abutment Cap at Br. No. 1282/1 (R1)Документ6 страницBar Bending Schedule (BBS) Project Name:-For A2 Abutment Cap at Br. No. 1282/1 (R1)sonuОценок пока нет

- Cantilever R.C. Retaining Wall As Per Is Codes: Job No.: Design By: Date: Page NoДокумент8 страницCantilever R.C. Retaining Wall As Per Is Codes: Job No.: Design By: Date: Page NoRanjeet JadhavОценок пока нет

- Wingwall StabilityДокумент2 страницыWingwall StabilityHiren PatelОценок пока нет

- CRW 13MRДокумент25 страницCRW 13MRraghu kiranОценок пока нет

- Peralihan Peralihan Peralihan Load Dial Beban Tegangan Geser Vertical Horisontal Horisontal Reading Horisontal (kg/cm2) (Div) (Div) (CM) (Div) (KG) 0 0 0 0Документ17 страницPeralihan Peralihan Peralihan Load Dial Beban Tegangan Geser Vertical Horisontal Horisontal Reading Horisontal (kg/cm2) (Div) (Div) (CM) (Div) (KG) 0 0 0 0MARIA CORAZON LAY CORBAFOОценок пока нет

- LP1 RP5Документ84 страницыLP1 RP5praloy dasОценок пока нет

- Darbharevu DesignДокумент59 страницDarbharevu DesignD.V.Srinivasa RaoОценок пока нет

- Description Symbol Value Unit RemarksДокумент1 страницаDescription Symbol Value Unit RemarksRakesh SapkotaОценок пока нет

- Single Lane Road BridgДокумент20 страницSingle Lane Road BridgDevendrasinh PadhiyarОценок пока нет

- Section 1-1 Section 2-2: Detail - A Detail - BДокумент1 страницаSection 1-1 Section 2-2: Detail - A Detail - BRutik PatelОценок пока нет

- Scour SpreadsheetДокумент78 страницScour SpreadsheetRASHID KHANОценок пока нет

- Gs Alafc LoadcnДокумент1 страницаGs Alafc LoadcndsureshcivilОценок пока нет

- 34 Hyd PDFДокумент3 страницы34 Hyd PDFAnkitaОценок пока нет

- Parameter Value: Inputs For Bend Scour OnlyДокумент25 страницParameter Value: Inputs For Bend Scour OnlysumitanuragОценок пока нет

- Howe Truss Computation Analysis2Документ11 страницHowe Truss Computation Analysis2Wingartz Vendiola PosedioОценок пока нет

- Drainage Culvert SN-1 (RS)Документ7 страницDrainage Culvert SN-1 (RS)Waqas AnjumОценок пока нет

- Design of Pipe Encasement For Road Crossing at 8.405KmДокумент11 страницDesign of Pipe Encasement For Road Crossing at 8.405KmRamakanth PuttyОценок пока нет

- Retaining Wall 12m Without Earth QuakeДокумент17 страницRetaining Wall 12m Without Earth QuakeKADALI RAVINDRAОценок пока нет

- BRG-S-T-D-RD 85+835-1X30Документ19 страницBRG-S-T-D-RD 85+835-1X30Aziz ul HakeemОценок пока нет

- Design of Valve Chamber 350mm Dia Pipe - 04112020Документ6 страницDesign of Valve Chamber 350mm Dia Pipe - 04112020Mukesh JangidОценок пока нет

- PCC Return WallДокумент19 страницPCC Return Wallneeta rautelaОценок пока нет

- Eksenel Ve Yanal Yük Kazik HesabiДокумент99 страницEksenel Ve Yanal Yük Kazik Hesabialptekin1Оценок пока нет

- Soil Data PDFДокумент118 страницSoil Data PDFKiran MahajanОценок пока нет

- Amit GuptaДокумент1 страницаAmit GuptaSaurabh PandeyОценок пока нет

- BR No Knw-Amx Section 1 X 2 X3 RCCC Box: 605-1 Return WallДокумент3 страницыBR No Knw-Amx Section 1 X 2 X3 RCCC Box: 605-1 Return Wallravi4paperОценок пока нет

- Navarasapuram DesignДокумент42 страницыNavarasapuram DesignD.V.Srinivasa RaoОценок пока нет

- DSOS Design of Stair + Deflection R0Документ5 страницDSOS Design of Stair + Deflection R0Sneha RedkarОценок пока нет

- Flood Wall PN KhannaДокумент2 страницыFlood Wall PN KhannaSushmit SharmaОценок пока нет

- Cut and CoverДокумент8 страницCut and CoverAkshay DuggalОценок пока нет

- Saikat SaraniДокумент11 страницSaikat SaraniPartha GangopadhyayОценок пока нет

- AbutmentДокумент1 страницаAbutmentआशीष खोखरОценок пока нет

- Intze Tank-50kL Design 18M STAGING - SBC 8TON PER SMTДокумент53 страницыIntze Tank-50kL Design 18M STAGING - SBC 8TON PER SMTRajendra MittalОценок пока нет

- Steel GirderДокумент42 страницыSteel GirderPutri PuttОценок пока нет

- Sump .XLS (2.00 Lakhs)Документ35 страницSump .XLS (2.00 Lakhs)subramanyam kumarОценок пока нет

- B85 - Tie Beam Transverse TB-1Документ8 страницB85 - Tie Beam Transverse TB-1FrederickV.VelascoОценок пока нет

- Comb WalkayДокумент37 страницComb Walkayramesh_madkatte1082Оценок пока нет

- Hgiel 1129 Dve 9 HW 291+100 Fly DN 02Документ189 страницHgiel 1129 Dve 9 HW 291+100 Fly DN 02Chandan SharmaОценок пока нет

- The World Bank: Uttarakhand Disaster Recovery ProjectДокумент14 страницThe World Bank: Uttarakhand Disaster Recovery Projectvicky rawatОценок пока нет

- Preparation of Standard Drawing of Pedestrian Bridge Span: 25 M Load CalculationsДокумент13 страницPreparation of Standard Drawing of Pedestrian Bridge Span: 25 M Load CalculationsRoshan KejariwalОценок пока нет

- Analysis of Fatigue Life Consumed For Single Axle LoadДокумент4 страницыAnalysis of Fatigue Life Consumed For Single Axle LoadvishwasОценок пока нет

- DESIGN-CBR Training MercuДокумент6 страницDESIGN-CBR Training MercuDani RamdaniОценок пока нет

- Flyover-1x30 m-Width2X12Документ8 страницFlyover-1x30 m-Width2X12Hemant GaikwadОценок пока нет

- Counterfort Retaining WallДокумент7 страницCounterfort Retaining WallMohammedОценок пока нет

- 01-Orma Garage Bridge Superstructure DesignДокумент12 страниц01-Orma Garage Bridge Superstructure DesignEngineeri TadiyosОценок пока нет

- Calculation Sheet: Section Properties: Longitudinal Section A L1 X Y (MM) (MM) Grillage MemberДокумент30 страницCalculation Sheet: Section Properties: Longitudinal Section A L1 X Y (MM) (MM) Grillage MemberJennifer HudsonОценок пока нет

- Abutment Column DesignДокумент8 страницAbutment Column DesignTasa NandaОценок пока нет

- FFB3Документ8 страницFFB3prajjwal patidarОценок пока нет

- Bar Bending Schedule (BBS) Project Name:-D.O.C - 27.3.22 For Well Cap at Br. No. 1282/1 (P1 Well Cap)Документ12 страницBar Bending Schedule (BBS) Project Name:-D.O.C - 27.3.22 For Well Cap at Br. No. 1282/1 (P1 Well Cap)sonuОценок пока нет

- 1 X 10 PDFДокумент14 страниц1 X 10 PDFTatsamYadavОценок пока нет

- Dome Design: 14900 MM 2300 MM 125 MMДокумент2 страницыDome Design: 14900 MM 2300 MM 125 MMnavneet3bawaОценок пока нет

- RCC 7m C.F Re WallДокумент30 страницRCC 7m C.F Re WallArun RawatОценок пока нет

- AB AQ 10 Aqueduct AbutmentДокумент25 страницAB AQ 10 Aqueduct AbutmentachsangantengОценок пока нет

- Water TankДокумент4 страницыWater Tankraghu kiranОценок пока нет

- Culvert Design 1Документ66 страницCulvert Design 1kanishkaОценок пока нет

- Catchment Area Ab Road1Документ66 страницCatchment Area Ab Road1skumarsrОценок пока нет

- Flyover FaislabadДокумент72 страницыFlyover Faislabadnespak06Оценок пока нет

- Sleeperwall 1Документ6 страницSleeperwall 1John SmithОценок пока нет

- Pad Footing 1Документ4 страницыPad Footing 1John SmithОценок пока нет

- Timber DesignДокумент1 страницаTimber DesignJohn SmithОценок пока нет

- Beam DesignДокумент2 страницыBeam DesignJohn SmithОценок пока нет

- Wind Analysis 1Документ5 страницWind Analysis 1John SmithОценок пока нет

- Timber Propped Beam 1Документ4 страницыTimber Propped Beam 1John SmithОценок пока нет

- Sleeperwall 1Документ6 страницSleeperwall 1John SmithОценок пока нет

- Beam DesignДокумент2 страницыBeam DesignJohn SmithОценок пока нет

- Timber Mullion 1Документ6 страницTimber Mullion 1John SmithОценок пока нет

- Timber Library V5.01: Member: 190mm X 45mm F7 KD Pine (Non-Laminated) Stress Grade - Table 2.4Документ4 страницыTimber Library V5.01: Member: 190mm X 45mm F7 KD Pine (Non-Laminated) Stress Grade - Table 2.4John SmithОценок пока нет

- Timber Member 1Документ4 страницыTimber Member 1John SmithОценок пока нет

- Retwall 1Документ7 страницRetwall 1John SmithОценок пока нет

- Wall Tie 1Документ4 страницыWall Tie 1John SmithОценок пока нет

- Timber Roof Beam 1Документ4 страницыTimber Roof Beam 1John SmithОценок пока нет

- Timber Floor Beam 1Документ4 страницыTimber Floor Beam 1John SmithОценок пока нет

- Timber Column 1Документ4 страницыTimber Column 1John SmithОценок пока нет

- Post Footing 1Документ3 страницыPost Footing 1John SmithОценок пока нет

- Eccentric Pad Footing 1Документ4 страницыEccentric Pad Footing 1John SmithОценок пока нет

- Footings - Piers & Pads 1Документ3 страницыFootings - Piers & Pads 1John SmithОценок пока нет

- Residential Slab Design 1Документ5 страницResidential Slab Design 1John SmithОценок пока нет

- Masonry Wall 1Документ4 страницыMasonry Wall 1John SmithОценок пока нет

- Timber Circular Columns 1Документ4 страницыTimber Circular Columns 1John SmithОценок пока нет

- Pad Footing 1Документ4 страницыPad Footing 1John SmithОценок пока нет

- Reinforced Masonry Pier 1Документ4 страницыReinforced Masonry Pier 1John SmithОценок пока нет

- Masonry Library 1Документ2 страницыMasonry Library 1John SmithОценок пока нет

- Footings - Piered Beam 1Документ6 страницFootings - Piered Beam 1John SmithОценок пока нет

- Strength and Microscale Properties of Bamboo FiberДокумент14 страницStrength and Microscale Properties of Bamboo FiberDm EerzaОценок пока нет

- Spine Beam - SCHEME 4Документ28 страницSpine Beam - SCHEME 4Edi ObrayanОценок пока нет

- Central Banking and Monetary PolicyДокумент13 страницCentral Banking and Monetary PolicyLuisaОценок пока нет

- Safety Inspection Checklist Project: Location: Inspector: DateДокумент2 страницыSafety Inspection Checklist Project: Location: Inspector: Dateyono DaryonoОценок пока нет

- Typical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpДокумент2 страницыTypical World Coordinates Are: Pos X-Axis Right Pos Y-Axis Back Pos Z-Axis UpSabrinadeFeraОценок пока нет

- 254 AssignmentДокумент3 страницы254 AssignmentSavera Mizan ShuptiОценок пока нет

- 1.6 Program AdministrationДокумент56 страниц1.6 Program Administration'JeoffreyLaycoОценок пока нет

- TRX Documentation20130403 PDFДокумент49 страницTRX Documentation20130403 PDFakasameОценок пока нет

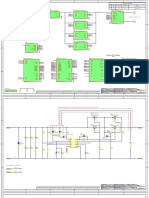

- Scheme Bidirectional DC-DC ConverterДокумент16 страницScheme Bidirectional DC-DC ConverterNguyễn Quang KhoaОценок пока нет

- 1 Ton Per Hour Electrode Production LineДокумент7 страниц1 Ton Per Hour Electrode Production LineMohamed AdelОценок пока нет

- Manulife Health Flex Cancer Plus Benefit IllustrationДокумент2 страницыManulife Health Flex Cancer Plus Benefit Illustrationroschi dayritОценок пока нет

- Colibri - DEMSU P01 PDFДокумент15 страницColibri - DEMSU P01 PDFRahul Solanki100% (4)

- Procurement Audit PlanДокумент12 страницProcurement Audit PlanMustafa Bilal100% (1)

- SyllabusДокумент9 страницSyllabusrr_rroyal550Оценок пока нет

- Math 1 6Документ45 страницMath 1 6Dhamar Hanania Ashari100% (1)

- Marketing Management - Pgpmi - Class 12Документ44 страницыMarketing Management - Pgpmi - Class 12Sivapriya KrishnanОценок пока нет

- Cara Membuat Motivation LetterДокумент5 страницCara Membuat Motivation LetterBayu Ade Krisna0% (1)

- Ril Competitive AdvantageДокумент7 страницRil Competitive AdvantageMohitОценок пока нет

- A.2 de - La - Victoria - v. - Commission - On - Elections20210424-12-18iwrdДокумент6 страницA.2 de - La - Victoria - v. - Commission - On - Elections20210424-12-18iwrdCharisse SarateОценок пока нет

- Si KaДокумент12 страницSi KanasmineОценок пока нет

- Relationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourДокумент16 страницRelationship Between Principal Leadership Skills and Teachers' Organizational Citizenship BehaviourToe ToeОценок пока нет

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentДокумент7 страницA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiОценок пока нет

- RODECaster Pro II - DataSheet - V01 - 4Документ1 страницаRODECaster Pro II - DataSheet - V01 - 4lazlosОценок пока нет

- SDM Case AssignmentДокумент15 страницSDM Case Assignmentcharith sai t 122013601002Оценок пока нет

- Vocabulary Practice Unit 8Документ4 страницыVocabulary Practice Unit 8José PizarroОценок пока нет

- 2 and 3 Hinged Arch ReportДокумент10 страниц2 and 3 Hinged Arch ReportelhammeОценок пока нет

- Idmt Curve CalulationДокумент5 страницIdmt Curve CalulationHimesh NairОценок пока нет

- Resources and Courses: Moocs (Massive Open Online Courses)Документ8 страницResources and Courses: Moocs (Massive Open Online Courses)Jump SkillОценок пока нет

- CNS Manual Vol III Version 2.0Документ54 страницыCNS Manual Vol III Version 2.0rono9796Оценок пока нет

- Dbms UPDATED MANUAL EWITДокумент75 страницDbms UPDATED MANUAL EWITMadhukesh .kОценок пока нет