Академический Документы

Профессиональный Документы

Культура Документы

Budget Estimate for Building 400 Geothermal Projects

Загружено:

Nico Dimas0 оценок0% нашли этот документ полезным (0 голосов)

25 просмотров26 страницThe document provides cost estimates for two alternatives to upgrade the HVAC system for Building 400:

Alternative 2 involves installing water-to-water heat pumps and would cost an estimated total of $4,319,980. This includes well drilling, piping, installing 15 heat pumps, retrofitting existing air handling units, replacing VAV reheat coils, and control system upgrades.

Alternative 3 involves installing central geothermal chillers and would cost an estimated total of $3,809,677. This option replaces the heat pumps with chillers but otherwise involves similar well drilling, piping, air handling unit, and control system work.

Исходное описание:

Оригинальное название

Appendix F (Cost Analysis Tables).pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document provides cost estimates for two alternatives to upgrade the HVAC system for Building 400:

Alternative 2 involves installing water-to-water heat pumps and would cost an estimated total of $4,319,980. This includes well drilling, piping, installing 15 heat pumps, retrofitting existing air handling units, replacing VAV reheat coils, and control system upgrades.

Alternative 3 involves installing central geothermal chillers and would cost an estimated total of $3,809,677. This option replaces the heat pumps with chillers but otherwise involves similar well drilling, piping, air handling unit, and control system work.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

25 просмотров26 страницBudget Estimate for Building 400 Geothermal Projects

Загружено:

Nico DimasThe document provides cost estimates for two alternatives to upgrade the HVAC system for Building 400:

Alternative 2 involves installing water-to-water heat pumps and would cost an estimated total of $4,319,980. This includes well drilling, piping, installing 15 heat pumps, retrofitting existing air handling units, replacing VAV reheat coils, and control system upgrades.

Alternative 3 involves installing central geothermal chillers and would cost an estimated total of $3,809,677. This option replaces the heat pumps with chillers but otherwise involves similar well drilling, piping, air handling unit, and control system work.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 26

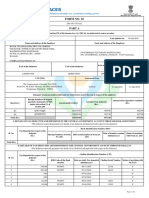

Budget Estimate (Building 400)

Alternative 2 - Water to Water Heat Pump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 54,582 LF $ 10 $ 545,820 4.33-in bore

3 Thermal Bentonite Grout 2,300 BAG $ 30 $ 69,000

4 Geothermal Piping 115,022 LF $ 5.80 $ 667,129 Means 33 51 13.10 1040

5 Facility Piping 789 LF $ 29.50 $ 23,276 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 15 EA $ 20,000 $ 300,000 Vendor pricing

7 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

8 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 272 EA $ 4,792 $ 1,303,424 currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 0 EA $ 391 $ - Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 29 DAY $ 1,882 $ 54,584 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 29 DAY $ 1,618 $ 46,908 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 125 PTS $ 800 $ 100,000 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 121,936 $ 60,968 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 509,933

Subtotal $ 3,909,484

Bonding (1.5%) $ 58,642

Permitting (0.5%) $ 19,547

Design (6%) $ 234,569

Construction Management (1.5%) $ 58,642

Project Management (1%) $ 39,095

TOTAL $ 4,319,980

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 54,582 LF $ 10 $ 545,820 4.33-in bore

3 Thermal Bentonite Grout 2,300 BAG $ 30 $ 69,000

4 Geothermal Piping 115,022 LF $ 5.80 $ 667,129 Means 33 51 13.10 1040

5 Facility Piping 789 LF $ 29.50 $ 23,276 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 0 LS $ 104,000 $ -

7 Chiller Condensing Pipe Retrofits 1 EA $ 7,470 $ 7,470 Means D3030 130 1010

8 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

9 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 272 EA $ 4,792 $ 1,303,424 currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 0 EA $ 391 $ - Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 14 DAY $ 1,882 $ 26,351 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 14 DAY $ 1,618 $ 22,645 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 35 PTS $ 800 $ 28,000 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 69,440 $ 34,720 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 443,442

Subtotal $ 3,399,720

Bonding (1.5%) $ 50,996

Permitting (0.5%) $ 16,999

Design (6%) $ 203,983

Construction Management (1.5%) $ 50,996

Project Management (1%) $ 33,997

TOTAL $ 3,756,691

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 1 of 26

Budget Estimate (Building 400)

Alternative 4 - Water to Water Heat Pump with Auxiliary Boiler

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 18,538 LF $ 10 $ 185,383 4.33-in bore

3 Thermal Bentonite Grout 800 BAG $ 30 $ 24,000

4 Geothermal Piping 39,330 LF $ 5.80 $ 228,116 Means 33 51 13.10 1040

5 Facility Piping 789 LF $ 29.50 $ 23,276 Means 22 11 13.44 0610

6 20 Ton Water to Water HP 12 LS $ 20,000 $ 240,000 Vendor pricing

7 Boiler 1 LS $ 27,100 $ 27,100 Means 23 52 23.20 3300, 1530 MBH Gas Fired Boiler

Assumes utility brings gas to road outside of facility, 1-in SDR 11 Means

8 Natural Gas Piping 140 LF $ 7.45 $ 1,043 33 51 Means 13.10 1040

9 Gas Meter, Regulator, and Other Appurtenances 1 LS $ 1,500 $ 1,500 ROM

10 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

11 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

12 General Site Work and Excavation 15 DAY $ 1,467 $ 22,009 3 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 26 DAY $ 1,882 $ 48,937 2 days per heat pump and AHU, Means Crew R-18

15 Electrical Installation 26 DAY $ 1,618 $ 42,055 2 days per heat pump and AHU, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

18 Control Points 107 PTS $ 800 $ 85,600 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 118,773 $ 59,386 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 180,326

Subtotal $ 1,382,503

Bonding (1.5%) $ 20,738

Permitting (0.5%) $ 6,913

Design (6%) $ 82,950

Construction Management (1.5%) $ 20,738

Project Management (1%) $ 13,825

TOTAL $ 1,527,666

Alternative 5 - Central Geothermal Chillers (Cooling Only)

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 21,298 LF $ 10 $ 212,976 4.33-in bore

3 Thermal Bentonite Grout 900 BAG $ 30 $ 27,000

4 Geothermal Piping 45,125 LF $ 6 $ 261,725 Means 33 51 13.10 1040

5 New Chiller 0 LS $ 104,000 $ -

6 Chiller Condensing Pipe Retrofits 1 EA $ 7,470 $ 7,470 Means D3030 130 1010

7 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

8 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

9 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

10 Mechanical Installation 14 DAY $ 1,882 $ 26,351 2 days per AHU and 5 days per chiller, Means Crew R-18

11 Electrical Installation 14 DAY $ 1,618 $ 22,645 2 days per AHU and 5 days per chiller, Means Crew Q-2

12 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

13 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

14 Control Points 35 PTS $ 800 $ 28,000 temp/humidity, OA damper control, 3 TBD)

15 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 69,440 $ 34,720 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

16 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 121,625

Subtotal $ 932,455

Bonding (1.5%) $ 13,987

Permitting (0.5%) $ 4,662

Design (6%) $ 55,947

Construction Management (1.5%) $ 13,987

Project Management (1%) $ 9,325

TOTAL $ 1,030,363

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 2 of 26

Budget Estimate (Building 401)

Alternative 2 - Water to Water Heat Pump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 34,117 LF $ 10 $ 341,172 4.33-in bore

3 Thermal Bentonite Grout 1,400 BAG $ 30 $ 42,000

4 Geothermal Piping 72,046 LF $ 5.80 $ 417,867 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 10 EA $ 20,000 $ 200,000 Vendor pricing

7 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

8 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 110 EA $ 4,792 $ 527,120 currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 199 EA $ 391 $ 77,710 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 24 DAY $ 1,882 $ 45,173 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 24 DAY $ 1,618 $ 38,820 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 95 PTS $ 800 $ 76,000 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 104,437 $ 52,219 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 310,364

Subtotal $ 2,379,456

Bonding (1.5%) $ 35,692

Permitting (0.5%) $ 11,897

Design (6%) $ 142,767

Construction Management (1.5%) $ 35,692

Project Management (1%) $ 23,795

TOTAL $ 2,629,299

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 34,117 LF $ 10 $ 341,172 4.33-in bore

3 Thermal Bentonite Grout 1,400 BAG $ 30 $ 42,000

4 Geothermal Piping 72,046 LF $ 5.80 $ 417,867 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 0 LS $ 104,000 $ -

7 Chiller Condensing Pipe Retrofits 1 EA $ 7,470 $ 7,470 Means D3030 130 1010

8 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

9 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 110 EA $ 4,792 $ 527,120 currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 199 EA $ 391 $ 77,710 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 14 DAY $ 1,882 $ 26,351 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 14 DAY $ 1,618 $ 22,645 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 35 PTS $ 800 $ 28,000 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 69,440 $ 34,720 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 266,410

Subtotal $ 2,042,476

Bonding (1.5%) $ 30,637

Permitting (0.5%) $ 10,212

Design (6%) $ 122,549

Construction Management (1.5%) $ 30,637

Project Management (1%) $ 20,425

TOTAL $ 2,256,936

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 3 of 26

Budget Estimate (Building 401)

Alternative 4 - Water to Water Heat Pump with Auxiliary Boiler

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 16,654 LF $ 10 $ 166,536 4.33-in bore

3 Thermal Bentonite Grout 700 BAG $ 30 $ 21,000

4 Geothermal Piping 35,373 LF $ 5.80 $ 205,161 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610

6 20 Ton Water to Water HP 8 LS $ 20,000 $ 160,000 Vendor pricing

7 Boiler 1 LS $ 27,100 $ 27,100 Means 23 52 23.20 3300, 1530 MBH Gas Fired Boiler

Assumes utility brings gas to road outside of facility, 1-in SDR 11 Means

8 Natural Gas Piping 140 LF $ 7.45 $ 1,043 33 51 Means 13.10 1040

9 Gas Meter, Regulator, and Other Appurtenances 1 LS $ 1,500 $ 1,500 ROM

10 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

11 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

12 General Site Work and Excavation 15 DAY $ 1,467 $ 22,009 3 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 22 DAY $ 1,882 $ 41,408 2 days per heat pump and AHU, Means Crew R-18

15 Electrical Installation 22 DAY $ 1,618 $ 35,585 2 days per heat pump and AHU, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

18 Control Points 83 PTS $ 800 $ 66,400 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 104,774 $ 52,387 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 155,470

Subtotal $ 1,191,938

Bonding (1.5%) $ 17,879

Permitting (0.5%) $ 5,960

Design (6%) $ 71,516

Construction Management (1.5%) $ 17,879

Project Management (1%) $ 11,919

TOTAL $ 1,317,092

Alternative 5 - Central Geothermal Chillers (Cooling Only)

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 15,041 LF $ 10 $ 150,408 4.33-in bore

3 Thermal Bentonite Grout 600 BAG $ 30 $ 18,000

4 Geothermal Piping 31,986 LF $ 6 $ 185,517 Means 33 51 13.10 1040

5 New Chiller 0 LS $ 104,000 $ -

6 Chiller Condensing Pipe Retrofits 1 EA $ 7,470 $ 7,470 Means D3030 130 1010

7 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

8 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

9 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

10 Mechanical Installation 14 DAY $ 1,882 $ 26,351 2 days per AHU and 5 days per chiller, Means Crew R-18

11 Electrical Installation 14 DAY $ 1,618 $ 22,645 2 days per AHU and 5 days per chiller, Means Crew Q-2

12 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

13 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

14 Control Points 35 PTS $ 800 $ 28,000 temp/humidity, OA damper control, 3 TBD)

15 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 69,440 $ 34,720 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

16 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 99,458

Subtotal $ 762,513

Bonding (1.5%) $ 11,438

Permitting (0.5%) $ 3,813

Design (6%) $ 45,751

Construction Management (1.5%) $ 11,438

Project Management (1%) $ 7,625

TOTAL $ 842,577

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 4 of 26

Budget Estimate (Building 402)

Alternative 2 - Water to Water Heat Pump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 34,137 LF $ 10 $ 341,370 4.33-in bore

3 Thermal Bentonite Grout 1,400 BAG $ 30 $ 42,000

4 Geothermal Piping 72,088 LF $ 5.80 $ 418,109 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 10 EA $ 20,000 $ 200,000 Vendor pricing

7 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

8 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 133 EA $ 4,792 $ 637,336 currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 252 EA $ 391 $ 98,406 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 24 DAY $ 1,882 $ 45,173 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 24 DAY $ 1,618 $ 38,820 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 95 PTS $ 800 $ 76,000 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 104,437 $ 52,219 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 330,067

Subtotal $ 2,530,510

Bonding (1.5%) $ 37,958

Permitting (0.5%) $ 12,653

Design (6%) $ 151,831

Construction Management (1.5%) $ 37,958

Project Management (1%) $ 25,305

TOTAL $ 2,796,214

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 34,137 LF $ 10 $ 341,370 4.33-in bore

3 Thermal Bentonite Grout 1,400 BAG $ 30 $ 42,000

4 Geothermal Piping 72,088 LF $ 5.80 $ 418,109 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 1 LS $ 83,500 $ 83,500 Means 23 64 19.10 1160, 100 TON CHILLER

7 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

8 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

9 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 133 EA $ 4,792 $ 637,336 currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 252 EA $ 391 $ 98,406 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 19 DAY $ 1,882 $ 35,762 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 19 DAY $ 1,618 $ 30,733 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 42 PTS $ 800 $ 33,600 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 86,939 $ 43,469 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 302,294

Subtotal $ 2,317,590

Bonding (1.5%) $ 34,764

Permitting (0.5%) $ 11,588

Design (6%) $ 139,055

Construction Management (1.5%) $ 34,764

Project Management (1%) $ 23,176

TOTAL $ 2,560,937

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 5 of 26

Budget Estimate (Building 402)

Alternative 4 - Water to Water Heat Pump with Auxiliary Boiler

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 10,327 LF $ 10 $ 103,270 4.33-in bore

3 Thermal Bentonite Grout 400 BAG $ 30 $ 12,000

4 Geothermal Piping 22,087 LF $ 5.80 $ 128,103 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610

6 20 Ton Water to Water HP 5 LS $ 20,000 $ 100,000 Vendor pricing

7 Boiler 1 LS $ 27,100 $ 27,100 Means 23 52 23.20 3300, 1530 MBH Gas Fired Boiler

Assumes utility brings gas to road outside of facility, 1-in SDR 11 Means

8 Natural Gas Piping 140 LF $ 7.45 $ 1,043 33 51 Means 13.10 1040

9 Gas Meter, Regulator, and Other Appurtenances 1 LS $ 1,500 $ 1,500 ROM

10 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

11 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

12 General Site Work and Excavation 15 DAY $ 1,467 $ 22,009 3 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 19 DAY $ 1,882 $ 35,762 2 days per heat pump and AHU, Means Crew R-18

15 Electrical Installation 19 DAY $ 1,618 $ 30,733 2 days per heat pump and AHU, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

18 Control Points 65 PTS $ 800 $ 52,000 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 94,275 $ 47,137 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 119,549

Subtotal $ 916,545

Bonding (1.5%) $ 13,748

Permitting (0.5%) $ 4,583

Design (6%) $ 54,993

Construction Management (1.5%) $ 13,748

Project Management (1%) $ 9,165

TOTAL $ 1,012,782

Alternative 5 - Central Geothermal Chillers (Cooling Only)

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 14,872 LF $ 10 $ 148,716 4.33-in bore

3 Thermal Bentonite Grout 600 BAG $ 30 $ 18,000

4 Geothermal Piping 31,630 LF $ 6 $ 183,456 Means 33 51 13.10 1040

5 New Chiller 1 LS $ 83,500 $ 83,500 Means 23 64 19.10 1160, 100 TON CHILLER

6 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

7 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

8 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

9 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

10 Mechanical Installation 19 DAY $ 1,882 $ 35,762 2 days per AHU and 5 days per chiller, Means Crew R-18

11 Electrical Installation 19 DAY $ 1,618 $ 30,733 2 days per AHU and 5 days per chiller, Means Crew Q-2

12 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

13 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

14 Control Points 42 PTS $ 800 $ 33,600 temp/humidity, OA damper control, 3 TBD)

15 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 86,939 $ 43,469 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

16 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 115,077

Subtotal $ 882,257

Bonding (1.5%) $ 13,234

Permitting (0.5%) $ 4,411

Design (6%) $ 52,935

Construction Management (1.5%) $ 13,234

Project Management (1%) $ 8,823

TOTAL $ 974,894

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 6 of 26

Budget Estimate (Building 403)

Alternative 2 - Water to Water Heat Pump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 31,000 LF $ 10 $ 310,000 4.33-in bore

3 Thermal Bentonite Grout 1,300 BAG $ 30 $ 39,000

4 Geothermal Piping 65,500 LF $ 5.80 $ 379,900 Means 33 51 13.10 1040

5 Facility Piping 685 LF $ 29.50 $ 20,208 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 10 EA $ 20,000 $ 200,000 Vendor pricing

7 AHU CHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

8 AHU HHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 181 EA $ 4,792 $ 867,352 currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 251 EA $ 391 $ 98,016 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 20 DAY $ 1,882 $ 37,644 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 20 DAY $ 1,618 $ 32,350 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 5 EA $ 5,000 $ 25,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 85 PTS $ 800 $ 68,000 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 90,438 $ 45,219 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 5 LS $ 8,000 $ 40,000 source

Contingency (15%) $ 341,720

Subtotal $ 2,619,852

Bonding (1.5%) $ 39,298

Permitting (0.5%) $ 13,099

Design (6%) $ 157,191

Construction Management (1.5%) $ 39,298

Project Management (1%) $ 26,199

TOTAL $ 2,894,937

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 31,000 LF $ 10 $ 310,000 4.33-in bore

3 Thermal Bentonite Grout 1,300 BAG $ 30 $ 39,000

4 Geothermal Piping 65,500 LF $ 5.80 $ 379,900 Means 33 51 13.10 1040

5 Facility Piping 685 LF $ 29.50 $ 20,208 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 0 LS $ 104,000 $ -

7 Chiller Condensing Pipe Retrofits 1 EA $ 7,470 $ 7,470 Means D3030 130 1010

8 AHU CHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

9 AHU HHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 181 EA $ 4,792 $ 867,352 currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 251 EA $ 391 $ 98,016 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 10 DAY $ 1,882 $ 18,822 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 10 DAY $ 1,618 $ 16,175 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 5 EA $ 5,000 $ 25,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 25 PTS $ 800 $ 20,000 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 55,441 $ 27,721 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 5 LS $ 8,000 $ 40,000 source

Contingency (15%) $ 297,766

Subtotal $ 2,282,873

Bonding (1.5%) $ 34,243

Permitting (0.5%) $ 11,414

Design (6%) $ 136,972

Construction Management (1.5%) $ 34,243

Project Management (1%) $ 22,829

TOTAL $ 2,522,574

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 7 of 26

Budget Estimate (Building 403)

Alternative 4 - Water to Water Heat Pump with Auxiliary Boiler

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 8,257 LF $ 10 $ 82,573 4.33-in bore

3 Thermal Bentonite Grout 300 BAG $ 30 $ 9,000

4 Geothermal Piping 17,740 LF $ 5.80 $ 102,894 Means 33 51 13.10 1040

5 Facility Piping 685 LF $ 29.50 $ 20,208 Means 22 11 13.44 0610

6 20 Ton Water to Water HP 8 LS $ 20,000 $ 160,000 Vendor pricing

7 Boiler 1 LS $ 27,100 $ 27,100 Means 23 52 23.20 3300, 1530 MBH Gas Fired Boiler

Assumes utility brings gas to road outside of facility, 1-in SDR 11 Means

8 Natural Gas Piping 140 LF $ 7.45 $ 1,043 33 51 Means 13.10 1040

9 Gas Meter, Regulator, and Other Appurtenances 1 LS $ 1,500 $ 1,500 ROM

10 AHU CHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

11 AHU HHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

12 General Site Work and Excavation 15 DAY $ 1,467 $ 22,009 3 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 18 DAY $ 1,882 $ 33,880 2 days per heat pump and AHU, Means Crew R-18

15 Electrical Installation 18 DAY $ 1,618 $ 29,115 2 days per heat pump and AHU, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 5 EA $ 5,000 $ 25,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

18 Control Points 73 PTS $ 800 $ 58,400 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 90,775 $ 45,388 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 5 LS $ 8,000 $ 40,000 source

Contingency (15%) $ 113,832

Subtotal $ 872,712

Bonding (1.5%) $ 13,091

Permitting (0.5%) $ 4,364

Design (6%) $ 52,363

Construction Management (1.5%) $ 13,091

Project Management (1%) $ 8,727

TOTAL $ 964,347

Alternative 5 - Central Geothermal Chillers (Cooling Only)

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 13,696 LF $ 10 $ 136,955 4.33-in bore

3 Thermal Bentonite Grout 600 BAG $ 30 $ 18,000

4 Geothermal Piping 29,161 LF $ 6 $ 169,131 Means 33 51 13.10 1040

5 New Chiller 0 LS $ 104,000 $ -

6 Chiller Condensing Pipe Retrofits 1 EA $ 7,470 $ 7,470 Means D3030 130 1010

7 AHU CHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

8 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

9 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

10 Mechanical Installation 10 DAY $ 1,882 $ 18,822 2 days per AHU and 5 days per chiller, Means Crew R-18

11 Electrical Installation 10 DAY $ 1,618 $ 16,175 2 days per AHU and 5 days per chiller, Means Crew Q-2

12 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

13 Economizing and Outside Air Function 5 EA $ 5,000 $ 25,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

14 Control Points 25 PTS $ 800 $ 20,000 temp/humidity, OA damper control, 3 TBD)

15 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 55,441 $ 27,721 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

16 Demolition 5 LS $ 8,000 $ 40,000 source

Contingency (15%) $ 85,083

Subtotal $ 652,301

Bonding (1.5%) $ 9,785

Permitting (0.5%) $ 3,262

Design (6%) $ 39,138

Construction Management (1.5%) $ 9,785

Project Management (1%) $ 6,523

TOTAL $ 720,792

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 8 of 26

Budget Estimate (Building 404)

Alternative 2 - Water to Water Heat Pump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 23,742 LF $ 10 $ 237,420 4.33-in bore

3 Thermal Bentonite Grout 1,000 BAG $ 30 $ 30,000

4 Geothermal Piping 50,258 LF $ 5.80 $ 291,498 Means 33 51 13.10 1040

5 Facility Piping 741 LF $ 29.50 $ 21,860 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 7 EA $ 20,000 $ 140,000 Vendor pricing

7 AHU CHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

8 AHU HHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 137 EA $ 4,792 $ 656,504 currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 208 EA $ 391 $ 81,224 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 17 DAY $ 1,882 $ 31,997 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 17 DAY $ 1,618 $ 27,498 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 5 EA $ 5,000 $ 25,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 67 PTS $ 800 $ 53,600 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 79,939 $ 39,970 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 5 LS $ 8,000 $ 40,000 source

Contingency (15%) $ 268,802

Subtotal $ 2,060,816

Bonding (1.5%) $ 30,912

Permitting (0.5%) $ 10,304

Design (6%) $ 123,649

Construction Management (1.5%) $ 30,912

Project Management (1%) $ 20,608

TOTAL $ 2,277,202

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 23,742 LF $ 10 $ 237,420 4.33-in bore

3 Thermal Bentonite Grout 1,000 BAG $ 30 $ 30,000

4 Geothermal Piping 50,258 LF $ 5.80 $ 291,498 Means 33 51 13.10 1040

5 Facility Piping 741 LF $ 29.50 $ 21,860 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 1 LS $ 107,500 $ 107,500 Means 23 64 19.10 1200, 145 TON CHILLER

7 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

8 AHU CHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

9 AHU HHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 137 EA $ 4,792 $ 656,504 currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 208 EA $ 391 $ 81,224 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 15 DAY $ 1,882 $ 28,233 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 15 DAY $ 1,618 $ 24,263 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 5 EA $ 5,000 $ 25,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 32 PTS $ 800 $ 25,600 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 72,940 $ 36,470 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 5 LS $ 8,000 $ 40,000 source

Contingency (15%) $ 258,152

Subtotal $ 1,979,167

Bonding (1.5%) $ 29,688

Permitting (0.5%) $ 9,896

Design (6%) $ 118,750

Construction Management (1.5%) $ 29,688

Project Management (1%) $ 19,792

TOTAL $ 2,186,979

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 9 of 26

Budget Estimate (Building 404)

Alternative 4 - Water to Water Heat Pump with Auxiliary Boiler

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 11,433 LF $ 10 $ 114,327 4.33-in bore

3 Thermal Bentonite Grout 500 BAG $ 30 $ 15,000

4 Geothermal Piping 24,409 LF $ 5.80 $ 141,571 Means 33 51 13.10 1040

5 Facility Piping 741 LF $ 29.50 $ 21,860 Means 22 11 13.44 0610

6 20 Ton Water to Water HP 7 LS $ 20,000 $ 140,000 Vendor pricing

7 Boiler 1 LS $ 27,100 $ 27,100 Means 23 52 23.20 3300, 1530 MBH Gas Fired Boiler

Assumes utility brings gas to road outside of facility, 1-in SDR 11 Means

8 Natural Gas Piping 140 LF $ 7.45 $ 1,043 33 51 Means 13.10 1040

9 Gas Meter, Regulator, and Other Appurtenances 1 LS $ 1,500 $ 1,500 ROM

10 AHU CHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

11 AHU HHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

12 General Site Work and Excavation 15 DAY $ 1,467 $ 22,009 3 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 17 DAY $ 1,882 $ 31,997 2 days per heat pump and AHU, Means Crew R-18

15 Electrical Installation 17 DAY $ 1,618 $ 27,498 2 days per heat pump and AHU, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 5 EA $ 5,000 $ 25,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

18 Control Points 67 PTS $ 800 $ 53,600 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 87,275 $ 43,638 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 5 LS $ 8,000 $ 40,000 source

Contingency (15%) $ 121,037

Subtotal $ 927,951

Bonding (1.5%) $ 13,919

Permitting (0.5%) $ 4,640

Design (6%) $ 55,677

Construction Management (1.5%) $ 13,919

Project Management (1%) $ 9,280

TOTAL $ 1,025,386

Alternative 5 - Central Geothermal Chillers (Cooling Only)

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 10,926 LF $ 10 $ 109,263 4.33-in bore

3 Thermal Bentonite Grout 500 BAG $ 30 $ 15,000

4 Geothermal Piping 23,345 LF $ 6 $ 135,402 Means 33 51 13.10 1040

5 New Chiller 1 LS $ 107,500 $ 107,500 Means 23 64 19.10 1200, 145 TON CHILLER

6 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

7 AHU CHW Coil Retrofits 5 EA $ 5,500 $ 27,500 Number of AHUs

8 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

9 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

10 Mechanical Installation 15 DAY $ 1,882 $ 28,233 2 days per AHU and 5 days per chiller, Means Crew R-18

11 Electrical Installation 15 DAY $ 1,618 $ 24,263 2 days per AHU and 5 days per chiller, Means Crew Q-2

12 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

13 Economizing and Outside Air Function 5 EA $ 5,000 $ 25,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

14 Control Points 32 PTS $ 800 $ 25,600 temp/humidity, OA damper control, 3 TBD)

15 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 72,940 $ 36,470 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

16 Demolition 5 LS $ 8,000 $ 40,000 source

Contingency (15%) $ 95,201

Subtotal $ 729,876

Bonding (1.5%) $ 10,948

Permitting (0.5%) $ 3,649

Design (6%) $ 43,793

Construction Management (1.5%) $ 10,948

Project Management (1%) $ 7,299

TOTAL $ 806,513

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 10 of 26

Budget Estimate (Building 406)

Alternative 2 - Water to Water Heat Pump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 34,792 LF $ 10 $ 347,920 4.33-in bore

3 Thermal Bentonite Grout 1,400 BAG $ 30 $ 42,000

4 Geothermal Piping 73,463 LF $ 5.80 $ 426,087 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 10 EA $ 20,000 $ 200,000 Vendor pricing

7 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

8 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 70 EA $ 4,792 $ 335,440 currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 221 EA $ 391 $ 86,301 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 24 DAY $ 1,882 $ 45,173 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 24 DAY $ 1,618 $ 38,820 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 95 PTS $ 800 $ 76,000 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 104,437 $ 52,219 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 285,146

Subtotal $ 2,186,116

Bonding (1.5%) $ 32,792

Permitting (0.5%) $ 10,931

Design (6%) $ 131,167

Construction Management (1.5%) $ 32,792

Project Management (1%) $ 21,861

TOTAL $ 2,415,658

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 34,792 LF $ 10 $ 347,920 4.33-in bore

3 Thermal Bentonite Grout 1,400 BAG $ 30 $ 42,000

4 Geothermal Piping 73,463 LF $ 5.80 $ 426,087 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 1 LS $ 94,500 $ 94,500 Means 23 64 19.10 1180, 125 TON CHILLER

7 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

8 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

9 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 70 EA $ 4,792 $ 335,440 currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 221 EA $ 391 $ 86,301 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 19 DAY $ 1,882 $ 35,762 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 19 DAY $ 1,618 $ 30,733 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 42 PTS $ 800 $ 33,600 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 86,939 $ 43,469 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 259,023

Subtotal $ 1,985,846

Bonding (1.5%) $ 29,788

Permitting (0.5%) $ 9,929

Design (6%) $ 119,151

Construction Management (1.5%) $ 29,788

Project Management (1%) $ 19,858

TOTAL $ 2,194,360

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 11 of 26

Budget Estimate (Building 406)

Alternative 4 - Water to Water Heat Pump with Auxiliary Boiler

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 10,017 LF $ 10 $ 100,168 4.33-in bore

3 Thermal Bentonite Grout 400 BAG $ 30 $ 12,000

4 Geothermal Piping 21,435 LF $ 5.80 $ 124,325 Means 33 51 13.10 1040

5 Facility Piping 765 LF $ 29.50 $ 22,568 Means 22 11 13.44 0610

6 20 Ton Water to Water HP 6 LS $ 20,000 $ 120,000 Vendor pricing

7 Boiler 1 LS $ 27,100 $ 27,100 Means 23 52 23.20 3300, 1530 MBH Gas Fired Boiler

Assumes utility brings gas to road outside of facility, 1-in SDR 11 Means

8 Natural Gas Piping 140 LF $ 7.45 $ 1,043 33 51 Means 13.10 1040

9 Gas Meter, Regulator, and Other Appurtenances 1 LS $ 1,500 $ 1,500 ROM

10 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

11 AHU HHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

12 General Site Work and Excavation 15 DAY $ 1,467 $ 22,009 3 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 20 DAY $ 1,882 $ 37,644 2 days per heat pump and AHU, Means Crew R-18

15 Electrical Installation 20 DAY $ 1,618 $ 32,350 2 days per heat pump and AHU, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

18 Control Points 71 PTS $ 800 $ 56,800 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 97,774 $ 48,887 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 123,025

Subtotal $ 943,190

Bonding (1.5%) $ 14,148

Permitting (0.5%) $ 4,716

Design (6%) $ 56,591

Construction Management (1.5%) $ 14,148

Project Management (1%) $ 9,432

TOTAL $ 1,042,224

Alternative 5 - Central Geothermal Chillers (Cooling Only)

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 14,287 LF $ 10 $ 142,870 4.33-in bore

3 Thermal Bentonite Grout 600 BAG $ 30 $ 18,000

4 Geothermal Piping 30,403 LF $ 6 $ 176,336 Means 33 51 13.10 1040

5 New Chiller 1 LS $ 94,500 $ 94,500 Means 23 64 19.10 1180, 125 TON CHILLER

6 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

7 AHU CHW Coil Retrofits 7 EA $ 5,500 $ 38,500 Number of AHUs

8 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

9 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

10 Mechanical Installation 19 DAY $ 1,882 $ 35,762 2 days per AHU and 5 days per chiller, Means Crew R-18

11 Electrical Installation 19 DAY $ 1,618 $ 30,733 2 days per AHU and 5 days per chiller, Means Crew Q-2

12 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

13 Economizing and Outside Air Function 7 EA $ 5,000 $ 35,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

14 Control Points 42 PTS $ 800 $ 33,600 temp/humidity, OA damper control, 3 TBD)

15 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 86,939 $ 43,469 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

16 Demolition 7 LS $ 8,000 $ 56,000 source

Contingency (15%) $ 114,782

Subtotal $ 879,996

Bonding (1.5%) $ 13,200

Permitting (0.5%) $ 4,400

Design (6%) $ 52,800

Construction Management (1.5%) $ 13,200

Project Management (1%) $ 8,800

TOTAL $ 972,395

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 12 of 26

Budget Estimate (Building 407)

Alternative 2 - Water to Water Heat Pump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 37,539 LF $ 10 $ 375,390 4.33-in bore

3 Thermal Bentonite Grout 1,600 BAG $ 30 $ 48,000

4 Geothermal Piping 79,232 LF $ 5.80 $ 459,545 Means 33 51 13.10 1040

5 Facility Piping 581 LF $ 29.50 $ 17,140 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 10 EA $ 20,000 $ 200,000 Vendor pricing

7 AHU CHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

8 AHU HHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 0 EA $ 4,792 $ - currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 244 EA $ 391 $ 95,282 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 14 DAY $ 1,882 $ 26,351 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 14 DAY $ 1,618 $ 22,645 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 2 EA $ 5,000 $ 10,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 70 PTS $ 800 $ 56,000 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 69,440 $ 34,720 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 2 LS $ 8,000 $ 16,000 source

Contingency (15%) $ 216,527

Subtotal $ 1,660,044

Bonding (1.5%) $ 24,901

Permitting (0.5%) $ 8,300

Design (6%) $ 99,603

Construction Management (1.5%) $ 24,901

Project Management (1%) $ 16,600

TOTAL $ 1,834,349

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 37,539 LF $ 10 $ 375,390 4.33-in bore

3 Thermal Bentonite Grout 1,600 BAG $ 30 $ 48,000

4 Geothermal Piping 79,232 LF $ 5.80 $ 459,545 Means 33 51 13.10 1040

5 Facility Piping 581 LF $ 29.50 $ 17,140 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 1 LS $ 107,500 $ 107,500 Means 23 64 19.10 1200, 145 TON CHILLER

7 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

8 AHU CHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

9 AHU HHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 0 EA $ 4,792 $ - currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 244 EA $ 391 $ 95,282 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 9 DAY $ 1,882 $ 16,940 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 9 DAY $ 1,618 $ 14,558 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 2 EA $ 5,000 $ 10,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 17 PTS $ 800 $ 13,600 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 51,942 $ 25,971 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 2 LS $ 8,000 $ 16,000 source

Contingency (15%) $ 192,355

Subtotal $ 1,474,724

Bonding (1.5%) $ 22,121

Permitting (0.5%) $ 7,374

Design (6%) $ 88,483

Construction Management (1.5%) $ 22,121

Project Management (1%) $ 14,747

TOTAL $ 1,629,570

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 13 of 26

Budget Estimate (Building 407)

Alternative 4 - Water to Water Heat Pump with Auxiliary Boiler

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 11,174 LF $ 10 $ 111,737 4.33-in bore

3 Thermal Bentonite Grout 500 BAG $ 30 $ 15,000

4 Geothermal Piping 23,865 LF $ 5.80 $ 138,415 Means 33 51 13.10 1040

5 Facility Piping 581 LF $ 29.50 $ 17,140 Means 22 11 13.44 0610

6 20 Ton Water to Water HP 8 LS $ 20,000 $ 160,000 Vendor pricing

7 Boiler 1 LS $ 27,100 $ 27,100 Means 23 52 23.20 3300, 1530 MBH Gas Fired Boiler

Assumes utility brings gas to road outside of facility, 1-in SDR 11 Means

8 Natural Gas Piping 140 LF $ 7.45 $ 1,043 33 51 Means 13.10 1040

9 Gas Meter, Regulator, and Other Appurtenances 1 LS $ 1,500 $ 1,500 ROM

10 AHU CHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

11 AHU HHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

12 General Site Work and Excavation 15 DAY $ 1,467 $ 22,009 3 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 12 DAY $ 1,882 $ 22,586 2 days per heat pump and AHU, Means Crew R-18

15 Electrical Installation 12 DAY $ 1,618 $ 19,410 2 days per heat pump and AHU, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 2 EA $ 5,000 $ 10,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

18 Control Points 58 PTS $ 800 $ 46,400 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 69,777 $ 34,888 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 2 LS $ 8,000 $ 16,000 source

Contingency (15%) $ 106,650

Subtotal $ 817,650

Bonding (1.5%) $ 12,265

Permitting (0.5%) $ 4,088

Design (6%) $ 49,059

Construction Management (1.5%) $ 12,265

Project Management (1%) $ 8,177

TOTAL $ 903,503

Alternative 5 - Central Geothermal Chillers (Cooling Only)

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 15,098 LF $ 10 $ 150,984 4.33-in bore

3 Thermal Bentonite Grout 600 BAG $ 30 $ 18,000

4 Geothermal Piping 32,107 LF $ 6 $ 186,219 Means 33 51 13.10 1040

5 New Chiller 1 LS $ 107,500 $ 107,500 Means 23 64 19.10 1200, 145 TON CHILLER

6 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

7 AHU CHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

8 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

9 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

10 Mechanical Installation 9 DAY $ 1,882 $ 16,940 2 days per AHU and 5 days per chiller, Means Crew R-18

11 Electrical Installation 9 DAY $ 1,618 $ 14,558 2 days per AHU and 5 days per chiller, Means Crew Q-2

12 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

13 Economizing and Outside Air Function 2 EA $ 5,000 $ 10,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

14 Control Points 17 PTS $ 800 $ 13,600 temp/humidity, OA damper control, 3 TBD)

15 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 51,942 $ 25,971 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

16 Demolition 2 LS $ 8,000 $ 16,000 source

Contingency (15%) $ 94,682

Subtotal $ 725,897

Bonding (1.5%) $ 10,888

Permitting (0.5%) $ 3,629

Design (6%) $ 43,554

Construction Management (1.5%) $ 10,888

Project Management (1%) $ 7,259

TOTAL $ 802,116

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 14 of 26

Budget Estimate (Building 408)

Alternative 2 - Water to Water HeatPump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 36,270 LF $ 10 $ 362,700 4.33-in bore

3 Thermal Bentonite Grout 1,500 BAG $ 30 $ 45,000

4 Geothermal Piping 76,567 LF $ 5.80 $ 444,089 Means 33 51 13.10 1040

5 Facility Piping 741 LF $ 29.50 $ 21,860 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 13 EA $ 20,000 $ 260,000 Vendor pricing

7 AHU CHW Coil Retrofits 6 EA $ 5,500 $ 33,000 Number of AHUs

8 AHU HHW Coil Retrofits 6 EA $ 5,500 $ 33,000 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 74 EA $ 4,792 $ 354,608 currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 230 EA $ 391 $ 89,815 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 25 DAY $ 1,882 $ 47,055 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 25 DAY $ 1,618 $ 40,438 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 6 EA $ 5,000 $ 30,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 108 PTS $ 800 $ 86,400 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 107,937 $ 53,968 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 6 LS $ 8,000 $ 48,000 source

Contingency (15%) $ 301,556

Subtotal $ 2,311,933

Bonding (1.5%) $ 34,679

Permitting (0.5%) $ 11,560

Design (6%) $ 138,716

Construction Management (1.5%) $ 34,679

Project Management (1%) $ 23,119

TOTAL $ 2,554,686

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 36,270 LF $ 10 $ 362,700 4.33-in bore

3 Thermal Bentonite Grout 1,500 BAG $ 30 $ 45,000

4 Geothermal Piping 76,567 LF $ 5.80 $ 444,089 Means 33 51 13.10 1040

5 Facility Piping 741 LF $ 29.50 $ 21,860 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 1 LS $ 107,500 $ 107,500 Means 23 64 19.10 1200, 145 TON CHILLER

7 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

8 AHU CHW Coil Retrofits 6 EA $ 5,500 $ 33,000 Number of AHUs

9 AHU HHW Coil Retrofits 6 EA $ 5,500 $ 33,000 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 74 EA $ 4,792 $ 354,608 currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 230 EA $ 391 $ 89,815 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 17 DAY $ 1,882 $ 31,997 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 17 DAY $ 1,618 $ 27,498 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 6 EA $ 5,000 $ 30,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 37 PTS $ 800 $ 29,600 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 79,939 $ 39,970 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 6 LS $ 8,000 $ 48,000 source

Contingency (15%) $ 263,862

Subtotal $ 2,022,942

Bonding (1.5%) $ 30,344

Permitting (0.5%) $ 10,115

Design (6%) $ 121,377

Construction Management (1.5%) $ 30,344

Project Management (1%) $ 20,229

TOTAL $ 2,235,351

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 15 of 26

Budget Estimate (Building 408)

Alternative 4 - Water to Water Heat Pump with Auxiliary Boiler

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 11,133 LF $ 10 $ 111,333 4.33-in bore

3 Thermal Bentonite Grout 500 BAG $ 30 $ 15,000

4 Geothermal Piping 23,780 LF $ 5.80 $ 137,923 Means 33 51 13.10 1040

5 Facility Piping 741 LF $ 29.50 $ 21,860 Means 22 11 13.44 0610

6 20 Ton Water to Water HP 8 LS $ 20,000 $ 160,000 Vendor pricing

7 Boiler 1 LS $ 27,100 $ 27,100 Means 23 52 23.20 3300, 1530 MBH Gas Fired Boiler

Assumes utility brings gas to road outside of facility, 1-in SDR 11 Means

8 Natural Gas Piping 140 LF $ 7.45 $ 1,043 33 51 Means 13.10 1040

9 Gas Meter, Regulator, and Other Appurtenances 1 LS $ 1,500 $ 1,500 ROM

10 AHU CHW Coil Retrofits 6 EA $ 5,500 $ 33,000 Number of AHUs

11 AHU HHW Coil Retrofits 6 EA $ 5,500 $ 33,000 Number of AHUs

12 General Site Work and Excavation 15 DAY $ 1,467 $ 22,009 3 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 20 DAY $ 1,882 $ 37,644 2 days per heat pump and AHU, Means Crew R-18

15 Electrical Installation 20 DAY $ 1,618 $ 32,350 2 days per heat pump and AHU, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 6 EA $ 5,000 $ 30,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

18 Control Points 78 PTS $ 800 $ 62,400 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 97,774 $ 48,887 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 6 LS $ 8,000 $ 48,000 source

Contingency (15%) $ 130,323

Subtotal $ 999,143

Bonding (1.5%) $ 14,987

Permitting (0.5%) $ 4,996

Design (6%) $ 59,949

Construction Management (1.5%) $ 14,987

Project Management (1%) $ 9,991

TOTAL $ 1,104,053

Alternative 5 - Central Geothermal Chillers (Cooling Only)

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 14,134 LF $ 10 $ 141,336 4.33-in bore

3 Thermal Bentonite Grout 600 BAG $ 30 $ 18,000

4 Geothermal Piping 30,081 LF $ 6 $ 174,467 Means 33 51 13.10 1040

5 New Chiller 1 LS $ 107,500 $ 107,500 Means 23 64 19.10 1200, 145 TON CHILLER

6 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

7 AHU CHW Coil Retrofits 6 EA $ 5,500 $ 33,000 Number of AHUs

8 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

9 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

10 Mechanical Installation 17 DAY $ 1,882 $ 31,997 2 days per AHU and 5 days per chiller, Means Crew R-18

11 Electrical Installation 17 DAY $ 1,618 $ 27,498 2 days per AHU and 5 days per chiller, Means Crew Q-2

12 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

13 Economizing and Outside Air Function 6 EA $ 5,000 $ 30,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

14 Control Points 37 PTS $ 800 $ 29,600 temp/humidity, OA damper control, 3 TBD)

15 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 79,939 $ 39,970 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

16 Demolition 6 LS $ 8,000 $ 48,000 source

Contingency (15%) $ 111,272

Subtotal $ 853,084

Bonding (1.5%) $ 12,796

Permitting (0.5%) $ 4,265

Design (6%) $ 51,185

Construction Management (1.5%) $ 12,796

Project Management (1%) $ 8,531

TOTAL $ 942,658

\\PLD2-FS1\Project\Projects\GABEL\Gabel-Tomah VAMC-3617147319\4.0_Deliverables\4.4_Calcs-Analysis\Calculations\Tomah VA Cost Estimate Rev1.xlsxTomah VA Cost Estimate Rev1.xlsx Page 16 of 26

Budget Estimate (Building 424)

Alternative 2 - Water to Water Heat Pump

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 21,384 LF $ 10 $ 213,840 4.33-in bore

3 Thermal Bentonite Grout 900 BAG $ 30 $ 27,000

4 Geothermal Piping 45,306 LF $ 5.80 $ 262,777 Means 33 51 13.10 1040

5 Facility Piping 567 LF $ 29.50 $ 16,727 Means 22 11 13.44 0610 (Includes CV Reheat)

6 20 Ton Water to Water HP 7 EA $ 20,000 $ 140,000 Vendor pricing

7 AHU CHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

8 AHU HHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

9 VAV Reheat Coils Demolition/Replacement 9 EA $ 4,792 $ 43,128 currently exist, Means 23 05 05.10 3800

10 Convectors Demolition/Replacement 3 EA $ 391 $ 1,172 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

11 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

12 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

13 Mechanical Installation 11 DAY $ 1,882 $ 20,704 1 day per heat pump and 2 per AHU, Means Crew R-18

14 Electrical Installation 11 DAY $ 1,618 $ 17,793 1 day per heat pump and 2 per AHU, Means Crew Q-2

15 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

16 Economizing and Outside Air Function 2 EA $ 5,000 $ 10,000 Damper control motors

6 pts per heat pump (EWT, LWT, COMP Status, Pump Status, Run Status,

O/I Control), 5 pts per AHU (OA temp/humidity, OA damper control, 3

17 Control Points 52 PTS $ 800 $ 41,600 TBD)

18 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 58,941 $ 29,470 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

19 Demolition 2 LS $ 8,000 $ 16,000 source

Contingency (15%) $ 138,398

Subtotal $ 1,061,053

Bonding (1.5%) $ 15,916

Permitting (0.5%) $ 5,305

Design (6%) $ 63,663

Construction Management (1.5%) $ 15,916

Project Management (1%) $ 10,611

TOTAL $ 1,172,463

Alternative 3 - Central Geothermal Chillers

Item Description Quantity UOM Unit Cost Extended Price Notes/Assumptions

1 Mobilization/Demobilization 1 LS $ 10,000 $ 10,000 Historical

2 Geothermal Well Drilling 21,384 LF $ 10 $ 213,840 4.33-in bore

3 Thermal Bentonite Grout 900 BAG $ 30 $ 27,000

4 Geothermal Piping 45,306 LF $ 5.80 $ 262,777 Means 33 51 13.10 1040

5 Facility Piping 567 LF $ 29.50 $ 16,727 Means 22 11 13.44 0610 (Includes CV Reheat)

6 New Chiller 1 LS $ 73,500 $ 73,500 MEANS 23 64 19.10 1140, 85 TON CHILLER

7 Chiller Condensing Pipe Retrofits 0 EA $ 7,470 $ - Means D3030 130 1010

8 AHU CHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

9 AHU HHW Coil Retrofits 2 EA $ 5,500 $ 11,000 Number of AHUs

Means D3040 134 1010, VAV Terminal 1250 CFM, Assume power lines

10 VAV Reheat Coils Demolition/Replacement 9 EA $ 4,792 $ 43,128 currently exist, Means 23 05 05.10 3800

11 Convectors Demolition/Replacement 3 EA $ 391 $ 1,172 Means 23 82 33.10 2226, 21"H x 36"L, Means 23 05 05.10 2976

12 General Site Work and Excavation 10 DAY $ 1,467 $ 14,672 2 week POP, Means Crew B-12E

13 Equipment Crane 3 DAY $ 1,924 $ 5,772 Means Crew B-12A

14 Mechanical Installation 9 DAY $ 1,882 $ 16,940 2 days per AHU and 5 days per chiller, Means Crew R-18

15 Electrical Installation 9 DAY $ 1,618 $ 14,558 2 days per AHU and 5 days per chiller, Means Crew Q-2

16 Programming Existing BMS 1 LS $ 30,000 $ 30,000 Historical

17 Economizing and Outside Air Function 2 EA $ 5,000 $ 10,000 Damper control motors

7 pts per chiller (EWT, LWT, Status, O/I Control, 3 TBD), 5 pts per AHU (OA

18 Control Points 17 PTS $ 800 $ 13,600 temp/humidity, OA damper control, 3 TBD)

19 Miscellaneous Materials, Equipment, and Appurtenances 50% % $ 51,942 $ 25,971 Percent of crew costs

Remove/dispose of CHW coils, remove unused piping and conduit back to

20 Demolition 2 LS $ 8,000 $ 16,000 source

Contingency (15%) $ 122,648

Subtotal $ 940,304

Bonding (1.5%) $ 14,105

Permitting (0.5%) $ 4,702

Design (6%) $ 56,418

Construction Management (1.5%) $ 14,105

Project Management (1%) $ 9,403