Академический Документы

Профессиональный Документы

Культура Документы

Henkel Medical PSA Selector Guide

Загружено:

KongfuzdОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Henkel Medical PSA Selector Guide

Загружено:

KongfuzdАвторское право:

Доступные форматы

1 MIL COATINGS

PEEL FROM

TACK PEEL FROM SS, OZF/IN

HDPE, OZF/IN

PRODUCT SHEAR

NAME 1 WEEK @ (72°F) (H)

20 24 1 WEEK 1 WEEK 20 24

OZF/IN 95°F/95%

MIN. HR. @ RT @ 158°F MIN. HR.

R.H.

LOCTITE® DURO-TAK® AH 115™ 106 72 65 91 93 84 26 26 18 (8.8 psi)

>168 (4.4 psi)1

LOCTITE DURO-TAK 109A

® ® ™

42 50 64 66 90 88 6 7

1 (4.4 psi)

LOCTITE® DURO-TAK® 151A™ 81 85 96 96 115 105 45 47 10 (4.4 psi)

20 (2.2 psi)

LOCTITE DURO-TAK 194B

® ® ™

50 94 91 96 96 92 20 21

1.5 (4.4psi)

LOCTITE® DURO-TAK® 230A™ 49 49 66 71 83 72 7 6 104 (8.8 psi)

>168 (4.4 psi)

LOCTITE DURO-TAK 1057

® ® ™

35 54 69 85 121 77 6 8

5 (8.8 psi)

LOCTITE® DURO-TAK® 1068™ 45 60 78 94 145 110 13 20 11 (8.8 psi)

18 (4.4 psi)

LOCTITE® DURO-TAK® 1070™ 34 42 56 75 131 96 0.4 6

3 (8.8 psi)

LOCTITE® DURO-TAK® 1077™ 9 50 78 80 72 79 2 1 44 (8.8 psi)

44 (4.4 psi)

LOCTITE® DURO-TAK® 1093™ 56 56 74 91 121 99 6 10

3 (8.8 psi)

LOCTITE® DURO-TAK® 1154™ 30 34 34 37 48 35 6 9 >168 (4.4 psi)

25 (4.4 psi)

LOCTITE DURO-TAK 1194

® ® ™

31 53 54 63 97 81 16 16

2.3 (8.8 psi)

>168 (4.4 psi)

LOCTITE® DURO-TAK® 2539™ 21 55 58 70 86 92 3 5

93 (8.8 psi)

LOCTITE® DURO-TAK® 2835™ 35 64 67 75 92 73 5 16 87 (8.8 psi)

LOCTITE® DURO-TAK® 3511NA™ 30 49 53 59 98 70 8 7 >168 (4.4 psi)

48 (4.4 psi)

LOCTITE® DURO-TAK® 4315™ 18 51 56 66 62 76 7 6

7.6 (8.8 psi)

12 10 19 25 36 28 1 1 >168 (4.4 psi)

LOCTITE® DURO-TAK® 4621-11™

10 8 12 10 34 15 1 4 >168 (4.4 psi)

LOCTITE® DURO-TAK® 5495™ 14 (4.4 psi)

39 64 133 141 125 135 19 20

2 (8.8 psi)

LOCTITE® DURO-TAK® 5659™ 30 50 59 80 92 82 3 20 >168 (8.8 psi)

18 (4.4 psi)

LOCTITE® DURO-TAK® 5886™ 34 42 56 75 131 96 0.4 6 3 (8.8 psi)

1

LOCTITE® DURO-TAK® 109A™: Coating aged for 1 week at 160⁰F.

= Removable Grades - 0.8 mil data

LOCTITE® DURO-TAK® Solution Acrylic Selector Guide | 5

2 MIL COATINGS

PEEL FROM

TACK PEEL FROM SS, OZF/IN HDPE, OZF/ SAFT, °F

SHEAR SHEAR

PRODUCT IN

(72°F) (158°F)

NAME 1 WEEK @

OZF/ 20 24 1 WEEK 1 WEEK 20 24 (H) (H) AL

95°F/95% PET

IN MIN. HR. @ RT @ 158°F R.H. MIN. HR. FOIL

LOCTITE® DURO-TAK® AH 115™ 132 125 130 138 109 115 66 68 17 (8.8 psi) >168 375+ 210

0.8

1 (4.4 psi)

LOCTITE® DURO-TAK® 109A™ 82 70 74 76 110 90 16 16 >168 375+ 375+

>168 (4.4 psi) aged1

aged1

LOCTITE® DURO-TAK® 151A™ 90 80 100 150 144 150 45 50 5 (4.4 psi) 0.6 201 178

LOCTITE® DURO-TAK® 194B™ 70 98 105 98 108 95 32 34 18 (2.2 psi) 4.1 187 165

LOCTITE® DURO-TAK® 230A™ 79 61 74 80 104 83 12 14 137 (8.8psi) >168 375+ 375+

> 168 (4.4 psi)

LOCTITE® DURO-TAK® 1057™ 69 64 78 96 124 85 12 13 33 375+ 347

5 (8.8 psi)

LOCTITE® DURO-TAK® 1068™ 46 77 98 103 147 123 8 10 40 (8.8 psi) 10 253 231

112 (4.4 psi)

LOCTITE® DURO-TAK® 1070™ 54 62 73 79 159 112 7 7 5 263 193

6 (8.8 psi)

LOCTITE® DURO-TAK® 1077™ 35 80 90 94 139 101 9 4 >168 (8.8 psi) >168 375+ 375+

40 (4.4 psi)

LOCTITE® DURO-TAK® 1093™ 77 71 92 113 158 109 14 17 8 332 275

3 (8.8 psi)

LOCTITE® DURO-TAK® 1154™ 48 50 52 61 84 76 14 11 >168 (4.4 psi) >168 317 274

88 (4.4 psi)

LOCTITE® DURO-TAK® 1194™ 50 63 62 77 108 77 16 16 37 278 241

2.9 (8.8 psi)

LOCTITE® DURO-TAK 2539™ 26 57 64 77 105 95 18 19 >168 (8.8 psi) >168 330 276

LOCTITE® DURO-TAK® 2835™ 51 68 75 81 102 76 18 19 101 (8.8 psi) >168 342 287

>168 (4.4 psi)

LOCTITE® DURO-TAK® 3511NA™ 52 51 55 59 113 74 16 17 >168 375+ 375+

63 (8.8 psi)

156 (4.4 psi)

LOCTITE® DURO-TAK® 4315™ 25 55 64 73 120 92 17 19 >168 292 213

8.6 (8.8 psi)

LOCTITE® DURO-TAK® 4621-11™ 1 14 21 25 39 37 1 1 > 168 (4.4 psi) 80.5 375+ 375+

LOCTITE® DURO-TAK® 5495™ 66 85 142 140 161 131 22 23 3.5 (8.8 psi) 0.9 201 176

26 (4.4 psi)

LOCTITE® DURO-TAK® 5659™ 40 64 79 87 102 89 13 24

> 168 (8.8 psi)

> 168 375 + 375+

LOCTITE® DURO-TAK® 5886™ 112 (4.4 psi)

54 62 73 79 159 112 7 7 5 263 193

6 (8.8 psi)

6 | LOCTITE® DURO-TAK® Solution Acrylic Selector Guide

PRODUCT PORTFOLIO

WITH SKIN CONTACT APPROVAL FOR MEDICAL APPLICATIONS

PEEL

FROM

SOLIDS %

TACK, SS

(OZF/IN)

PEEL FROM SS (OZF/IN) SHEAR

PRODUCT FEATURES & VISC., LDPE

SOLVENT BLEND (OZF/IN) (72°F)

NAME APPLICATIONS cP (H)

1 WK 1 WEEK @1 95°F/

WK

20 24 20 24

MIN HR @ RT @ 158°F 95% R.H. MIN HR

2 MIL COATINGS

35.5% ethyl acetate,

LOCTITE® Dressings and wound care. 26% toluene,

DURO-TAK® Medical device assembly & attachment. 18.5% hexane, 132 125 130 138 109 115 104 103 120

43.5 1,600 (4.4 psi)

AH 115™ Superior extended wear properties. 15% heptane,

5% isopropanol

LOCTITE® 33% heptane,

EKG & foot care.

DURO-TAK® 32% isopropanol, 88 102 170 1.9

Medical labeling and device assembly. 51 2,600 61 73 147 21 18

30% ethyl acetate, (4.4 psi)

129NA™ Good peel and tack. 5% toluene

LOCTITE® Wound dressings. 88% ethyl acetate,

DURO-TAK® Exceptional MVTR. 8% isopropanol, 52 100 185 154 180 94 16 18 1.6

40 1,700

Good long term wear. 4% methanol (4.4 psi)

222A™

LOCTITE® 52% ethyl acetate,

DURO-TAK® EKG pads, medical tapes and devices. 45 62 83 111 163 125 20 24 10

32.5 1,100 36% ethanol,

Longer term wear. (4.4 psi)

737NA™ 12% toluene

LOCTITE® 83% ethyl acetate,

Ostomy, and wound care. 41 5,300 59 76 148 174 181 125 8 7 0.3

DURO-TAK® 17% toluene

Aggressive peel and tack. (4.4 psi)

788NA™

LOCTITE® Dressings and wound care. 34% isopropanol,

Superior shear performance. 48 50 52 61 84 76 6 >168

DURO-TAK® 48 3,000 33% ethyl acetate, 6

Lower skin trauma. (4.4 psi)

1154™ 28% heptane, 5% toluene

LOCTITE® PVC bandages and dressings. 45% toluene,

DURO-TAK® Good plasticizer resistance. 37% heptane, 58 51 57 73 97 80 7 8 >168

49 4,300 (4.4 psi)

2480™ Excellent shear strength. 17% isopropanol

LOCTITE® Surgical drapes and wound care. 54% ethyl acetate,

DURO-TAK® Aggressive with clean removability. 25% toluene, 66 85 142 140 161 131 31 20 26

45 2,000 (4.4 psi)

2495™ Excellent clarity. 21% ethanol

LOCTITE® Ostomy, foot care, wound dressings. 97% ethyl acetate,

DURO-TAK® Aggressive peel and tack. Excellent 55 74 178 169 175 157 25 27 0.5

45.5 11,000 3% ethanol (4.4 psi)

2999™ water resistance.

LOCTITE® EKG & medical foam tapes. 53% ethyl acetate, 1.5

DURO-TAK® Good low temperature performance. 48 4,000 47% toluene 70 98 105 98 108 95 43 44

(4.4 psi)

5889™ Good LSE adhesion.

TEST CONDITIONS

All products were coated at 1 and 2 mil coating thickness on silicone-

coated 60# densified kraft liner and transferred to 2 mil polyester.

PEEL ADHESION (TESTED AT 12 IN. PER MINUTE): VINYL COMPATIBILITY:

• 180° Peel from SS and HDPE with 1 in. wide strip: conditioned and run at Roll Storage on Vinyl (158°F for 1 week)*

72°F/50% relative humidity.

• 180° Peel from SS at 158°F with 1 in. wide strip: conditioned at 158°F for 7 Superior <50% loss in peel

days and run at 72°F/50% relative humidity. Excellent 50%-60% loss in peel

• 180° Peel from SS at 95°F/95% RH: conditioned for 7 days at 95°F/95% Good 60%-70% loss in peel

relative humidity, tested at 72°F/50% relative humidity. Fair 70%-100% loss in peel

Not recommended >100% loss in peel

SHEAR (72°F): CONDITIONED AND RUN AT 72°F/50% RELATIVE

HUMIDITY ON SS:

• 2.2 psi (1 in. long x ½ in. wide x 500 g) Resistance to Vinyl Shrinkage (140°F for 1 week)*

• 4.4 psi (1 in. long x ½ in. wide x 1,000 g) Superior <0.1% shrinkage on vinyl

• 8.8 psi (1 in. long x ½ in. wide x 2,000 g) Excellent 0.1%-0.2% shrinkage on vinyl

Good 0.2%-0.5% shrinkage on vinyl

Fair 0.5%-0.7% shrinkage on vinyl

Not recommended >0.7% shrinkage on vinyl

*General-purpose 4 mil calendered monomeric and polymeric vinyl.

LOCTITE® DURO-TAK® Solution Acrylic Selector Guide | 7

Вам также может понравиться

- Tyfo SCH-41 CompositeДокумент2 страницыTyfo SCH-41 Compositeyusak santosoОценок пока нет

- r1 Forecast Oli Area Jawa 2021Документ58 страницr1 Forecast Oli Area Jawa 2021ArifinОценок пока нет

- Moisture Separator - Brochure - 1521101259Документ16 страницMoisture Separator - Brochure - 1521101259Hanhan Subhan UmbaraОценок пока нет

- Evonik Additives For PU Shoe SoleДокумент12 страницEvonik Additives For PU Shoe SoleSigneyWangОценок пока нет

- Especificaciones Bomba Graco Modelo 515Документ1 страницаEspecificaciones Bomba Graco Modelo 515Bryan GuerreroОценок пока нет

- Tyfo SCH-41-2X Composite: Using Tyfo S EpoxyДокумент2 страницыTyfo SCH-41-2X Composite: Using Tyfo S EpoxyAnito ShobithОценок пока нет

- DOWEX UPCORE Mono C 600 PDFДокумент2 страницыDOWEX UPCORE Mono C 600 PDFlisazulmayetiОценок пока нет

- Toilets & Lavs: China Products BrochureДокумент8 страницToilets & Lavs: China Products BrochureIntanОценок пока нет

- Sanitario + Flux + SensorДокумент2 страницыSanitario + Flux + SensorFernando CaicedoОценок пока нет

- XilinxДокумент20 страницXilinxAvila Cruz JaimeОценок пока нет

- r3 Forecast Oli Aceh 2021Документ31 страницаr3 Forecast Oli Aceh 2021ArifinОценок пока нет

- HISSAN Pocket Book Product Guide English 1Документ119 страницHISSAN Pocket Book Product Guide English 1benny280512Оценок пока нет

- Baño - Griferia - KOHLER - K-74013M+0.50GPMДокумент3 страницыBaño - Griferia - KOHLER - K-74013M+0.50GPMGiordano Tuanama YapoОценок пока нет

- Basco Products K Ltd. Price List Effective 12.09.19 MinДокумент25 страницBasco Products K Ltd. Price List Effective 12.09.19 MinkansiimecОценок пока нет

- Seaflo Neo SL Z (1606) PDFДокумент2 страницыSeaflo Neo SL Z (1606) PDFTrịnh Minh KhoaОценок пока нет

- Tyfo SEH-51A CompositeДокумент2 страницыTyfo SEH-51A Compositeyusak santosoОценок пока нет

- Stok de MaterialesДокумент2 страницыStok de Materialesasesor.comercialgrupodmatОценок пока нет

- FFCДокумент2 страницыFFCCesar ZarateОценок пока нет

- Global Approved ProductsДокумент4 страницыGlobal Approved ProductsOrrazip OilujОценок пока нет

- Fork Oil PDFДокумент12 страницFork Oil PDFGabor SzollosiОценок пока нет

- Ultrascale Plus Fpga Product Selection GuideДокумент8 страницUltrascale Plus Fpga Product Selection GuidemofiwОценок пока нет

- LAGE System 24 InstructionsДокумент32 страницыLAGE System 24 Instructionslimbert_Оценок пока нет

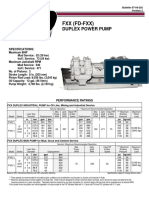

- FXE Duplex Pump BulletinДокумент2 страницыFXE Duplex Pump BulletinjoseОценок пока нет

- Select CatalogДокумент68 страницSelect CatalogVictorIbañezОценок пока нет

- Gotoh Parts Collection 2012Документ40 страницGotoh Parts Collection 2012Yuri JoОценок пока нет

- Mini-Striker Hoja de DatosДокумент4 страницыMini-Striker Hoja de DatosAlvaro Neisa LopezОценок пока нет

- CAD Architectural Selector Guide - December - 2018Документ2 страницыCAD Architectural Selector Guide - December - 2018Robert AditjiptoОценок пока нет

- FXG Duplex Pump SpecificationsДокумент2 страницыFXG Duplex Pump SpecificationsJunior Francisco QuijanoОценок пока нет

- 9851 3136 01d DHR 6 BrochureДокумент4 страницы9851 3136 01d DHR 6 BrochureMiguel CastroОценок пока нет

- Brochure-Dryer FX SeriesДокумент2 страницыBrochure-Dryer FX SeriesTaufan JustvandsОценок пока нет

- SBR LatexДокумент2 страницыSBR LatexMazharYasinОценок пока нет

- Commercial Faucet Wallmount Sink Faucets: Specification: (Example)Документ2 страницыCommercial Faucet Wallmount Sink Faucets: Specification: (Example)jmarrero488307Оценок пока нет

- High Pressure UCV Catalog 2020Документ10 страницHigh Pressure UCV Catalog 2020МаксимОценок пока нет

- EcoShield VpCI 380Документ2 страницыEcoShield VpCI 380dalt.guniОценок пока нет

- RANCHER-65N Data-SheetДокумент4 страницыRANCHER-65N Data-SheetJosé Pablo Villalta CalderónОценок пока нет

- Dust CollectorДокумент23 страницыDust CollectorIgnacio Alejandro Jose Helo VarelaОценок пока нет

- Ram 624Документ9 страницRam 624Pedro Schiavi StoiberОценок пока нет

- DownloadДокумент3 страницыDownloadMaria MaiaОценок пока нет

- Inodoro DireccionДокумент2 страницыInodoro DireccionVal Sá Adriana GpeОценок пока нет

- Hyosung Sf50 Prima 2007 Part CatalogueДокумент76 страницHyosung Sf50 Prima 2007 Part CatalogueRobert 70% (1)

- COP 1640+ / COP 1640EX: ServiceДокумент2 страницыCOP 1640+ / COP 1640EX: ServiceESRA0% (1)

- Tyfo SCH-7UP Composite: Using Tyfo S EpoxyДокумент2 страницыTyfo SCH-7UP Composite: Using Tyfo S Epoxyyusak santosoОценок пока нет

- Chicago Area/Metro East Rule: Motor Vehicle RefinishingДокумент2 страницыChicago Area/Metro East Rule: Motor Vehicle RefinishingOliver Augusto Fuentes LópezОценок пока нет

- Hubercarb and Geotex Ground Calcium Carbonates For Paints, Coatings, Adhesives, Caulks and Sealants PDFДокумент4 страницыHubercarb and Geotex Ground Calcium Carbonates For Paints, Coatings, Adhesives, Caulks and Sealants PDFXuân Giang NguyễnОценок пока нет

- 74013M-4 TAUT - 0.50 GPMДокумент2 страницы74013M-4 TAUT - 0.50 GPMGiordano Tuanama YapoОценок пока нет

- Drilling DuplexДокумент1 страницаDrilling DuplexEduardo Vilela RomeroОценок пока нет

- Uniroyal Data BookДокумент30 страницUniroyal Data Bookaris_aquino_1Оценок пока нет

- DFE-310, DFE-126: Technical Data SheetДокумент3 страницыDFE-310, DFE-126: Technical Data SheetWHWENОценок пока нет

- Protective Coatings Spray Packs BIGДокумент2 страницыProtective Coatings Spray Packs BIGJaelani Painting n Powder Coating WagnerОценок пока нет

- DSS Peerless Webinar Example Steam Trap Survey 2022Документ8 страницDSS Peerless Webinar Example Steam Trap Survey 2022Raj GaikwadОценок пока нет

- HFK131 Food and DairyДокумент2 страницыHFK131 Food and DairyjeffersonfriasОценок пока нет

- SAKRETE 8.6 Oz. Rapid Setting Anchoring Epoxy-60200221 - The Home DepotДокумент5 страницSAKRETE 8.6 Oz. Rapid Setting Anchoring Epoxy-60200221 - The Home Depotming_zhu10Оценок пока нет

- Kudu Bro New Pump Models Int A4 WebДокумент2 страницыKudu Bro New Pump Models Int A4 WebXXXXОценок пока нет

- P300 (Fluid O Tech)Документ2 страницыP300 (Fluid O Tech)Serge LapointeОценок пока нет

- 1028 FD FXX Duplex Power Pump PDFДокумент2 страницы1028 FD FXX Duplex Power Pump PDFjoseОценок пока нет

- Product: Which Deoxit® Spray Should I Use?Документ2 страницыProduct: Which Deoxit® Spray Should I Use?Thiago RodriguesОценок пока нет

- Ersatzteilliste SPX PowerTeam Ventil 9506 9507 9508 9509Документ5 страницErsatzteilliste SPX PowerTeam Ventil 9506 9507 9508 9509luisОценок пока нет

- RACORДокумент25 страницRACORDaniel LaymeОценок пока нет

- Adhesive Bonding of Thermoplastic Materials1Документ5 страницAdhesive Bonding of Thermoplastic Materials1kgrier8966Оценок пока нет

- People Like Us Seth GodinДокумент23 страницыPeople Like Us Seth GodinKongfuzdОценок пока нет

- How To Choose Which PSA To UseДокумент16 страницHow To Choose Which PSA To UseKongfuzd100% (1)

- 250 Ways To Say It in Business English PDFДокумент123 страницы250 Ways To Say It in Business English PDFArtyom SentsovОценок пока нет

- Acrylic PSA HenkelДокумент2 страницыAcrylic PSA HenkelKongfuzdОценок пока нет

- Getting The Word Out2 Seth GodinДокумент1 страницаGetting The Word Out2 Seth GodinKongfuzdОценок пока нет

- How To Choose Which PSA To UseДокумент16 страницHow To Choose Which PSA To UseKongfuzd100% (1)

- Task 3 - New Research Proposal, C Vides o ZamudioДокумент3 страницыTask 3 - New Research Proposal, C Vides o ZamudioOctavio LópezОценок пока нет

- Material Safety Data Sheet (PKE)Документ8 страницMaterial Safety Data Sheet (PKE)ffeedsupplierОценок пока нет

- (Zakiedited) TK06 FINALREPORTДокумент204 страницы(Zakiedited) TK06 FINALREPORTRiedo YusharyahyaОценок пока нет

- Consolidated List of Fdcs Licensed by Slas But Not Permitted by DCG (I)Документ8 страницConsolidated List of Fdcs Licensed by Slas But Not Permitted by DCG (I)NAVNEET BAGGAОценок пока нет

- Definition of TermsДокумент6 страницDefinition of TermsFrancisco ZieОценок пока нет

- Radiant Energy ReportДокумент17 страницRadiant Energy ReportJelo CatipayОценок пока нет

- Membrane Potential MCQ-WPS OfficeДокумент5 страницMembrane Potential MCQ-WPS OfficeFavourОценок пока нет

- Post-Laboratory Report Experiment 2: Potential of A Galvanic CellДокумент5 страницPost-Laboratory Report Experiment 2: Potential of A Galvanic CellerizaОценок пока нет

- Marine Science Semester 1 ReviewДокумент18 страницMarine Science Semester 1 ReviewJoe Xavier ReidyОценок пока нет

- Humphery DavyДокумент3 страницыHumphery Davydr jameer kamateОценок пока нет

- Iriotec - 8850 - Merck - TDS (For Rest of The World) PDFДокумент2 страницыIriotec - 8850 - Merck - TDS (For Rest of The World) PDFxy2zjgОценок пока нет

- CHROME STEEL SLEEVE Kavya Int Brochure PDFДокумент4 страницыCHROME STEEL SLEEVE Kavya Int Brochure PDFjoseluispaillachoОценок пока нет

- Proposal Defense PresentationДокумент52 страницыProposal Defense PresentationJanine TacaisanОценок пока нет

- Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionДокумент11 страницHydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator AdsorptionSebastian Chaverra100% (1)

- A176Документ2 страницыA176Claudenir AlvesОценок пока нет

- Quantum TunnellingДокумент11 страницQuantum Tunnellingrr1819100% (1)

- Aijstpme (2012) 5 (4) 7-20Документ14 страницAijstpme (2012) 5 (4) 7-20maziar60Оценок пока нет

- Chapter 11 - Chemical Reactions PDFДокумент17 страницChapter 11 - Chemical Reactions PDFapi-239855791Оценок пока нет

- Ozone Layer Depletion - Health and Environmental EffectsДокумент9 страницOzone Layer Depletion - Health and Environmental EffectsHemanth RajОценок пока нет

- Typical Specification - Russian PCI Coal - KravaskyДокумент1 страницаTypical Specification - Russian PCI Coal - Kravaskynaresh adusumilliОценок пока нет

- 25X5 GI Strip - Data SheetДокумент1 страница25X5 GI Strip - Data SheetSandeep VijayakumarОценок пока нет

- Anatomy & Physiology Made Incredibly Visual!Документ412 страницAnatomy & Physiology Made Incredibly Visual!Cereal KillerОценок пока нет

- Applications of Egg Shell and Egg Shell Membrane As AdsorbentsДокумент13 страницApplications of Egg Shell and Egg Shell Membrane As AdsorbentsAhmed AliОценок пока нет

- Kseeb SSLC Class 10 Science Previous Year Paper 2019Документ12 страницKseeb SSLC Class 10 Science Previous Year Paper 2019ghs niduvani niduvaniОценок пока нет

- Lactobacillus Plantarum Strain (BAA-793) Via Solid State FermentationДокумент7 страницLactobacillus Plantarum Strain (BAA-793) Via Solid State FermentationChairun NisaОценок пока нет

- Coordinated Sciences IGSCE 0654 - s12 - QP - 63 PDFДокумент20 страницCoordinated Sciences IGSCE 0654 - s12 - QP - 63 PDFjanovaОценок пока нет

- BG1005 Materials Sciences_ Homework #1Документ4 страницыBG1005 Materials Sciences_ Homework #1blueworld_918094Оценок пока нет

- Philippine Red Cross Molecular Laboratory: Covid-19 RT-PCR Test Report & CertificationДокумент1 страницаPhilippine Red Cross Molecular Laboratory: Covid-19 RT-PCR Test Report & CertificationFrancis SevillenoОценок пока нет

- Atomic Structure MCQS: 1 Year N0tes Chemistry NewДокумент11 страницAtomic Structure MCQS: 1 Year N0tes Chemistry NewHaider Jalal100% (9)

- Gamma RayДокумент5 страницGamma RayDenisha Betaci GultomОценок пока нет