Академический Документы

Профессиональный Документы

Культура Документы

Battery Maintenance

Загружено:

Lily Mimbela0 оценок0% нашли этот документ полезным (0 голосов)

221 просмотров1 страницаBatteries should be boost charged if the open circuit voltage (voltmeter) reading is below 12. Volts. A battery that has not begun to accept the MINIMUM (1 / 2 of recommended) charging current WITHIN 15 minutes at the ambient temperature will explode.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документBatteries should be boost charged if the open circuit voltage (voltmeter) reading is below 12. Volts. A battery that has not begun to accept the MINIMUM (1 / 2 of recommended) charging current WITHIN 15 minutes at the ambient temperature will explode.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

221 просмотров1 страницаBattery Maintenance

Загружено:

Lily MimbelaBatteries should be boost charged if the open circuit voltage (voltmeter) reading is below 12. Volts. A battery that has not begun to accept the MINIMUM (1 / 2 of recommended) charging current WITHIN 15 minutes at the ambient temperature will explode.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

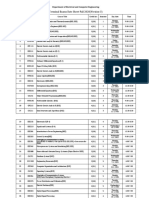

CAT BATTERY CARE & MAINTENANCE GUIDE ®

Important: Always Wear Eye Protection

SAFETY PRECAUTIONS LOAD TESTING JUMP STARTING CHARGING TIPS

FOLLOW SAFETY PRECAUTIONS – WEAR PROPER EYE PROTECTION.

SHIELD EYES AND FACE AT ALL TIMES... NEVER LEAN DIRECTLY OVER BATTERY

Batteries should be boost charged if the

FOLLOW SAFETY PRECAUTIONS– SET AT 1/2 COLD CRANKING WHEN TESTING, JUMP STARTING OR PERFORMING OTHER MAINTENANCE. BATTERY CHARGING

AMPERE (CCA) RATING*. open circuit voltage (voltmeter) reading is

WEAR PROPER EYE PROTECTION. Be sure any vent caps are tight and level, 3. Connect one end of negative (-) booster

RATE/TIME TABLES

below 12.4 volts. See chart at right. Amp Hour Rating Charging Rate

First perform an open circuit voltage test 4. Set the tester for one-half the battery’s then place a damp rag over the vent caps of cable to negative (-) terminal of assisting • Prior to charging, read the manufacturer’s 15-34 5 Amps

using the Caterpillar® Digital Voltmeter, 0°F cold crank rating and apply the load both batteries. Be sure machines/vehicles battery, wired to ground. instructions for proper charger hook-up and use. 35-49 7.5 Amps

4C6600, for a fast, accurate test. for 15 seconds. Battery ambient tempera- do not touch each other. • Turn charger OFF and disconnect battery prior 50-69 10 Amps

4. Complete hook-up by connecting other

ture must be 10°C (50°F) or greater. to hook-up to avoid dangerous sparks. 70-99 15 Amps

Then perform an adjustable load test. 1. Connect one end of positive (+) booster end of negative (-) booster cable TO 100-129 20 Amps

A load test is the best way to determine if cable to positive (+) terminal of discharged ENGINE BLOCK OF STALLED MACHINE • Use charts below for normal charge of a battery 130-164 25 Amps

the battery is delivering adequate electrical 9.5 VOLTS OK FOR 12V BATTERY! battery, wired to starter or solenoid. OR VEHICLE-AS FAR AWAY FROM based on the ambient temperature at time of 165-199 30 Amps

performance. Make sure your variable load 4.7 VOLTS OK FOR 6V BATTERY! BATTERY AS POSSIBLE... AWAY FROM charge. Note – there is a potential of battery 200-249 35 Amps

tester is working properly. 2. Connect other end of positive (+) booster MOVING FAN AND FUEL LINES. explosion when batteries are overcharged.

Important: Always Wear Eye Protection Perform all work in a well ventilated area. 5. With the load still on the battery, check cable to positive (+) terminal of assisting OPEN CIRCUIT VOLTAGE

• A battery that has NOT begun to accept the

Never lean directly over a battery while the tester reading. A steady reading of battery. 5. Start both machines or vehicles and 12 Volt 8 Volt 6 Volt Charging

ALWAYS WEAR SAFETY GLASSES AND A MINIMUM (1/2 of recommended) charging

boosting, testing or charging it. IF DISCHARGED–RECHARGE! 9.5 volts for 12V battery or 4.7 volts for 6V remove cables in reverse order of Battery Battery Battery Time

current WITHIN 15 minutes at the highest

FACE SHIELD WHEN WORKING ON OR battery while under load indicates a good connection. Discard the rag. Load Test

1. You can’t load test a discharged battery. charger setting (or voltage) should be replaced.

NEAR BATTERIES. PROTECT YOUR EYES! 12.40 & 8.27 & 6.20 & No

Always attempt to charge it before load battery. • If violent gassing or spewing of electrolyte above above above Charging

All batteries generate explosive hydrogen Batteries contain corrosive sulfuric acid

testing if below 12.4 volts. If above 12.0 volts, PROTECT YOUR EYES! occurs or the battery case feels hot to the touch, Required

gas. Keep sparks, flames and cigarettes that can destroy clothing and burn the 1 4 2

remove surface charge before charging. LESS THAN 9.5 VOLTS OR 4.7 VOLTS 3 temporarily reduce or halt charging. 12.39- 8.26- 6.19- 2.0

away from batteries at all times. Do not skin. Neutralize acid spills with a paste 12.20 8.13 6.10 Hours

connect or disconnect “live” circuits. To Refer to the charging instructions below for RECHARGE OR REPLACE. + IMPORTANT: connect to ground, away • NEVER attempt to charge a frozen battery.

made of baking soda and water. + Booster 12.19- 8.12- 6.09- 3.0

important information. from battery... AWAY FROM MOVING Allow it to warm up to room temperature

avoid creating sparks, always turn charging 6. If the reading is below 9.5 or 4.7 volts Battery! 12.00 8.00 6.00 Hours

BE CAREFUL! FAN AND FUEL LINES. before placing on charge.

and testing equipment OFF before attach- under load, boost charge the battery and Below Below Below 4.0

ing or removing clamps. NEVER USE COMPRESSED AIR FOR TURN TESTER OFF! IMPORTANT: BOTH BATTERIES OR SETS OF BATTERIES MUST BE THE SAME VOLTAGE! PROTECT YOUR EYES! 12.00 8.00 6.00 Hours

test it again. If the second reading is still

ALWAYS DISCONNECT GROUNDED CABLE CLEANING NEAR A BATTERY. 2. To avoid sparking, be sure load tester low, replace the battery. DO NOT MIX VOLTAGES! Optimum charging volts for 12-volt battery vs. temperature for lead acid batteries, utilizing an alternator.

FIRST AND CONNECT IT LAST TO PREVENT Rapid air movement from compressed air is OFF and battery is disconnected before TEMP C TEMP F *MF CA/CA *LOW ANTIMONY *HYBRID AGM GEL

DANGEROUS SPARKS. combined with dust, dirt, etc. will create hook-up. Use computer memory saver to Opt Voltage Opt Voltage Opt Voltage Opt Voltage Opt Voltage

static electricity, which may lead to an retain the machine’s electronic memory (If the CCA rating is unknown, use 200 DRY CHARGE ACTIVATION > 52 > 126 12.94 12.64 12.64 12.64 12.64

explosion. while the battery is disconnected. * for auto batteries, 350 for commercial

IMPORTANT... WEAR PROPER EYE PROTECTION!

41-52

26-40

105-126

78-104

13.32

13.80

13.02

13.50

13.02

13.50

12.90

13.02

12.80

13.02

batteries and 100 for small-engine 20-25 68-77 14.10 14.10 14.10 13.50 13.50

RED TO POSITIVE & batteries.) IMPORTANT 0-19 32-67 14.46 14.16 14.16 14.16 14.16

PROPER INSTALLATION BLACK TO NEGATIVE. Each vent opening is sealed with a remov- 4. If a boost charge is required, the battery <0 < 32 15.90 15.60 15.60 15.60 15.60

3. Connect the positive (+) tester clamp to able plastic plug. Do not remove this plug is to be charged for 20 minutes at the Optimum charging volts for 12-volt battery vs. temperature for lead acid batteries, utilizing a charger.

the positive (+) battery terminal. Then FOR COMPLETE LOAD TEST PROCEDURE until you are ready to fill the battery with following rates: TEMP TEMP *MF *MF *LOW *LOW

FOLLOW SAFETY PRECAUTIONS – 4. Put corrosion protection washers on

connect the negative (-) tester clamp to INFORMATION REFER TO THE electrolyte. Only when you are ready to fill,

• 15 amp for 12 Volt batteries under 600 CCA C F CA/CA CA/CA ANTIMONY ANTIMONY *HYBRID *HYBRID AGM AGM GEL GEL

WEAR PROPER EYE PROTECTION. battery terminals, install new battery in the negative (-) battery terminal. Always CATERPILLAR BATTERY LOAD TESTER remove and discard the seal plugs. Use Float Equalize Float Equalize Float Equalize Float Equalize Float Equalize

1. Before removing old battery, mark the • 40 amp for 12 Volt batteries 600-1200 CCA Volts Volts Volts Volts Volts Volts Volts Volts Volts Volts

same position as old one, and tighten protect your eyes. SEHS9249. large vent caps to close openings when

positive (+) and negative (-) cables for battery is filled and placed in service. • 60 amp for all 8 Volt batteries and 80 176 12.90 14.70 12.60 13.20 12.60 13.80 12.90 13.50 12.80 12.90

hold-down. Be sure terminals will clear 12 Volt batteries over 1200 CCA 60 140 12.94 14.74 12.64 13.24 12.64 13.84 12.90 13.54 12.80 12.94

proper connection to the new battery. hood, fender, box lid, etc. ACTIVATION • 40 amp for all 6 Volt batteries 40 104 13.32 15.12 13.02 13.62 13.02 14.22 13.02 13.92 13.02 13.32

2. Always disconnect the ground cable first 5. Connect positive (+) cable first, 20 68 13.80 15.60 13.50 14.10 13.50 14.70 13.50 14.40 13.50 13.80

1. Fill each cell to proper level with battery-

[usually negative (-)] to avoid any sparking 5. After boost charging, the battery is to be 0 32 14.46 16.26 14.16 14.76 14.16 15.36 14.16 15.06 14.16 14.46

around battery. Then disconnect the then connect ground cable last. Use a

special side terminal torque tool to tighten

ROTATE BATTERY STOCK grade sulfuric acid of 1.265 specific gravity.

Battery and acid must be at a temperature

load tested again at 1/2 the CCA rating for

10 seconds. The battery may be put into

-30 -22 15.90 17.70 15.60 16.20 15.60 16.80 15.60 16.50 15.60

*Use Caterpillar Data Sheet, PEHJ0073 to identify chemical construction of Caterpillar Batteries to determine recommended charging

15.90

positive (+) cable and carefully remove of 16°C to 38°C (60°F to 100°F) at time of voltages in previous tables.

side terminal cables without damage. service if 10 second voltages are as listed

the old battery. USE OLDEST BATTERIES FIRST. filling.

Never over tighten or hammer cables in step 3.

3. Clean and inspect the battery tray. When 2. Apply a load of 1/2 the CCA rating for

necessary, replace the tray and hold-down onto terminals.

assembly. Also replace the battery cables if 6. Coat terminals and cable connection

Batteries require periodic stock rotation

and routine charging. Always rotate stock

MONTH 10 seconds.

6. Recycle all scrap batteries. Your Cat

Dealer accepts spent batteries for recycling. CHOOSE PLENTY OF POWER

needed. Cable ends MUST be clean and with a corrosion protection spray. A- January G - July 3. The battery is ready for use or must

using the FIFO (First In, First Out) method... Starting Power Starting Power

corrosion free. be given a “booster” charge with 10

instead of FISH (First In, Still Here). B- February H - August CHOOSE COLD CRANKING AMPS... Available from Battery Required By Engine

seconds test voltage reading as follows:

C- March J - September NOT MONTHS OF WARRANTY!

Batteries used at Caterpillar manufacturing Size Ready Boost 105% 110%

facilities or shipped from the battery D- April K - October Always use a battery that has enough cranking

IN-MACHINE/VEHICLE SERVICE manufacturer for the replacement market

have a label affixed to the battery (or

E- May L - November

12V

8V

6V

9V or more

6V or more

4.5V or more

below 9V

below 6V

below 4.5V

power, reserve capacity and vibration resistance

to get the job done. Consider the machine or

stamped on battery carton if provided) F- June M- December vehicle manufacturer’s recommended capacity to

FOLLOW SAFETY PRECAUTIONS – Scrape or brush off the residue and wash 100% 100%

with the following shipping date codes: be a minimum-capacity guideline. A machine or

WEAR PROPER EYE PROTECTION.

Prior to any testing, visually inspect the

the area with clean water. Following your

visual inspection, check the battery’s state YEAR

BATTERY STORAGE TIPS vehicle that has a lot of electrical accessories

such as on-board computers, air conditioning,

battery. Look for: of charge with a voltmeter. two-way radios, etc., will need a more powerful

PROTECT YOUR EYES! 8 - 1998 3 - 2003

• Cracked or broken case or cover Example: A3 = Battery shipped Storage temperature is critical for batteries. • Do not stack batteries more than 2 high battery for optimum performance. 65% 155%

• Leaking case-to-cover seal NEVER USE COMPRESSED AIR FOR January 2003 9 - 1999 4 - 2004 Batteries should be stored in a cool, dry (3 high if automotive). Batteries must be Along with electrical accessories, temperature

• Damaged or leaking terminals CLEANING NEAR A BATTERY. 0 - 2000

area in an upright position. Keep them as in cartons or have protected corrugated also has an effect on battery performance.

5 - 2005 cool as possible, but above freezing for packaging placed between each stacked 40% 210%

• Loose cable connections Rapid air movement from compressed air

maximum life. layer. Machines or vehicles that are operated

• Corrosion combined with dust, dirt, etc. will create

REMEMBER... IF BATTERIES ARE STORED 1 - 2001 6 - 2006

static electricity, which may lead to an • Test non-maintenance free wet batteries in extremely hot or cold climates may need a

WET OR DRY, YOU MUST ALWAYS ROTATE 2 - 2002 battery with a higher CCA rating. 18% 268%

Neutralize any corrosion with a baking explosion. 7 - 2007 • Never stack batteries directly on top of each every 4-6 months, Maintenance Free every

soda/water paste or battery cleaner spray. YOUR STOCK! other unless they are in cartons or on ship- 12 months, and recharge if necessary. REMEMBER... YOU CAN’T BUY A

ping pallets protected by corrugated • Dry batteries that are not activated have Temperature has a dramatic effect on a battery’s ability to crank an

Note: The Cat Digital Battery Analyzer (Part # 177-2330) enables you to determine whether a battery is bad or in need of a

BATTERY WITH TOO MUCH POWER! engine. Not only do cold temperatures rob batteries of power, they also

recharge in just 20 seconds, without having to remove the battery from the machine or vehicle. It quickly and accurately tests the packaging. unlimited shelf life. thicken motor oil, making engines harder to start. And heat can damage

condition of 12-volt and 6-volt batteries, even discharged to as low as one volt.

batteries by causing internal components to wear out quickly while also

ALWAYS TEST BATTERY BEFORE making engines difficult to start.

For Sales and Service Call: INSTALLATION, AND CHARGE IF NECESSARY. © 2007 Caterpillar

PEWP4050-03

Printed in U.S.A.

Вам также может понравиться

- Coulomb's Law PacketДокумент4 страницыCoulomb's Law PacketMohit MjОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- KitechДокумент5 страницKitechkhushinmakimОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Notes - Power Transmission PlanningДокумент2 страницыNotes - Power Transmission PlanningKashaf ShahidОценок пока нет

- Date Sheet-Terminal Exams - Fall 20-1Документ6 страницDate Sheet-Terminal Exams - Fall 20-1Muhammad Zaeem AkmalОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- EEE 315 ELECTRICAL MACHINES III Supplementary EXAM - 2017Документ5 страницEEE 315 ELECTRICAL MACHINES III Supplementary EXAM - 2017Abkul KunniОценок пока нет

- Ds 1ln6 Uu U Utp Cat6 4p0.565 PVC CMДокумент1 страницаDs 1ln6 Uu U Utp Cat6 4p0.565 PVC CMFelisha FebryОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Safety Instrumentation Module - 5 Operation, Maintenance, Testing, Reporting and Management of PSMPДокумент104 страницыSafety Instrumentation Module - 5 Operation, Maintenance, Testing, Reporting and Management of PSMPkrushnasamy subramaniyan100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- MM410 Catalogue 09-01 enДокумент14 страницMM410 Catalogue 09-01 enbajricaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- IEM Rotary UPS Brochure 2019.compressedДокумент6 страницIEM Rotary UPS Brochure 2019.compressedGordon FreemanОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- TV Protection ModeДокумент3 страницыTV Protection Modejudas_priest_12345100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Chapter One: Smart City SolutionsДокумент27 страницChapter One: Smart City Solutionssnehal sabnisОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- PMMCДокумент66 страницPMMCEvoque YTОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Sa Max700 PDFДокумент124 страницыSa Max700 PDFAngeler Jp100% (1)

- Yamaha Yas-207 - Ats-2070 - Cu207 - Ats-Cu2070 - ns-wsw42 PDFДокумент50 страницYamaha Yas-207 - Ats-2070 - Cu207 - Ats-Cu2070 - ns-wsw42 PDFboroda241050% (2)

- Socomec AtysДокумент2 страницыSocomec AtysmehdivinciОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Ug Physics On 16Документ59 страницUg Physics On 16Ruban PravinОценок пока нет

- Energy ManagementДокумент55 страницEnergy ManagementNjitnumОценок пока нет

- Work - Instruction 66-33KV TRANSFORMERДокумент5 страницWork - Instruction 66-33KV TRANSFORMERTAHIR HUSAINОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Temperature Effects in SemiconductorsДокумент20 страницTemperature Effects in Semiconductorsohenri100Оценок пока нет

- SA PowerBu D9225Документ86 страницSA PowerBu D9225juanlasserre9444Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- 37 Sensor Kit TutorialДокумент81 страница37 Sensor Kit Tutorialurba7bОценок пока нет

- 6FX2001-5QS12 Datasheet enДокумент2 страницы6FX2001-5QS12 Datasheet enJuan Perez RosasОценок пока нет

- BSCPH 202Документ4 страницыBSCPH 202pp1560078Оценок пока нет

- S60SC4M Mxqwqqs PDFДокумент11 страницS60SC4M Mxqwqqs PDFBaharak BaghiОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Cheat Sheet Bs 5467 and Bs 6724Документ2 страницыCheat Sheet Bs 5467 and Bs 6724EMIL SONU SAMОценок пока нет

- Lecture Impedance and Admittance On Smith ChartsДокумент15 страницLecture Impedance and Admittance On Smith ChartsBill WhiteОценок пока нет

- SRNE MPPT-Solar-Charge-Controller-ML2420-SpecificationДокумент5 страницSRNE MPPT-Solar-Charge-Controller-ML2420-Specificationwyatt-jangoОценок пока нет

- Isl 83202Документ12 страницIsl 83202prithivirajОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- (NB24-T554-01D) Specsheet 01152010Документ2 страницы(NB24-T554-01D) Specsheet 01152010nextekpowerОценок пока нет