Академический Документы

Профессиональный Документы

Культура Документы

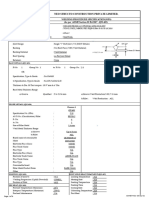

Welding Procedure Specification (WPS) Nº46 Prequalified Qualified by Testing (De Acuerdo A AWS D1.6)

Загружено:

Jimmy David Espinoza MejiaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Welding Procedure Specification (WPS) Nº46 Prequalified Qualified by Testing (De Acuerdo A AWS D1.6)

Загружено:

Jimmy David Espinoza MejiaАвторское право:

Доступные форматы

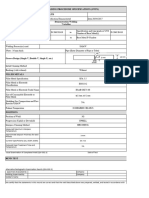

WELDING PROCEDURE SPECIFICATION (WPS) Nº46

PREQUALIFIED QUALIFIED BY TESTING X

(De acuerdo a AWS D1.6)

Identification # WPS FIANSA 46 Rev. 0

Company name FIANSA SOCIEDAD ANONIMA Originated by Ing. Luis Mujica Dominguez

Welding process SMAW Date 8/10/2007

Process type Manual Authorised by Ing. James Noriega

Project Caldera #4 - LAREDO S.A.A Date 8/10/2007

Revised by Ing. Sigfrido Ahon

Date 8/10/2007

Joint design used Position

Joint type Butt joint (B) Welding position: Groove 3G

Joint design Square grove weld Fillet

Backing No Vertical progression

Backing material No Electrical characteristics

Root opening (R)* (mm.) 3 Transfer mode (GMAW) -

Root face (f)* (mm.) 0 Current type DCEP

Grove angle (a)* (deg.) Other

Radius (J - U)* (deg.) - Technique

Back gouging - Stringer or weave bead Weave bead

Back gouging method - Multi/single pass (per side) Single Pass

Base metals Number of electrodes 1

Longitudinal

Spec. type or grade DIN 1.4003 Spacing: -

(in.)

Thickness: Groove (in.) 1/4 Lateral (in.) -

Fillet (in.) Angle (deg.) -

Diameter (Pipe) (in.) - Contact tube to work (in.) -

Filler metals Peening -

AWS Specification A 5.4-92 Interpass cleaning Slag Removed

AWS Classification E308L - 16 Preheat

Shielding Preheat temp.: Min. (°F) None

Flux Interpass temp.: Min.(°F) None

Electrode-flux (class) - Max.(°F)) None

Gas composition Post weld heat treatment

Gas flow rate (cfh) 15-25 Temperature (°F) None

Gas cup size (in.) - Time (hrs) -

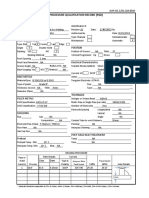

Welding procedure

Filler Current Travel

Filler metal metal type / speed

Layer Pass Process

class

Amps Volts Joint Details

diameter polarity

(in.) (in./min)

1 1er SMAW E308L - 16 3/32 DCEP 55 - 60 4-5 26 - 28

2 2do SMAW E308L - 16 3/32 DCEP 50 - 60 3-4 26 - 28

3

2

1

4

3 3-4to SMAW E308L - 16 3/32 DCEP 50 - 60 3-4 26 - 28 R

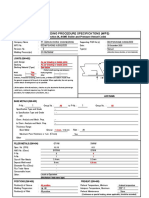

Welding Supervisor QA Manager

Name Signature Name Signature

Ing. Luis Mujica Ing. James Noriega

Date Date

8/10/2007 8/10/2007

Вам также может понравиться

- WPS For SSДокумент1 страницаWPS For SSdeepakОценок пока нет

- WPS 84281 R06Документ1 страницаWPS 84281 R06Ritesh kumarОценок пока нет

- Draf WPSДокумент2 страницыDraf WPSMj EdinОценок пока нет

- WPS for Urea Reclaimer Butt Joint WeldingДокумент1 страницаWPS for Urea Reclaimer Butt Joint Weldingasirul_meОценок пока нет

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Документ2 страницыASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Welding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YesДокумент2 страницыWelding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YessdgshhОценок пока нет

- SPL - PQR-WPS-SWPS SmawДокумент7 страницSPL - PQR-WPS-SWPS Smawgopuvinu4uОценок пока нет

- Prequalified Qualified by TestingДокумент5 страницPrequalified Qualified by Testingcarlosoliveros1967Оценок пока нет

- WPS for Welding ASTM A36 Steel with E7018 ElectrodesДокумент1 страницаWPS for Welding ASTM A36 Steel with E7018 Electrodeshenry ayalaОценок пока нет

- QW 482 WPSДокумент2 страницыQW 482 WPSsmit patelОценок пока нет

- Computer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Документ1 страницаComputer Engineering, Inc.: P WPS D1.1 - C - AWS 5.2.0 Form 2000 Rev. 0Erick GoyesОценок пока нет

- WPS - BilДокумент8 страницWPS - BilShahdeoОценок пока нет

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherДокумент2 страницыProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamОценок пока нет

- Aws D1.6 - SS316 WPSДокумент1 страницаAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Template SRFWДокумент1 страницаTemplate SRFWDylan TriggОценок пока нет

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Документ2 страницыProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahОценок пока нет

- WPS & PQRДокумент13 страницWPS & PQRValentin RadulescuОценок пока нет

- Welding Procedure Specification (WPS) : Page: 1/1Документ5 страницWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirОценок пока нет

- PQR Saw ProcessДокумент1 страницаPQR Saw ProcessARUL ARON JOSEОценок пока нет

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Документ9 страниц(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaОценок пока нет

- Welding Procedure Specification (WPS)Документ2 страницыWelding Procedure Specification (WPS)Rejoy babyОценок пока нет

- WPS 1.1Документ1 страницаWPS 1.1Juan Diego Carvajal100% (1)

- Template Pipe PlateДокумент1 страницаTemplate Pipe PlateFarhan AmzarОценок пока нет

- Draft WPSДокумент3 страницыDraft WPSWale OyeludeОценок пока нет

- WPS Welding Performance SpecialistДокумент2 страницыWPS Welding Performance SpecialistGobinath GovindarajОценок пока нет

- DraftДокумент32 страницыDraftAnilkumarОценок пока нет

- Preliminary WPS for 12.7mm SMAW WeldingДокумент3 страницыPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- Toaz - Info Welding Procedure Specification Format PRДокумент3 страницыToaz - Info Welding Procedure Specification Format PRKarim ZahranОценок пока нет

- Quinco Steel Inc.: Welding Procedure Specification (WPS)Документ1 страницаQuinco Steel Inc.: Welding Procedure Specification (WPS)wmajordan13Оценок пока нет

- Welding Procedure Specifications (WPS) : AWS D1.1Документ2 страницыWelding Procedure Specifications (WPS) : AWS D1.1BS AhnОценок пока нет

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Документ2 страницыAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataОценок пока нет

- PQR Gmaw3gДокумент5 страницPQR Gmaw3gPatel VvnОценок пока нет

- P WPS Smaw Ceym 001 021Документ1 страницаP WPS Smaw Ceym 001 021juan carlos garavitoОценок пока нет

- Preliminary - Welding Procedure Specification (WPS)Документ1 страницаPreliminary - Welding Procedure Specification (WPS)Rudi DaОценок пока нет

- Welding Procedure Specification: PQR 2" Dia-5.54mm THKДокумент2 страницыWelding Procedure Specification: PQR 2" Dia-5.54mm THKNil BorichaОценок пока нет

- Filled WPS Single FCAWДокумент3 страницыFilled WPS Single FCAWAhmad ShaheenОценок пока нет

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONДокумент3 страницыWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirДокумент3 страницыWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Welding Procedure Specification: ST NDДокумент1 страницаWelding Procedure Specification: ST NDMaung SleeperОценок пока нет

- QC E7018 CJP B-L1a OverheadДокумент1 страницаQC E7018 CJP B-L1a Overheadwmajordan13Оценок пока нет

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4Документ1 страницаData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7503-0DB32-3FA4jitendra patelОценок пока нет

- AWS D1.1 - Example PQR & WPS DocumentsДокумент4 страницыAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Wps - Asme Ix - Gtaw - PipaДокумент5 страницWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeДокумент6 страницWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberОценок пока нет

- 1nb1354-4aa40-4aa0-Z A65+g50+k11+k97+l27+w72Документ2 страницы1nb1354-4aa40-4aa0-Z A65+g50+k11+k97+l27+w72Lance AyoubОценок пока нет

- GMAW welding parameters for SS400 pipeДокумент2 страницыGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Документ2 страницыTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaОценок пока нет

- LARSEN & TOUBRO LTD. WELDING PROCEDURE SPECIFICATIONДокумент2 страницыLARSEN & TOUBRO LTD. WELDING PROCEDURE SPECIFICATIONRohiОценок пока нет

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-3AB03-5AA4Документ1 страницаData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE7501-3AB03-5AA4Shekhar PhaseОценок пока нет

- 07.3 111 FW ML PF WPS 20mm EngДокумент1 страница07.3 111 FW ML PF WPS 20mm EngViktorОценок пока нет

- Welding Procedure Data Sheet for Steel Groups 1-3Документ1 страницаWelding Procedure Data Sheet for Steel Groups 1-3suronocaturatmojoОценок пока нет

- PWPS CS To SS446-3Документ5 страницPWPS CS To SS446-3BIIS QAQC Babu SivaОценок пока нет

- Wps API-mwt 2020Документ24 страницыWps API-mwt 2020afshohil anamОценок пока нет

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Документ1 страницаAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetОценок пока нет

- Smaw Wps FinalДокумент3 страницыSmaw Wps FinalsheikmoinОценок пока нет

- Welding Procedure Specification (WPS) : Joint Design PositionДокумент9 страницWelding Procedure Specification (WPS) : Joint Design PositionpetermanroelibraryОценок пока нет

- ARL-AL-WPS-001 welding procedureДокумент2 страницыARL-AL-WPS-001 welding procedurerajuajiОценок пока нет

- (P1) NSC-1020-TR-0102-1.1-WPS-06Документ6 страниц(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaОценок пока нет

- Astm 20M PDFДокумент33 страницыAstm 20M PDFDee DeeОценок пока нет

- Problem ExamДокумент1 страницаProblem ExamJimmy David Espinoza MejiaОценок пока нет

- FlexibilidadДокумент2 страницыFlexibilidadJimmy David Espinoza MejiaОценок пока нет

- Inspection and Test Plan for Hydrostatic TestДокумент12 страницInspection and Test Plan for Hydrostatic TestJimmy David Espinoza MejiaОценок пока нет

- Astm A860a-860mДокумент5 страницAstm A860a-860mCarlos Abril FlorezОценок пока нет

- Punto a (mm) F (N) u (mm) h (N) uh/2 Δa RДокумент2 страницыPunto a (mm) F (N) u (mm) h (N) uh/2 Δa RJimmy David Espinoza MejiaОценок пока нет

- University of Liège - Aerospace & Mechanical Engineering: Ludovic NoelsДокумент48 страницUniversity of Liège - Aerospace & Mechanical Engineering: Ludovic NoelsJimmy David Espinoza MejiaОценок пока нет

- ASTM STANDARDS 2004 PART 5Документ5 страницASTM STANDARDS 2004 PART 5Jimmy David Espinoza MejiaОценок пока нет

- Fracture Mech MasterДокумент390 страницFracture Mech MasterJimmy David Espinoza MejiaОценок пока нет

- Body Crunch & Exercise Bike-2018Документ4 страницыBody Crunch & Exercise Bike-2018Jimmy David Espinoza MejiaОценок пока нет

- Astm Parte 3Документ5 страницAstm Parte 3Jimmy David Espinoza MejiaОценок пока нет

- ASTM A 6m-01a PDFДокумент63 страницыASTM A 6m-01a PDFLizz EstradaОценок пока нет

- Torsion TestingДокумент13 страницTorsion TestingJimmy David Espinoza MejiaОценок пока нет

- Photo ChekДокумент2 страницыPhoto ChekJimmy David Espinoza MejiaОценок пока нет

- GuideДокумент89 страницGuideAsif HameedОценок пока нет

- Instruction Manual Manual de Instrucciones: 4-151-026-61 (1) CECH-2001AДокумент120 страницInstruction Manual Manual de Instrucciones: 4-151-026-61 (1) CECH-2001ARocío RodríguezОценок пока нет

- Examen Medico Ocupacional Frank TorresДокумент17 страницExamen Medico Ocupacional Frank TorresJimmy David Espinoza MejiaОценок пока нет

- Software Guide PM1405 EngДокумент33 страницыSoftware Guide PM1405 EngJimmy David Espinoza MejiaОценок пока нет

- Astm E94 - Guia Estandar para Radiografia PDFДокумент13 страницAstm E94 - Guia Estandar para Radiografia PDFJimmy David Espinoza MejiaОценок пока нет

- Imecon: TransmittalДокумент1 страницаImecon: TransmittalJimmy David Espinoza MejiaОценок пока нет

- 660 Series Type B Certificate Termination Letter Aug 2009 Final PDFДокумент1 страница660 Series Type B Certificate Termination Letter Aug 2009 Final PDFJimmy David Espinoza MejiaОценок пока нет

- API Creep RuptureДокумент3 страницыAPI Creep RuptureRavi Raj100% (1)

- Certificate Number Utc08181Документ1 страницаCertificate Number Utc08181Jimmy David Espinoza MejiaОценок пока нет

- Semt/Mec Manta, Ecuador: 10-1R Eloy Alfaro IntlДокумент16 страницSemt/Mec Manta, Ecuador: 10-1R Eloy Alfaro IntlDavid CordovillaОценок пока нет

- Mobile GIS Platforms and Applications with ArcGISДокумент28 страницMobile GIS Platforms and Applications with ArcGISZachary Perkins100% (1)

- Steel Design 6 April 2023 PDFДокумент2 страницыSteel Design 6 April 2023 PDFTristan CatapangОценок пока нет

- Principles of Differential RelayingДокумент115 страницPrinciples of Differential RelayingelitesankarОценок пока нет

- SP 5500 V5.1 1.0Документ17 страницSP 5500 V5.1 1.0Rama Tenis CopecОценок пока нет

- As Statistics Mechanics 1Документ240 страницAs Statistics Mechanics 1claire zhouОценок пока нет

- Propeller Model Tests GuideДокумент12 страницPropeller Model Tests GuideOdpewğw RlelelwОценок пока нет

- Certificate: Shear MachineДокумент3 страницыCertificate: Shear MachinegilbertoОценок пока нет

- Staad FoundationДокумент25 страницStaad FoundationAnonymous nwByj9L100% (2)

- Ellipse Properties and GraphingДокумент24 страницыEllipse Properties and GraphingREBY ARANZOОценок пока нет

- MC Maths - Lesson Plans - Stage 6 - C05Документ9 страницMC Maths - Lesson Plans - Stage 6 - C05syasmiitaОценок пока нет

- Java Array, Inheritance, Exception Handling Interview QuestionsДокумент14 страницJava Array, Inheritance, Exception Handling Interview QuestionsMuthumanikandan Hariraman0% (1)

- Swiftautoid SA T9680 Black Series 2D Imager Andriod Industrial TabletДокумент2 страницыSwiftautoid SA T9680 Black Series 2D Imager Andriod Industrial TabletAirul MutaqinОценок пока нет

- Cadillac: Operator'S ManualДокумент63 страницыCadillac: Operator'S ManualRaj jainОценок пока нет

- Justifying The CMM: (Coordinate Measuring Machine)Документ6 страницJustifying The CMM: (Coordinate Measuring Machine)pm089Оценок пока нет

- Answer: 60% Answer: Geography 55%: Harmonic Mean-Is Good at Handling Large OutliersДокумент2 страницыAnswer: 60% Answer: Geography 55%: Harmonic Mean-Is Good at Handling Large Outliersroshia maeОценок пока нет

- Dev - Mag - 09Документ26 страницDev - Mag - 09georgpiorczynskiОценок пока нет

- Components of A BarrageДокумент21 страницаComponents of A BarrageEngr.Hamid Ismail CheemaОценок пока нет

- Standard Normal Distribution Table PDFДокумент1 страницаStandard Normal Distribution Table PDFWong Yan LiОценок пока нет

- Sky Telescope 201304Документ90 страницSky Telescope 201304Haydn BassarathОценок пока нет

- Is 15894-2018Документ25 страницIs 15894-2018surender kumarОценок пока нет

- Cot 2018-2019Документ11 страницCot 2018-2019Crush Na Crush KitaОценок пока нет

- EEE415 Digital Image Processing: Frequency Domain FilteringДокумент50 страницEEE415 Digital Image Processing: Frequency Domain FilteringFAISAL NAWABОценок пока нет

- Tensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositeДокумент4 страницыTensile Properties of Ground Coffee Waste Reinforced Polyethylene CompositemhmmdzulvaОценок пока нет

- Frege: Sense and Reference One Hundred Years LaterДокумент215 страницFrege: Sense and Reference One Hundred Years LaterfabioingenuoОценок пока нет

- Business Calculus NotesДокумент38 страницBusiness Calculus NotesTom KowalskiОценок пока нет

- (Artigo) - Non-Oriented Electrical Steel Sheets - D. S. PETROVI PDFДокумент9 страниц(Artigo) - Non-Oriented Electrical Steel Sheets - D. S. PETROVI PDFcandongueiroОценок пока нет

- EE - Revision Through Question - GATE - 2020 PDFДокумент138 страницEE - Revision Through Question - GATE - 2020 PDFRamesh KumarОценок пока нет

- Daily production planning and capacity analysisДокумент27 страницDaily production planning and capacity analysisahetОценок пока нет

- CREATE A CORRECTLY SCALED NETWORK FROM SCRATCHДокумент5 страницCREATE A CORRECTLY SCALED NETWORK FROM SCRATCHMauricio Senior RamírezОценок пока нет