Академический Документы

Профессиональный Документы

Культура Документы

Piping Color Coding

Загружено:

puniveinИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Piping Color Coding

Загружено:

puniveinАвторское право:

Доступные форматы

COATINGS MANUAL

HAMPTON ROADS SANITATION DISTRICT

6.0 EQUIPMENT AND PIPING COLOR IDENTIFICATION CODE

The objective of this Equipment and Piping Color Identification Code is to provide easy and

rapid identification of the various unit process equipment and piping in a treatment plant. The

large amount of equipment and piping in the treatment plant requires that a simple system be

used to identify and distinguish the equipment and piping.

A. The Color Shade Code should be used to provide a uniform shade of color when using

various manufacturers and types of coatings (see Color Shade Code). The color should

be based on the U.S. Government Federal Register 595 Paint Color Number.

B. The Color Selection Code should be used to select the color for all equipment and piping

in the treatment plant. The selected color for individual equipment and piping would be

based on the type of flow involved.

C. The Equipment and Piping Color Identification Code should be used to identify all

equipment in the treatment plant (see Equipment & Piping Color Identification Code).

The identification for all equipment should include both the proper coating color and the

proper stenciled markings.

1.) Stenciled marking should be placed on multiple units of equipment to indicate the

unit number, i.e., No. 1, No. 2, etc.

2.) Stenciled markings should be black or white in color to contrast with the

equipment background color as appropriate.

3.) Stenciled markings should be 2 ½ inches in size.

D. The Equipment and Piping Color Identification Code should be used to identify all piping

in the treatment plant. The identification for all piping should include both the proper

coating color and the proper stenciled markings.

1.) Stenciled markings should include both the proper unit process flow abbreviations

and a directional arrow indicating the proper flow direction as appropriate.

2.) Stenciled markings should be placed wherever pipes pass thru walls, at the influent

and effluent of pumps or valves, at intersections, and at regular intervals along pipe

runs as appropriate.

3.) Stenciled markings should be black or white in color to contrast with the pipe

background color as appropriate.

TD/Coatings Manual 2006

6-1

COATINGS MANUAL

HAMPTON ROADS SANITATION DISTRICT

4.) Stenciled markings for pipes should be all capital letters sized as follows:

Pipe Size Letter Size

Up to 1 ½ inch ½ inch

2 to 6 inches 1 ¼ inch

8 inches and up 2 ½ inch

E. Color Shade Code

U.S. Government Federal Register 595

Color Shade

Paint Color Number

Aluminum 17178

Black 17038

Blue 15050

Brown 10091

Gray 16473

Green, Dark 14062

Green, Light 14533

Orange 12246

Red 11105

White 17875

Yellow 13655

TD/Coatings Manual 2006

6-2

COATINGS MANUAL

HAMPTON ROADS SANITATION DISTRICT

F. EQUIPMENT AND PIPING COLOR IDENTIFICATION CODE

Equipment and Piping Color Identification Code

Unit Process Flow Color Abbreviation

Non Potable Water Lt. Green NPW

Non Potable Well Water Lt. Green NPWW

Potable Water Dk. Green PW

Drain Gray DRAIN

Drainage Pump Station Gray DPSD

Discharge

Electrical Conduit Red

Fire Protection Red FIRE

Floor Drain Gray FD

Fuel Oil Black FO

Fuel Oil Supply Black FOS

Fuel Oil Return Black FOR

Hot Water Supply Lt. Green HWS

Hot Water Return Lt. Green HWR

Hot Water Reverse Return Lt. Green HW REV RET

HVAC Gray HVAC

Hydraulic Oil Black HDO

Hot Potable Water Dk. Green HPW

Lube Oil Black LO

Natural Gas Yellow NAT GAS

Polymer Dry Air Blue DA

Process Drain Gray DRAIN

Propane Yellow LP

Roof Drain Gray RD

Seal Water Lt. Green SW

Service Air ( Low Blue LPSA

Pressure)

Service Air (High Blue HPSA

Pressure)

Sanitary Drain Gray DRAIN

Sanitary Sewer Force Gray SSFM

Main

Spray Water Lt. Green SPRAY

Steam Aluminum STEAM

Storm Drain Gray STORM

Sump Pump Discharge Gray SPD

Tank Drain Gray DRAIN

Vacuum Blue VAC

Vent Gray V

Odor Control Odorous Air Gray OA

Scrubber Blowdown Orange SBD

Scrubber Chemical Feed Orange SCF

TD/Coatings Manual 2006

6-3

COATINGS MANUAL

HAMPTON ROADS SANITATION DISTRICT

Equipment and Piping Color Identification Code

Unit Process Flow Color Abbreviation

Scrubber Recirculation Orange SRC

Cleaning

Scrubber Recirculation Orange SRD

Discharge

Scrubber Recirculation Orange SRS

Suction

Scrubber Drain Gray DRAIN

Scrubber Exhaust Gray SCRUB EXH

Scrubber Intake Gray SCRUB INTK

Scrubber (vessel) Gray ---

Cyclone Influent Gray CYCL INF

Cyclone Recycle Gray CYCL RCY

Preliminary Grit Gray GRIT

Treatment Raw Wastewater Influent Gray RWI

Screened Effluent Gray SE

Septic Tank Unloading Gray SEPTIC UNLDG

Primary Clarifier Influent Gray PCI

Primary Primary Clarifier Effluent Gray PCE

Treatment Primary Clarifier Solids Brown PCS

Primary Scum Gray SCUM

Oxidation Tower Influent Gray OTI

Oxidation Tower Effluent Gray OTE

Intermediate Clarifier Gray ICI

Intermediate Influent

Treatment Intermediate Clarifier Gray ICE

Effluent

Intermediate Biosolids Brown INS

Intermediate Scum Gray SCUM

Aerated Supernatant ASR

Return

Anaerobic Influent Gray ANI

Anaerobic Effluent Gray ANE

Anoxic Influent Gray AXI

Anoxic Effluent Gray AXE

Anoxic Recycle Gray ARCY

Aeration Influent Gray ARI

Biological Aeration Effluent Gray ARE

Treatment Mixed Liquor Brown MLSS

Nitrified Recycle Gray NRCY

Secondary Clarifier Gray SCI

Influent

Secondary Clarifier Gray SCE

Effluent

Secondary Scum Gray SCUM

Return Activated Solids Brown RAS

Waste Activated Solids Brown WAS

TD/Coatings Manual 2006

6-4

COATINGS MANUAL

HAMPTON ROADS SANITATION DISTRICT

Equipment and Piping Color Identification Code

Unit Process Flow Color Abbreviation

Contact Tank Effluent Gray CTE

Disinfection

Contact Tank Scum Gray SCUM

Final Effluent Gray FNE

Effluent Pumping

Holding Pond Drain Gray DRAIN

Feed Scum Gray FD SCUM

Concentrated Scum Gray CN SCUM

Scum Disposal Scum Concentrator Gray SCB

Subnatant

Scum Gray SCUM

Decant Supernatant Return Gray DSR

Decant Tank Drain Gray DRAIN

Flotation Thickener Feed Brown FTFS

Solids

Flotation Thickener Gray FTRCY

Recycle

Flotation Thickened Solids Brown FTS

Flotation Thickener Gray FSB

Subnatant

Solids Gravity Belt Thickener Brown GBFS

Thickening Feed Solids

Gravity Belt Thickener Gray GBFL

Filtrate

Gravity Belt Thickened Brown GBTS

Solids

Gravity Thickener Feed Brown GTFS

Solids

Gravity Thickened Solids Brown GTS

Gravity Thickener Gray GSP

Overflow/Supernatant

Primary Digester Feed Brown PDFS

Solids

Primary Digested Solids Brown PDS

Digester Recirculation Brown DRS

Solids

Primary Digester Gray PDSP

Digestion Supernatant

Primary Digester Transfer Brown PDXS

Solids

Secondary Digested Solids Brown SDS

Secondary Digester Gray SDSP

Supernatant

Digester Gas Yellow DGAS

Solids Holding Holding Tank Feed Solids Brown HTFS

Tank

Solids Conditioning Tank Feed Brown CNFS

Conditioning Solids

TD/Coatings Manual 2006

6-5

COATINGS MANUAL

HAMPTON ROADS SANITATION DISTRICT

Equipment and Piping Color Identification Code

Unit Process Flow Color Abbreviation

Centrifuge Feed Solids Brown CFS

Centrifuge Biosolids Cake Brown CCK

Centrifuge Centrate Gray CCT

Centrifuge Thickened Brown CTS

Solids Biosolids

Dewatering Centrifuge Thickening Gray CTCT

Centrate

Foreign Biosolids Loading Brown FLS

Foreign Biosolids Brown FUS

Unloading

Incinerator Feed Cake Brown IFC

Incinerator Ash Brown ASH

Solids Incinerator Scrubber Gray ISE

Incineration Water Effluent

Scrubber Intake Gray SI

Scrubber Exhaust Gray SE

Nitrification Enhancement Gray NEFINF

Facility Influent

Nitrification Enhancement Brown NEFARE

Nitrification Facility Aeration Effluent

Enhancement Nitrification Enhancement Brown NEFSCE

Facility Facility Secondary

Effluent

Nitrification Enhancement Brown NEFS

Facility Solids

Acid Wash Supply Orange AWS

Acid Wash Return Orange AWR

Alum Orange ALUM

Ammonia Orange AMMONIA

Caustic Orange CAUSTIC

Caustic Solution Orange CAUSTIC SOL

Dry Polymer Orange DPOLY

Ferric/Ferrous Orange FERRIC/FERROUS

Chemicals Hydrogen Peroxide Orange PEROXIDE

Liquid Polymer Orange LPOLY

Muriatic Orange MURIATIC

Polymer Solution Orange POLY SOL

Sodium Bisulfite Purple BISULFITE

Sodium Bisulfite Solution Orange BISULFITE SOL

Sodium Hypochlorite Orange HYPO

Sodium Hypochlorite Orange HYPO SOL

Solution

Chemical Storage Chemical Tanks Gray OR (Name of Chemical)

Tanks White

Bollards Yellow ---

TD/Coatings Manual 2006

6-6

COATINGS MANUAL

HAMPTON ROADS SANITATION DISTRICT

Equipment and Piping Color Identification Code

Unit Process Flow Color Abbreviation

Water Reclaimed Water Main Purple RWM

Reclamation

Misc Abandoned ABAND

Sample Unit (Unit Process

Process Name)/SAMP

Color

TD/Coatings Manual 2006

6-7

Вам также может понравиться

- Ball MillДокумент7 страницBall MillAndres Acosta RozoОценок пока нет

- Letseng Diamonds Plant 2 DocumentationДокумент14 страницLetseng Diamonds Plant 2 DocumentationKgotsofalang Kayson NqhwakiОценок пока нет

- Data Book Vendor RequirementsДокумент4 страницыData Book Vendor RequirementsTim HardingОценок пока нет

- Prob (Comminution) PDFДокумент3 страницыProb (Comminution) PDFanasabdullahОценок пока нет

- WWTFSludge Thickener No 2 RehaДокумент28 страницWWTFSludge Thickener No 2 RehamhreteabОценок пока нет

- SelectionДокумент87 страницSelectionRAVI ANANTHAKRISHNANОценок пока нет

- Spek Plate and Frame Filter PressДокумент2 страницыSpek Plate and Frame Filter PressRatri Puspita WardaniОценок пока нет

- HydroFloat CPF - Cu ApplicationДокумент34 страницыHydroFloat CPF - Cu ApplicationNicolas PerezОценок пока нет

- #21. Pearce, Gagnon, Klein, MacIver, Makni, Fisher, - Kumar - Investigation of A Novel HPGR and Size Classification Circuit PDFДокумент11 страниц#21. Pearce, Gagnon, Klein, MacIver, Makni, Fisher, - Kumar - Investigation of A Novel HPGR and Size Classification Circuit PDFManolo Sallo ValenzuelaОценок пока нет

- 35 Alex Doll - Formato PRM16Документ24 страницы35 Alex Doll - Formato PRM16rodrigoalcaino100% (1)

- BallSim OpenДокумент44 страницыBallSim OpenGonzalo LopezОценок пока нет

- Technical Bulletin 1Документ8 страницTechnical Bulletin 1RANAIVOARIMANANAОценок пока нет

- Date: Project No: Purpose: Procedure: FeedДокумент5 страницDate: Project No: Purpose: Procedure: FeedRogger Renato Salinas LopezОценок пока нет

- 3 - 2C Ah-5vcmДокумент1 страница3 - 2C Ah-5vcmMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- Red MudДокумент24 страницыRed MudAfan Taufiq Faturohman100% (1)

- Gears Their Designs & Uses: Andrei Lozzi 2012Документ23 страницыGears Their Designs & Uses: Andrei Lozzi 2012atulsemiloОценок пока нет

- Screw Screw Screw Screw Pump Pump Pump PumpДокумент2 страницыScrew Screw Screw Screw Pump Pump Pump PumpvictorvikramОценок пока нет

- Cyanide Control in The Metallurgical Process of Gold Extraction in AngloGold (S.a.)Документ8 страницCyanide Control in The Metallurgical Process of Gold Extraction in AngloGold (S.a.)Luis La TorreОценок пока нет

- Grinding Mill Drawings PDFДокумент1 страницаGrinding Mill Drawings PDFBender Doblador RodriguezОценок пока нет

- CIP / CIL Interstage Screening: Your Specialist in Screening MediaДокумент4 страницыCIP / CIL Interstage Screening: Your Specialist in Screening MediaevalenciaОценок пока нет

- Ballsim DirectДокумент21 страницаBallsim DirectAnonymous TsKN7XZBОценок пока нет

- Fundamental Properties of Flotation Frothers and Their Effect On FlotationДокумент8 страницFundamental Properties of Flotation Frothers and Their Effect On FlotationJose Luis Barrientos RiosОценок пока нет

- VFD Calculators For Fan & Pump ApplicationsДокумент16 страницVFD Calculators For Fan & Pump ApplicationsAFRI-N-HARIОценок пока нет

- SAME: Jan 2010Документ40 страницSAME: Jan 2010promechmagsОценок пока нет

- Vibrating Mill PDFДокумент6 страницVibrating Mill PDFPhanHathamОценок пока нет

- PROCESS DESIGN CALCULATION Mas GitoДокумент32 страницыPROCESS DESIGN CALCULATION Mas GitosehonoОценок пока нет

- Data Sheet For Rotary Calciner - TEPLДокумент2 страницыData Sheet For Rotary Calciner - TEPLpuneet gehlotОценок пока нет

- PallaДокумент16 страницPallaJuan Alberto Giglio FernándezОценок пока нет

- 1 X 600 MW JPL Seoni Project Madhya Pradesh: Stockpile Capacity CalculationДокумент8 страниц1 X 600 MW JPL Seoni Project Madhya Pradesh: Stockpile Capacity Calculationdnyanesh_accОценок пока нет

- Guideline: Conveyor Manufacturers Association of Sa LimitedДокумент37 страницGuideline: Conveyor Manufacturers Association of Sa LimitedYudhistira PratamaОценок пока нет

- Cyclosim SingleДокумент9 страницCyclosim SinglehadryanaОценок пока нет

- Goulds Model XHD - Heavy Duty Slurry PumpДокумент11 страницGoulds Model XHD - Heavy Duty Slurry Pumpalvarito12Оценок пока нет

- Peripheral Launder HydraulicsДокумент2 страницыPeripheral Launder HydraulicsahmadОценок пока нет

- Material Flow SheetДокумент1 страницаMaterial Flow Sheetharsha0% (1)

- Beneficiation of Cassiterite From Primary Tin OresДокумент11 страницBeneficiation of Cassiterite From Primary Tin OresSULMAGОценок пока нет

- Ball MillsДокумент2 страницыBall MillsJuan GonzalezОценок пока нет

- Multistage Flowsheets Sabc1Документ189 страницMultistage Flowsheets Sabc1joseluisОценок пока нет

- 3 - 2C Ah-6vcmДокумент1 страница3 - 2C Ah-6vcmMamiherintsoa Issaia RanaivoarimananaОценок пока нет

- Flotation Enters Its Second Centenary With Higher Intensity and Bigger CapacityДокумент13 страницFlotation Enters Its Second Centenary With Higher Intensity and Bigger CapacityOvidio Jaime CruzОценок пока нет

- CH 12 Rod & Ball MillsДокумент40 страницCH 12 Rod & Ball Millsismael1806Оценок пока нет

- MIPAC MPA App Note SAG MillsДокумент2 страницыMIPAC MPA App Note SAG MillsTanaji_maliОценок пока нет

- Calculation Cover Sheet Date: Author: Project: Calc No: TitleДокумент6 страницCalculation Cover Sheet Date: Author: Project: Calc No: TitleRajeshkumar ElangoОценок пока нет

- A New Empirical Model For The Hydrocyclone Corrected EfficiencyДокумент6 страницA New Empirical Model For The Hydrocyclone Corrected EfficiencyTsakalakis G. Konstantinos100% (4)

- PasteThickener TechnologyДокумент5 страницPasteThickener TechnologyRodri GermánОценок пока нет

- Ball and Pebble Milling Theory and PracticeДокумент11 страницBall and Pebble Milling Theory and PracticeCésar Cedillo RodríguezОценок пока нет

- PumpsДокумент9 страницPumpsMohamed TallyОценок пока нет

- A8 0 MineralsProcessing GBДокумент6 страницA8 0 MineralsProcessing GBAnonymous T8aah3JfОценок пока нет

- PowderДокумент10 страницPowder1977julОценок пока нет

- Dm-dcld-f-cm-0017 Rev 4 Ems Test ChargesДокумент112 страницDm-dcld-f-cm-0017 Rev 4 Ems Test ChargesPervaiz BaigОценок пока нет

- Expert Systems in Mineral and Metal Processing-Elsevier LTD, Pergamon (1992)Документ201 страницаExpert Systems in Mineral and Metal Processing-Elsevier LTD, Pergamon (1992)Nataniel LinaresОценок пока нет

- Compilation of Mineral Processing Formulas PDFДокумент11 страницCompilation of Mineral Processing Formulas PDFEmerald MasterОценок пока нет

- Chris - Rule - Stirred Milling in The PGM IndustryДокумент59 страницChris - Rule - Stirred Milling in The PGM IndustryJakesОценок пока нет

- Breaking Down Energy Consumption in Industrial Grinding MillsДокумент12 страницBreaking Down Energy Consumption in Industrial Grinding Millsrolandoh1Оценок пока нет

- Research Report of Mineral Processing 2Документ17 страницResearch Report of Mineral Processing 2MarcialОценок пока нет

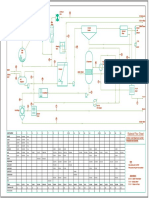

- Raw Water SystemДокумент11 страницRaw Water SystemChandraОценок пока нет

- Models For Mining Equipment SelectionДокумент7 страницModels For Mining Equipment SelectionMuwafaq2002100% (2)

- Piping Color Identification Code: A - For Tape Only or Color Band by Paint in PipelineДокумент1 страницаPiping Color Identification Code: A - For Tape Only or Color Band by Paint in PipelinehabebeОценок пока нет

- Coven in 253Документ6 страницCoven in 253Howard VelasquezОценок пока нет

- 1 Colour Code 1.1 GeneralДокумент4 страницы1 Colour Code 1.1 GeneralNathachai LeewathanakijОценок пока нет

- D G 220553 M I P: GeneralДокумент4 страницыD G 220553 M I P: GeneralmucorОценок пока нет

- The Mystery of Berry Berenson and 9-11Документ5 страницThe Mystery of Berry Berenson and 9-11HierocrypticОценок пока нет

- Name - Date - Class - Density NotesДокумент2 страницыName - Date - Class - Density NotesBranchley LefrancОценок пока нет

- The Principles and Practice of Naviga TionДокумент10 страницThe Principles and Practice of Naviga TionDin Muhammad MujahidОценок пока нет

- Effect of Coffee Processing Plant Effluent On The Physicochemical Properties of Receiving Water Bodies, Jimma Zone EthiopiaДокумент8 страницEffect of Coffee Processing Plant Effluent On The Physicochemical Properties of Receiving Water Bodies, Jimma Zone EthiopiaNigist FekedeОценок пока нет

- Lightspeed Oneforma GuidelinesДокумент59 страницLightspeed Oneforma GuidelinesKim Chi PhanОценок пока нет

- Mm204E Thermodynamics-Ii Second Midterm Exam: Q1 Q2 Q3 Q4 Q5 Total /20 /20 /20 /20 /20 /100Документ2 страницыMm204E Thermodynamics-Ii Second Midterm Exam: Q1 Q2 Q3 Q4 Q5 Total /20 /20 /20 /20 /20 /100Ali DoğruОценок пока нет

- Circuit Breaker TestingДокумент27 страницCircuit Breaker TestingAjay Talajiya50% (2)

- The Correlation Between Migraine Headache And.10Документ6 страницThe Correlation Between Migraine Headache And.10Luther ThengОценок пока нет

- Saudi Aramco Improves Field Management Practices With Intelligent SurveillanceДокумент4 страницыSaudi Aramco Improves Field Management Practices With Intelligent Surveillancereza mahaseniОценок пока нет

- 02 - Financial Accounting - Accounts Receivable ReportsДокумент28 страниц02 - Financial Accounting - Accounts Receivable ReportsjohnОценок пока нет

- Sant Gadge Baba Amravati University: Examination Application Form SUMMER 2021Документ3 страницыSant Gadge Baba Amravati University: Examination Application Form SUMMER 2021Bramhanand pawarОценок пока нет

- Exclusion of Oral by Documentary EvidenceДокумент6 страницExclusion of Oral by Documentary EvidenceShashikantSauravBarnwalОценок пока нет

- Rachel Woodward - Military GeographyДокумент7 страницRachel Woodward - Military GeographyPeter BalogОценок пока нет

- Mcdowell Review of Reverse Anthropology 19Документ1 страницаMcdowell Review of Reverse Anthropology 19PeriantroОценок пока нет

- Cap Analysis: (Municipality of Calinog)Документ21 страницаCap Analysis: (Municipality of Calinog)mpdo calinogОценок пока нет

- Applications: Functions andДокумент350 страницApplications: Functions andJason UchennnaОценок пока нет

- Bio Physics: Prepared by Gayathry SatheesanДокумент19 страницBio Physics: Prepared by Gayathry SatheesanrehandeshmukhОценок пока нет

- Factoring Perfect Square Trinomials: Lesson 4Документ29 страницFactoring Perfect Square Trinomials: Lesson 4Jessa A.Оценок пока нет

- ISC Class 12 Maths Important QuestionsДокумент2 страницыISC Class 12 Maths Important QuestionsdhinchakclashersОценок пока нет

- Alt Bar Fri Hun Pat Price Rain Res Type Est Willwait: Example Attributes GoalДокумент19 страницAlt Bar Fri Hun Pat Price Rain Res Type Est Willwait: Example Attributes GoalSan JongОценок пока нет

- Memory Research Paper ExampleДокумент8 страницMemory Research Paper Examplexhzscbbkf100% (1)

- Degrees of Plagiarism Activity PDFДокумент20 страницDegrees of Plagiarism Activity PDFDhamma_StorehouseОценок пока нет

- 2020 Oulade The Neural Basis of Language DevelopmentДокумент7 страниц2020 Oulade The Neural Basis of Language DevelopmentzonilocaОценок пока нет

- What Is Validity in ResearchДокумент6 страницWhat Is Validity in ResearchRuhi KapoorОценок пока нет

- Influence of Drying and Hydrothermal Treatment of Corn On The Denaturationof Salt-Soluble Proteins and Color ParametersДокумент10 страницInfluence of Drying and Hydrothermal Treatment of Corn On The Denaturationof Salt-Soluble Proteins and Color ParametersShania GintingОценок пока нет

- Breeding Objectives, Selection Criteria and Breeding System of Indigenous Goat Types in Bale Zone, Oromia, EthiopiaДокумент10 страницBreeding Objectives, Selection Criteria and Breeding System of Indigenous Goat Types in Bale Zone, Oromia, EthiopiareinpolyОценок пока нет

- Mzumbe University Mbeya Campus College Department of Administrative StudiesДокумент6 страницMzumbe University Mbeya Campus College Department of Administrative StudiesFrancisco Hagai GeorgeОценок пока нет

- Akash Final PDFДокумент28 страницAkash Final PDFMohnish AkhilОценок пока нет

- Uw Math Stat394 Hw4 SolДокумент4 страницыUw Math Stat394 Hw4 SolRizsОценок пока нет

- Promass 63 ManualДокумент48 страницPromass 63 Manualleopoldo alejandro antio gonzalezОценок пока нет