Академический Документы

Профессиональный Документы

Культура Документы

Astm 694

Загружено:

Darshan Panchal0 оценок0% нашли этот документ полезным (0 голосов)

71 просмотров4 страницыASTM 694 F60

Оригинальное название

ASTM 694

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документASTM 694 F60

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

71 просмотров4 страницыAstm 694

Загружено:

Darshan PanchalASTM 694 F60

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/259356316

ASTM A694 F60 – HEAT TREATMENT AND MECHANICAL PROPERTIES

Article · December 2013

CITATIONS READS

0 12,088

4 authors, including:

Martin BALCAR

ZDAS, a.s.

22 PUBLICATIONS 37 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

www.gramat.org View project

All content following this page was uploaded by Martin BALCAR on 19 December 2013.

The user has requested enhancement of the downloaded file.

number of technological changes and introduction of

ASTM A694 F60 – HEAT TREATMENT new process elements in the field of steel making

and subsequent thermomechanical treatment.

AND MECHANICAL PROPERTIES Verification of quenching temperature

influence on properties and structure of F60 forged

Martin BALCAR, Jaroslav NOVÁK, Libor SOCHOR, steel contributes to optimization of complex HSLA

Pavel FILA, Ludvík MARTÍNEK steel making technology at ZDAS, a.s.

ŽĎAS, a.s., Strojírenská 6, 2. EXPERIMENTAL MATERIAL

591 71 Žďár nad Sázavou, Czech Republic,

Verification of quenching temperature

Tel.:+420 566 64 2136, Fax.: +420 566 64 2831, influence on structure and mechanical properties of

Email: martin.balcar@zdas.cz modified F60 steel according to ASTM A694 made by

EOP/LF/VD technology was carried out on forged

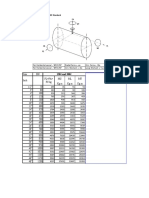

piece samples with dimensions (100x100x150)mm.

Abstract Basic chemical composition of the steel is shown in

Table 1.

Production of heavy steel forgings of

microalloy steels seeks possibilities to take Table 1: Basic chemical composition HSLA steel F60

advantages associated with the benefit of application (wt. %)

of microalloying elements and thermomechanical

treatment at the level of mechanical properties

attained, known from production of sheets, strips and

tubes.

The paper documents the influence of

quenching temperature on values of mechanical

properties and structure of F60 steel according to

ASTM A694. Verification of quenching temperature

influence contributes to optimization and

Modified F60 steel according to ASTM A694

determination of a complex method of microalloy

is typical low carbon steel with addition of alloying

steel heat treatment.

elements, manganese, silicon, nickel and

Steel structure and mechanical properties

molybdenum. Moreover, the steel is microalloyed by

after the quenching constitute initial as well as basic

vanadium, aluminium and niobium. Concentration of

criterion to achieve requested mechanical properties

other elements is at the level like residual elements

at properly chosen tempering temperature.

and the rest is iron [1], [2].

After the forming process, the forgings were

“anti-flake” annealed up to a temperature of 650°C

Keywords: A694 F60, HSLA steel, Quenching and

for a period of 10 hours and subsequently normalized

Tempering, Mechanical Properties

at a temperature of 930°C with air cooling.

1. INTRODUCTION 3. LABORATORY HEAT TREATMENT

As the requirements for structural steel The heat treatment itself was carried out on

properties are growing, the development of use of forged steel samples under laboratory conditions.

microalloying elements even in the field of production Verification of influence of austenitization –

of forgings and castings takes place. quenching temperature (TA) on the structure and

Production of heavy steel forgings of mechanical properties was proposed for the

microalloy steels does not allow to immediately take temperature range (880 to 940)°C with subsequent

advantages associated with the benefit of application water quenching and tempering TT = 620°C with air

of microalloying elements and thermomechanical cooling. Sample marking and heat treatment carried

treatment known from production of sheets, strips out are as follows:

and tubes. In the case of production of steel forgings,

the forming and heat treatment process mainly L1: TA = 880°C/6 hrs/Water + TT = 620°C/8 hrs/Air

features different forming and heat treatment L2: TA = 890°C/6 hrs/Water + TT = 620°C/8 hrs/Air

conditions compared to thin-walled products (sheets, L3: TA = 900°C/6 hrs/Water + TT = 620°C/8 hrs/Air

strips, tubes). L4: TA = 910°C/6 hrs/Water + TT = 620°C/8 hrs/Air

Development and verification of F60 steel L5: TA = 920°C/6 hrs/Water + TT = 620°C/8 hrs/Air

production and treatment technology according to L6: TA = 930°C/6 hrs/Water + TT = 620°C/8 hrs/Air

ASTM A694 under ZDAS, Inc. conditions constitute a L7: TA = 940°C/6 hrs/Water + TT = 620°C/8 hrs/Air

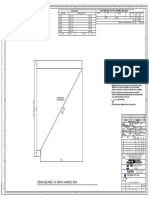

5. MICROSTRUSCTURE OF HSLA STEEL

ASTM A694 F60

Similarly as in the case of mechanical

properties evaluation, steel structure evaluation was

carried out in the given point of the sample.

Steel structure for concrete heat treatment

states (TA = 880, 900, 920, 940°C) is shown below:

Figure 1: Forged sample (100x100x150)mm

4. MECHANICAL PROPERTIES OF HSLA

STEEL ASTM A694 F60

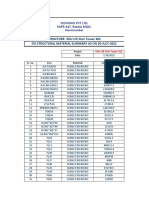

The samples to determine attained

parameters of mechanical properties and to evaluate

the structure were taken from central zones of the

forgings. Evaluation of mechanical properties was

carried out in longitudinal direction. Table 2 shows

the requested level and attained values of

mechanical properties of individual F60 steel

samples.

Table 2: Mechanical properties HSLA steel F60 –

acc. quenching temperature

Austenitization temperature influence on

change in mechanical properties of forged, quenched

and tempered F60 steel is visible from Table 2. It is

obvious that steel strength increase accompanied by

significant toughness drop takes place as the

austenitization temperature is increasing.

After the quenching and tempering, the ACKNOWLEDGMENTS

microstructure of all samples – forgings is practically

The paper has been solved within the EUREKA of

the same. Ferrite, bainite, granular pearlite and

the OE 08009 E!4092 MICROST project. The project

sorbite occur. It is evident from a series of snaps

was implemented based on government resources

magnified 500 times, where the secondary grain can

with financial support of the Ministry of Education,

be compared better, that the secondary grain does

Youth and Sport of the Czech Republic

not change notably as the quenching temperature is

increasing.

Above mentioned fact is confirmed by results

REFERENCES

of evaluation of austenitic grain size by means

[1] Hulka, K.: Characteristic Feature of Titanium,

oxidation method according to ASTM E 112 – 97 with

Vanadium and Niobium as MicroalloyAdditions

using the LECO IA32 image analysis. Results of

to Steel [online]. [cit. 2008-03-30].

austenitic grain size measurement are shown in

Table 3. http://www.cbmm.com.br/portug/sources/techlib

/info/charact/charact.htm

Table 3: Grain size - HSLA steel F60 - ASTM E 112 –

LECO IA32 [2] Charleux, M. : Precipitation behaviour and its

effect on strengthening of an HSLA –

Nb/Tisteel, Metalurgical and materiale

transactions A, Vol. 32A, 2001, p. 1635 -1647

[3] Balcar, M., Novák, J., Sochor, L., Fila, P.,

Martínek, L.: ASTM A694 F60 Heat treatment

and mechanical properties. In: 20. mezinárodní

konference metalurgie a materiálů METAL

2011. 18. – 20. května 2011. Brno, Hotel

Voroněž, TANGER s.r.o. Ostrava. CD-ROM.

ISBN 978-80-87297-22-2

[4] Balcar, M., Havelková, L.: Vliv stopových prvků

na houževnatost oceli. In: Teorie a praxe výroby

a zpracování oceli. Rožnov pod Radhoštěm,

From the results shown in Table 3, it is not TANGER, s.r.o., Ostrava, 2009, p. 10 – 15.

possible to observe direct influence of quenching ISBN 978-80-87294-01-7

temperature on austenitic grain size change. All the

[5] Skobir, D. A., Godec, M., Balcar, M., Jenko, M.:

samples show a very fine structure [3], [4], [5].

The influence of the microalloying elements of

HSLA steel on the microstructure and

6. CONCLUSIONS mechanical properties. Materials and

Technology, 2010, Issue 44, No. 6, p. 343 –

From results of experimental work attained

349. ISSN 1580-2949

follows direct influence of quenching temperature on

mechanical properties of ASTM A694 F60 steel. Was

observed growth in strength values and drop in

impact value as the temperature of quenching was

increasing. The most favorable results of mechanical

properties were attained with quenching

temperatures 880°C, 890°C and 900°C.

Steel microstructure after the quenching and

tempering is comparable for all the samples. Ferrite,

bainite, granular pearlite and sorbite occur.

Evaluation of austenitic grain size by oxidation

method according to ASTM E 112-97 confirmed the

grain size uniformity, when comparing all

experimental samples, without provable influence of

quenching temperature.

Further optimization of steel mechanization

properties and structure can be awaited after the

verification of influence of the tempering temperature.

Subsequently, it will be possible to determine a

complex optimized heat treatment process for HSLA

steel ASTM A694 F60.

View publication stats

Вам также может понравиться

- Gics-In-India Getting Ready For The Digital WaveДокумент81 страницаGics-In-India Getting Ready For The Digital Wavevasu.gaurav75% (4)

- Model DPR & Application Form For Integrated RAS PDFДокумент17 страницModel DPR & Application Form For Integrated RAS PDFAnbu BalaОценок пока нет

- ASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Документ3 страницыASTM A694 F60 - Heat Treatment and Mechanical Properties - ICRF 2012Noushad Bin JamalОценок пока нет

- Semi-Hot Stamping As An Improved Process of Hot StampingДокумент8 страницSemi-Hot Stamping As An Improved Process of Hot StampingAndress SsalomonnОценок пока нет

- Effects of Austenitizing and Forging On Mechanical Properties of MIL A-12560/AISI 4340 SteelДокумент6 страницEffects of Austenitizing and Forging On Mechanical Properties of MIL A-12560/AISI 4340 SteelsatrioherbirowoОценок пока нет

- Materials Science & Engineering A: Ludmila Ku Cerov A, Karolina Burdov A, ST Ep An Jení Cek, Iveta ChenaДокумент15 страницMaterials Science & Engineering A: Ludmila Ku Cerov A, Karolina Burdov A, ST Ep An Jení Cek, Iveta ChenaJimmy the ReverendОценок пока нет

- Obiukwu Osita, Udeani Henry, Ubani ProgressДокумент12 страницObiukwu Osita, Udeani Henry, Ubani ProgressPrashant KumarОценок пока нет

- Panduan BeasiswaДокумент7 страницPanduan BeasiswaAmalia Tri WОценок пока нет

- Experiment Short and BadДокумент15 страницExperiment Short and BadMossstazzzaОценок пока нет

- Mechanical Characterization of Dual Phase and Austempered Aisi 1040 Normalized SteelДокумент12 страницMechanical Characterization of Dual Phase and Austempered Aisi 1040 Normalized SteelTJPRC PublicationsОценок пока нет

- Ijirt155149 PaperДокумент8 страницIjirt155149 PaperMohamed HassanОценок пока нет

- Development of Bake-Hardenable Al-Killed Steel Sheet by Box Annealing ProcessДокумент10 страницDevelopment of Bake-Hardenable Al-Killed Steel Sheet by Box Annealing ProcessRamírez WillebaldoОценок пока нет

- Behaviour of Structural Carbon Steel at High Temperatures PDFДокумент10 страницBehaviour of Structural Carbon Steel at High Temperatures PDFAlex GigenaОценок пока нет

- Effectof Carburization Timeand Temperatureonthe Mechanical Propertiesof MildДокумент6 страницEffectof Carburization Timeand Temperatureonthe Mechanical Propertiesof MildGond AbhishekОценок пока нет

- Development of High Strength Hot Rolled Coils With Enhanced Formability PropertyДокумент5 страницDevelopment of High Strength Hot Rolled Coils With Enhanced Formability PropertyparmindersinОценок пока нет

- XIII. Effects - of - Carburization - Time - and - Temperature - On - TДокумент7 страницXIII. Effects - of - Carburization - Time - and - Temperature - On - THà ThắngОценок пока нет

- Enhancement of Mechanical Properties On Aluminum Alloys - A ReviewДокумент3 страницыEnhancement of Mechanical Properties On Aluminum Alloys - A ReviewhsemargОценок пока нет

- 1931 6834 1 SMДокумент12 страниц1931 6834 1 SMchpinto10% (1)

- Materials Science & Engineering A: G.M.A.M.El Fallah, H.K.D.H. Bhadeshia TДокумент9 страницMaterials Science & Engineering A: G.M.A.M.El Fallah, H.K.D.H. Bhadeshia Tsayyed bassir ajellehОценок пока нет

- Microstructure and Properties of Quenched-and-Aged Plates Produced From A Copper-Bearing HSLA SteelДокумент7 страницMicrostructure and Properties of Quenched-and-Aged Plates Produced From A Copper-Bearing HSLA Steelardeshir yarakzadehОценок пока нет

- Mechanical Properties Enhancement of Conventional Mild Steel For Fastener ApplicationДокумент8 страницMechanical Properties Enhancement of Conventional Mild Steel For Fastener ApplicationTeddy MokhoОценок пока нет

- C0608052634 PDFДокумент9 страницC0608052634 PDFKavin PrakashОценок пока нет

- 03.investigation of Thermo Mechanical Effect On Structure and Properties of Aluminium Alloy 6082Документ4 страницы03.investigation of Thermo Mechanical Effect On Structure and Properties of Aluminium Alloy 6082ganeshji loОценок пока нет

- Heat Treatment of Nodular Cast IronДокумент4 страницыHeat Treatment of Nodular Cast IronRoman_RomeoОценок пока нет

- Development of High-Strength Steel Wire With Superior WeldabilityДокумент5 страницDevelopment of High-Strength Steel Wire With Superior WeldabilitySmruti Ranjan PattanayakОценок пока нет

- The Effect of Heat Treatment On Mechanical Properties and Corrosion Behavior of AISI420 Martensitic Stainless SteelДокумент6 страницThe Effect of Heat Treatment On Mechanical Properties and Corrosion Behavior of AISI420 Martensitic Stainless Steelanon_506964735Оценок пока нет

- Estudio Termodinamico AceroДокумент8 страницEstudio Termodinamico AceroJuan rodriguezОценок пока нет

- Metals-11-00474-V2 OKДокумент22 страницыMetals-11-00474-V2 OKRebeca Francis Moran CamposОценок пока нет

- Microstructural Effects On Fatigue Crack Growth Behavior of A Microalloyed SteelДокумент11 страницMicrostructural Effects On Fatigue Crack Growth Behavior of A Microalloyed SteelcqgaОценок пока нет

- Effects of HT On Continuous Cast Direct Rrolling 6065, Cold Rolling Char, Tensile Fracture PropertiesДокумент13 страницEffects of HT On Continuous Cast Direct Rrolling 6065, Cold Rolling Char, Tensile Fracture PropertiestarunОценок пока нет

- Corrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips BurnersДокумент13 страницCorrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips Burnersravikanth_rОценок пока нет

- AL Si CuДокумент7 страницAL Si CuRiedl LaurentiuОценок пока нет

- Volchok 22Документ4 страницыVolchok 22amitkkambleОценок пока нет

- Hardox Welding PDFДокумент13 страницHardox Welding PDFPankaj KumbhareОценок пока нет

- Plasma Nitriding of AISI 52100 Ball Bearing Steel and Effect of Heat Treatment On Nitrided LayerДокумент7 страницPlasma Nitriding of AISI 52100 Ball Bearing Steel and Effect of Heat Treatment On Nitrided LayerSubodh RanjanОценок пока нет

- Study of The Mechanical Properties of Low Carbon Content HSLA SteelsДокумент8 страницStudy of The Mechanical Properties of Low Carbon Content HSLA SteelsPatricio G. ArrienОценок пока нет

- Erdem 2005Документ7 страницErdem 2005vinayakОценок пока нет

- Barényi Et Al. - 2019 - Material and Technological Aspects While ProcessinДокумент6 страницBarényi Et Al. - 2019 - Material and Technological Aspects While ProcessinHICHAM SBAITIОценок пока нет

- Determination of The Stability of Retained Austenite in TRIP-aided Bainitic SteelДокумент4 страницыDetermination of The Stability of Retained Austenite in TRIP-aided Bainitic SteelYue FeiОценок пока нет

- Effect of Heat Treatment On The Fracture Toughness of AISI 4140 SteelДокумент6 страницEffect of Heat Treatment On The Fracture Toughness of AISI 4140 Steelou82muchОценок пока нет

- Physical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)Документ4 страницыPhysical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)rodrigosiqueiraОценок пока нет

- Effects of Carburizing Process Variables On MechanДокумент7 страницEffects of Carburizing Process Variables On Mechanashav patelОценок пока нет

- The Influence of Heat Treatment On The Microstructure and PDFДокумент43 страницыThe Influence of Heat Treatment On The Microstructure and PDFtblosОценок пока нет

- Heat Treatment Study On Carbon SteelДокумент6 страницHeat Treatment Study On Carbon SteelramaОценок пока нет

- Efecto de Los Parámetros de Tratamiento Térmico en Las Características de La Fundición de Hierro Dúctil Austemperizado de Pared Delgada."Документ7 страницEfecto de Los Parámetros de Tratamiento Térmico en Las Características de La Fundición de Hierro Dúctil Austemperizado de Pared Delgada."Orlando RangelОценок пока нет

- Pack Carburizing Mild SteelДокумент13 страницPack Carburizing Mild SteelyanuarОценок пока нет

- Characteristics of St.37 Steel Materials With Temperature and Time On Heat Treatment Test Using FurnaceДокумент5 страницCharacteristics of St.37 Steel Materials With Temperature and Time On Heat Treatment Test Using FurnaceAbolfazl HabibiОценок пока нет

- Barényi Et Al. - Changes in Mechanical Properties of Armoured UHSLAДокумент8 страницBarényi Et Al. - Changes in Mechanical Properties of Armoured UHSLAHICHAM SBAITIОценок пока нет

- AISI 1022-Coil SpherodisationДокумент10 страницAISI 1022-Coil SpherodisationP I GuddimathОценок пока нет

- Effect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelДокумент7 страницEffect of Heat Treatment On Microstructures and Mechanical Prop of Spring SteelMahmood KhanОценок пока нет

- 1 s2.0 S2214785318307089 MainДокумент5 страниц1 s2.0 S2214785318307089 MainMehtap KuzuОценок пока нет

- Sae 1025Документ6 страницSae 1025Mada PerwiraОценок пока нет

- Effect of Heat Treatment On Mechanical PropertiesДокумент11 страницEffect of Heat Treatment On Mechanical Properties4035VAID P KULKARNI SEMECHAОценок пока нет

- Improvement of Mechanical Properties of Alloy Steel Type (40x) by Using Heat TreatmentsДокумент11 страницImprovement of Mechanical Properties of Alloy Steel Type (40x) by Using Heat Treatmentsyared sitotawОценок пока нет

- Mechanical Characterization of Deformed and Heat Treated Copper-Eutectoid Steel Powder Reinforced CompositesДокумент14 страницMechanical Characterization of Deformed and Heat Treated Copper-Eutectoid Steel Powder Reinforced CompositesTJPRC PublicationsОценок пока нет

- Mechanical Properties of A Recrystallized Low Carbon Steel: R. Mendoza, A. Molina, F. Serrania, J.A. Juarez-IslasДокумент5 страницMechanical Properties of A Recrystallized Low Carbon Steel: R. Mendoza, A. Molina, F. Serrania, J.A. Juarez-IslasRina OktapianiОценок пока нет

- 4340qt-Ht-Iq1-Diff Heatr TestДокумент9 страниц4340qt-Ht-Iq1-Diff Heatr Testjohn smithОценок пока нет

- 1 s2.0 S0921509314015780 MainДокумент7 страниц1 s2.0 S0921509314015780 MainAli UzunОценок пока нет

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014От EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014Оценок пока нет

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОт EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОценок пока нет

- Sr. No. Type Material of Construction Item Description: Pressure KG/CM G Temperature °C MOCДокумент3 страницыSr. No. Type Material of Construction Item Description: Pressure KG/CM G Temperature °C MOCDarshan PanchalОценок пока нет

- IBIC Nozzle Local LoadДокумент1 страницаIBIC Nozzle Local LoadDarshan PanchalОценок пока нет

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcДокумент270 страницVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalОценок пока нет

- Design Notes and AssumptionsДокумент19 страницDesign Notes and AssumptionsDarshan PanchalОценок пока нет

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcДокумент130 страницVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalОценок пока нет

- Pressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionДокумент3 страницыPressure KG/CM G Temperature °C MOC: Sr. No. Type Material of Construction Item DescriptionDarshan PanchalОценок пока нет

- Transportation - Bearing LoadДокумент3 страницыTransportation - Bearing LoadDarshan PanchalОценок пока нет

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcДокумент4 страницыVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalОценок пока нет

- Vdu Lift Stair Tower 302 - Complete Bolt List-IfcДокумент4 страницыVdu Lift Stair Tower 302 - Complete Bolt List-IfcDarshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalОценок пока нет

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcДокумент130 страницVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Darshan PanchalОценок пока нет

- Vdu Lift Stair Tower 302 - Site Bolt List-IfcДокумент270 страницVdu Lift Stair Tower 302 - Site Bolt List-IfcDarshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR37-0829 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR36-0828 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR38-0830 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalОценок пока нет

- VDU Lift Stair Tower 302 - Material Summary - ListДокумент4 страницыVDU Lift Stair Tower 302 - Material Summary - ListDarshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR5-0797 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-SR25-0817 - Rev 0Darshan PanchalОценок пока нет

- B224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Документ1 страницаB224-CDU-TPL-101-CV-FD-LZ302-FR2-0601 - Rev 0Darshan PanchalОценок пока нет

- Forum Disussion For Hertz AllowableДокумент5 страницForum Disussion For Hertz AllowableDarshan PanchalОценок пока нет

- Eaai S 23 02045 PDFДокумент28 страницEaai S 23 02045 PDFAnjali JainОценок пока нет

- GSE v. Dow - AppendixДокумент192 страницыGSE v. Dow - AppendixEquality Case FilesОценок пока нет

- Adding and Subtracting FractionsДокумент4 страницыAdding and Subtracting Fractionsapi-508898016Оценок пока нет

- 2008 Kershaw CatalogДокумент38 страниц2008 Kershaw CatalogDANILA MARECHEKОценок пока нет

- Genie PDFДокумент277 страницGenie PDFOscar ItzolОценок пока нет

- Combining Wavelet and Kalman Filters For Financial Time Series PredictionДокумент17 страницCombining Wavelet and Kalman Filters For Financial Time Series PredictionLuis OliveiraОценок пока нет

- Schermer 1984Документ25 страницSchermer 1984Pedro VeraОценок пока нет

- 8D & 7QC ToolsДокумент117 страниц8D & 7QC ToolsAshok Kumar100% (1)

- Characteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesДокумент14 страницCharacteristics of Trochoids and Their Application To Determining Gear Teeth Fillet ShapesJohn FelemegkasОценок пока нет

- Translations Telugu To English A ClassifДокумент111 страницTranslations Telugu To English A ClassifGummadi Vijaya KumarОценок пока нет

- Programming MillДокумент81 страницаProgramming MillEddy ZalieОценок пока нет

- General Characteristics of Phonemes: Aspects of Speech SoundsДокумент8 страницGeneral Characteristics of Phonemes: Aspects of Speech SoundsElina EkimovaОценок пока нет

- PUPiApplyVoucher2017 0006 3024Документ2 страницыPUPiApplyVoucher2017 0006 3024MätthëwPïńëdäОценок пока нет

- 5 - Perception and Individual Decision Making in Organizational BehaviorДокумент25 страниц5 - Perception and Individual Decision Making in Organizational BehaviorJanaVrsalovićОценок пока нет

- Transformational LeadershipДокумент75 страницTransformational LeadershipvincentpalaniОценок пока нет

- International Business ManagementДокумент3 страницыInternational Business Managementkalaiselvi_velusamyОценок пока нет

- IELTS Material Writing 1Документ112 страницIELTS Material Writing 1Lê hoàng anhОценок пока нет

- Technology 6 B Matrixed Approach ToДокумент12 страницTechnology 6 B Matrixed Approach ToNevin SunnyОценок пока нет

- USTH Algorithm RecursionДокумент73 страницыUSTH Algorithm Recursionnhng2421Оценок пока нет

- HYDRAULIC WINCH-MS1059 - Operation & Maintenance Manual Rev AДокумент33 страницыHYDRAULIC WINCH-MS1059 - Operation & Maintenance Manual Rev Azulu80Оценок пока нет

- Ziarek - The Force of ArtДокумент233 страницыZiarek - The Force of ArtVero MenaОценок пока нет

- Preblending of Raw Materia1Документ26 страницPreblending of Raw Materia1Mohammed Abdo100% (1)

- Model No. TH-65JX850M/MF Chassis. 9K56T: LED TelevisionДокумент53 страницыModel No. TH-65JX850M/MF Chassis. 9K56T: LED TelevisionRavi ChandranОценок пока нет

- The Chulalongkorn Centenary ParkДокумент6 страницThe Chulalongkorn Centenary ParkJack FooОценок пока нет

- Chapter 3 Depreciation - Sum of The Years Digit MethodPart 4Документ8 страницChapter 3 Depreciation - Sum of The Years Digit MethodPart 4Tor GineОценок пока нет

- Volvo Catalog Part2Документ360 страницVolvo Catalog Part2Denis Konovalov71% (7)

- Assignment 1 Brief: ScenarioДокумент4 страницыAssignment 1 Brief: ScenarioChâu TrầnОценок пока нет

- Invoice ApprovalДокумент54 страницыInvoice ApprovalHamada Asmr AladhamОценок пока нет