Академический Документы

Профессиональный Документы

Культура Документы

2 SafetyRiskAnalysis-GasPlantItaly

Загружено:

SDP02Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2 SafetyRiskAnalysis-GasPlantItaly

Загружено:

SDP02Авторское право:

Доступные форматы

See

discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/317971294

Safety Risk Analysis of a Natural Gas Compression Plant in Italy

Poster · June 2016

DOI: 10.13140/RG.2.2.31167.92322

CITATIONS READS

0 21

4 authors, including:

Okoroma J. U. Olushola Tomilayo Olapade

Politecnico di Torino AGH University of Science and Technology in Kraków

7 PUBLICATIONS 4 CITATIONS 8 PUBLICATIONS 0 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Petroleum Engineering (Drilling ) View project

The role of subsea activities in the framework of the new EU Directive 30/2013 on Oil and Gas safety for offshore installations View project

All content following this page was uploaded by Okoroma J. U. on 28 June 2017.

The user has requested enhancement of the downloaded file.

Safety Risk Analysis on a Natural Gas Compression Plant in Italy

Okoroma Justice (MSc.), Milan Kumar (MSc.), Olapade Olushola (MSc.), Mohammed Al-Salman (MSc.)

Petroleum Engineering, Politecnico di Torino, Italy

1.0 Abstract 3.0 Hazard Identification: FMECA & HAZOP Study

This work considers the risk analysis of a Natural Gas Compression facility and

associated Fire Fighting system. Different analyses were carried out on the system in the Failure Mode Effect and Criticality Analysis (FMECA)- sheet 1 of 10 Hazard and Operability Study (HAZOP)- sheet 1 of 25

course of the project. The risk assessment was approached both qualitatively and

quantitatively. The Hazard and Operability (HAZOP) Study and Failure Mode Effect and

Criticality Analysis (FMECA) make up the qualitative analyses carried out on the natural

gas plant and the fire fighting system respectively. The quantitative approach involved

the Event Tree Analysis (ETA) and the Fault Tree Analysis (FTA); ETA for the natural gas

plant, and FTA for the fire fighting system.

The normal operational configurations were selected for both systems. The failure

modes were identified for the components and their probabilities were estimated based

on whether unavailability, unreliability or both is/are being considered. The TOP (or

minimal cut set) obtained from the FTA was used in the determination of the failure

probability for the fire fighting system which is a combination of the TOP for

unavailability and unreliability of the system. Same was done for the shutdown system.

Consequence analysis was performed using the Quick Method and the damages due to

the Reference Initiating Events (RIE) obtained from the ETA were evaluated based on the

results obtained from the frequency calculations of events and accidental sequences in

the ETA. The results revealed unacceptable risks implying that additional risk reduction

measures must be pursued. Results also showed risks belonging to “as low as reasonably

practicable” category. In both cases, recommendations were suggested to ensure safer

plant operation.

2.0 Process Description 5.0 Probabilistic Analysis: ETA & FTA 6.0 Consequence Analysis & Risk Assessment

Event tree analysis (ETA) diagram – Sheet 1 of 2 Computation of damages, frequencies and risks

It is a simple compressing process of natural gas. Gas, coming from separators where liquid

phase is removed from gaseous phase, arrives to the suction scrubber for further separation of

entrained liquid that could be potentially dangerous to the compressor. After sufficient

scrubbing, the gas is compressed by a turbo-compressor and cooler in a discharge cooler before

going to a discharge scrubber. At the end, natural gas is ready to be fed to the grid.

There is also a fire-fighting system which uses two substances: foam and water. Foam operates

on temperature and also on oxygen removal, thanks to its’ sweltering effect that brings about a

temperature decrease and the separation between fuel and oxidant, blowing out the flame.

4.0 Reference Initiating Event Frequency vs Damage plot for Risk Acceptability

Distribution of Risks

Fault tree analysis (FTA) diagram– Sheet 1 of 2

Areal view of damage with respect to plant

7.0 Conclusion & Recommendations

Grouping of IE’s and

The risk assessment revealed that upon an event leading to jet fire, a total of 17 fatalities

Selection of RIE are foreseen within the high lethality area, while 49 people will be affected within the

irreversible injury zone. As expected, the damages done by UVCE are reduced as

compared to jet fire (uncontrolled and with domino effects), 6 fatalities and 15 casualties

or irreversible injury victims. The size of affected area predominantly fell within the plant

layout (above 70%) while a smaller part was outside the plant.

Accidental sequences and calculated frequencies – Sheet 1 of 2

Nodes| Description / Components Routine maintenance should be performed on the pressure sensor low instrument

1 Suction Scrubber including process gas line from upstream separator, and scrubber’s liquid leg installed on the pump’s common discharge line and control system. Also, scheduled

2 H.P. Compressor, including suction line, discharge line, BDV line and PSV line check of the mechanical sealing system of compressor is recommended. Safety radius

3 H.P. Compressor Discharge Cooler should be set up around the plant to prevent damages to buildings or potential

4 Recycle (line and valve) from HP Compressor Discharge Cooler outlet to Suction Scrubber inlet industries producing or using flammables/explosive chemicals, since a disaster could

5 Discharge Scrubber including process gas line from compressor, and scrubber’s liquid leg have domino effect on the environs. Continuous and proper maintenance of the plant

should be strictly carried out to reduce the vulnerability of the area.

References: [1] Carpignano A., Risk Assessment, Risk Analysis / Safety and Risk Analysis Methodologies, Part 1, 3 and 5. Dipartimento Di Energetica, Politecnico di Torino.

[2] Ganci F., Risk Analysis lecture slides – Hazardous substances, FMECA and Criticality Analysis, HAZOP, Selection of Initiating Events, ETA, FTA, Consequence Analysis.

View publication stats

Вам также может понравиться

- Class 10 Science Super 20 Sample PapersДокумент85 страницClass 10 Science Super 20 Sample PapersParas Tyagi100% (1)

- Useful Tips For A Successful HAZOP StudyДокумент7 страницUseful Tips For A Successful HAZOP StudySDP02Оценок пока нет

- BS en Iso 23936-2-2011Документ78 страницBS en Iso 23936-2-2011Franklin Osorio Sanchez67% (3)

- GGS Operating Manual Vol 1Документ271 страницаGGS Operating Manual Vol 1SDP02100% (1)

- 0 Egpc-Aud-001-Aprc Bowtie Voume 5Документ111 страниц0 Egpc-Aud-001-Aprc Bowtie Voume 5mohamed ashor100% (1)

- Fertil Hazop StudyДокумент9 страницFertil Hazop Studypkannan0% (1)

- Consequence Modeling and PSMДокумент35 страницConsequence Modeling and PSMTom Tao100% (1)

- Hazop ProcedureДокумент15 страницHazop Procedureartlet100% (1)

- Jacketed Vessel Design CalculusДокумент4 страницыJacketed Vessel Design Calculusmaspiqdo100% (1)

- Risk Bow-Tie MethodДокумент21 страницаRisk Bow-Tie MethodchatraqnОценок пока нет

- Steam Purity Considerations For New TurbinesДокумент46 страницSteam Purity Considerations For New Turbinesomertrik100% (1)

- Case Study On Dresser Rand Ethylene CompressorДокумент18 страницCase Study On Dresser Rand Ethylene CompressorSDP02Оценок пока нет

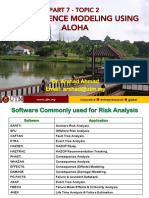

- Consequence Modeling Using AlohaДокумент40 страницConsequence Modeling Using AlohaNageswar MakalaОценок пока нет

- Consequence Analysis of BLEVE Scenario I PDFДокумент4 страницыConsequence Analysis of BLEVE Scenario I PDFArun KumarОценок пока нет

- LOPA and Risk Graphs For SIL DeterminationДокумент11 страницLOPA and Risk Graphs For SIL DeterminationShweta181Оценок пока нет

- 2 Consequence Modelling - Overview of HazardsДокумент75 страниц2 Consequence Modelling - Overview of HazardsJeampierr Jiménez Chero100% (1)

- SP-1075 HSE Specification - Fire and Explosion Risk ManagementДокумент65 страницSP-1075 HSE Specification - Fire and Explosion Risk ManagementJohnОценок пока нет

- The Evaluation of Safety Barriers Using The Method LopaДокумент7 страницThe Evaluation of Safety Barriers Using The Method LopaDiegoОценок пока нет

- Quantitative Risk AssessmentДокумент113 страницQuantitative Risk AssessmentJay JayОценок пока нет

- FRED - QRA - Consequence Modelling - Learnings From QRA - Overview of HazardsДокумент75 страницFRED - QRA - Consequence Modelling - Learnings From QRA - Overview of HazardsJohn ObidiОценок пока нет

- Properties of Bio-Based PolyurethaneДокумент200 страницProperties of Bio-Based PolyurethaneMust BoujaataОценок пока нет

- SCS 2019 Presentation-Mark Skelton-Risk Based Decision Making and ALARP-How Low Is Low EnoughДокумент25 страницSCS 2019 Presentation-Mark Skelton-Risk Based Decision Making and ALARP-How Low Is Low EnoughkhaleedsyedОценок пока нет

- Input Documents and Deliverables Quantitative Risk Assessment (QRA) Study: Study Input Documents DeliverablesДокумент9 страницInput Documents and Deliverables Quantitative Risk Assessment (QRA) Study: Study Input Documents Deliverablessandhyakasturi123Оценок пока нет

- En 1.4301Документ1 страницаEn 1.4301sheinilaОценок пока нет

- Fire Explosion Hazard ManagementДокумент11 страницFire Explosion Hazard ManagementEbenezer AaronОценок пока нет

- How To Perform Bow Tie AnalysisДокумент21 страницаHow To Perform Bow Tie AnalysisKareem RasmyОценок пока нет

- PHA Training - Day 1Документ50 страницPHA Training - Day 1ahmad jamalОценок пока нет

- Hazardous Area ClassificationДокумент7 страницHazardous Area Classificationhassenova.kОценок пока нет

- Topic III Hazardous Area ClassificationДокумент22 страницыTopic III Hazardous Area ClassificationJulius ChavezОценок пока нет

- NFPA Combustible Dust CodeДокумент11 страницNFPA Combustible Dust CodeRoadieОценок пока нет

- QRAДокумент10 страницQRApgupta71100% (1)

- 6.18 Offshore Emergency Shutdown System Design PhilosophyДокумент8 страниц6.18 Offshore Emergency Shutdown System Design Philosophymohameda20Оценок пока нет

- Barrier PS ManagementДокумент27 страницBarrier PS ManagementMarcus HartfelderОценок пока нет

- Hazop PDFДокумент33 страницыHazop PDFSDP02Оценок пока нет

- 1 Heat Exchanger VDFДокумент26 страниц1 Heat Exchanger VDFPablo TorresОценок пока нет

- Use and Misuse of Enabling Conditions and Conditional Modifiers in Layers of Protection Analysis (LOPA)Документ22 страницыUse and Misuse of Enabling Conditions and Conditional Modifiers in Layers of Protection Analysis (LOPA)userscribd2011Оценок пока нет

- BS EN 12583 - 2000 - Gas Supply Systems. Compressor Stations. Functional Requirements - Withdrawn PDFДокумент44 страницыBS EN 12583 - 2000 - Gas Supply Systems. Compressor Stations. Functional Requirements - Withdrawn PDFSDP02Оценок пока нет

- SIL - Hse Research ReportДокумент82 страницыSIL - Hse Research ReportAndrew BullОценок пока нет

- Norsok L-004 Piping Fabrication 2010 PDFДокумент30 страницNorsok L-004 Piping Fabrication 2010 PDFarifin rizal100% (1)

- PSV Sizing and Reaction Force Modelling Rev 1.1Документ11 страницPSV Sizing and Reaction Force Modelling Rev 1.1Hoang-Vu BuiОценок пока нет

- Safety in the Chemical Laboratory and Industry: A Practical GuideОт EverandSafety in the Chemical Laboratory and Industry: A Practical GuideОценок пока нет

- Explosion Protection - E PDFДокумент7 страницExplosion Protection - E PDFAPCAОценок пока нет

- Carboxylic Acid Questions-1Документ6 страницCarboxylic Acid Questions-1Jape GarridoОценок пока нет

- Kenexis: Understanding Fire and Gas Mapping Software and EffigyДокумент34 страницыKenexis: Understanding Fire and Gas Mapping Software and EffigyShakeel AhmedОценок пока нет

- Bow TieДокумент2 страницыBow TieAnonymous ocCa18RОценок пока нет

- BS en 12583 - 2014 - Gas Infrastructure. Compressor Stations. Functional Requirements.Документ56 страницBS en 12583 - 2014 - Gas Infrastructure. Compressor Stations. Functional Requirements.SDP02Оценок пока нет

- The QRAQ Project Volume 4 Frequency of R PDFДокумент66 страницThe QRAQ Project Volume 4 Frequency of R PDFNelson Alvarez0% (1)

- Chastainw Advancesinlayerofprotectionanalysis PDFДокумент37 страницChastainw Advancesinlayerofprotectionanalysis PDFanon_770350620100% (1)

- Best Practices: Consider These Safety-Instrumented SystemДокумент18 страницBest Practices: Consider These Safety-Instrumented SystemardiyantoОценок пока нет

- Major Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsОт EverandMajor Accidents to the Environment: A Practical Guide to the Seveso II-Directive and COMAH RegulationsОценок пока нет

- Basics of Trips, Interlocks, Permissives & Sequences1Документ202 страницыBasics of Trips, Interlocks, Permissives & Sequences1Charles RobiansyahОценок пока нет

- Guidelines for Determining the Probability of Ignition of a Released Flammable MassОт EverandGuidelines for Determining the Probability of Ignition of a Released Flammable MassОценок пока нет

- Hazop/HazidДокумент20 страницHazop/HazidOmar DhiebОценок пока нет

- Essential Practices for Creating, Strengthening, and Sustaining Process Safety CultureОт EverandEssential Practices for Creating, Strengthening, and Sustaining Process Safety CultureОценок пока нет

- Introduction To HacДокумент51 страницаIntroduction To HacYuliyaОценок пока нет

- Adi Emea 6 Fire & Gas DetectionДокумент34 страницыAdi Emea 6 Fire & Gas DetectionAlbertОценок пока нет

- ALOHA Final Techdoc and QAДокумент51 страницаALOHA Final Techdoc and QAAubrey WessonОценок пока нет

- UC 2018 Phast - Safeti 8.1 WorkshopДокумент14 страницUC 2018 Phast - Safeti 8.1 Workshopanub0025Оценок пока нет

- Societal Risk MappingДокумент31 страницаSocietal Risk MappingCalОценок пока нет

- Layer of Protection AnalysisДокумент9 страницLayer of Protection Analysiscera211164Оценок пока нет

- Guidance On Performing Transportation Risk Analysis of Hazardous MaterialsДокумент221 страницаGuidance On Performing Transportation Risk Analysis of Hazardous MaterialsDidik SupriyadiОценок пока нет

- Chemical Exposure IndexДокумент23 страницыChemical Exposure IndexwankartikaОценок пока нет

- Ammonia As A Refrigerant PD 2014 PDFДокумент15 страницAmmonia As A Refrigerant PD 2014 PDFEleonoraОценок пока нет

- Proposal Event TreeДокумент8 страницProposal Event TreeMufti Sinergi SolusiОценок пока нет

- Paper 2Документ8 страницPaper 2Nitesh Kirnake100% (1)

- NFPA Codes and Their Relevance To Chemical Processes: Jonathan Eisenberg, P.E. Jeremy LebowitzДокумент29 страницNFPA Codes and Their Relevance To Chemical Processes: Jonathan Eisenberg, P.E. Jeremy LebowitzEko PoerwantoОценок пока нет

- AeSolutions Risk Criteria Selection and The Impacts On LOPA ResultsДокумент13 страницAeSolutions Risk Criteria Selection and The Impacts On LOPA ResultsAnonymous bHh1L1Оценок пока нет

- Essentials On Safety Instrumented SystemsДокумент9 страницEssentials On Safety Instrumented Systemstibi1000Оценок пока нет

- Protected System: Protecting Relief Device EquipmentДокумент23 страницыProtected System: Protecting Relief Device Equipmentanamaria ursuОценок пока нет

- Hemp RaddДокумент78 страницHemp RaddMuhammad.SaimОценок пока нет

- Comparison of Methane and Ethane Gas Release Using ALOHAДокумент1 страницаComparison of Methane and Ethane Gas Release Using ALOHAShashank TiwariОценок пока нет

- ChamberlainДокумент14 страницChamberlainAbhi KothariОценок пока нет

- Classification of PSM Barriers I Travers P McCullochДокумент9 страницClassification of PSM Barriers I Travers P McCullochNhut NguyenОценок пока нет

- GAPS Guidelines: Hydraulic GradientДокумент5 страницGAPS Guidelines: Hydraulic GradientKadiri OlanrewajuОценок пока нет

- HAZOP Budgeting Tool: Practical Solutions For Today's HSE ChallengesДокумент2 страницыHAZOP Budgeting Tool: Practical Solutions For Today's HSE ChallengesifalerinОценок пока нет

- Fire & Explosion Hazard Management: 04 Days TrainingДокумент2 страницыFire & Explosion Hazard Management: 04 Days TrainingMuhammad.SaimОценок пока нет

- Risk Analysis of A Typical Chemical Industry Using ORA ProcedureДокумент17 страницRisk Analysis of A Typical Chemical Industry Using ORA ProcedureUsama NiaziОценок пока нет

- Shell and Tube Heat-Exchanger-DesignДокумент8 страницShell and Tube Heat-Exchanger-DesignIonescu ViorelОценок пока нет

- Effects of The Primary Explosion Site and Bulk Cloud in VCE Prediction: A Comparison With Historical AccidentsДокумент7 страницEffects of The Primary Explosion Site and Bulk Cloud in VCE Prediction: A Comparison With Historical AccidentsKonstantinKotОценок пока нет

- NC DBP - Compressor Station Fire and Gas Replacement Project PDFДокумент1 страницаNC DBP - Compressor Station Fire and Gas Replacement Project PDFSDP02Оценок пока нет

- TLV Tc1 Self Acting Temperature Regulator FlangedДокумент2 страницыTLV Tc1 Self Acting Temperature Regulator FlangedSDP02Оценок пока нет

- Pressure Testing Requirements For Valves CBD-P-07 Rev.00Документ9 страницPressure Testing Requirements For Valves CBD-P-07 Rev.00SDP02100% (1)

- Anti-Surge Control ConceptsДокумент6 страницAnti-Surge Control ConceptsJose Gustavo Robles MoralesОценок пока нет

- CRP Sampling LiteratureДокумент24 страницыCRP Sampling LiteratureSDP02Оценок пока нет

- 2 SafetyRiskAnalysis-GasPlantItalyДокумент2 страницы2 SafetyRiskAnalysis-GasPlantItalySDP02Оценок пока нет

- Appendix 18 - Final Report Plant 4 - Ammonia Refrigeration and Compression PDFДокумент8 страницAppendix 18 - Final Report Plant 4 - Ammonia Refrigeration and Compression PDFSDP02Оценок пока нет

- Section 2 - Technical Description - A4U4R7Документ12 страницSection 2 - Technical Description - A4U4R7SDP02Оценок пока нет

- Capability Statement: Safety EngineeringДокумент25 страницCapability Statement: Safety EngineeringSDP02Оценок пока нет

- Api 550 e - 0903Документ66 страницApi 550 e - 0903SDP02Оценок пока нет

- Nomenclature of CompressorДокумент11 страницNomenclature of CompressorRama KrishnanОценок пока нет

- Appendix 1 HAZOPWorksheets 1 PDFДокумент37 страницAppendix 1 HAZOPWorksheets 1 PDFSDP02Оценок пока нет

- Fuel Superheating PaperДокумент6 страницFuel Superheating PaperSDP02Оценок пока нет

- Smoke Detector RM40 Li Wireless: Art. No. 55811Документ1 страницаSmoke Detector RM40 Li Wireless: Art. No. 55811SDP02Оценок пока нет

- Ansi Valve Leakage Standards Gemco ValveДокумент1 страницаAnsi Valve Leakage Standards Gemco ValvenithyaОценок пока нет

- KPMG Situation of The Ukrainian Natural Gas Market and Transit System 2017-04-10Документ58 страницKPMG Situation of The Ukrainian Natural Gas Market and Transit System 2017-04-10SDP02Оценок пока нет

- Ger 3942 Gas Fuel Cleanup System Design Considerations HDGTДокумент22 страницыGer 3942 Gas Fuel Cleanup System Design Considerations HDGTSDP02Оценок пока нет

- (Alan R. Katritzky, Otto Meth-Cohn, and Charles W.Документ1 287 страниц(Alan R. Katritzky, Otto Meth-Cohn, and Charles W.Ganesh KashinathОценок пока нет

- CellcommworksheetДокумент1 страницаCellcommworksheetYolpy AvukovuОценок пока нет

- Evamarine: Drying Time Set-To-Touch Hard Dry Painting Interval Min MaxДокумент1 страницаEvamarine: Drying Time Set-To-Touch Hard Dry Painting Interval Min MaxcelescopitoОценок пока нет

- GDL 10 Series Gas Diffusion Layer: SigracetДокумент2 страницыGDL 10 Series Gas Diffusion Layer: SigracetAhmed Emad AhmedОценок пока нет

- 0237e CHBДокумент1 страница0237e CHBSaif Ahmed SiddiquiОценок пока нет

- STP 491-1971Документ90 страницSTP 491-1971Tim SchouwОценок пока нет

- Exp 5 - Flow in PipesДокумент21 страницаExp 5 - Flow in PipesHarvin Rao0% (1)

- hssc0500t Chaptest AДокумент6 страницhssc0500t Chaptest AAseel AburajabОценок пока нет

- Ecosystem CyclesДокумент11 страницEcosystem CyclesMohammad ShormanОценок пока нет

- Abstract of ASTM A574M 1997Документ7 страницAbstract of ASTM A574M 1997Jesse ChenОценок пока нет

- Watford 2001Документ7 страницWatford 2001CARDIO 2019Оценок пока нет

- Numerical Analysis For Energy Performance Optimization of Hollow Bricks For Roofing. Case Study - Hot Climate of AlgeriaДокумент10 страницNumerical Analysis For Energy Performance Optimization of Hollow Bricks For Roofing. Case Study - Hot Climate of Algeriamah0809Оценок пока нет

- ChapterEight1 - 20 of SpectrocopicДокумент20 страницChapterEight1 - 20 of SpectrocopicHung Le VanОценок пока нет

- Oxygen Content Using A 14-Mev Neutron Activation and Direct-Counting TechniqueДокумент8 страницOxygen Content Using A 14-Mev Neutron Activation and Direct-Counting Techniqueruben carcamoОценок пока нет

- WBJEE 13 Solution - PhysicsДокумент2 страницыWBJEE 13 Solution - PhysicsSaumyasankar SarangiОценок пока нет

- Beta OxidationДокумент41 страницаBeta Oxidationguna sundariОценок пока нет

- Chemical Engineering CommunicationsДокумент16 страницChemical Engineering CommunicationsMichelle Quilaqueo NovoaОценок пока нет

- IbandronateДокумент6 страницIbandronateAashishThakurОценок пока нет

- AYJR 2022 July - Shift 2Документ70 страницAYJR 2022 July - Shift 2आस्तिक शर्माОценок пока нет

- GT 2 Paper 1 SolutionsДокумент26 страницGT 2 Paper 1 SolutionsAnand MurugananthamОценок пока нет

- Mil STD 650Документ210 страницMil STD 650Roberto Carlos Cabana Orellana100% (1)

- Quiz 1 With AnswerДокумент3 страницыQuiz 1 With AnswerAltra ZОценок пока нет

- Engineering Mechanics: Second PartДокумент18 страницEngineering Mechanics: Second Partاحمد سلمان عزيز , مسائيCОценок пока нет