Академический Документы

Профессиональный Документы

Культура Документы

WPS for GTAW Welding of Aluminum Butt Joints

Загружено:

mahmoud_allam3Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WPS for GTAW Welding of Aluminum Butt Joints

Загружено:

mahmoud_allam3Авторское право:

Доступные форматы

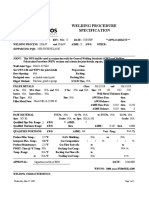

WELDING PROCEDURE

SPECIFICATION

WPS - 2010-xxxx-23 REV. NO.: 2 DATE: 10/8/2009 **APPLICABILITY**

WELDING PROCESS: GTAW- and GTAW- ASME: X AWS: X OTHER:

SUPPORTING PQR: 200-23-P P-WS-10-1 P-WS-10-2 P-WS-151-1

P-WS-100-2 P-WS-100-1 2010-xxxx-23

JOINT: This WPS shall be used in conjunction with the General Welding Standards (GWS) and Welding

Fabrication Procedure (WFP) sections and criteria for joint details, repairs, NDE, inspection etc.

Weld Joint Type: Butt/Groove/Fillet Class: Full/Partial Penetration

See GWS 1-06 and WFP's for joint details Preparation: Thermal (plasma) /Mechanical

Root Opening: 0 - 3/32 Backing: None/Strap/back welding

Backgrind root: or purged Backing Mat.: Al

Bkgrd Method: Grind if not purged GTAW Flux: N/A Backing Retainer: N/A

FILLER METALS: Class: ER4043 and ER4043

A No: N/A SFA Class: 5.10 and 5.10 F No: 23 and 23 Size: 1/16 3/32 1/8

Insert: N/A Insert Desc.: N/A Weld Metal Thickness Ranges:

Flux: Type: NA Size: 0 AWS Root Pass: 0.032 thru 0.75

Filler Metal Note: AWS Balance: 0.032 thru 0.75

ASME Root Pass: 0.032 thru 0.187

ASME Balance: 0.064 thru 0.75

BASE MATERIAL P/S No. 23 Gr No. All to: P/S No. 23 Gr No. All

Spec. B-209 Al- Plate & sheet Grade: All to: Spec. B-209 Al- Plate & sheet Grade: All

Qualified Pipe Dia. Range: ≥ AWS: 6 ASME: 0.75

Qualified Thickness Range: AWS: 0.032 thru 0.750 ASME: 0.032 thru 0.750

QUALIFIED POSITIONS: AWS: All ASME: All Vert. Prog.: V/Up

Preheat Min. Temp.: 70 °F GAS: Shielding: Argon or

Interpass Max. Temp.: 500 °F Gas Composition: 100 / 0 / 0 % 0/ 0/ 0%

Preheat Maintenance: 70 °F Gas Flow Rate cfh: 10 to 25 0 to 0

PWHT: Time @ °F Temp. 0 Backing Gas/Comp: Argon 100 %

Temp. Range: 0 °F Backing Gas Flow cfh: 3 to 10

to 0 °F Trailing Gas/Comp: N/A 0%

APPROVAL: Signatures on file at ENG DATE: 10/8/2009

Thursday, October 08, 2009 Page 1 of 2

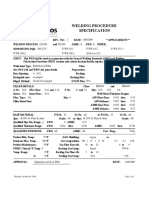

WPS NO: 2010-xxxx-23

WELDING CHARACTERISTICS:

Current: AC and AC Tungsten Type: EWTh-2 Transfer Mode: N/A

Ranges: Amps 25 to 300 Tungsten Dia.: 3/32 Pulsing Cycle: 40 to 60

Volts 12 to 22 Background Current: 40%

Fuel Gas: N/A Flame: N/A Braze temp. °F 0 to 0

WELDING TECHNIQUE: For fabrication specific requirements such as fittup, cleaning, grinding, PWHT and

inspection criteria refer to Volume 2, Welding Fabrication Procedures

Technique: Manual Cleaning Method: Wire Brush, File, Grind

Single Pass or Multi Pass: M Stringer or Weave bead (S/W): S/W or Oscillation: N

GMAW Gun Angle °: 0 to 0 Forehand or Backhand for GMAW (F/B): N/A

No Pass >1/2": GMAW/FCAW Tube to work distance: N/A

Maximum K/J Heat Input: 0 Travel speed: Variable Gas Cup Size: # 5

PROCEDURE QUALIFIED FOR:

Charpy "V" Notch: N/A Nil-Ductil Transition Temperature: N/A Dynamic Tear: N/A

Comments:

Weld Manual Filler Metals Nozzle

Layer Process Size Amp Range Volt Range Travel/ipm Angle Other

1 GTAW- ER4043 1/16 25 to 160 12 to to 0 to 0

2 GTAW- ER4043 3/32 150 to 250 to to

3 GTAW- ER4043 1/8 240 to 300 to to

4 GTAW- ER4043 1/8 to to to

REM. * Weld layers are representative only - actual number of passes and layer sequence may vary.

ML-1/2 projects or jobs must determine if the supporting documentation for this WPS complies with quality requirements of the

project/job.

Use of LANL Welding Procedures and Welder Qualifications for non-LANL work shall be at the sole risk and responsibility of

the Subcontractor, and the Subcontractor shall indemnify and save LANL and the Government harmless from any and all

claims, demands, actions or causes of action, and for any expense or loss by reason of Subcontractor's and their employees

posession and use of LANL procedures and qualifications.

Thursday, October 08, 2009 Page 2 of 2

Вам также может понравиться

- WPS NMB 001Документ6 страницWPS NMB 001mohamed nasserОценок пока нет

- Company Logo Added to QAP DocumentДокумент4 страницыCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- Sample Forms WPS PQRДокумент22 страницыSample Forms WPS PQRGMОценок пока нет

- Procedure Qualification Record PQRДокумент3 страницыProcedure Qualification Record PQRNMBaihakiARОценок пока нет

- WFP 2-01 ASME B31 Piping Welding ProcedureДокумент8 страницWFP 2-01 ASME B31 Piping Welding Procedureleodavid87Оценок пока нет

- Welder Qualification Test RequestДокумент1 страницаWelder Qualification Test RequestgoguluОценок пока нет

- Material Traceability ProcedureДокумент12 страницMaterial Traceability Procedureqamar qateebОценок пока нет

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFДокумент26 страницNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosОценок пока нет

- D1.5M D1.5 2015 AMD1 Form O 2 FillableДокумент1 страницаD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1Оценок пока нет

- Welding Log BookДокумент1 страницаWelding Log Booksamsurendran_mech4020Оценок пока нет

- ITP Inspection and Test Plan for Aqaba Screening Project Steel FabricationДокумент3 страницыITP Inspection and Test Plan for Aqaba Screening Project Steel FabricationKhaled GamalОценок пока нет

- Poster Welding P VoxXa PDFДокумент1 страницаPoster Welding P VoxXa PDFAd Man GeTigОценок пока нет

- Gate & Globe PDFДокумент0 страницGate & Globe PDFZoebairОценок пока нет

- Welding Consumables Control RegisterДокумент1 страницаWelding Consumables Control RegisterAli MhaskarОценок пока нет

- 2596 (Asme)Документ1 страница2596 (Asme)fracevОценок пока нет

- DVS 2207-3Документ12 страницDVS 2207-3gura9054Оценок пока нет

- Sfa-5.6Документ20 страницSfa-5.6vannie_yundaОценок пока нет

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Документ6 страницRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriОценок пока нет

- Difference Between Weld Layer Versus Bead Versus PassДокумент6 страницDifference Between Weld Layer Versus Bead Versus Passlram70Оценок пока нет

- Handle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsДокумент1 страницаHandle Parts Carefully & Zero Tolerance To Be Maintained As Regards To Nicks, Scratches & DentsSAKTHIVEL AОценок пока нет

- Welding Procedure Specification For GTAWДокумент9 страницWelding Procedure Specification For GTAWraja reyhanОценок пока нет

- Thermal Power Project Weld Inspection ReportДокумент1 страницаThermal Power Project Weld Inspection ReportAshwani DograОценок пока нет

- Welding Parameters Control PipelineДокумент1 страницаWelding Parameters Control PipelinemusheerОценок пока нет

- FactoryДокумент72 страницыFactorywhitebrosОценок пока нет

- 12 Storage of Parent MaterialsДокумент3 страницы12 Storage of Parent MaterialselmiraОценок пока нет

- Preparation and Control of WeldingДокумент3 страницыPreparation and Control of Weldingbalakumar rajaramОценок пока нет

- Painting Report Cd3Документ15 страницPainting Report Cd3sivaОценок пока нет

- Sample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Документ2 страницыSample PQR Form (GTAW & SMAW - Page 1) Procedure Qualification Record (PQR)Luis Carlos Clericci LimonОценок пока нет

- AWS D8.1M-2007 LeibleДокумент40 страницAWS D8.1M-2007 Leiblejorge solisОценок пока нет

- DPT Report 02Документ2 страницыDPT Report 02Amit Hasan100% (1)

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Документ2 страницыSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzОценок пока нет

- Hydraulic crash barriers ITPДокумент4 страницыHydraulic crash barriers ITPmoytabura96Оценок пока нет

- KGP-Flamme Cutting Proce For BEI PDFДокумент4 страницыKGP-Flamme Cutting Proce For BEI PDFoomoomОценок пока нет

- Fermi Lab Orbital Welding ProcedureДокумент2 страницыFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- QC Sample Manual GenericДокумент34 страницыQC Sample Manual GenericIan Stewart PorterОценок пока нет

- Alu WpsДокумент4 страницыAlu WpsdselvakuuОценок пока нет

- Welder TrainingДокумент13 страницWelder Trainingויליאם סן מרמיגיוסОценок пока нет

- PWPS - GTSM-73 Rev-AДокумент5 страницPWPS - GTSM-73 Rev-AVimin PrakashОценок пока нет

- NDT Request (Template)Документ4 страницыNDT Request (Template)Bethel NdifonОценок пока нет

- Welders ManagementДокумент11 страницWelders ManagementStanley AlexОценок пока нет

- PWHT Job Card For p91 Butt Weld 14'' SupportДокумент2 страницыPWHT Job Card For p91 Butt Weld 14'' Support9703422499Оценок пока нет

- General Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelsДокумент14 страницGeneral Procedure of Manufacturing The Custom Built Sound Proof Enclosures With PanelspawanОценок пока нет

- 2019 Product Catalog WebДокумент104 страницы2019 Product Catalog WebIan Niko100% (1)

- QA 01 001 2013 Rev0 Quality Manual PDFДокумент53 страницыQA 01 001 2013 Rev0 Quality Manual PDFMau Atenas PerezОценок пока нет

- Stainless steel welding procedure qualification recordДокумент1 страницаStainless steel welding procedure qualification recordchandraОценок пока нет

- Welding Procedure DocumentДокумент7 страницWelding Procedure DocumentikponmwonsaОценок пока нет

- ASME Definitions, Welding Positions, Materials GuideДокумент9 страницASME Definitions, Welding Positions, Materials GuideSankar KrishnanОценок пока нет

- Visual Inspection FormatДокумент2 страницыVisual Inspection Formattuan mai vanОценок пока нет

- Pickling Work InstructionДокумент1 страницаPickling Work InstructionmanesarkarОценок пока нет

- Weld ShrinkageДокумент16 страницWeld ShrinkageWeff JingОценок пока нет

- WPS MCC 001 PDFДокумент1 страницаWPS MCC 001 PDFNuwan RanaweeraОценок пока нет

- Procedure for Flame Straightening Structural SteelДокумент3 страницыProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- Arc StrikeДокумент9 страницArc StrikeBulut YildizОценок пока нет

- WPS GTAW-SMAW h1Документ1 страницаWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzОценок пока нет

- Baking register tracks electrode usageДокумент3 страницыBaking register tracks electrode usageShivam TiwariОценок пока нет

- WPS for Welding HY80 SteelДокумент2 страницыWPS for Welding HY80 Steelsrb metallurgОценок пока нет

- Welding Procedure for Stainless Steel PipesДокумент2 страницыWelding Procedure for Stainless Steel Pipes模具工程系鄭德彥Оценок пока нет

- 1000 XXXX HY80 HSLA100Документ2 страницы1000 XXXX HY80 HSLA100srb metallurgОценок пока нет

- Welding Procedure SpecificationДокумент2 страницыWelding Procedure SpecificationFrancisco HoyosОценок пока нет

- Method For Mechanical Properties EvaluationДокумент5 страницMethod For Mechanical Properties Evaluationmahmoud_allam3Оценок пока нет

- Steam Generators 2Документ33 страницыSteam Generators 2gbharathreddysОценок пока нет

- Fracture Toughness of The Heat Affected Zone in Girth WeldsДокумент7 страницFracture Toughness of The Heat Affected Zone in Girth Weldsmahmoud_allam3Оценок пока нет

- PICKLING Gel FOR STAILESS STEEL PdsДокумент2 страницыPICKLING Gel FOR STAILESS STEEL Pdsmahmoud_allam3Оценок пока нет

- Furnaces and RefractoriesДокумент36 страницFurnaces and Refractoriesengkassem100% (5)

- Study of Ductile-Brittle Transition Temperature of 9Cr-1Mo SteelsДокумент2 страницыStudy of Ductile-Brittle Transition Temperature of 9Cr-1Mo Steelsmahmoud_allam3Оценок пока нет

- 1english Reg Final Nov 2010 PDFДокумент367 страниц1english Reg Final Nov 2010 PDFmahmoud_allam3Оценок пока нет

- Nitrogen Purging For Stainless SteelДокумент4 страницыNitrogen Purging For Stainless Steelmahmoud_allam3Оценок пока нет

- Color Metallurgy of Cast IronДокумент13 страницColor Metallurgy of Cast Ironmahmoud_allam3Оценок пока нет

- ASME New Code Case LetterДокумент1 страницаASME New Code Case Lettermahmoud_allam3Оценок пока нет

- Passivating Gel For Stainless SteelДокумент2 страницыPassivating Gel For Stainless Steelmahmoud_allam3Оценок пока нет

- Engineering, Steel Fabrication and Process Equipment ManufacturerДокумент4 страницыEngineering, Steel Fabrication and Process Equipment Manufacturermahmoud_allam3Оценок пока нет

- Code Case 2891 U-2 CerДокумент1 страницаCode Case 2891 U-2 Cermahmoud_allam3Оценок пока нет

- Projects Follow UpДокумент1 страницаProjects Follow Upmahmoud_allam3Оценок пока нет

- Request For Code CaseДокумент2 страницыRequest For Code Casemahmoud_allam3Оценок пока нет

- Journal Modified 9% CR Steels For AdvancedДокумент6 страницJournal Modified 9% CR Steels For Advancedmahmoud_allam3Оценок пока нет

- Code Case 2891 U-2 CerДокумент1 страницаCode Case 2891 U-2 Cermahmoud_allam3Оценок пока нет

- Color Metallurgy of Cast IronДокумент13 страницColor Metallurgy of Cast Ironmahmoud_allam3Оценок пока нет

- WPS for GTAW Welding of Aluminum Butt JointsДокумент2 страницыWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3Оценок пока нет

- 16-2819 Welders InterpretationДокумент1 страница16-2819 Welders Interpretationmahmoud_allam3Оценок пока нет

- Presentation For WeldingДокумент31 страницаPresentation For Weldingmahmoud_allam3Оценок пока нет

- Aluminim WPSДокумент5 страницAluminim WPSmahmoud_allam3Оценок пока нет

- 10 1 1 161 3015Документ7 страниц10 1 1 161 3015rinshadОценок пока нет

- Heat Treatment of 9 CRДокумент12 страницHeat Treatment of 9 CRmahmoud_allam3Оценок пока нет

- Assessment of Welding ConsumablesДокумент17 страницAssessment of Welding Consumablesmahmoud_allam3Оценок пока нет

- Welding CrMo Steels for Power and Petrochemical ApplicationsДокумент11 страницWelding CrMo Steels for Power and Petrochemical Applicationsmahmoud_allam3100% (1)

- Welding of P91Документ10 страницWelding of P91mahmoud_allam3Оценок пока нет

- WPS for GTAW Welding of Aluminum Butt JointsДокумент2 страницыWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3Оценок пока нет

- Aluminim WPSДокумент5 страницAluminim WPSmahmoud_allam3Оценок пока нет

- Aotai Welding Catalogue 2023Документ140 страницAotai Welding Catalogue 2023Noki AfandiОценок пока нет

- 02 Samss 006Документ17 страниц02 Samss 006inatt101Оценок пока нет

- Techweld BrochureДокумент12 страницTechweld BrochurekratingdiengОценок пока нет

- Eweldm 180Документ16 страницEweldm 180Alex LopezОценок пока нет

- Pipeline WeldingДокумент61 страницаPipeline Weldingravi00098Оценок пока нет

- Hobart Handler 210 ManualДокумент56 страницHobart Handler 210 Manualdon_paauwОценок пока нет

- A Review of Wire Arc Additive Manufacturing and Advances in Wire Arc Add ManufacturingДокумент23 страницыA Review of Wire Arc Additive Manufacturing and Advances in Wire Arc Add ManufacturingSaketh BachuОценок пока нет

- GMAW PreTest1Документ3 страницыGMAW PreTest1Winalyn PersiaОценок пока нет

- Effect of External Magnetic Field On Welding: Group MembersДокумент11 страницEffect of External Magnetic Field On Welding: Group MembersChandrakiran AlapatiОценок пока нет

- HDSD Mig OTC DM350 PDFДокумент72 страницыHDSD Mig OTC DM350 PDFHOryshorОценок пока нет

- ASTM A707 GR L5 CL4Документ6 страницASTM A707 GR L5 CL4Ruben Dario Espinoza VasquezОценок пока нет

- ssp239 - Audi A2 Body PDFДокумент64 страницыssp239 - Audi A2 Body PDFJames ChoongОценок пока нет

- Welding Products Catalogue Provides SolutionsДокумент8 страницWelding Products Catalogue Provides SolutionsNeetesh SoniОценок пока нет

- CSWIP Question Answers PDFДокумент32 страницыCSWIP Question Answers PDFAnonymous SA40GK6100% (2)

- NTTC R3 PDFДокумент72 страницыNTTC R3 PDFAJ AcuñaОценок пока нет

- GET Wear SystemsДокумент19 страницGET Wear SystemsIvanОценок пока нет

- Maintenance Checklist Cookery NC Ii: Housekeeping ScheduleДокумент8 страницMaintenance Checklist Cookery NC Ii: Housekeeping ScheduleJulie Fe de Alca0% (1)

- Conformances: Type: NeutralДокумент2 страницыConformances: Type: NeutralsampathkumarОценок пока нет

- Esab Marathon PacДокумент2 страницыEsab Marathon PacRAJAN BABU M100% (1)

- English/Metric Gas Flow Rate Conversion ChartДокумент1 страницаEnglish/Metric Gas Flow Rate Conversion ChartTAMILОценок пока нет

- Wel 23 BДокумент8 страницWel 23 BWilly UioОценок пока нет

- New Microsoft Office Word DocumentДокумент16 страницNew Microsoft Office Word DocumentsarathОценок пока нет

- Power Source CharacteristicsДокумент22 страницыPower Source CharacteristicsKyОценок пока нет

- BEL Q PaperДокумент79 страницBEL Q Papersrijin0% (1)

- CWB Level 2 Study Modules 4-5-6-7-8!9!12!17!18-19-22 Flashcards - Quizlet - PDF (CWB 2)Документ129 страницCWB Level 2 Study Modules 4-5-6-7-8!9!12!17!18-19-22 Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedОценок пока нет

- Welding II Curriculum MapДокумент9 страницWelding II Curriculum Mapapi-525855204Оценок пока нет

- Wa0082 PDFДокумент34 страницыWa0082 PDFmiteshОценок пока нет

- CuniДокумент32 страницыCunikampit100% (1)

- Thesis FypДокумент47 страницThesis FypMohd AymanОценок пока нет